Top Böhme Abrasion Tester in China. From manufacturing to construction and from packaging to product design, almost every industry greatly relies on understanding the tensile strength of plastic materials. The determination of tensile strength helps in evaluating a material’s performance in relation to the amount of tension and stress it can endure which is necessary for the product to be dependable and secure. It does not matter whether you are a veteran or a novice; understanding plastic materials’ performance and quality requires proficiency in evaluating material performance using tensile strength tests.

This guide will walk you through everything there is to know about performing tensile strength tests on plastic materials. We will explain the importance of these tests, introduce the tools and techniques, discuss the techniques, and give standards to achieve accurate and useful results. If you are ready to enhance your knowledge on the testing of materials and, consequently, the outcome of your projects, this is the guide that you were looking for.

What is the Plastic Tensile Strength Test?

The plastic tensile strength test gauges the breaking points of a plastic material by determining the maximum tensile, i.e., pulling force it can endure without succumbing to fracture. This test analyzes the strength, flexural resilience, and other components of mechanical performance of the material when stress is applied. Usually, the test is done following prescribed guidelines like those developed by ASTM or ISO so that there is uniformity and dependability in the outcomes. The information gathered assists in assessing the best use of the plastic from packing materials to parts of vehicles.

Understanding Tensile Test Basics

Parameters to Consider During Tensile Testing

While conducting a plastic material evaluation, testing in tensile testing mode will require multiple parameters to be calculated which include:

Maximum Tensile Stress: This is the primary point of distress that an object experiences before its rupture. Units such as megapascals (MPa) or pounds per square inch (psi) are used to report the value.

Yield Strength: Represents the stage in which the object starts to change its shape permanently. To put it simply, any force applied to it will allow it to be removed without the object going back to its original shape.

Anchor Elongation: This is the maximum point an object can stretch and still resist breaking. As a stretchable object, this ability adds to the ductility of the object.

This also serves the purpose of ductility; only in a break anchoring form can it aid in stretching without breaking, while offering the other ability.

Modulus of Elasticity (Young’s Modulus): This measures the material stiffness and displays how much it can withstand deformation under stress.

Material Resistance: An object’s rigidity.

Breaking apart tensile test ingitrate serves as a foundation, shoulders for standards which differ from one industry to the next. For material choice and blueprint designing becomes irrelevant, needing more data on:

The Packaging Design Department: The aim is to use materials that increase the feasibility of function combined with property, allowing aids high breaking anchoring.

Automotive Supporting Elements: This requires having parts that cope with high resistance deformation and expand on top of an already existing environmental harshness, serving as fatigue.

The Most Recent Focus in Research Based on Features of Automations in Devices for Tensile Testing Equipment

Improved automation systems with enhanced accuracy, digital screens, external real-time data analysis, and other features have recently been added to tensile testing equipment. Such systems automatically interface with reporting software, enabling engineers to easily analyze performance trends. Furthermore, new standards for testing requirements use sustainability criteria by assessing bioplastics and recycled materials to mitigate environmental degradation.

Importance of Plastic Tensile Strength in Industry

Like other industries, plastic tensile strength is highly important in product design, manufacturing, and application in skeletal construction, automotive parts, Aerospace, subsea engineering plugs, safety equipment like as seatbelts, and even strappings for packaging boxes. It indicates whether a material can withstand being pulled and is essential for rthe eliable, robust performance of plastic mechanisms.

Ultra-precision machining and other types of lightweight, high-precision requirements are on the rise, according to the latest domestic reports. Highly advanced polymers are replacing traditional metals in vehicle frame and body construction which can now withstand fuel-efficient ultra-lightweight structures. Other industries, such as Civil Engineering, are also adopting heavy-duty polymers in reinforced concrete composites to reach sustainable green constructions.

The bio-based and recycled polymers sector, with heightened strength, appears to be making strides as of 2023. It Provides an eco-conscious option while maintaining a high-level performance. For instance, there is a worldwide expectation that the bioplastic market will increase in value to $29 billion by 2028, which corresponds to an annual percentage growth rate of (CAGR) 9.7%. This shows how important tensile strength testing has become towards the validation of the integrity and functionality of materials that are considered sustainable.

If businesses install the latest advancements in tensile testing technology as well as elevate the goals for material standards, they will yield more innovation, while simultaneously addressing economic and environmental challenges. Changes such as these highlight the importance of tensile strength in the future of plastic material applications pertaining to industrial use.

Key Factors Affecting Tensile Properties

When it comes to industrial plastics, multiple factors determine their tensile properties. An understanding of these factors helps in the advancement of material performance and development for environmentally friendly applications. Moreover, these factors include:

1. Material Composition

Tensile strength is affected by the polymers and fillers that compose a material. As an example, materials with greater alignment of their polymer chains tend to have better tensile properties. According to recently conducted studies, the inclusion of carbon fiber or glass fiber into polymer matrices have shown an improvement of almost 30% in tensile strength, which underscores the importance of reinforcements regarding performance.

2. Processing Conditions

Attributes of tensile strength are defined by the manufacturing process. The sequential operations of a process may differ in such characteristics as speed of extrusion, temperature of molding, and cooling rate of the plastic. Research confirms that the reduction of cooling rates improves tensile strength due to enhanced crystallization, although transparency might suffer in some plastics.

3. Environmental Factors

Over time, exposure to environmental factors, like temperature and humidity, can degrade tensile properties. An increase in temperature often weakens polymer bonds which reduces tensile strength and moisture can lead to hydrolysis in certain plastics over time. For example, data indicates that materials like polycarbonate can lose up to 15% of tensile strength when exposed to 80% relative humidity for 10 days.

4. Supplements and Stabilisers

Additive plastic products like impact modifiers, UV stabilizers and antioxidants affect tensile properties, which results in either prolonging the lifespan of the material or mitigating the damage caused by external forces. For instance, UV stabilizers mitigate tensile property degradation when polymer materials are exposed to the sun.

5. Aging and Fatigue

The application of repeated stress or prolonged use tends to lower the tensile performance of the material. Fatigue testing for tensile strength shows that polypropylene-based composites suffer from an average strength reduction of 12% after one million cycles of loading.

6. Recycled Content

The incorporation of recycled content in the production of plastic materials is beneficial for the environment, but poses a challenge to maintaining the tensile properties of the plastic. More than 30% recycled content in a polymer composite could yield plastic materials with 20% lower tensile modulus and no added reinforcement.

All of these factors highlight the importance of reliable testing and bespoke formulations aimed at optimizing tensile strength within the confines of ecological and economic considerations.

How to Choose the Right Test Method for Plastic Materials?

The following are the factors which you need to keep in mind to select the appropriate test method for testing plastic materials.

Material Properties: Specify what needs to be measured such as tensile strength, impact resistance or thermal stability.

Standards and Guidelines: Ensure that you do not deviate from the ASTM or ISO standards while performing your tests.

Application Requirements: Ensure that the test corresponds to the material application so that the actual performance can be evaluated accurately.

Environmental Factors: Identify all the surroundings which include: temperature, humidity and chemicals that can be used on the material, and determine their effects.

Testing Equipment: Ensure that the measuring equipment you require is available and is capable of measuring the properties of interest.

Selecting test methods that focus on these factors will assist in achieving reliable results on the testing materials.

Comparing ASTM and ISO Standards

The American Society For Testing and Materials (ASTM) and International Organization for Standardization (ISO) are two global organizations that set industry benchmarks. Both work towards the maintenance of quality, safety, and efficiency in different fields. However, they approach the goal differently in terms of scope and methodology.

Important Contrasts Between ASTM and ISO Standards

Focus and Scope:

Most of the standards in ASTM are created in the United States but are adopted around the globe. They have an extensive range that includes materials, products, systems, and services.

In comparison to ASTM, ISO is a worldwide organization that has body members from different countries. Their standards tend to focus on harmonization and global applicability to ensure it welcomes inputs from industries and regions.

Procedures for Development:

ASTM standards are created based on the consensus of the members of the ASTM, which includes the industry, experts, scientists, and stakeholders. They are more focused on the performance-based requirements and the framing of relevant testing methods.

ISO standards require collaboration from representatives of the body of national standards from different nations. These usually go through thorough processes of review and checking to incorporate various international perceptions, focusing on international acceptance.

Use and Adoption:

In the United States, ASTM is referenced in the Constitution and standards are widely used in particular fields like construction, manufacturing, and petroleum.

ISO sets international standards that are accepted and utilized in various industries, even in information technology, healthcare, environmental management, and quality systems.

Subtle Differences:

ISO and ASTM standards covering the same subjects often have some technical differences: For instance:

Mechanical testing standards, such as tensile testing of metals, have some differences in specimen size, reporting formats, and testing speed.

With regard to testing the tensile properties of plastics, ASTM D638 and ISO 527 conflict in the measurement parameters and types of samples used.

Costs:

Both ASTM and ISO keep individually priced standards behind a paywall. ISO documents tend to be expensive due to their broad international reach while individual ASTM standards are generally priced lower.

Efforts to Harmonize

ASTM and ISO try to work together to align their standards in an attempt to minimize redundancy and confusion. When collaboration happens, they can issue joint standards or portions of one’s methodology is adopted by the other.

Data and Figure

Recent figures indicate that there are over 12,800 and 24,000 in use worldwide which cover a wide variety of applications. ISO and ASTM standards, respectively.

The ISO 9001 family which enables quality management systems, has been incorporated by more than 1 million entities in 170 countries.

ASTM standards are mentioned in 50% of U.S. federal regulations, displaying their relevance for domestic policymaking.

Industry Implementation

Companies frequently select the standards relevant to their business strategy. For example:

A United States-based manufacturing company may emphasize ASTM standards for its domestic projects.

A globally operating company will most often use ISO standards to fulfill international trading obligations.

Now, utilizing these differences alongside harmonized standards, businesses can ensure legal compliance while maintaining uniformity in quality, performance, and safety regardless of operating location.

Selecting a Test Procedure for Different Plastic Material Types

For the performance, quality, and safety plastic materials, the selection of the test procedure based on the provided application requires the utmost precision to materials selection. There are different testing standards that are available for each plastic and it comes with varied properties as well as an industry which it will used. Below is a rough anaerobic outline for the rest of the instructions provided.

1. Tensile Strength Testing

Maximally stretching a plastic material by applying stress will lead to breaking it, thus tensile strength testing helps in accessing the Mantel Strength that a material can endure, and is able to withstand. This is a very important property for any structural application that involves placing a mechanical load on it.

Standard Used: ASTM D638 or ISO 527.

Commonly applied to thermoplastics and composites used in automotive or aerospace components.

Key Data

Stress at Yield (PSI or MPa)

Elongation at Break (%)

Young’s Modulus (PSI or MPa)

2. Flexural Testing

Flexural testing is the ability to resist the deformation of s material. Such materials are used for plastics employed in structural designs.

Standard Used: ASTM D790 or ISO 178.

Used for materials like polycarbonate or polypropylene in construction or heavy machinery.

Key Data:

Flexural Strength

Flexural Modulus

3. Impact Testing

Impact testing evaluates the impact resistance and impact toughness of a specific plastic material by measuring the absorbed impact energy. This is important for materials that need to withstand shocks and impacts.

Standard Used: ASTM D256 (Izod Impact) or ISO 179.

Application: Often critical for packaging, sporting goods, and outdoor equipment.

Key Data:

Impact Energy (Joules or foot-pounds)

Assessment under different temperatures.

4. Thermal Properties Testing

Testing the thermal properties of plastics ensures their functionality under different temperatures.

Standard Used:

ASTM D648 for Heat Deflection Temperature (HDT)

ASTM E831 for Coefficient of Thermal Expansion (CTE)

Application: Ideal for engineering plastics used in electronics, automotive, and aerospace.

Key Data:

Heat Deflection Temperature (°C or °F)

Thermal Expansion (µm/m°C)

5. Flammability Testing

Testing the flammability of plastic is important in cases where the material will be used in conditions with potential fire hazards. This test analyzes how the plastic reacts to fire.

Standard Used: UL 94 or ISO 1210.

Application: Essential in electrical and building materials.

Key Data:

Horizontal Burn Rate

Vertical Burn Rate

Material Self-Extinguishing Behavior

6. Chemical Resistance Testing

The Chemical resistance testing examines the resistance of plastic materials to a range of chemicals such as acids, alkalis or solvents.

Standards Used: ASTM D543.

Purpose: Commonly applied to industrial-grade plastics and their use in pipelines and chemical storage.

Critical Information:

Change in Weight (%)

Visual Damage

Retention of Tensile Strength

Shifts in the Testing of Plastics

Shifts in the test technology focus on using automated systems to perform rapid evaluations. For instance:

Smart sensors have been added to Digital Tensile Testers, enabling them to provide real-time stress-strain curves.

DMA (Dynamic Mechanical Analysis) is becoming more popular for the precise estimation of viscoelastic properties which is one of the core functions of DMA.

By leveraging the newest technologies available for the selection of test procedures, manufacturers and companies can be sure that their plastic materials fulfill the stringent standards set by the industry and requirements for uses.

Role of Specimen Preparation in Accurate Results

The impact that specimen preparation has on testing accuracy (for example, on materials, polymers, or plastics) is profound and should not be underestimated. Processes that are prepared accurately prevent inconsistencies within defects, irregularities, and contamination. As other examples, the specimen’s surface finish, shape and texture, and uniformity into the resultant specimen all influence the specimen’s tensile strength, impact resistance, or thermal analysis.

Standards provide a framework for achieving uniformity. As an example, ASTM D638 and ISO 2818 offer guidelines for the actual machining of plastic specimens along with tensile testing. According to the standards, specimens must be machined and prepped to the exact geometrical shapes as dry-stressed, controlled environment conditioned frames. Studies done in preparation illustrate the relevance of meticulous detailing as specimen preparation inadequacies induce up to 20% variations in outcome measurement.

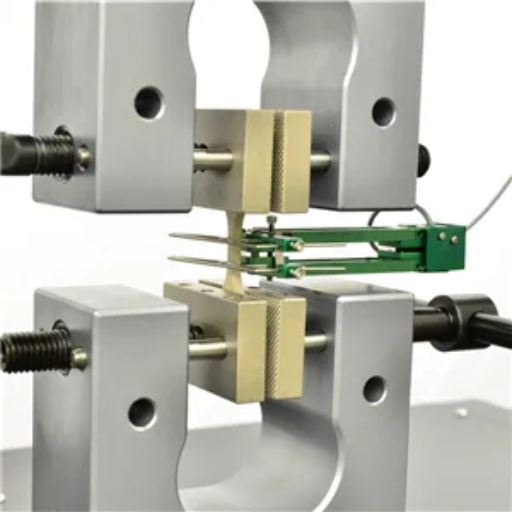

Elsewhere, specimen preparation is made easier through advanced technologies. Along with judges who add detailed, layered accuracy of micrometers within contact measuring systems, automated cutters and millers remove humans from the equation, thus allowing enhanced precision. Proper maintenance is essential, especially provided to plastic specimens such as nylons, known for their hygroscopic nature, since moisture presence, as highlighted, clinically skews test data. Standardized procedures and modernized tools allow laboratories and manufacturers to ensure precision and uniformity of test results, thereby evaluating material properties more efficiently, achieving defined quality control parameters, and optimally improving their material selection.

Step-by-Step Guide to Conducting ASTM D638 Testing

Cut and Prepare Test Specimens

Use the ASTM D638 guideline for cutting the specimen into the precise shape and dimensions needed. Make sure the material is conditioned properly if required, especially for hydration-sensitive plastics.

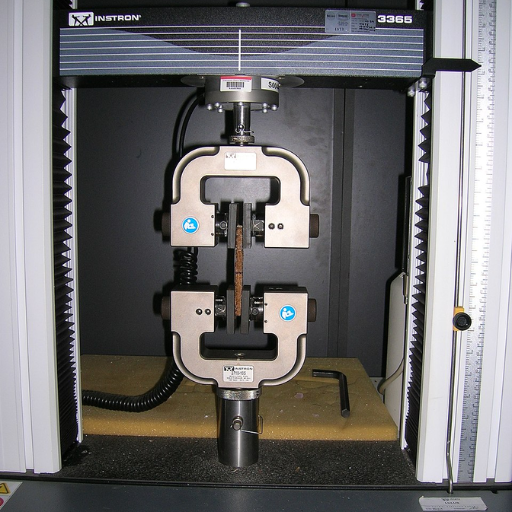

Set up Testing Equipment

Integrate the appropriate load cells and testing grips into a universal testing machine. Ensure calibration is done per the manufacturer’s recommendations.

Secure the Test Specimen

Insert the specimen into the testing equipment’s grips with the proper care needed to avoid damaging the specimen. Make sure that no twisting occurs that would cause misalignment during testing.

Perform the Tensile Test

Run the machine at the prescribed crosshead speed, noting that all force and elongation measurements should be captured at the moment when the material fails.

Evaluate Test Results

From the data gathered, compute tensile strength, elongation at break, and other applicable results compliant with the ASTM D638 standard.

Report Findings

Prepare a report that carefully outlines all data collected, the conditions observed, and any other notes of interest, presented in a clear and easy-to-follow manner.

Preparing the Specimen for Plastic Tensile Strength Test

Accurate results from a plastic tensile strength test rely on precise specimen preparation, which is critical. Under the ASTM D638 standard, a specimen must be molded or cut into a given shape and size, usually a flat “dogbone” or dumbbell shape, to enable proper replication of testing conditions across samples.

Key Steps for Specimen Preparation:

Selection of the Material

Begin with a homogeneous plastic sample containing no visible flaws or impurities. Make sure the sample is appropriate for the intended application, be it thermoplastics or thermosetting materials, or other types of polymers.

Specimen Measures

Use the preset measures according to the ASTM D638 guidelines. The Type I does not deviate from: length 165 mm, gauge length 50 mm, width 13 mm at narrowest point. Allowable thickness is between 3.2 mm and 4 mm. Ensuring precision in these dimensions is important to achieve greater accuracy in results.

Cutting/Molding Process

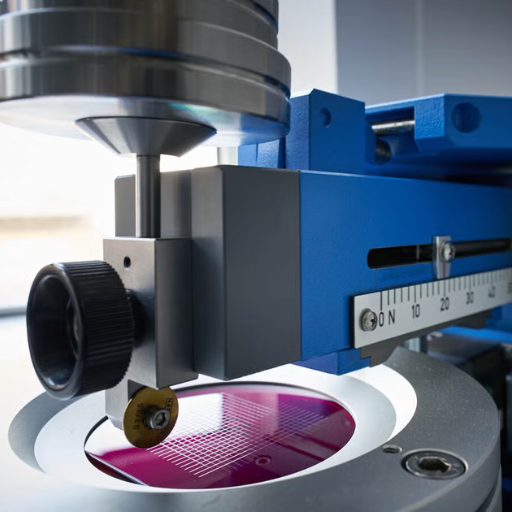

Cutting: Use accurate cutting implements like CNC machines or laser cutters to the required dimension and ensure all edges are smooth and devoid of burrs.

Molding: For injection molded specimens, optimum values for mold temperature, pressure, and cooling time should be established to prevent internal stresses or warping in parts.

Surface Finish

In preparation for a tensile test, smooth the specimen surface to avoid stress concentrations. Sanding or polishing may be necessary to prepare machined specimens.

Conditioning the Specimen

Condition the specimens as per ASTM D618 or other comparable standards. Generally, specimen samples are stored at 23°C (±2°C) with a relative humidity of 50% (±5%) for no less than 40 hours to attain the desired material characteristic equilibrium.

Data on Plastic Specimen Preparation

The most recent advancements have introduced automated cutting and shaping systems for specimens, enhancing manual error repeatability and reduction. For example, CNC machining technology provides remarkable accuracy with tolerances of ±0.1 mm. In addition, research indicates that inadequate surface treatment can lead up to15% increase in tensile strength variance which accentuates the need for precise handling of specimens.

Following best practices and industry standards, precise preparation of the plastic specimen boosts confidence that testing results will be consistent across exercises while accurately reflecting practical conditions.

Setting Up the Tensile Testing Machine

Follow proper techniques when setting up a tensile testing machine to guarantee reliable results. First, choose a suitable load cell based on the tensile force you expect. For example, modern machines often come with load cells ranging from 10 N to 500 kN, depending on the strength of the material. The load cell must be calibrated to ASTM or ISO standards to avoid any inaccuracies during testing.

Next, position the specimen’s mid-section in the grips. Thin metals and plastics tend to slide when under tension, so hydraulic grips are easier to use as they securely grasp the material. Specimen alignment is crucial as any deviations can result in stress concentration which leads to unreliable results. Recent research suggests even a minor misalignment (1°) can produce a 5-10% difference in elongation measurement.

Remember to set straining parameters directly on the machine. Some predefined parameters include: test speed, strain rate and gauge length. Standard strain rates for plastics are around 5 mm/min, but other documents, such as ASTM D638, have different recommendations. Gauge length and the geometry of the specimen should match—if precise elongation data is required, use an extensometer.

Last, make sure the conditions that are set for the environment fit the requirements of testing. Factors such as heat and moisture content can strongly affect test outcomes, especially for polymers. For example, a temperature of 23°C and a relative humidity of 50% is the default testing environment for many materials’ moisture conditions. After all variables are configured, conduct a test run with a sample specimen to check the accuracy and functionality of the apparatus before proceeding with actual tests.

Interpreting Stress-Strain Curves and Elongation Data

The analysis of stress-strain allows us to evaluate the mechanical properties of materials, which include its strength, ductility, and resilience. Each material’s response depends on the stress level applied which is represented through a number of regions on the graph, some of which include, Elastic region, Yield point, Plastic deformation, and fracture point.

Elastic region is the initial linear section of the graph where the material returns to its original form after stress is removed. Every material has a different slope for this linear region which gives us the modulus of elasticity which gives indication of the stiffness of the material. Metallic products or metals are a perfect example of this because steel has a higher modulus which keeps it from being deformed easily.

A material enters into plastic deformation state when it has reached the yield point, this means that permanent changes will begin to occur. This change is best suited for aluminum or titanium alloys due to their high yield strength and resistance to unending deformation. Marking The highest stress of the material before it failures of necking is called Ultimate tensile strength (UTS).

Elongation data helps stress-strain analysis by providing a measure of stretchable ductility, which is a material’s ability to elongate to a certain limit before fracturing. For instance, rubber and polymers have high elongation percentages which are ideal for operations requiring flexibility, unlike ceramics having low elongation and high strength.

In real-world applications, these attributes are particularly important in materials choices for aerospace engineering, civil engineering, and automobile industry. For example, ductility may be prioritized for metal forming for automotive body panels, but is lower for rigid components like engine parts, where strength and stiffness are more critical.

Reviewing stress-strain curves and deviation and elongation coordinates allows optimal balance between strength and ductility with other material properties to reduce failure possibilities under defined operational stress levels while improving product durability.

What are the Key Tensile Properties of Plastics?

Some of the fundamental tensile properties of plastics are:

Tensile Strength: Divulged as the maximum stress a plastic material can bear while being stretched or pulled before fracturing.

Elongation at Break: The ratio at which a plastic can stretch before breaking, mostly represented in percentage form.

Elastic Modulus: Also referred to as Young’s Modulus, this is the measure of how stiff the plastic is. It quantifies how much the material deforms under stress.

Yield Strength: The stress at which deformation of the plastic can begin to occur.

Understanding these parameters about other characteristics assists in evaluating a plastic’s toughness, pliability, resistance to scratches and various other aspects for different applications.

Understanding Yield Strength and Ultimate Tensile Strength

Both Yield Strength and Ultimate Tensile Strength (UTS) are two plastic properties that are incredibly important with respect to how a material behaves when being mechanically stressed, deformed or broken. Yield strength, also known as yield limit, denotes the amount of stress a mechanical body can take before undergoing permanent deformation, while UTS refers to the limit above which a material can no longer withstand stress before breaking apart.

Yield Strength value matters for the applications dealing with maintaining specific forms under static load and the impact of the applied vertical or horizontal shear forces. In the case of plastics, yield strength is usually less than metals which is typically between 2,000 to 10,000 psi, depending on the kind of plastic. For example, High Density Polyethylene (HDPE) is said to possess a yield strength nearly approaching 4000 psi for its yield strength while polycarbonate is said to achieve nearly 9000 psi.

Ultimate Tensile Strength (UTS), as the name suggests, measures the absolute maximum limit that a certain material is capable of bearing without fracture. This value is important to note while evaluating the strength of heat-resistant plastic employed in severe straining conditions which is known as the engineering grade of plastic. UTS of plastics, when being stretched till they yield, is observed to have a very broad range with certain materials like Nylon stretching its limits to possess a UTS of 10000 psi and achieving values of above 14000 to 16000 psi marks and engineering plastics such as Polyether Ether Ketone (PEEK) have significantly higher upper limit.

What skeletal muscles and bones do to the human body is assisted by connective tissues. The binding, cushioning, and supporting functions are done by connective tissue. These tissues are available in different parts of the body. Areolar tissues are in the skin, bones are there to give the framework to the body, blood is the connective tissue found in the vascular system while lymph is the connective tissue found in the lymphatic system.

While connective tissues are distributed throughout the body, connective tissues such as epithelium serve as the outer layer protecting the skin, cartilage exists almost in every joint, serves as a shock absorber, ligament binds together different types of tissues while adipose where the fats are stored.

Significance of Modulus of Elasticity and Elongation at Break

The modulus of elasticity or Young’s modulus is one of the most important parameters in the material science field since it depicts the stiffness or rigidity of a material. This value shows the level at which a material will deform under stress until its elastic limit. It provides a gauge for a material’s reliability in bearing loads. For example, steel is one of the metals with the highest elasticity modulus because of its low deformation under stress which is critical in construction and manufacturing.

On the other hand, elongation at break is known as the amount of stretch a material can withstand before breaking. This property is very important for applications where bendability and ductility is very critical. For instance, elastomers or rubber like polymers have very great elongation at break which is useful in gaskets, seals, and flexible hoses.

The data collected from other materials studies indicate that some materials like high density polyethylene (HDPE) can have an elongation at break of between 600% to 1000% which is hugely different from aluminum which averages around 10%. In the same way, the elasticity modulus of stainless steel is close to 200 GPa which shows that it is more rigid than polymers which range between 0.1 GPa to 10 GPa depending on the type.

Striking a balance between the two properties is often crucial. Take, for example, aerospace components. These parts not only have to attain a certain level, strain, but also need a high modulus of elasticity in order to endure stress and elongation at breakwithout any severe failures. With all the data and testing, along with understanding these factors, engineers and manufacturers are able to create precise, safe, and efficient components designfully with specific operational requirements in mind.

Analyzing Deformation and Stiffness in Polymer Materials

In many cases, the performance of polymer materials critically relies on their deformation and stiffness. The molecular structure’s impact on these features has recently received attention. Polymers containing highly organized crystalline regions exhibit greater stiffness and deformation under stress, while those with amorphous structures tend to be more flexible with greater elongation until breaking.

Materials Today published a study in 2023 that analyzed the stiffness of advanced composite polymers, reporting modulus of elasticity values surpassing 120 GPa for carbon-fiber reinforced polymer matrix composites. Besides, the recent progress in nano-reinforcement techniques like adding graphene nanoparticles to the matrix has been proven to considerably increase stiffness while still maintaining flexibility for the material.

Polymer deformation and stiffness assessment is still dominated by methods like dynamic mechanical analysis (DMA) and tensile strength testing. Data from recent experiments indicate that temperature and moisture absorption are critical to these properties. For example, softening a polymer by heating it above its glass transition temperature (Tg) usually decreases stiffness and increases deformation because of molecular mobility, as increased mobility in the material usually means lower strength. These findings are now used by manufacturers to guide the design of polymers intended for use in high-stress and high-temperature environments, such as automotive and aerospace applications.

Moreover, the behavior of polymers under different conditions can be simulated with the use of computers. Advanced simulations can now predict parameters such as stiffness and deformation, which accelerates the design process and reduces material wastage.

Pushing the limits of how far polymers can perform, industries integrate empirical testing data with sophisticated materials, such as nano-reinforcements, and add computational predictions into the mix. As rigorous engineering requirements pose new challenges, advanced polymers are designed through continued innovations to meet next-generation engineering needs.

What are the Best Practices for Mechanical Testing of Plastics?

Choose Proper Testing Criteria

Selection of testing criteria should be grounded on reputable standards such as ISO or ASTM in order to maintain result accuracy, consistency, and comparability.

Correct Sample Preparation

Specimen preparation should be performed within the guidelines of the provided dimensions to structural detail to eliminate any irregularities that could impact results.

Environmental Control

Undertake testing in a controlled environment with constant force and restraint, temperature, and humidity to mitigate discrepancies in material behavior.

Maintenance of Equipment

Maintenance of testing instruments is critical for the accuracy and reliability of measurement values and data collected.

Test Methods Selection

Selection of test methods aligned with the specific mechanical property being tested, such as, but not limited to, tensile strength, impact resistance, flexural properties need to be chosen.

Result Analysis

Proper analysis and validation of the results documented entails the recording of all test parameters, conditions, and results, ensuring detail, traceability, and proper analysis.

Ensuring Accurate Materials Testing Results

It is always important to find ways to be more accurate when testing materials, and to do this, one must integrate existing methods with modern technology. The latest have reputable and highly dependable repeatable results. Given below are some of the new practices:

Automation of Data Recording

New test devices have typical automated data collection which include computer operated recorders, accurate measurement devices, and real time processes. Newer model UTMs with automatic data collection add load cells with accuracy of almost ±0.5%. This greatly aids in C-tests calibrations and compressive tests consintancy.

Use of Chambers to Control the Environment

Controlling outside forces like temperature, humidity, and pressure is very important in dealing with materials and their behavior when subjected to testing. Using climate controlled chambers provide stablibility while minimizing outside factors. Most researchers claim that controlling environment within ±2°C can guarantee error margin reduction upto 15%, thus optimizing conditions.

Employ NDT for Some Uses

NDT methods like ultrasound and CT scans allow finding structural flaws on the inside without causing any damage to the outer part of the sample. A survey done in 2023 showed that many industries using NDT methods recorded upto 30% better rates while detecting problems compared to the older means used.

Employ Data Management and the Analyzing Power of AI

The use of cloud databases allows for the improved storage of test results as they can now be kept in a single area which ensures better traceability and access. Moreover, trends, patterns, and outliers in testing data can easily be recognized with the assistance of artificial intelligence (AI). To exemplify, software platforms powered with AI can analyze data with 25% more efficiency and accuracy.

Along with proper marking and well-defined procedures, these technologies greatly support reliability in materials testing. Organizations can offer dependable results and insightful recommendations by integrating advanced technologies with traditional methodologies in their testing procedures.

Common Challenges and Solutions in Plastic Tensile Testing

While plastic tensile testing is an essential method for evaluating a material’s properties, it does come with its problems. Below, we will list issues faced during the testing, alongside useful solutions that utilize new data and knowledge:

1. Issues with Sample Preparation

Challenge: If a sample is cut incorrectly, surfaces are rough, or if the sample measurements are not uniform, test plastic tensile machine may return inaccurate results.

Solution: Using sophisticated lasers or CNC machining can result in specimen preparation that is both precise and equal. Recent advances suggest that automated specimen preparation systems, according to industry claims, can lessen variability by as much as 15%. Furthermore, adhering to appropriate ASTM or ISO standards on sample geometry guarantees compliance to ensure reliable results.

2. Equipment Calibration Errors

Challenge: Any testing apparatus, ranging from a tensile tester to grips, can over time become unsynchronized, leading to inaccurate data generation.

Solution: Set up a systematic calibration timetable for your tensile testing machinery aligned with recognized benchmarks. Research suggests that equipment which undergoes frequent calibration has greater accuracy in data collection, leaning closer to the 20% mark. Automation with alert software within calibration systems will make the process even more efficient.

3. Grip Selection and Sample Slippage

Challenge: Use of incorrect grips clamping onto soft or highly elastic materials during the test could result in unintentional sampling bias, leading to incorrect results.Solution: Use suitable grips, such as pneumatic grips for soft plastics and wedge grips for stiffer plastics. Slipping can also be avoided by the treatment of the gripping surface, for instance, by applying sandpaper. More recent grip designs also have configurable pressure control which can further reduce sample damage.

4. Environmental Testing Conditions

Challenge: Changes in temperature and humidity may occur during testing, affecting the properties of the material and leading to errors.

Solution: As per standard procedures, tensile testing should be done under specified controlled environments. Directly incorporated into testing machines, specialized temperature chambers are gaining popularity, for instance, those that control temperature to within +/- 1°C provide consistent testing conditions for sensitive, temperature dependent polymers.

5. Analysis of Stress-Strain Graphs

Challenge: The more complex a stress-strain curve becomes, the more difficult it is to interpret. This is particularly true for plastic materials that display non-linear, visco-elastic behavior.

Solution: Utilize software powered by artificial intelligence to analyze curves that require intense scrutiny to devise an automated and precise interpretation of the results. According to the latest statistics, AI-assisted analysis mitigates interpretation inaccuracies by over 30% while consistently measuring material performance indicators such as modulus of elasticity and elongation at fracture.

Developing modern strategies and technologies to deal with the challenges of plastic tensile testing ensures that the evaluations conducted are highly accurate and reliable. Such innovations increase confidence in the results while also enabling informed decision-making regarding the design and materials to use for the products in question.

Utilizing Testing Software for Enhanced Data Analysis

The development of modern testing software has changed the method of capturing, processing, and analyzing data during plastic tensile testing. These tools allow users to capture raw data as it is being collected, allowing for real-time transformation into actionable insights. For instance, automatic trend identification along with statistical analysis, graphs, and charts to provide components of detailed reports are advanced system features. This automation decreases human error while increasing result consistency.

With such software, certainly, heel cracking a benefit is the effortless incorporation of machine learning algorithms and predictive modeling. These technologies can utilize historical test data to forecast the performance of a material under different conditions which enables researchers to optimize formulations without excessive trial-and-error experiments. Editable software platforms for testing are now offered by industry leaders such as Instron and ZwickRoell, giving customers the flexibility to customize their software to specific requirements and aiding in uniformity throughout different industries.

Also, collaborative data sharing as well as access has been made easier through cloud-based testing software systems which is why they are on the rise. Such platforms enable access to the data by various stakeholders, engineers, designers, and quality assurance, enabling them to take part in drafting decisions as the work is being done. This not only speeds up product development timelines but also serves as a central repository for test data that allows for audits and compliance evaluation.

The Google Trends Data shows an increase in interest or automation in tensile testing which has been a popularly searched word over the past few months. This shows the increasing appreciation for automated tools in the testing of materials. Companies can now, more than ever, take advantage of new software features to optimize material evaluation and innovate within the industry.

Reference Sources

- Plastic strength of thin-walled members

This analysis determines the plastic strength of stub columns based on test data and advanced elastic-plastic FEM analysis.

- Development of Control Setup for a Material Testing Machine

This study focuses on assessing the compressive strength of recycled high-density plastics employing a material testing machine.

- A review of foundation failures on plastic clays

This paper presents an investigation of the yield shear strength concept and undrained shear strength test results on plastic clays.

Frequently Asked Questions (FAQs)

Q: What is the purpose of testing plastic strength?

A: The purpose of testing plastic strength is to determine the tensile strength, elasticity, and other mechanical properties of plastic materials. This helps in understanding how the material will perform under different stress and strain conditions, ensuring its suitability for specific applications.

Q: What is ASTM D638, and why is it important for tensile testing of plastics?

A: ASTM D638 is a standard test method used for determining the tensile properties of plastics. It is important because it provides a consistent procedure to measure properties such as tensile strength, elongation, and tensile modulus, allowing for the comparison and evaluation of different plastic materials.

Q: What are the key steps in the tensile strength test for plastics?

A: Key steps in the tensile strength test include preparing the specimen, mounting it on a tensile testing machine, applying tensile force, and recording the stress-strain data. The test continues until the plastic material breaks, and the results are used to determine its tensile properties.

Q: How does one prepare a specimen for a tensile strength test?

A: Specimen preparation involves cutting the plastic material into a specific shape and size according to the test method requirements, such as ASTM D638. The specimen should be free from defects and uniform in thickness to ensure accurate results.

Q: What is the significance of the stress-strain curve in tensile testing?

A: The stress-strain curve is significant because it provides a graphical representation of a material’s response to tensile stress. It helps in identifying key properties like yield strength, ultimate tensile strength, and elongation at break, which are crucial for assessing the material’s performance.

Q: Can you explain the term ‘tensile modulus’?

A: Tensile modulus, also known as the modulus of elasticity, is a measure of a material’s stiffness or resistance to elastic deformation under tensile stress. It is calculated as the ratio of stress to strain in the elastic region of the stress-strain curve.

Q: What equipment is used to conduct a tensile strength test on plastics?

A: A tensile testing machine, often referred to as a universal testing machine, is used to conduct tensile strength tests on plastics. This machine applies tensile force to the specimen and records the resulting data to determine tensile properties.

Q: How do ASTM D638 and ISO standards differ in tensile testing?

A: ASTM D638 and ISO standards both provide guidelines for tensile testing, but they may differ in terms of test procedures, specimen shapes, and sizes. It is essential to follow the specific standard relevant to the intended application for accurate results.

Q: What role does elongation at break play in evaluating plastic materials?

A: Elongation at break is a measure of how much a plastic material can stretch before breaking. It provides insights into the material’s ductility and toughness, which are important factors in applications where flexibility and impact resistance are crucial.

Q: Why is it important to measure the tensile properties of plastics?

A: Measuring the tensile properties of plastics is important for ensuring that the material will perform adequately under expected service conditions. It helps manufacturers and engineers select suitable materials for their products, minimizing the risk of failure in real-world applications.