The activities performed in testing need to be very precise and rigorous to ensure that the product’s reliability and performance are guaranteed. Enter force-testing fixtures: an all-important aid in engineering and operational fields in the quest to recreate the conditions of the real world and measure forces with the utmost accuracy. Both theoretical design and practical applications get linked together with these devices as they test the scope of strength, endurance, and functionality across all categories of industries.

This article sheds light on force testing fixtures, delving into their importance, working, and how they get assimilated in the overall testing scheme. Looking for a way to upgrade an industrial testing approach, or simply brushing up on the technologies that make quality assurance go? This article will help shed light on how to optimize these essential tools in application.

Understanding Fixtures and Their Importance

What is a Test Fixture?

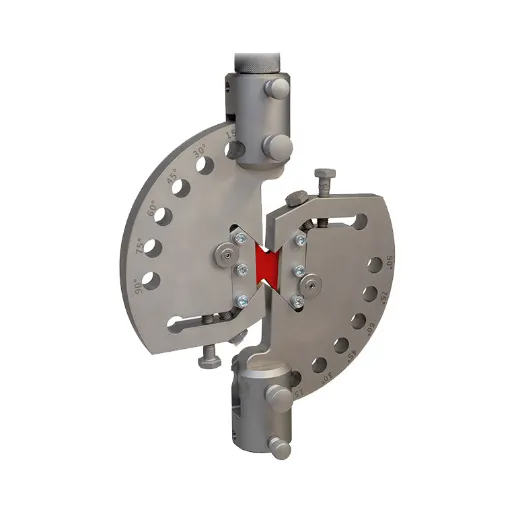

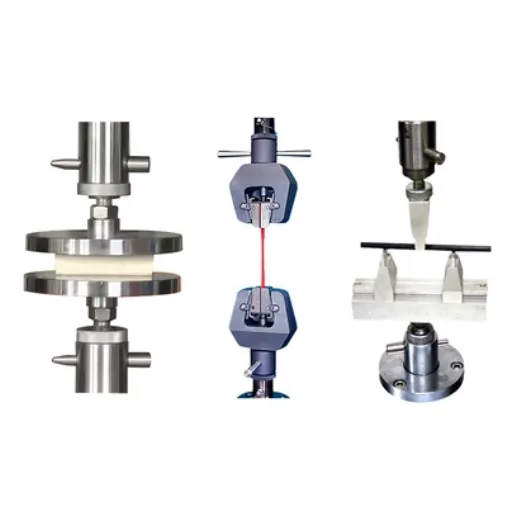

A test fixture is a particular tool or device used to secure sample material or otherwise hold it in position during testing. It makes the measuring of forces-such as tension, compression, and shear-consistent, precise, and repeatable. The fixture keeps the sample properly oriented for the force-testing steps to yield accurate and trustworthy results.

Force-testing fixtures are needed in industry and research because they adapt the testing machine to work on a certain application or material being tested. Without the fixture, the specimens might move, deform in unintended ways, or fail unevenly, resulting in meaningless data. A fixture is given consideration for the physical characteristics and shapes of the test materials, which might be solid, flexible, or irregularly shaped. This, however, shall maintain the integrity of the testing procedure.

Thus, by using a test fixture, the engineers and scientists can ensure the smooth flow of their work, prevent possible errors in measurements, and maintain quality assurance across all domains. They, thus, form a fundamental part of force testing that enables materials to be understood more deeply with respect to their capabilities, while at the same time ensuring the production of products that adhere to safety and performance standards.

The Role of Fixtures in Testing Environments

Fixtures stand as a critical element in force testing environments, instilling stability and consistency in testing procedures. They are intended to hold or support materials, components, or products under conditions that are both controlled and repeatable so as not to interfere with outside variables that could otherwise render a test whose results do not truly represent the performance and properties of the material or product under evaluation. One well-designed fixture can provide good test accuracy and hence credibility to the test procedure.

Key Benefits of Proper Fixture Design:

- Alignment: Ensures forces are applied evenly and in the intended direction

- Repeatability: Reduces variation factors between tests

- Accuracy: Prevents distorted or inaccurate results

- Safety: Meets safety requirements and product development standards

Primarily, a force testing fixture provides alignment. Proper alignment ensures that the force is applied in an even manner and in the direction intended to do so; any deviation in these conditions can yield distorted or inaccurate results. This is very important in an industrial environment where materials or components are tested for their strength, elasticity, or durability. Any variances from aligned tests would create data that could ultimately be used to contradict safety requirements or product developments. Hence the use of precise fixtures developed specifically for the job helps avoid such errors and, in turn, increases the efficiency of the testing procedure.

Fixtures also provide repeatability for force testing by reducing the factors of variation in the tests. This is important for quality assurance when it comes to ensuring that manufacturers receive consistent performance levels from their products. For researchers and engineers, repeatability can give them a high degree of confidence about the properties of their materials. By relying on fixtures that are well designed and fit for purpose, the tester can ensure similar test conditions for all test runs and subsequent analysis and decisions abiding by the different standards. A fixture is, therefore, a much-needed element in the making of a product that is reliable, safe, and high-performing.

Relevance of Fixtures Across Industries

Fixtures play crucial roles in force testing in various industries for accurate and repeatable measurements. The primary function of fixtures is to hold a specimen firmly in test conditions so as to apply force consistently and uniformly on the specimen. Any inconsistency might introduce variables in the measured results from which the data would not be proper for analysis and final judgment. Thus, fixtures serve to uphold the veracity of force measurement.

| Industry | Application | Safety Standards |

|---|---|---|

| Automotive | Seatbelt and airbag testing | Force resistance standards |

| Aerospace | Materials and component stress testing | Aircraft safety and performance |

| Manufacturing | Product quality and durability testing | Industry compliance standards |

In automotive, aerospace, and manufacturing industries, force testing fixtures are used to determine the final quality and safety of their products. For instance, under the automotive industry, fixtures test whether seatbelts or airbags can sustain certain forces to meet safety standards. Likewise, force testing in aerospace ensures that materials and components maintain under severe stress, ultimately assuring the safety and performance of aircraft. Fixtures are just as much a necessity as the materials themselves, given the exacting requirements imposed upon these industries.

The application of force testing fixtures is equally important during research and development. Engineers and scientists rely on them to test prototypes, optimize designs, and contrast material properties in early production stages. By providing consistent and accurate test conditions, fixtures assist in innovation while helping to reduce the risk for product failure. The application of force testing fixtures across industries is a testimony to their indispensability in producing reliable, high-performing, and safe products.

Setup and Teardown Processes for Test Fixtures

Establishing a Test Fixture Setup

Setting up a test fixture for force testing is a job that requires careful consideration so as to have accurate and reproducible results. The first step is to clearly establish the test requirements, considering the type of material or product to be tested and the force range under consideration, as well as specific testing conditions. This guides the selection of fixtures that suit the intended application. The fixtures should hold the test sample securely but must not introduce undue stress or deformation so as not to interfere with what essentially are real-life testing conditions.

Critical Setup Considerations:

- Establish clear test requirements and parameters

- Select appropriate fixtures for the specific application

- Ensure secure sample holding without introducing stress

- Maintain real-life testing conditions

Next, the test setup must be properly installed onto the force testing machine, adhering to stringent alignment procedures. Proper alignment during test procedure avoids erroneous force reading, or unequal load on the test. After installation, the fixture and equipment must be fully calibrated before further testing can take place, with the tester ensuring that the force applied by the machine AS WELL AS the force measured by it correlate with the defined parameters.

A trial run must then be conducted to verify that the setup is reliable. This permits the identification and correction of potential problems such as improper clamping, misalignments, or even irregular behavior of the sample. Through a systematic review of all these steps, test fixtures can be established to foster accuracy, repeatability, and integrity in the force testing process.

Teardown Procedures After Testing

Teardown procedures following force testing should be done carefully to maintain the quality and longevity of the test fixtures. The first step involves releasing the sample from the fixture with due care. All other components must be disengaged methodically while observing any safety precautions to avoid damage to the fixture or injury. Dismantling any part of the test fixture before full withdrawal of force from the sample must be strictly avoided.

Following removal of the sample, inspect the test fixture for any signs of wear or damage. Examine fixings and clamps for possible damage to any suspended elements; look at the fasteners, evaluate their level of wear, and compare it with the level of wear considered acceptable. If any tests fixtures or its parts show signs of excessive wear, they are to be replaced or repaired before the next test to ensure the fixture remains both accurate and reliable for that test.

Lastly, clean each and every component of the test fixture, leaving none behind. This acts against any debris, residue, or contaminants from the testing process and consequently helps maintain the accuracy of the fixture with no repercussions that may arise during the next test. Test fixtures are then stored in specified storage areas, under controlled storage conditions that keep them free of dust, moisture, and corrosion. By doing so, the test fixture stays ready to be used and its life expectancy increases.

Best Practices for Effective Setup and Teardown

When preparing a force testing fixture, the preciseness, longevity, and efficiency should be fully considered. Setup begins when the fixture components are clean, undamaged, and properly aligned. Calibrations must be done prior to every test to assure that the force testing equipment meets the specifications required. This minimizes incorrect results and provides consistency between tests.

Best Practice Checklist:

- Clean and inspect all components

- Verify proper alignment

- Calibrate before each test

- Document procedures thoroughly

- Label components accurately

- Store in controlled environment

- Regular maintenance scheduling

- Follow standardized procedures

In the teardown process, disassemble the fixture components with great care and clean each element by suitable methods to remove residues or contaminants that may have accumulated. Inspect the components for wear, cracks, deformation, or other signs that can compromise test accuracy in the future. If one of the above is detected, repair or replace the affected part immediately. Accurate labeling and documenting fixtures’ condition add to good maintenance and traceability.

At last, store the disassembled fixtures in an environment shielded from dust, moisture, and extreme temperature, as these factors could degrade their quality. The use of a dedicated storage system to organize the components would help in maintaining their accessibility for the next testing session. Following these best practices enhances force testing fixtures reliability and longevity and saves time and resources, which might otherwise go into rectifying errors and sudden equipment failures.

Using Multiple Fixtures in Testing

Benefits of Multiple Fixtures

No fewer than four benefits are to be touted in the aid of multiple force testing fixtures, all aimed toward efficiency and reliability in test processes. Multiple fixtures can allow one to test different items through the test simultaneously, maximizing output and minimizing time consumed. This is especially useful when working with parts of different sizes, shapes, or materials, since dedicated fixtures can provide thorough and accurate testing as per individual requirements.

Efficiency

Test multiple items simultaneously, maximizing output and minimizing time consumption

Accuracy

Better consistency and accuracy through dedicated fixtures for specific applications

Flexibility

Different load thresholds and force applications for broader testing capabilities

Reliability

Minimized measurement errors and inconsistencies through specialized fixtures

Another important advantage is a better degree of consistency and accuracy in test results. The chances of any measurement error or inconsistency are minimized with individual fixtures assigned to specific applications. Dedicated fixtures could also offer better alignment and stability during the test and thus better data acquisition and subsequently better repeatability in experimentation and quality assessments.

Furthermore, multiple fixtures help provide good flexibility for testing procedures. Different fixtures allow testing at different load thresholds and at different force applications, giving the operators a broader range of tests to perform-being ensured that one test asked would not affect the reliability of the other. This particular flexibility will be needed in a field where they may be forced to examine a large number of components under varied conditions, which in turn will help better product development and quality control.

How to Organize Multiple Fixtures

To organize multiple and force testing fixtures, an approach of high degree and systematic convoluted way is taken to ensure operational efficiency and precision. The next step is to arrange the fixtures according to their respective applications, such as tensile testing, compression testing, or torsion testing. It ensures operational proficiency and eases the choice of the fixture to be used by the operator according to the test in hand. Each fixture should be marked clearly with a brief explanation of its use and compatible testing equipment to reduce the scope for errors.

Organization Strategies:

- Categorize by Application: Group fixtures by testing type (tensile, compression, torsion)

- Clear Labeling: Mark each fixture with its use and compatible equipment

- Accessibility Design: Frequently used fixtures should be easily accessible

- Inventory Management: Maintain comprehensive inventory lists

- Storage Systems: Use shelving units, drawers, or modular storage

Establish a separate (and well-organized) storage area where fixtures are easily accessible. Shelving units, drawers, or modular storage systems should be placed on location, in a manner that keeps the fixtures orderly. Grouping fixtures by compatibility with testing machines or by types of components they are meant to test is expected. Fixtures that are used frequently should immediately be accessible, and an inventory list should be maintained to prevent misplaced fixtures, further to save downtime in testing operations.

Regular maintenance schedules and inspections need to be established to keep the fixtures in good condition. Inspect fixtures for wear or damage after every use, and clean them in order to ensure that it remains accurate and reliable for subsequent testing. If possible, operators may elect for a digital tracking system that monitors fixture conditions and usage. Proper organization, storage, and taxation will further ever allow maximizing the efficiency and lifespan of several fixtures employed in force testing operations.

Group Testing with Shared Fixtures

A group test with shared fixtures means using common setups to test different components or materials in similar conditions. By doing so, evidence and results of many tests may be consistent and comparable amongst themselves. Shared fixtures save time-they require fewer changes and drastically reduce downtime. Their implementation also helps standardize the test conditions, contributing to more trustworthy data collection during force testing.

To ensure maximum efficiency, group testing requires the proper alignment and setup of the fixtures. Each fixture should be inspected for wear, mechanical integrity, and calibration before use to guarantee that it will perform accurately. Regular maintenance and adjustment of the fixtures should be part of the schedule to help avoid measurement errors and make sure the fixtures are performing evenly throughout a series of tests. Also, operators should follow procedures during testing that are standardized so as to have consistency across the samples.

Besides, shared fixtures also help cut costs by lessening the availability of redundant equipment. Operators must remember to keep track of the use of the fixtures to best engage in wear-and-tear management. With either a digital or manual system for recording, one can best monitor usage trends and conduct preventive maintenance. With a sharing plan combined with diligent upkeep, shared fixtures under force testing can greatly boost operational efficiency with regard to preserving data.

Step-by-Step Guide on How to Use a Force Testing Fixture

Initial Preparation and Setup

Inspect the Fixture

The first thing to check is whether the fixture used for force testing is free of any damage or dirt. Moving parts must be checked for smooth operation. Ensure that no component is missing. Such inspection guarantees that the equipment will perform satisfactorily and safely during the test.

Calibrate the Equipment

Calibration determines the accuracy and consistency of the results produced. Set the required pressure, force limits, or any other needed parameters as per the manufacturer’s instructions. If the fixture is linked to any digital measuring means, also ensure that the software is updated and properly set to the testing specifications.

Secure the Workpiece

Place the specimen inside the fixture, ensuring accurate positioning and secure fastening. Any misalignment or loose free workpiece will yield inaccurate results or damage the equipment. Make use of the clamping/locking mechanisms of the fixture as required for a stable hold during testing.

Important: Following these steps lays the groundwork for good force testing while ensuring that the collected data are reliable and reducing the wear and tear of the equipment. During all stages of testing, always consider safety and double-check settings before starting a test.

Executing the Test Function with Fixtures

Mechanical testing forces offer a stubbornly fine line for ensuring the precise and accurate results. Fixture testing forces operate to hold the workpiece, applying force to it, so that the unwanted movements will not interfere with data reliability. A stable fixture is a must for any specific dimension and characteristic of the test sample as well as the force being measured.

Test Execution Protocol:

- Workpiece Positioning: Carefully position the workpiece inside the fixture

- Alignment Verification: Ensure perfect alignment with force direction

- Clamping Security: Use clamping mechanisms to prevent slippage

- Force Application: Apply force uniformly across the specimen

- Continuous Monitoring: Observe force throughout the test procedure

A prototypical procedure using fixtures to perform a test begins with the careful positioning of the workpiece inside the fixture. Sometimes this may mean adjusting the workpiece so that it aligns perfectly with the direction of the applied force. The workpiece is then secured in place using a clamping mechanism present elsewhere on the fixtures; from this point, slippage must never be allowed. Secondly, before taking up the test operation as such, verify that the direction of the applied force is perfectly aligned with the longitudinal area of the specimen so force is uniformly applied across the specimen. A correct setup safeguards against errors, maximizes the precision of testing, and minimizes the chance of injury to both the specimen and the apparatus.

Conduct the test by observing the force exerted upon the specimen and keep the procedure within the predetermined parameters. Results repeatability is enhanced if consistent operating conditions, including temperature and speed of force application, are maintained. After conducting the test, examine the fixture and workpiece for any signs of wear or damage and record the results for further analysis. If conducted systematically, these steps will maintain the integrity of the test process, through which good-quality, reliable results will be produced.

Collecting and Analyzing Test Data

Performing test data collection and analysis for forces testing fixtures requires streamlined procedures to ensure precision and reliability. The very first step involves the calibration of all equipment used during the testing to ensure no measurement error. One performs calibration as defined by appropriate standards and uses suitable reference tools to verify calibration. If rightly calibrated, the data so collected show the actual force imposed onto the fixture.

| Data Collection Phase | Key Activities | Quality Measures |

|---|---|---|

| Pre-Testing | Equipment calibration, reference tool verification | Standard compliance checks |

| During Testing | Force monitoring, displacement recording | Consistent data format |

| Post-Testing | Statistical analysis, trend identification | Benchmark comparison |

As the testing proceeds, all recorded values for measured forces, displacements, and any noted changes in the fixture or workpiece should be thoroughly monitored all along. Data-acquisition sheets or computer software should be used to input the data in a consistent format. Re-testing under identical conditions several times is also advisable to verify the consistency and reliability of the measurements. Through repetition, the chances of outliers in data are reduced; hence, the results better represent how the fixture behaves under given conditions.

Post collection of data, a comprehensive analysis-assisted deep dive into the data should be undertaken so as to extract meaningful conclusions. These analysis techniques are usually statistical methods to identify trends, averages, or anomalies in the data. A comparison of these results to the expected performance criteria for the fixture then assesses the effectiveness of the fixture. Whenever discrepancies evolve in the test data, then the reasons for such discrepancies should be analyzed, and the necessary amendments be made to those discrepancies, which arise due to poor test setup or equipment failure. This whole picture of force testing data then becomes tremendously constructive in truly evaluating the reliability and performance of each fixture, thereby making the decision-making and improvements better.

Avoiding Common Mistakes with Test Fixtures

Identifying Potential Errors in Setup

Errors regarding force testing fixtures may arise from alignment issues, wrong calibration, or incompatible components. For example, if the fixture is not aligned with the applied forces, the data will be inconsistent or the specimen may suffer damage during testing. Alternatively, the wrong force values might be recorded because the equipment has been used with an inadequate set of calibration values or was not calibrated to suit the test at hand. Finally, using the wrong type of fixture for the material or force being tested may compromise the reliability of the results.

Setup Errors

- Alignment issues with applied forces

- Inadequate calibration values

- Incompatible fixture-material combinations

- Improper fixture assembly

Environmental Factors

- Temperature fluctuations

- Excessive vibrations

- Humidity variations

- Unstable testing environment

Operator Errors

- Improper assembly procedures

- Failure to follow protocols

- Inadequate pre-test inspection

- Insufficient training

Another source of error can come from the environment: fluctuations in temperature, vibrations, or humidity could all interfere with the fixture producing steady and consistent measurements. Temperature changes, for example, are apt to influence material properties and how the fixture behaves with the specimen. It is therefore important to have a stable and controlled environment for testing to minimize such discrepancies.

Finally, operator-related errors can cause setup-related errors. These include things like assembling the fixture improperly, not following procedure, or not conducting a pre-test inspection. Clear instructions, training, and periodic audits will make the process consistent with much lesser chances of human error. With the resolution of such issues early on, results can be obtained with much farther accuracy and reliability, sparing the late stages of practice involving unnecessary trial-and-error attempts.

Interpreting Test Results Accurately

An accurate interpretation of the results of any test in force testing fixtures starts with a thorough investigation of the data output. The values for force recorded will need to be carefully scrutinized as to whether they lie within accepted limits for that particular test. Any major irregularities that appear shall be cause for suspicion of an equipment calibration issue, either an incorrect setup or with the property itself. Ensuring a set of conditions for the testing is what renders the results reliable so on another note, one must look at the patterns or trends within the data. Sequential inconsistencies or anomalies could be a clue to a systemic problem within the setup or methodology itself. It is crucial to compare results with baseline or standard data to verify that the test results comply with given conditions, and statistical techniques will greatly aid in analyzing data to check the reliability of results and to identify any outliers.

Data Analysis Framework:

- Initial Scrutiny: Check if force values lie within accepted limits

- Pattern Recognition: Look for trends and anomalies in data sequences

- Baseline Comparison: Compare results with standard reference data

- Statistical Analysis: Use statistical techniques to identify outliers

- Documentation: Record all conditions and operator observations

All results should then be recorded with accompanying data about the test setup conditions as well as lodge operator comments. It improves test repeatability and easy-level troubleshooting should problems arise later. By adhering to a certain protocol and verifying the data with benchmark information, trustworthy conclusions can be drawn from the testing of a force testing fixture.

Maintaining Consistency Across Tests

It is crucial that a force testing fixture maintains consistency across tests to have accurate and reliable results. Consistency begins with not changing the test setup between iterations. Environmental factors like temperature, humidity, and lighting should be maintained consistently as these can adversely weigh in on the test outcome. Use of same kind of materials and equipment in every test is also a good practice for uniformity and minimum variability.

Furthermore, standardized procedures should be followed with extreme rigor. This may include calibrating your force testing fixture to the best available standard before each test and recording in detail every step of the procedure followed so that the entire process may be entirely repeatable. The key word is operators must follow a written standard computer test procedure that is, at minimum, the same every time it is executed including a description of the actions taken, the forces applied, and how the data is recorded. Periodic review of the standard test procedures to ensure they align with industry standards is encouraged to continually improve reliability.

Finally, quality control measures such as periodic verification against benchmark data become very valuable. Comparing the data with baseline data means that should inconsistencies come up, they will be quickly spotted, compromising the whole series of test results. Training the operators on the use of standardized procedures also helps minimize human error while establishing consistency throughout testing; thereby making a reliable framework in which the testing can be performed and evaluated for the performance of the fixture.

Frequently Asked Questions (FAQ)

Q: What is the role of test fixture design in ensuring accurate test results?

A: Test fixture design is crucial in ensuring accurate test results as it provides a stable and repeatable setup for the test execution. Properly designed test fixtures contribute significantly to minimizing variability and external factors that can affect the outcomes.

Q: How do test chambers include factors like temperature and humidity levels?

A: Test chambers include precise control over temperature and humidity levels, which are critical test conditions. These factors can significantly impact the performance of the device under test, and controlling them helps ensure that the test results are consistent and reliable.

Q: What factors can affect the performance of mechanical test fixtures?

A: Several factors can affect the performance of mechanical test fixtures, including the material properties, environmental conditions within the test chamber, and the alignment of fixture components. These factors must be carefully managed to avoid inaccurate results.

Q: Why is test time important in designing test fixtures?

A: Test time is important in designing test fixtures because it influences the efficiency and throughput of the testing process. Optimizing test time without compromising the quality of test conditions ensures that the test station operates effectively.

Q: How do automated fixtures enhance test execution?

A: Automated fixtures enhance test execution by reducing human error, increasing repeatability, and speeding up the testing process. They ensure that the test results are consistent by automating repetitive tasks and maintaining precise control over the test conditions.

Q: What are the benefits of using test fixtures tailored to specific applications?

A: Test fixtures tailored to specific applications offer precise alignment and support for the device under test, ensuring accurate test results. They are designed to handle the unique requirements and constraints of the specific test, leading to more reliable and valid outcomes.

Q: How do test fixtures provide support during functional testing?

A: Test fixtures provide essential support during functional testing by securely holding the device under test in place and facilitating the application of test conditions. This support is crucial for testing the functionality of the device accurately and reliably.

Q: In what ways can external factors impact leak testing results?

A: External factors such as temperature fluctuations, humidity, and vibration within the test chamber can impact leak testing results. Ensuring stable environmental conditions and proper fixture design helps mitigate these effects and maintain the integrity of the test results.

Q: Why is it important that test fixtures offer flexibility in their design?

A: It is important for test fixtures to offer flexibility in their design to accommodate a wide range of test conditions and device configurations. This flexibility ensures that the test fixture serves multiple testing scenarios, enhancing its utility and cost-effectiveness.

References

- Grip and Fixture Solutions for Force Testing – Quality Magazine – Explains the role of fixtures in force testing, including how they hold or support specimens during testing.

- Info – Force Test – Discusses the use of fixtures in pull testers and adhesion testing, detailing their applications.

- Force Testing: Purpose, Importance, Types of Testing – Xometry – Provides an overview of force testing, including its purpose, importance, and the role of fixtures in various testing scenarios.