Tensile testing with a universal machine is an important step in determining the mechanical character of a material. Testing lets you know how much force a material can take before it breaks, along with its ductility and elasticity. This blog post intends to be an ALL-IN-ONE guide for carrying out tensile testing in the most accurate and efficient way. We walk you step by step, through sample preparation, to result interpretation, so that you truly understand the specifics on how to get accurate results with reproducible output. If you want to enhance your material analysis or just learn the process, this article will surely help you reach mastery of tensile testing. Stay tuned as we unfold the essence, steps, and techniques behind this important procedure in materials science.

Introduction to the Universal Testing Machine

What is a Universal Testing Machine?

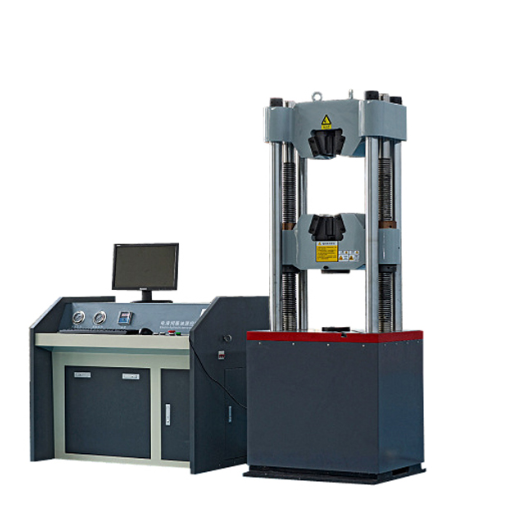

Considered as an indispensable equipment, a universal test machine is a piece of finely engineered apparatus for testing the mechanical properties of materials. The equipment checks the response of materials to a variety of forces applied such as tension, compression, bending, or shear. Materials are subjected to a predetermined load using the UTM, and properties, such as tensile strength, compressive strength, elongation, modulus of elasticity, are calculated. These data are indispensable for various engineering and material science applications.

Key Components of a UTM:

- Load Frame: The structure into which the specimen is held and to which the load is applied

- Crosshead: Moves as a result of the applied load

- Load Cells: Used for load measurement

- Grips or Fixtures: Hold the specimen firmly in place

- Control System: Computer-based monitoring and data recording system

Universal Testing Machines are essential in research and quality assurance settings. In industries such as construction, manufacturing, aerospace, and automotive, they are used to see that materials reach given performance specifications. These machines ascertain how a material behaves against stress, assist in the furtherance of product development, and, to a certain extent, check on safety and performance regulations. From their perspective of greater functionality and accuracy, these machines are indispensable in the study and better performance of materials.

Importance of Material Testing

And so, in order to develop a material to withstand the various industrial demands, material testing becomes an important factor for durability, reliability, and performance. One of the most important tools used here is the universal testing machine. The universal testing machine can perform a wide variety of mechanical tests such as tensile, compression, and bending tests on materials, thereby allowing engineers and researchers to find out their strength, elasticity, and ductility properties.

Benefits of UTM Testing:

- Ensures materials conform to industry standards and safety requirements

- Provides data that simulate real forces for material suitability assessment

- Minimizes risk and ensures conformity to engineering standards

- Contributes to safer and better project outcomes

Additionally, with regard to research and development and scientific innovation, universal testing machines contribute. With their assistance, manufacturers can test and improve new or alternative materials toward efficiency and sustainability. While developing lightweight materials for aerospace or creating composites for transportation, these UTMs are imperative in pushing the limits of material science and technology development.

Applications of UTM in Various Industries

Construction Industry

Testing strength and durability of materials such as concrete, steel, and composites. These tests ensure that materials used for building construction can withstand loads and stresses as per safety standards, aiding in the creation of safer and more reliable infrastructure.

Automotive Industry

Testing tensile strength and impact resistance of materials used in auto components such as metals, plastics, and rubber. These factors help manufacturers develop safer vehicles with better performance and lightweight materials promoting energy conservation.

Medical Device Industry

Testing reliability of materials used for implants, surgical instruments, and prosthetics. UTMs test materials for their mechanical properties to meet stringent regulatory requirements and demonstrate effective performance under stress.

Setting Up the Universal Testing Machine

Basic Introduction of UTM Machine Components

The Universal Testing Machine works on the principle of applying forces to test the mechanical properties of materials under different types of loads. It is used in testing, research, quality control, and manufacturing to provide a wide range of data including tensile strength, compression strength, bending, and the like. Thus, the machine ensures that the materials used in various industries fit the given standards of performance and safety.

Main UTM Components:

Frame Structure:

The central structure convertible to insert the sample and apply force along or transverse to it depending on the test method. Features both fixed and movable crossheads for adjusting tension or compression forces.

Grips and Fixtures:

Hold the material securely during testing to ensure accurate results and prevent slippage or misalignment.

Load Cell:

Critical component for measuring the force applied to the material. Converts mechanical force into electrical signals for precise data collection.

Control System:

Provides the operating interface for the UTM, modifying testing parameters such as speed and force application method, while data acquisition software collects and processes results in real time.

Calibration of the UTM

Critical Importance of Calibration

UTM calibration is essential to confirm the accuracy and reliability of test results. It checks and alters the machine to standard specifications relevant to force, displacement, and other measurable parameters, safeguarding product integrity by diminishing errors.

The process usually starts by comparing the measurements of the UTM with those of accurate reference standards. These standards often have traceability to either national or international-level measurement organizations so as to maintain the reliability of the standards used. Measurement accuracy for force and displacement is checked with specialized instruments like calibrated load cells and extensometers, respectively. Adjustments are then made to meet all specified standard requirements.

Calibration Best Practices:

- Regular calibrations enhance repeatability and accuracy of material testing

- Consider equipment usage level and test criticality when scheduling

- Follow industry standards for calibration frequency

- Maintain strict calibration schedules to guarantee reliable UTM operation

Safety Precautions for Operating UTM

Essential Safety Measures

1. Operator Training:

Operators must have sufficient exposure to the machine and all its components and functionalities. Proper training reduces chances of accidental acts that could cause injury or damage.

2. Personal Protective Equipment (PPE):

Operators must wear proper PPE including gloves, safety goggles, and in some instances, ear protection to prevent injuries from machine malfunctions or material hazards.

3. Testing Area Management:

Keep the testing area clear of non-essential people or objects to ensure all attention goes to safety in operation.

4. Regular Inspections:

UTM must be subjected to regular inspections, checking for wear, damage, or malfunctioning. Clamps, fixtures, and parts must be free from faults before machine use.

Performing a Tensile Test

Preparing the Sample for Testing

Before testing on the UTM, choose a specimen that complies with the standard dimensions and materials specifications for the test. In case the sample has visible defects such as cracks, irregularities, and surface damages, these will render the test results inaccurate and unreliable. The specimen must qualify according to the requirements of the relevant testing standards on the material being tested.

Sample Preparation Checklist:

- Measure and log initial dimensions (length, width, diameter, cross-sectional area)

- Use vernier calipers or micrometers for utmost accuracy

- Mark samples suitably for easy identification if testing multiple specimens

- Install specimen in grips or fixtures with uniform pressure

- Ensure proper alignment to prevent slippage during testing

If at all possible, the specimen can be installed in grips or fixtures of the UTM. The clamps should apply pressure uniformly to ensure that the specimen does not slip or become misaligned during testing. Misalignment would in itself affect test results and would contribute to unreliable data. Once the specimen is held between grips, set the test set-up check that all components are correctly positioned and the machine is ready to proceed in accordance with the testing procedure either specified. Executing these basic setups leads to an accurate and consistent tensile test result.

Steps to Operate a Tensile Test

Step-by-Step Testing Procedure

- Prepare the Specimen:

First of all, determine if there apply the specimen to the tensile test having reference to dimensions and standards. Clean the specimen and check for any defects or inconsistencies that may have an influence on the test result.

- Setting the Machine:

Switch on the Universal Testing Machine, and then select the appropriate program of tensile testing. Attach grips or fixtures accordingly to the type and material of specimen. Specimens must be carefully aligned within the grip area and must not be subjected to any intentional misalignment or induced lateral pressure that may influence the results during the test.

- Input Parameter Values:

Enter the test parameters required for the test-to-be: gauge length, crosshead speed, maximum load, etc., as given in the test standard to be used. Check the values entered again for their correctness.

- Conduct the Test:

Make sure to start the tensile test when the machine is activated. While the machine presses tension on the specimen, observe the process carefully. Keep an eye on the system, checking for anything out of the normal or for signs of equipment failure.

- Record Results and Analyze Data:

When the specimen finally breaks, the machine will output data: ultimate tensile strength, yield strength, and elongation. One must save these results and then interpret the data to understand the mechanical properties of the material.

Important Note: The diverging steps help brand consistency and accuracy when using a UTM. Follow safety rules in any testing procedure. Calibration of the machine should be verified before operation to ensure that it yields reliable results.

Monitoring the Test in Real-Time

In the course of testing in the UTM, real-time monitoring is of paramount importance to ensure data is collected properly and any anomalies are promptly attended to. The operators can watch the material as force is applied to it, helping them detect indications of unorthodox failure modes or discrepancies in testing conditions. A close watch on the display or software interface permits viewing of live data, such as stress, strain, and displacement, which help in ascertaining the mechanical properties of the specimen.

Data Collection

Ensure all data collection systems operate without interruptions. Monitor load cell operation and extensometer engagement for precision.

Graphical Analysis

Observe stress-strain curves continuously to detect sudden load drops or irregular strain increments that indicate issues.

Safety Monitoring

Keep safe distance from machine, employ protective barriers, and verify UTM functions per calibrated settings throughout testing.

Interpreting Tensile Test Results

Understanding Tensile Strength Measurements

The tensile strength measurements determine the maximum tensile stress a material undergoes before it fails. These measurements are taken using what is known as a UTM (Universal Testing Machine) in which tension is applied in a controlled way to the material sample until it breaks. The test records the capacity of the material to resist mechanical loads and also serves to analyze if it can be used for some particular applications.

Key Parameters in Tensile Testing

| Parameter | Definition | Application |

|---|---|---|

| Ultimate Tensile Strength | Highest stress a material can withstand before failure | Applications requiring heavy load resistance |

| Yield Strength | Stress at which material undergoes permanent deformation | Design safety factor calculations |

| Elongation | Percentage stretch before failure | Applications requiring flexibility and ductility |

| Modulus of Elasticity | Material stiffness against shape recovery after stretching | Maintaining exact dimensions under load |

Interpreting the results, engineers and researchers can select materials or develop designs accordingly. Materials with higher tensile strength are used for applications that need to withstand heavy loads, whereas materials with higher elongation are mostly applied wherever flexibility is the main parameter. When these measurements are well understood, they ensure safety, efficiency, and optimum operation in the fields of engineering and manufacturing.

Analyzing the Data for Quality Control

The quality control function mainly involves the compliance of materials with the given set of standards and thorough analysis of the collected data. All data points, such as tensile strength, hardness, and elasticity, must be examined by manufacturers to ensure that materials conform to the set tolerances. This produces early identification of any flaws or inconsistencies, which could otherwise lead to problems during production or actual application. The collection of accurate data and its proper evaluation are vital for the end product to have integrity.

Quality Control Process:

- Analyze stress-strain curves to understand material behavior under different loads

- Monitor production samples continuously for deviation identification

- Take corrective actions on process or material compositions when needed

- Reduce waste and enhance efficiency through proper monitoring

- Document processes and compare results against established benchmarks

- Use statistical methods to analyze trends and identify improvement areas

Documenting the process and comparing results against established benchmarks will reinforce the quality control processes. Using statistical methods, trends in the data can be analyzed to indicate where improvements are necessary or pose risks. By integrating detailed analyses into day-to-day operations, manufacturers maintain high standards while allowing for innovation and compliance with safety and performance requirements.

Troubleshooting Common Issues

Calibration Errors and Their Solutions

Any errors in the calibration of a Universal Testing Machine could yield inaccurate test results, diminishing the data’s worth for analysis. Many of these errors originate from poor setup of a test; other reasons may include environmental parameters or additional wear and tear to the equipment. Periodic calibration is done to ensure that the Universal Testing Machine is able to provide exact measurements and meets the industry standards.

Common Calibration Issues & Solutions

Load Cell Calibration Problems:

When the load cell is out of alignment or damaged, it introduces errors in force data. Solution: Inspect for damage, check alignment, and perform standard calibration using certified weights.

Temperature Variations:

Severe heat or cold affects machine components, causing measurement inconsistency. Solution: Maintain environment within specified temperature range and monitor conditions regularly.

Mechanical Wear:

Wear on grips, fixtures, or other mechanical parts impacts machine functionality. Solution: Regular maintenance, component inspection, and adherence to calibration schedules ensure optimal performance.

Addressing Machine Malfunctions

Common Causes of Malfunctions:

- Improper maintenance or calibration

- Physical damage to machine components

- Mechanical wear on grips, fixtures, or load cells

- Adverse environmental conditions (temperature fluctuations, high humidity)

Steps to Diagnose Problems:

- Thorough Inspection:

Conduct comprehensive inspection of all critical components. Look for obvious damage such as cracks, loose connections, or worn-out parts.

- Operating Conditions Check:

Ensure operating conditions comply with specifications in machine manual, particularly temperature and humidity conditions.

- Calibration Verification:

Inconsistency of results indicates need for recalibration using manufacturer-recommended procedures and tools to restore accuracy and reliability.

Preventative Measures:

- Follow routine maintenance including cleaning, inspection, and lubrication of mechanical parts

- Operate machine within prescribed limits and replace defective parts immediately

- Train operators for proper equipment use and early identification of wear or malfunction signs

- Maintain detailed records to track performance and identify recurring issues

Dealing with Inaccurate Readings

Often, inaccurate readings on a universal testing machine indicate the problems with calibration, faulty parts, or improper use. In this case, the first thing to check is the calibration of the machine. Periodical calibration must be performed following the accepted standard procedure to maintain the reliability of the machine’s readings. If the calibration is found to be inaccurate, then it must be corrected, basically, by placing certified standard weights or instruments for calibration.

Component Inspection

Check for wear or damage to critical components like load cell assemblies, grips, and sensors. Replace defective parts immediately and inspect all connections and mountings.

Procedure Compliance

Ensure testing procedures comply with proper sample preparation, correct sample placement, and appropriate machine settings for specific test requirements.

Documentation

Maintain detailed records of maintenance, calibration, and test results to help identify causes of errors and implement corrective measures.

Last but not least is ensuring that the testing procedures comply with proper sample preparation, correct placement of samples on the machine, and selecting appropriate settings of the machine for specific test requirements. Improper handling by the operator contributes to inconsistent results; therefore, training the staff to use the machine and troubleshoot it in all possible scenarios is necessary. Detailed records made of maintenance, calibration, and test results of the machine will serve as an indispensable help in identifying the causes of and correcting the errors.

Frequently Asked Questions (FAQ)

What is a universal testing machine; how does it operate?

Answer: The universal testing machine (UTM) is a very versatile system that tests for mechanical properties of a material. A force is applied to the test specimen until it breaks under full control. In so doing, the machine obtains parameters such as tensile strength, compressive strength, elongation, etc., which might prove to be valuable for quality control and research.

What is the procedure for performing tensile testing using a universal testing machine?

Answer: To perform tensile testing using a universal testing machine, first prepare the specimen in accordance with the correct standards. Place the specimen in the grips of the machine. Through the use of the control panel or interface on the software, set the desired rate of loading. Commence the test, during which the force is applied until failure of the specimen. Upon failure, the machine is halted automatically so one can proceed with analyzing the results.

What kinds of tests can a UTM conduct?

Answer: A UTM performs tensile tests, compression tests, flexural testing, and shear tests. Testing for different mechanical properties is offered by the test-e.g., tensile strength, bending strength, shear strength-underlying the goal to be tested from a particular material; thus, it is the instrument required in materials testing.

What is the significance of the control panel in operating a UTM?

Answer: The control panel is essential to operating a universal testing machine. It allows the user to set such parameters as load rate and test duration, monitor the test, and view the data in real time. The correct use of the control panel is necessary to meet the standard, be it ASTM or ISO, so that the results obtained will be true and valid.

How can I determine the tensile strength of materials using a UTM?

Answer: To undertake tensile testing, first the sample would be prepared and mounted on the machine. Then the UTM would exert tensile force on the sample until its failure, recording the value of the maximum load it could withstand. The second step involves utilizing such data to evaluate the material strength and further decide on whether this material is appropriate for particular applications.

What purpose does the hydraulic power unit have in the UTM?

Answer: The hydraulic power unit provides the force exerted on the specimen being tested. The unit collaborates with the control panel for maintaining stability during testing and also governs the application of load very precisely, which is very important to obtain accurate results in material testing.

How do I ensure stability during testing with a UTM?

Answer: To minimize the vibrations during testing and ensure accurate readings, it is advised to mount the test specimen correctly between the grips of the testing machine and to work with a UTM with good build and calibration. Regular maintenance and keeping the testing standards also contribute to the stability during testing.

What are the applications of a universal tensile tester in research and development?

Answer: A Universal tensile tester is used widely for quality control, characterization of materials, and product testing during research and development. It subjects materials to tests for mechanical properties and tries to associate these with the design and manufacturing processes so that products meet industrial standards and specifications.

References

- TensileMill CNC – How Universal Testing Machines (UTMs) Operate

A detailed guide on the operation of UTMs, including sample preparation, force application, and response measurement. - NL Test – How to Perform the Universal Testing Machine Experiment

Instructions on conducting tests with a UTM, from sample preparation to monitoring tension tests. - Presto Group – How to Operate a Tensile Test Universal Testing Machine

A step-by-step guide for operating a tensile test UTM, including material preparation and testing procedures. - ToronTech – Universal Tensile Tester: Types, Operation, Maintenance

A comprehensive guide covering UTM types, operational steps, and maintenance tips.