Hydraulic systems form the core of industrial machinery, allowing precise control, enormous force application, and fluid operation in various testing scenarios. A rather important application of hydraulic systems is the Universal Testing Machine (UTM) which assists in carrying out an exact material strength test. This article elaborates the concept behind hydraulic systems in UTMs, along with their design and importance to teaching the practical aspects of testing in engineering industries. This review provides a well-rounded understanding of core components of the hydraulic system and their integration within the machinery, be it an engineer, researcher, or industrialist. Stay around as we discuss how such systems enhance reliability and performance while coping with the demanding needs of material testing.

Introduction to Hydraulic Universal Testing Machines

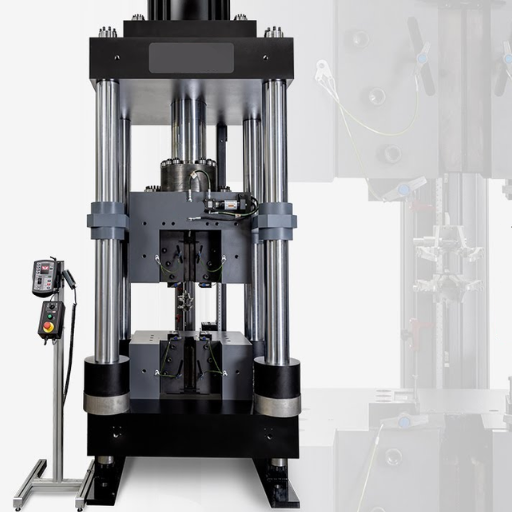

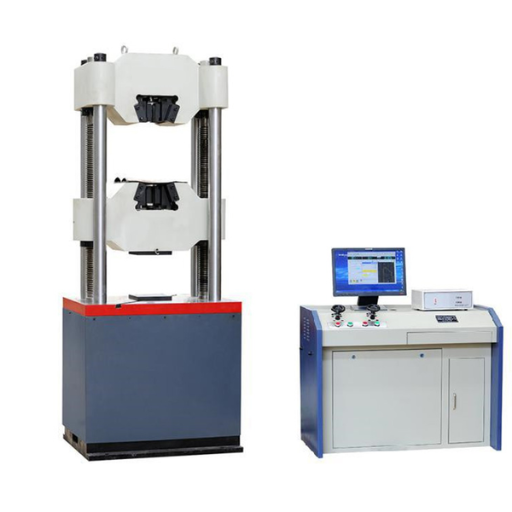

Hydraulic Universal Testing Machines (UTM) are highly specialized machines used to analyze the mechanical properties of a specimen subjected to varying load conditions. They carry out tests under precisely measured and controlled forces of hydraulic origin and are perfect for testing tensile strength, compressive strength, resistance to bending, etc., that is, many of the vital behaviors exhibited by materials. The machine basically consists of a hydraulic power pack, load frame, control system, and different types of testing fixtures all operating in unison to produce results that are duly accurate and reliable. These test machines are used extensively in sectors such as construction, aerospace, automotive manufacturing, and have applications that require critical appraisal of the materials for performance to different engineering standards.

What is a Universal Testing Machine?

The Universal Testing Machine is versatile mechanical testing equipment widely used in various industries to measure the mechanical properties of a material subjected to any kind of loading. A Universal Testing Machine is also capable of carrying out various types of tests on the specimens, viz. tensile test, compressive test, flexure test, shear test, etc. It is, therefore, indispensable in quality control, research, and development in many industries. It applies a controlled force to the specimen and accurately measures its response—stress, strain, deformation—crucial in determining the material’s ability to withstand a particular condition.

Modern UTMs employ sophisticated technology such as digital load cells and precision extensometers so that the measurements and the data acquisition are more accurate. These systems are supplemented with advanced software for analysis and reporting of the results as well as to comply with existing international standards such as ASTM and ISO. From testing building materials to aerospace components for endurance, universal testing machines have assured structural integrity and safety.

How Hydraulic Systems Operate in Testing Machines

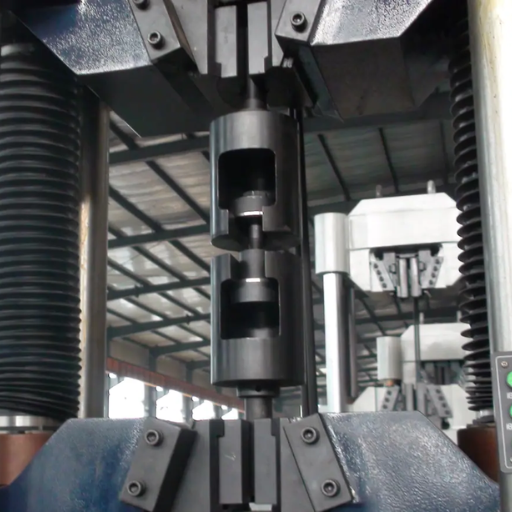

Hydraulic systems in testing machines use pressurized hydraulic fluid to produce the force required to perform material tests. These systems consist of various components, such as hydraulic pumps, control valves, hydraulic cylinders, and reservoirs. The pump pressurizes the fluid, which is directed via valves to control flow and regulate the force to be exerted. The hydraulic cylinders then convert this fluid pressure into linear mechanical motion to apply compressive or tensile forces accurately on test specimens.

Modern hydraulic testing machines also use integrated electronic controllers and sensors in order to further increase precision and repeatability. The controllers regulate pressure and flow rate with nuanced adjustments to achieve the necessary loading condition. Sensors provide feedback to ensure the force applied complies within specified limits by standards such as ASTM or ISO. By combining robust hydraulic engineering with modern automation, reliable results can be generated in a wide spectrum of material testing applications, including tensile strength, compression, and shear tests.

Types of Hydraulic Universal Testing Machines

There are several types of Hydraulic Universal Testing Machines, including single-column, dual-column, floor-standing, and table-top models.

|

Type |

Key Features |

Application |

Capacity |

Size |

|---|---|---|---|---|

|

Single-Column |

Compact, basic |

Lightweight |

Up to 20kN |

Small |

|

Dual-Column |

High stability |

Versatile |

Up to 300kN |

Medium |

|

Floor-Standing |

Heavy-duty |

Industrial |

Up to 2000kN |

Large |

|

Table-Top |

Space-saving |

Small-scale |

Up to 50kN |

Compact |

Functionality of Hydraulic Systems in Material Testing

Hydraulic systems hold greater significance in material testing, ensuring the precise control in the application of load. These systems employ pressurized hydraulic fluid to generate a force and execute a test under consistent and reliable conditions. Their key functions feature the ability to apply very high forces for a short time, provide a steady application of load, and allow very precise measurement using very responsive control systems. In essence, hydraulic systems are really suited for high-force range applications, which means that for tensile, compression, or bending tests, either industrially or at the research level, the hydraulic systems are employed. Being hard in construction, these systems can withstand forever and will never compromise the performance of the test even under operational conditions demanding absolute perfection.

Precision and Accuracy in Force Application

Through pressure and flow rate regulation, hydraulic systems demonstrate precision and accuracy in force application. Hydraulic systems employ servo valves and feedback sensors that ensure real-time adjustment from minimum deviation from their target performances. Also, the hydraulic systems have interfaces with computer control that achieves measurement accuracy down to micrometers and thus finds application in areas where precise force measurement is critical. Hydrostatic pains also play their part in maintaining a constant force transmission from the source to sink, thereby guaranteeing repeated and accurate results during engineering and testing processes.

Load Capacity: Understanding 600kN and 2000kN Ratings

Capacity ratings of 600kN and 2000kN are very important in that they serve to determine the operational boundaries and work options of every hydraulic system or testing equipment. Capacity ratings of 600kN specify the ability to generate or sustain maximum force of 600 kilonewtons, whereas a 2000kN rating specifies a maximum force of 2000 kilonewtons. Their rating systems correspond with their design in structure, material strengths, and use-case scenarios.

600kN-rated systems are generally applied in the materials testing (such as tensile, compression tests) of smaller components or in some moderately industrial tasks. The 2000kN-rated equipment loads into heavy-duty operations such as large-scale structural analysis of construction materials validation, and advanced load-bearing tests in civil engineering. Both of these capacities are determined by relatively rigorous procedures, such as ISO or ASTM standards, thus ensuring various performances that comply with safety and precision demands.

The choice of load capacity relies upon operational requirements, material properties, and the required safety margin to prevent mechanical failure during testing or application.

Benefits of Using Hydraulic Drives in Testing

1.High Precision and Control: Hydraulic systems have precise force and velocity control, which makes testing under varying conditions possible, ensuring reliability, interference-free results, and repeatability.

2.Range of Loading Capacities: Hydraulic drives can carry loads within a big range-from very low capacities to extremely high capacities-allowing it vast for various testing applications.

3.Quick Response Time: The hydraulic unit responds quickly to changes in inputs to grant smooth and efficient operations in dynamic testing.

4.Construction and Life Considerations: Designed for handling high pressures and operating in arduous environments, the hydraulic drive systems are known for their ruggedness and great life period, thereby also cutting down maintenance and replacement costs.

5.Energy Efficient: The modern hydraulic drives can be designed to attain the highest energy efficiency while reducing the amount of energy consumed during conducting test procedures and ensuring the employment of hydrostatic transmission.

Applications of Hydraulic Universal Testing Machines

Hydraulic Universal Testing Machines are widely used in all industries for material testing and quality control. They are commonly applied in tensile testing, compressive testing, and bending of materials to determine their mechanical properties-matters of metals, polymers, composites, and building materials. Penalized by this machine in industries like construction, aerospace, automotive, and manufacturing to ensure that raw materials adhere to stringent specifications for safety and performance. They are also utilized in R&D to study the behavior of new materials under different load conditions.

Tensile Testing in Various Industries

Tensile testing is a rather important technique that is applied in nearly all industries to determine the mechanical strength and ductility of various materials. Tensile tests in the automotive industry ascertain whether structural materials can resist stress, thus further assisting developers in creating vehicles that are safer and more reliable. The aerospace industry relies on tensile testing for materials intended for aircrafts and spacecrafts where extreme conditions and high precision are considered. Concrete is tested for tensile strength and elongation and failure limits of other materials, like steel and reinforced polymers, are applied in construction so as well. The test results provide information on tensile strength, elongation, and failure limits required for compliance with regulatory requirements and thus needed to assure actual performance of these materials in real-world applications.

Compression, Bending, and Shear Testing

Compression test is performed to test a material’s capacity to withstand compressive forces before it will deform or fail. These tests are essential for materials that will be placed under loads, such as concrete, metals, and ceramics, to ensure that they conform with the prescribed pressure tolerance.

Bending tests, or flexural tests, test the material response to force that induces bending. Bending tests measure important parameters like flexural strength and modulus, which describe the material’s ability to resist deformation when subjected to bending stress. These tests are performed on beams, plates, or sheets for structural or engineering purposes.

On the other hand, shear testing examines how a material reacts when a lateral force is applied to slide one layer over another. Shear strengths and shear modulus are vital properties that undergo measurement in this test to certify that materials used in fasteners, adhesives, and layered composites can withstand lateral stresses.

Real-World Examples: Manufacturing and Aerospace

In manufacturing scenarios, shear testing assumes a crucial role in selection and quality assurance of materials for highly demanding applications. For example, adhesives and welds used on automotive assembly lines undergo shear testing to ensure operational forces do not cause premature failure. In a similar vein, the metal sheets and layers of composites material used in structural components are rigorously tested for shear strength to establish confidence in their performance under load conditions.

Due to extreme conditions of operation, the aerospace industry relies heavily on shear testing for safety and performance validation of materials. Aircraft wings, fuselage panels, and turbine blades are all formed from materials that are lightweight yet strong, like carbon fiber composites. These materials must endure aerodynamic forces and vibrations without any compromise to their structural integrity. Shear testing guarantees the materials’ capability to resist shear stresses imposed during take-off, flight, and landing.

By virtue of shear testing within these industries, engineers are able to optimize product performance and ensure conformity with safety regulations while also minimizing the likelihood of catastrophic failures. This bolsters the significance and urgent necessity for highly accurate and repeatedly conducted shear tests within manufacturing and aerospace fields.

Choosing the Right Hydraulic System for Testing Needs

When choosing an adequate hydraulic system for testing requirements, several important factors are carefully evaluated. Firstly, it is important to determine the force or pressure required as per the tests conducted. Evaluate the load capacity with precision and with stability in mind. Then consider the degree of compatibility that it has with matters being tested to ensure that measurement alone can provide inconclusive results to a definite extension. The system efficiency should also be looked at-high-performance systems in long hours of testing. Next should be the ease of integrating these with currently used testing equipment as well as maintenance requirements of the system. Lastly, a good cost-benefit analysis involving operation and long-term costs versus initial investment must be performed to help with the decision-making process.

Factors to Consider: Load Capacity and Precision

I consider load capacity and precision as being paramount when selecting the right hydraulic system. Load capacity guarantees that the system is potently equipped to endure the maximum force requirements demanded for a specific application without ever compromising on performance or safety. I seek detailed specifications and testing particulars confirming its sustainance of load in continuous and peak conditions. Precision, being a measure affecting operational opportunity or target in applications where finer control is paramount or outright imperativeness in repeatability, has more than its weight. I check cylinders, valves, and hydraulics between the pumps, considering tolerance levels desired. Other considerations are the reputation of the manufacturer about reliability, how well the system will integrate with equipment currently in use, and the long-term cost-effectiveness of the system.

Compatibility with Different Materials

Material compatibility is an important factor in system design to avoid degradation, corrosion, or the kind of performing disturbances. In a hydraulic system, it is imperative for the designer to consider that all components interact with the fluids and environmental conditions in which they are placed in an acceptable manner. For instance, seals must be compatible with the type of hydraulic fluid used so that they do not swell or crack, while steels or aluminium alloys must resist abrasion or chemical attack when used at various operating pressures and temperatures. In assessing compatibility, the examination will revolve around chemical stability, thermal tolerance, mechanical durability, together with using different sources, such as material compatibility charts given by manufacturers or set forth in industry standards.

Standard Accessories for Enhanced Functionality

Standard accessories make equipment and its variants highly efficient across industries. Precision components-such as couplers, filtration, pressure gauges, and mounting brackets-can sometimes be included in these accessories. Couplers allow different components to be joined quickly and securely, with little possibility of fluid loss or operator injury. Filtration systems keep the fluid clean, extend the life of components, and accommodate the efficiency of the system. Pressure gauges allow monitoring for optimal operating conditions and avert damage due to deviations from required pressure. Mounting brackets and adapters add to the ease of installation and adaptability of the equipment. Choose accessories that will be a suitable match for specific operational and environmental requirements to ensure compatibility with the host equipment and longevity of the system.

Future Trends in Hydraulic Universal Testing Systems

In recent years, the hydraulic universal testing systems have been advancing with levels of automation, precision, and data integration. Smart sensor integration, combined with IoT capability, allows for monitoring a test’s performance on a real-time basis, maintenance prediction, and further expensive data analytics. Environment-friendly designs are coming into vogue, including energy-efficient components and biodegradable hydraulic fluids, on environmental concerns. Control software applications now enhance the user interface for testing, allowing for more intelligent and customizable tests. Increased reliability, efficiency, and maintenance of the changing standards in the industry are thus ensured with these trends.

Advancements in Servo Hydraulic Technology

In view of recent developments, a major paradigm shift has taken place in service hydraulics, primarily related to efficiency, precision, and control. Energy-saving designs have gained growing interest, leading to systems with low energy consumption through use of variable displacement pumps and regenerative circuits-every bit as good in performance as any other design. High-speed digital controllers with advanced algorithms further improve responsiveness and accuracy, allowing enhanced control in complex testing scenarios.

Moreover, real-time data acquisition and remote diagnostics form an interface of integration with IoT (Internet of Things) and cloud-based monitoring systems that enhance system maintenance and reduce downtime. Material advances, such as wear-resistant coatings and components of lesser weight yet corrosion-resistant have helped ensure hydraulic system durability and life. Technological improvements thus make the servo hydraulic system the most promising tool in commercial applications in terms of reliability, sustainability, and performance.

Innovations in Material Testing Procedures

Advances in material testing procedures have enabled further precision and efficiency with modern technology applications. UT and CT are NDT methods used for in-depth interior analysis without deranging the material. Automation and AI software further streamline testing activities towards quick and reliable results. Environmental chambers and microscale testing allow for very specific evaluations to suit the requirements of modern industries such as aerospace and biomedical engineering. Thus, these innovations make sure that materials are worthy of quality and safety concerns in most challenging applications.

Impact on Quality Control and Material Analysis

Hydraulic UTS went through paramount changes during the twentieth century, thus affecting crucially quality control and material analysis. Modern systems, which provide servo control and digital load management, can now exert huge loads with extreme precision during tensile, compression, and flexural tests. Better capability of data acquisition with real-time feedback facilitates deeper evaluation of material performance.

Simultaneously, other advanced software platforms are used to automate testing procedures and customize them for industry-specific standards, which, along with advanced load frames and hydraulic actuation technologies, offer greater durability and stability, even under very severe testing conditions. All these innovations enable the provision of accurate and repeatable results that concern the reliability of processes in the development of a product and in monitoring for compliance.

Industries utilizing these systems can look to providing rigorous quality control processes while expediting their material analysis, to enable the manufacture of confident and better products.

Reference Sources

-

A Review of the Servo Hydraulic Universal Testing Systems – This source explains the principles of servo-hydraulic universal testing machines, including how they apply controlled force or displacement to samples.

-

Hydraulic Testing Machines from 600 to 5000 kN – Details about hydraulic materials testing machines, their central hydraulic drive, and optional equipment.

-

Universal Testing Systems by Instron – Provides an overview of universal testing machines, including hydraulic-powered systems for static testing.

-

Hydraulic Universal Testing Machines – QT-HW2 Series – Discusses the design and applications of hydraulic universal testing machines for testing various materials like metals, composites, and concrete.

Frequently Asked Questions (FAQ)

Q:What do you mean by hydraulic universal testing machine?

A:A hydraulic universal testing machine (UTM) is a facility for testing the mechanical properties of materials under control of tensile and compression forces. It uses hydraulic power to create the load so that very fine measurements can be made and the materials can be tested evenly across a wide spectrum.

Q:How do the grips work in a hydraulic UTM?

A:The grips of hydraulic UTMs keep the test specimen rigidly in place during testing. Hydraulic grips are adjustable and can fit all sizes and shapes of materials such that when tension or compression forces are applied, the specimen is held tightly.

Q:What does the crosshead do in the hydraulic testing system?

A:The crosshead is the moving element in a hydraulic testing system that applies loads to the specimen. It is generally above the lower crosshead and can be positioned at various gauge lengths depending on testing standards and depending on the type of material to be tested.

Q:How is the calibration of Hydraulic UTM done?

A:Calibration of Hydraulic UTM consists of using standard weights along with the testing software to assure that the machine shall give correct results. Calibration is done to maintain the testing standards like ASTM E4 and ISO 7500-l, which states the accuracy required for testing machines.

Q:What are the advantages of a servo hydraulic universal testing machine?

A:Servo hydraulic universal testing machines will carry closed-loop control strategies that allow the force to be precisely controlled and varied during testing. Such control is vital when testing certain materials under constant force, i.e., very high precision applications such as testing high strength rebar. They also deliver the same accuracy on a variety of different tests.

Q:Can tensile testing and compression testing be done by a hydraulic UTM?

A:Hydraulic UTMs can indeed do both tensile and compression testing. Hydraulic efforts are transmitted along the two directions, thereby testing different materials such as metals, plastics, and composites.

Q:What is the importance of an extensometer in tensile testing?

A:During tensile testing, an extensometer is fixed to measure the elongation of the specimen in question as load is applied. The elongation measurement is then used to calculate the stiffness and strain of the specimen, which is valuable data for the analysis. Since persistent extinction is measured, the use of an extensometer guarantees that testing of a material will produce very reliable data on the properties of a material or specimen.

Q:What materials can be tested by hydraulic UTM?

A:Hydraulic UTM is for all testing materials from metals to plastics, powders, and concrete. With standard accessories to test for different sizes and types of specimens, they bring the environment for research, quality control, and product development.

Q:How do testing standards influence the working of Hydraulic UTM?

A:Testing standards as ASTM E8 and JIS specify the procedure and requirements for conducting tests on materials. The adherence to standards ensures that results produced by Hydraulic UTM are reliable and comparable to results in other laboratories and studies; this winds up building credibility to the testing process.