For material testing, one tends to emphasize precision, reliability, and flexibility. Hydraulic Universal Testing Machines (UTMs) are termed so because they are a standard test for the mechanical properties of materials under different forces and conditions. Including tension, compression, bending, and shearing, these machines perform several types of tests and are used in several industries such as construction, aerospace, and manufacturing. The article throws light upon the engineering of Hydraulic UTMs and their importance for material integrity and safety; hence usefulness for quality assurance and research. By the end, you will learn how these heavyweight test systems have been carving out material science and industrial applications for the present generation.

Understanding Hydraulic Universal Test Machines

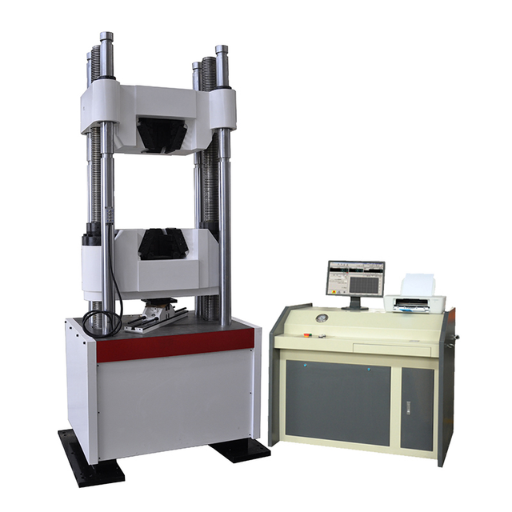

A Hydraulic Universal Testing Machine is any type of equipment that applies certain forces on materials to assess their mechanical properties under different conditions. The controlled force application with the hydraulic system is used for testing the materials for tension, compression, bending, and shearing in order to ascertain important parameters for the materials such as tensile strength, elasticity, and yield point. In this way, they ascertain that materials comply with the safety and performance standards. Hydraulic UTMs are highly respected in the engineering and industrial field due to their precision, reliability in service, and versatility with respect to various sizes and strengths of materials.

What is a Universal Test Machine (UTM)?

A Universal Test Machine (UTM) is versatile and very accurate testing apparatus used to check the mechanical properties of materials under a variety of conditions. Depending on the force it applies-machine acting tensile, compressive, or shear-it could measure parameters such as tensile strength, elasticity, yield point, and fracture toughness. Equipped with latest generation load cells, systems for data acquisition, and software giving the flexibility to customize the test procedure, a Universal Testing Machine provides precise, repeatable results. Different industries use Universal Testing Machines, including construction, aeronautical, automotive, and manufacturing, to ensure that an item meets a certain level of safety and compliance with standards. Modern UTMs are typically computer-controlled and very easy to operate, yet they still retain their reputation for precision, flexibility, and dependability.

How Hydraulic Systems Operate in Testing Machines

Hydraulic systems in testing machines work on the basis of fluid mechanics to generate the force required for the testing of a material with a high degree of uniformity. This system uses a hydraulic pump to pressurize the fluid, which then flows through a series of valves and actuators. The pressurized fluid actuates a piston inside a cylinder, converting hydraulic energy into the desired mechanical force, which is eventually applied to the test specimen. The direction of the force, as well as the magnitude, is ensured to be maintained at the desired level through sensors and control systems. Advanced hydraulic systems make use of proportional valves and feedback controls that practically allow adjustments on the order of microns, greatly improving both precision and repeatability for the testing process.

Key Features of Hydraulic Universal Testing Machines

1.High Load Capacity: The hydraulic universal machine can handle extremely high loads and is therefore used for testing larger, more robust materials such as metals, composites, and construction elements.

2.Precision Control: Featuring the latest control systems and proportional valves, the machine can apply force or displacement with extreme accuracy so that testing could be performed with complete accuracy.

3.Versatility: Designed for tensile, compression bending, and shear testing, the machine can test materials of various natures.

4.Heavy-duty Construction: With sturdy frames and components, the construction of hydraulic testing machines allows them to sustain high stresses and repeated use, ensuring long-term reliability.

5.Data Acquisition in Real-Time: A digital system and integrated sensors provide for real-time collection and monitoring of testing data, thereby improving data analysis and reporting.

Applications of Hydraulic Universal Testing Machines

Hydraulic UTMs are used widely in various industries and research fields. In materials science, these are tests to assess the mechanical properties of metals, polymers, composites, and other materials, either under tensile, compression, bending, or shear forces. In the automotive and aerospace sectors, these are used mainly for quality control and to confirm the structural integrity of critical components. UTMs are used in civil engineering to test construction materials like concrete and steel for regulatory compliance. Furthermore, hydraulic UTMs may be found in academia and research, product development, and the study of material behavior under controlled conditions. Hence, a hydraulic UTM is a source of very accurate and reliable data indispensable in industry and scientific advancement.

Industries that Benefit from Universal Test Machines

Being very versatile and precise in the field of material testing, UTMs find applicability across a huge range of industries. The aerospace industries use UTMs to measure the mechanical properties of advanced composites and high-strength alloys to ensure that such materials adhere to stringent standards for performance and safety. The automotive industries use them to test the materials of body panels, tires, and suspension systems for durability and reliability. In construction industries, these UTMs assess tensile strength, compressive strength, and elasticity of building materials that include concrete, steel, and rebar to conform to regulatory requirements. Others include biomedical, where tests on materials such as prosthetics and implants are carried out; and electronics, where tests involving mechanical stress are vital to product durability. In the end, universal UTMs could be used anywhere an accurate, standardized definition of material capacity must be carried out.

Specific Applications for Tensile Testing

Tensile tests are widely used in many industries and domains to guarantee optimal material functionality and product quality criteria. In construction, for instance, steels and concretes face tensile testing for verification of strength and elasticity meeting safety requirements. Similarly, the biomedical sector tensile tests artifacts, polymers in prosthetics, and applications to ensure they meet physiochemical and functional characteristics. In the electronics industry, tensile tests are of paramount importance to ascertain the mechanical reliability of components such as wires or solder joints to resist durability under stress. These tests yield reliable, precise data used in compliance, innovation, and industry-bases.

Range of Tests Conducted Using UTM

Universal Testing Machine (UTM) supports the conduct of many mechanical tests to study material properties in different environments. Most common tests are tensile tests to measure ability to withstand tension, compression tests for resistance to crushing and deformation, and flexural tests to investigate bending force capabilities. These machines are also used for shear tests, to analyze the resistance of materials to sliding forces and peel tests for adhesive scrutiny; Advanced UTMs carry on to fatigue testing for assessing durability under cyclic loading, and creep testing for long-term deformation against constant stress and temperature. All these tests provide comprehensive information on material performance to enable very precise engineering and material optimization.

Benefits of Using Hydraulic Testing Systems

The hydraulic testing systems can provide an attractive combination of precision with control, so these testing machines become necessary for testing the strength, elasticity, and durability of materials under various load conditions. Their ability to provide high levels of force provides for accurate and fine test results, even for very hard materials. Another important advantage of a hydraulic testing system is versatility-a wide range of test configurations and various specimen geometries can be tested. Such an arrangement assures consistent services on long-duration tests that lend themselves easily to research applications and industrial uses.

Why Choose a Hydraulic UTM?

Hydraulic UTMs offer massive force capacities and can be considered for testing materials of all types, including metals, composites, and polymers. Fine and high precision brings with it a detailed analysis of the material properties under extreme circumstances. Hydraulic UTMs are known to withstand the test of durability wherein performing extended and repeated testing activities. They can go for any type of tests like tensile testing, compression testing, and bending testing, making them super versatile in all industries, including construction, automotive, and aerospace. This implies the UTM being a reliable yet efficient instrument for research as well as industrial use.

Cost-Effectiveness and Efficiency in Material Testing

In material testing, cost-effectiveness and efficiency influence productivity and operation budgets directly. UTMs of today give the greatest value for long term by combining advanced testing capabilities with low maintenance that reduces time down of machine tools. The automated systems integrated in modern UTMs increase throughput significantly by reducing or removing dependence on manual labor while allowing several tests to be performed either simultaneously or in rapid succession. Also, the higher scalable and modular nature of today`s UTMs ensures that equipment will survive changes in testing requirements without profuse replacement. Choosing a UTM that contains energy-saving systems will lower operating costs over the years, accommodating both budget and environmental concerns. All combined, these factors ensure that the most efficient testing of materials is possible without compromising on quality or reliability.

Electromechanical vs Hydraulic Testing Machines

Electromechanical testing machines are ideal for low-to-medium force testing with precision and efficiency, while hydraulic testing machines excel in high-force applications and durability.

|

Key Point |

Electromechanical |

Hydraulic |

|---|---|---|

|

Force Range |

Low-to-Medium |

High |

|

Precision |

High |

Moderate |

|

Speed Control |

Excellent |

Limited |

|

Maintenance |

Minimal |

Regular |

|

Energy Use |

Efficient |

High |

|

Cost |

Moderate |

Higher |

|

Applications |

Versatile |

Heavy Duty |

Technical Innovations in Hydraulic Universal Testing Machines

1. Load Cell Technology Refined

Modern hydraulic UTM incorporates a load cell system of superior precision capable of measuring force for widely different types of material testing under various test conditions. These innovations attempt to offer reliability of data on the greatest accuracy required by different industries in mechanical property analysis.

2.Adaptive Control Systems

Adaptive control allows automatic compensation during testing to ensure optimum operation under varying test conditions. These systems increase test repeatability and reduce potential errors maintained by human interaction so that a set of consistent and reliable results can be generated.

3. Integrated Digital Interface

Modern-day hydraulic UTM offers an integrated digital interface for simplifying data acquisition and processing. The interface provides an intuitive software environment for automated reporting and compliance tracking, making it easy for labs to integrate with Laboratory Information Management Systems (LIMS).

4.Energy Optimization Mechanisms

Increased energy optimization by means of variable flow hydraulic pumps achieved through energy optimization mechanisms reduces the energy consumption of the implemented system. Reduced heat generation and lesser wear translate to longer equipment life and less maintenance cost.

5. Modular and Customizable Design

Modular configurations are nowadays made available to hydraulic UTMs, in terms of which laboratories can tailor the machine to specific testing needs. Customizable attachments and fixtures further extend the test capabilities, enriching the testing potential of these machines for a much wider scope of materials and use cases.

Through these advancements, technical innovations contribute to the enhancement of the performance, efficiency, power, and versatility of hydraulic universal testing machines toward catering to the growing technological demands of material testing of today.

Recent Advancements in Servo-Hydraulic Technology

The main developments in servo-hydraulic technology have in many ways focused on precision, energy efficiency, and adaptability for testing applications. Today, advanced digital controllers enable greater accuracy in data acquisition and control in real time. Increased programmability and automation allow the implementation of more complex test sequences while requiring less operator intervention. Energy-conserving options, such as variable-speed pumps, operate in a manner that consumes less energy by adjusting the output as needed by the system. Other modern incarnations, taking Industry 4.0 by storm, consider concepts such as IoT and remote monitoring as a means for predictive maintenance and enhanced operations. This makes sure that servo-hydraulic systems remain trustworthy, versatile, and catering to current engineering and testing requirements.

Meeting International Standards in Testing

Test applications of servo-hydraulic systems must undertake conformity to international widely recognized standards such as ISO/IEC 17025, ASTM, and DIN to be globally reliable and acceptable. Such conformity averts any discrepancies pertaining to the major facets of accuracy, traceability, and repeatability in test results, with paramount importance to attaining a final outcome accepted across all disciplines. Furthermore, conformity to these basic frameworks requires calibration of instruments within a tolerance and verification of instruments to a certified procedure, thus, acting as an added credential for research and quality assurance operations. These set requirements maintain the systems’ capability in complying with stringent regulatory demands and remaining competitive in present-day testing setups.

Future Trends in Hydraulic Testing Equipment

In my opinion, hydraulic testing equipment is shaping future trends with automation, precision, and sustainability. Smart technologies are already in a position to improve the accuracy and efficiency of testing by introducing IoT-enabled sensors and AI-driven diagnostics. Automation systems will enhance consistency and reduce manual interference at a great scale being demanded for fast cycle testing. Sustainability is presently considered the most pressing issue, where manufacturers are on the verge of producing environmentally friendly designs and energy-efficient systems to abide by international regulations and curtail carbon footprints. The evolution of these will mold the world of hydraulic testing to become more performant and environmentally conscious.

How to Choose the Right Hydraulic Universal Testing Machine

When it comes to hydraulic universal testing machines, there are some factors you must consider in order that the machine adequately fulfills your own testing needs. Check out the maximum load the machine can tolerate to understand if the same is sufficient for your testing materials and applications. Then, check for the accuracy or precision of the testing system, as this will significantly impact the reliability of your results. The adherence of the standard required by the machine, whether ASTM or ISO, will be necessary for compliance in some regulated industries. Also, check out its software capabilities which include data acquisition and analysis to facilitate testing. Elsewhere, this should assist you in tracing the uptime and the working life of the machine, so go with durability, minimal maintenance, and readily available technical support.

Factors to Consider Based on Specific Application Requirements

Choose a machine setting that best meets the requirements of an application, with very important factors that need to be explored and aligned with the operation. Begin by examining the material properties and mechanical testing requirements to be accounted for in the application, such as tensile strength, hardness, or thermal properties, so that the machine meets the necessary precision and accuracy. Furthermore, verify that it complies with industry standards (such as ASTM, ISO) to maintain actual compliance og precise results.

You should also look into determining the flexibility of the system so far as it is concerned with the workload to be dealt with, for instance, the specifications for the sizes of the test specimens and speeds of testing, as well as any possible upgrades that might be implemented later. There also goes the interface of the software, including data acquisition, customization, and reporting tools that must support flexibility to integrate efficiently into a reliable workflow for input, processing, and analysis. Consider also environmental parameters relevant to the tolerances of temperature and humidity if the system could be working under such extremes, intentionally so.

Durability and maintenance-friendly equipment should also be at very top consideration since these impede long-term return on investment. Do a good inquiry on the availability of technical support, realistic alternatives to spare parts, good warranty of the supplier, supplier identification, the whole technical backup of the supplier will be helpful to ensure good selection against appropriate standards to ensure reliable performance, good efficiency, and long lifespan in this specific industry or research.

Choosing Between Different Series Frame Configurations

Selecting between series frame configurations requires looking into very important considerations by focusing primarily on the application requirements, the load capacities of the structure, and modularity. Consider the load capacity of the frame and ensure that it is applicable to the environmental conditions that encompass exposure to elements and or vibrations. Thus, in terms of maintenance, giving preference to ease of integration with the existing systems stands to make a good judgment about scalability for the long term. In addition, make sure that you examine your alternative materials between aluminum or steel; compare them in crucial respects with particular regard to strength-to-weight ratio, corrosion resistance potential, and the extent to which they can be expected to influence the system efficiency. Review the specifications and compatibility well, as this will ensure that the frame configuration in question will satisfy the operational requirements and the technical parameters.

Evaluating Load Capacity: Why 1000 kN Matters

From the examination conducted, one understands that load capacity 1000 kN is of importance because it caters to very tough operating requirements while guaranteeing structural integrity and safety. Systems of large capacity reduce any possibility of mechanical failures once subjected to very high stresses, especially in industrial applications where performance consistency is very crucial. Furthermore, the benchmark of 1000 kN stands to minimize downtime by improving upon efficiency through the facility of placing heavier loads in fewer cycles. This capacity pertains to industry guidelines that speak for reliability and scalability – assuring that the systems that hold are very strong through the course of ever-changing operational conditions, so that they are really actually future-proof.

Reference Sources

- Hydraulic materials testing machines – ZwickRoell

- Hydraulic Universal Testing Machines – QT-HW2 Series

- Hydraulic Universal Tensile Test Machine – Testmak

- A Review of the Servo Hydraulic Universal Testing Systems – TensileMill CNC

- Top universal testing machine in China

Frequently Asked Questions (FAQ)

Q:What are hydraulic universal testing machines (UTMs)?

A:Hydraulic universal testing machines (UTMs) are versatile instruments used in materials testing to evaluate the mechanical properties of various materials under tension and compression. These machines are hydraulically operated and are used when precise control of applied load onto the specimen is desired. They are therefore best suited for static testing in many applications.

Q:What tests can be done on a hydraulic universal test machine?

A:The hydraulic universal test machine is capable of performing tensile testing, compression testing, flexure tests, and torsion tests. The machine can accommodate different test setups and fixtures, thus providing a comprehensive range of material evaluations.

Q:How do test fixtures work in hydraulic universal testing machines?

A:Test fixtures are special components that hold the specimen during test operations. Fixtures in hydraulic universal testing machines assist the testing process by keeping movements to a minimum where different kinds of support must be rendered to the sample; for example, a puncture test or an elongation test.

Q:What is the importance of extensometers in hydraulic testing?

A:Extensometers measure material deformation during testing. An extensometer, in a hydraulic universal testing machine, is used to measure elongation with very high resolution, which is necessary while calculating parameters like modulus and stiffness of a particular material. This data gathering from the test is crucial for conducting approved tests as per international standards.

Q:Can hydraulic universal test machines test different materials?

A:Yes, hydraulic universal tests machines can test various materials such as plastics, textiles, and metals. Because of this flexibility, users can change the test setup and fixtures as per the applications in hand, thus serving various industries.

Q:What is the capacity of hydraulic universal testing machines?

A:Hydraulic universal testing machines come in different capacities, with some that can produce a force of up to 600 kN. This makes it possible to test different materials and also ensures that the machine can be used for testing in both small and large scale.

Q:How do testing software and universal software assist UTMs in becoming more functional?

A:Through advanced analysis and report preparation, the testing and universal software enhances the functions of hydraulic universal testing machines. These software programs enable real-time monitoring and data collection while following international standards for testing, which simplifies the process of carrying out materials testing.

Q:Can hydraulic universal test machines be bought for specific applications?

A:Yes, there exists hydraulic universal test machines for specific applications that cater to the requirements of unique tests. These machines might have pre-configured test arrangements and special fixtures to suit the demands of specific industries and material types.

Q:What is the crosshead’s function in hydraulic universal testing machines?

A:The crosshead is an important component of a hydraulic universal testing machine, in that it is the moving part that applies load to the specimen. Precise movements of the crosshead are imperative to perform tensile as well as compression tests accurately and as per the pre-defined international standards.