Instrument And Equipment Wholesale

2025 Impact Testing Machine: Low-Temperature Charpy Testing Solution

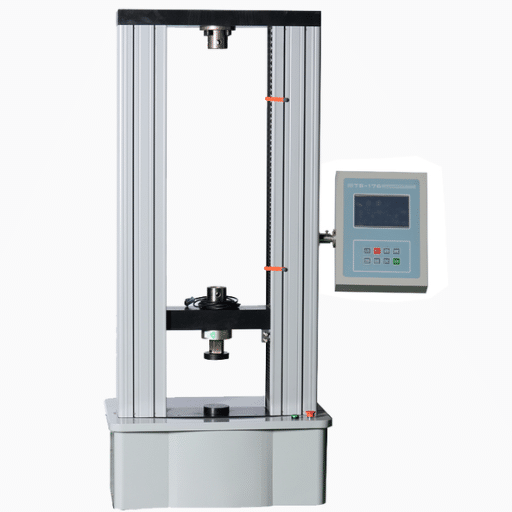

Our Impact Testing Machine delivers unmatched precision and reliability for evaluating material toughness. Designed for industries like aerospace, automotive, and construction, this charpy test machine ensures accurate results in testing the impact strength of metals, plastics, and composites. With advanced technology and robust construction, it meets global standards, offering durability and ease of use for rigorous testing environments.

What Is A Impact Testing Machine

-

An Impact Testing Machine evaluates how materials withstand sudden forces, critical for product safety and durability.

-

The charpy test machine uses a pendulum to strike notched samples, measuring absorbed energy accurately.

-

It ensures materials meet industry standards for toughness and reliability in demanding applications.

-

Our impact test equipment supports Charpy and Izod methods for versatile material testing.

-

Digital controls in the impact strength testing machine provide precise data for lab analysis.

2025 Trends in Impact Testing: Low-Temperature Charpy Tests and Automated Data Collection

The field of impact testing is advancing rapidly in 2025, with innovations like low-temperature Charpy tests and automated data acquisition systems redefining material toughness evaluation. These advancements are particularly critical for industries like aerospace and automotive, where materials must perform reliably under extreme conditions.

Key Features of 2025 Impact Testing Machines:

- Low-Temperature Testing: Evaluate material toughness at sub-zero temperatures, ensuring reliability in harsh environments.

- Automated Data Collection: AI-driven systems provide real-time analysis, reducing human error and improving test accuracy.

- Versatile Applications: From aerospace components to automotive crash safety, impact testing ensures materials meet stringent safety standards.

Essential Tests You Can Perform with a Impact Testing Machine

An Impact Testing Machine evaluates material toughness by simulating sudden forces. Ideal for industries like automotive and aerospace, this charpy test machine ensures accurate impact strength testing, meeting global standards for quality control.

Charpy Impact Test

The charpy impact test machine measures a material’s ability to absorb energy during fracture. A pendulum strikes a notched sample, recording energy absorption to assess toughness. This test is critical for metals, plastics, and composites, ensuring compliance with ASTM and ISO standards in industries like construction and manufacturing.

Izod Impact Test

Using an impact test equipment, the Izod test evaluates material resistance to sudden impacts. A pivoting arm strikes a vertically clamped sample, measuring energy absorbed. This test is vital for assessing polymers and composites, ensuring durability in applications like automotive parts and consumer goods manufacturing.

Low-Temperature Impact Testing

The impact strength testing machine conducts tests at sub-zero conditions to evaluate material behavior in extreme environments. By chilling samples, it assesses brittleness and toughness, crucial for aerospace and energy sectors where materials face harsh climates, ensuring reliability and safety in critical components.

High-Velocity Impact Testing

With advanced charpy testers, this test simulates high-speed impacts to analyze material performance under dynamic loads. It’s essential for aerospace and defense, ensuring materials withstand high-velocity forces, such as in aircraft structures or protective gear, enhancing safety and performance under stress.

How to Choose the Right Impact Testing Machine?

- Consider the load capacity range, ensuring it matches your testing needs from 0.1 J to 500 J for versatility across materials.

- Evaluate testing versatility, checking if it supports Charpy, Izod, and tensile tests for diverse applications like metals and plastics.

- Assess accuracy and precision with high-quality sensors, aiming for ±1% accuracy to meet industry standards like ASTM and ISO.

- Review environmental adaptability, verifying operation from -40°C to 100°C for real-world simulations in harsh conditions.

- Examine safety features, confirming overload protection and emergency stops to protect operators and equipment.

What are the uses of Impact Testing Machine?

- An Impact Testing Machine evaluates material toughness in aerospace, ensuring aircraft components withstand sudden impacts reliably.

- It assesses automotive part durability, using a charpy tester to verify crash resistance and safety compliance.

- The impact test equipment tests construction materials like steel and concrete for structural integrity under stress.

- An impact strength testing machine analyzes alloy properties in metallurgy for industrial applications and durability.

- It supports research by enabling impact testing of materials in labs to develop innovative, resilient materials.

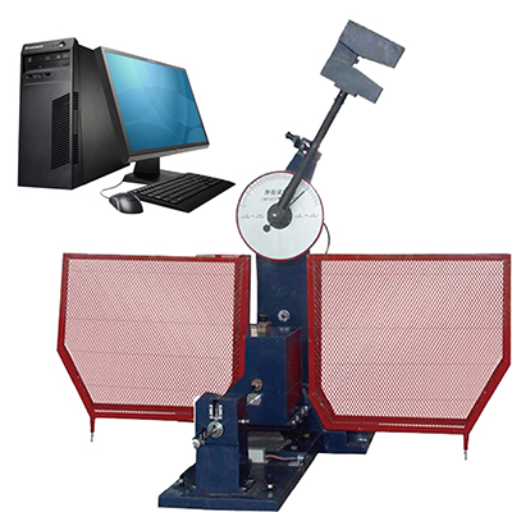

Impact Testing Machine Charpy Test Demonstration

Components of Impact Testing Machine

An Impact Testing Machine assesses material toughness through dynamic load tests like Charpy and Izod. The Testing Machine of precision-engineered components to ensure accurate measurement of energy absorption and fracture behavior.

View our Impact Testing Machine Price

Discover competitive pricing for our advanced Impact Testing Machines—precision, durability, and performance for your material testing needs.

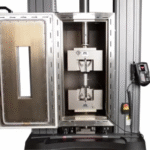

Semi-Automatic Impact Testing Machine

A Semi-Automatic Impact Testing Machine evaluates material toughness via Charpy or Izod tests, offering automated specimen handling, digital data logging, and compliance with ASTM/ISO standards for industries like automotive and aerospace.

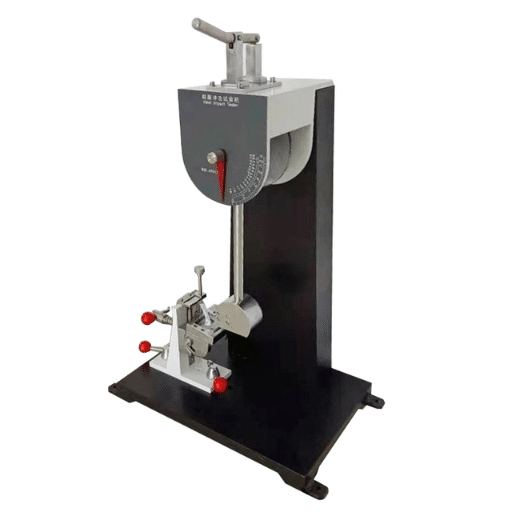

Computerized Impact Testing Machine

The Computerized Impact Testing Machine delivers precise, automated testing for material toughness using Charpy or Izod methods. Featuring advanced software, digital controls, and high accuracy, it ensures reliable data for industries like aerospace and automotive.

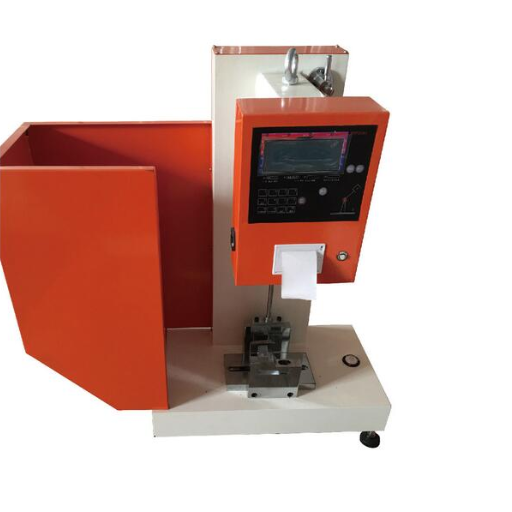

Low Temperature Impact Testing Machine

The Low Temperature Impact Testing Machine evaluates material toughness under sub-zero conditions, ensuring reliability in extreme environments. Ideal for aerospace, automotive, and construction, it conducts Charpy and Izod tests with precision.

Other Equipment For Impact Testing

Other Equipment for Impact Testing includes accessories like specimen preparation tools, environmental chambers, and calibration devices, enhancing the precision and versatility of impact testing machines for industries such as aerospace and automotive.

Why Choose Our Impact Testing Machine Manufacturers

The Impact Testing Machine is better for the aerospace, automobile, and construction industry because of its ease of use, flexibility, accuracy, and long lasting nature. Our charpy test machine with cutting edge sensors provides precise measurements of impact strength, assuring compliance with ASTM and ISO standards.

Its hardened steel frame makes it tough and able to resist numerous tests which is great for manufacturing or metallurgy labs. Impact tests done on our impact machines ensures vehicles parts, airplane structures, and even structural steel are safe and reliable, thus enhancing quality control in critical applications.

Impact Testing Machine 2025 Data Overview

| Parameter | Details |

|---|---|

| Load Capacity Range | Ranges from 0.1 J to 500 J for versatile impact testing applications. |

| Testing Versatility | Supports Charpy, Izod, and tensile impact tests for diverse materials. |

| Accuracy and Precision | Features high-precision sensors with ±1% accuracy for reliable results. |

| Environmental Conditions | Operates from -40°C to 100°C and 20% to 95% RH for real-world simulations. |

| Software and Automation | Includes intuitive software with automated data logging and analysis. |

| Speed Range | Adjustable from 0.5 m/s to 5.5 m/s for precise control of impact velocity. |

| Crosshead Travel | Offers up to 800 mm travel for testing various specimen sizes. |

| Extensometer Integration | Supports optional extensometers for accurate strain measurement. |

| Power Supply Options | Compatible with 110V/60Hz or 220V/50Hz based on regional needs. |

| Safety Features | Equipped with overload protection and emergency stop functions. |

Impact Test Equipment Supplier Technical Specifications: Impact Testing Machines

| Parameter | Specification |

|---|---|

| Impact Energy Range | 0.1 J to 500 J |

| Accuracy | ±1% |

| Testing Versatility | Supports Charpy, Izod, and tensile impact tests for metals, polymers, and composites |

| Environmental Conditions | Operates from -40°C to 100°C for real-world simulations |

| Software Integration | Automated data logging, real-time analysis, and compliance with ASTM/ISO standards |

| Safety Features | Overload protection, emergency stop functions, and safety enclosures |

Expert Insights on Impact Testing Machine

Why is an Impact Testing Machine critical for material testing?

An Impact Testing Machine evaluates material toughness by simulating sudden forces, crucial for ensuring safety in industries like aerospace and automotive. It measures energy absorption during impact, helping manufacturers meet ASTM and ISO standards, ensuring components withstand real-world stresses without failure.

What makes the charpy test machine effective for quality control?

The charpy test machine delivers precise measurements of material impact strength using a pendulum to strike notched samples. Its accuracy ensures reliable data for quality control in manufacturing, verifying that materials like metals and plastics meet durability requirements for critical applications.

How does impact test equipment support diverse industries?

Impact test equipment supports industries like construction, automotive, and energy by testing material resilience. It accommodates Charpy and Izod tests, assessing metals, polymers, and composites, ensuring components perform reliably under dynamic loads in demanding environments like pipelines or aircraft structures.

What are the advantages of impact test machines in research?

Impact Testing Machines provide precise data on material behavior under sudden forces, aiding research in material science. Their ability to test at various temperatures and speeds helps researchers develop stronger materials for applications in aerospace, automotive, and consumer goods industries.

How does the impact strength testing machine ensure compliance?

The impact strength testing machine adheres to global standards like ASTM, ISO, and EN, ensuring accurate testing of material toughness. Its advanced sensors and digital readouts provide reliable results, helping manufacturers comply with regulatory requirements for safety and performance across industries.

What role does impact testing of materials play in safety?

Impact testing of materials ensures components can withstand sudden forces, critical for safety in automotive, aerospace, and construction. Using a charpy tester, it identifies material weaknesses, preventing failures in critical applications like vehicle frames or structural steel, enhancing product reliability.

Case Study: Enhancing Steel Toughness Testing Accuracy by 10%

A leading steel-making concern recently procured a state-of-the-art low-temperature Charpy impact testing machine with automated data acquisition. Equipped with the most advanced sensors and real-time analysis, the machine can generate results with a 10% increase in accuracy compared with the former standards of testing. This breakthrough, therefore, has enabled the company to make much more accurate material choices, strictly adhering to safety specifications essential to highly demanding industries such as aerospace and automotive.

Embedded AI made the system capable of not only faster data collection but also automatic report generation with enhanced actionable insights. A tremendous reduction in manual effort and improvements to overall quality assurance have boosted capacity to maintain the competitive edge while adhering to the most stringent safety and performance requirements.

What Our Client Says

Understand from our clients what they say about doing business with us and the unique value addition we provide.

Blog Related to Charpy Impact Tester

Why Do We Need the Charpy Impact Test?

The Charpy Impact Test is very significant in evaluating the toughness of a material, and it offers a verifiable method for assessing the energy absorbed by a material while being fractured. The test measure is the resistance offered by a material to impact and tries to find out the critical temperature at which a material turns from ductile to brittle and vice versa. Fundamentally, without the knowledge of this temperature, one cannot get a grasp on how a given material is going to behave under varying temperature with stress conditions.

Using a standardized specimen with a notch ensures standardization and comparability of indicatives relating to its toughness-the testimony to this is very much needed in industries with typical high-performance requirements. Selected materials must be capable of sudden impacts and impulsive loading on Charpy, and aerospace industries provide solutions to ensure safety, durability, and performance of their applications. This test helps engineers in designing systems and products, which would stand strong and withstand environmental loads.”

How Does Impact Testing Work?

The impact testing is a vital strategy used to test the capability of a material to absorb energy when sudden forces or shocks are imposed. In this manner, the material is judged for toughness and resilience to see whether it can withstand real-world stresses. The common methods of impact testing are Charpy and Izod, where the energy absorbed by a pendulum striking the notched specimen is measured. They simulate the type of shock materials may be hit by in a sudden way, or perhaps forces that can be exerted in extreme cases during application.

With the onset of modernity, impact testing machines are duly modernized to provide precise data tied with a detailed analysis of material behavior using sensors and AI-based analysis tools-analyzing weaknesses-inter-section or fracture paths-energy dissipation characteristics, etc.-where implementation of these results is before construction, automobile, aerospace, and healthcare industries, where performance is placed upon the materials as a guarantee of safety, reliability, and durability.

Latest Blog Posts

Maintain Inventiveness by Following The Blog for the Latest Best Practices, Techniques, Innovations, and Insights in the Field.

Adhesion testing is an operation that is essential for the evaluation of the durability and reliability of bonded surfaces in […]

COF (Coefficient of Friction) is a very fundamental concept utilized everywhere, from plain interactions to very complicated engineering scenarios. From […]

Polymers have become very important materials for various industries including automobile manufacturing, medical devices, and so on. To know their […]

Friction is one of the basic forces in nature that greatly affects our daily lives and influences the tiniest to […]

Testing is one of the most important methods, among others, to ensure the quality and reliability of materials, goods, or […]

Adhesives have certainly proved to be critical in numerous industries, from construction, automotive, packaging, and consumer goods. However, the question […]

Get a Quote for Your Reliable Pellet Compression Testing Machine Today

Complementing our Impact Testing Machine, the Pellet Compression Testing Machine assesses the compressive strength of pellets in industries like pharmaceuticals, agriculture, and chemicals. With precise load cells and automated controls, it ensures pellets meet strict quality standards, optimizing production reliability.

Frequently Ask Questions

Q: What is the purpose of an Impact Testing Machine?

A: An Impact Testing Machine evaluates how materials withstand sudden forces, ensuring they meet safety and durability requirements for applications in industries like aerospace, automotive, and construction.

Q: What types of tests does the charpy test machine perform?

A: It conducts Charpy and Izod tests, measuring energy absorption to assess material toughness, critical for ensuring compliance with international standards like ASTM and ISO in various industries.

Q: How does a charpy impact test machine operate?

A: A pendulum strikes a notched sample, and the machine records energy absorbed during fracture. This data helps determine material toughness, ensuring reliability in high-stress environments like manufacturing.

Q: What are the advantages of impact test machines?

A: They ensure material safety, meet global standards, enhance product reliability, and support quality control by providing precise data on material performance under dynamic loads.

Q: Is the impact strength testing machine user-friendly?

A: Yes, its intuitive digital interface and automated controls simplify operation, allowing technicians to conduct tests efficiently with minimal training, even in high-throughput industrial settings.

Q: Can the charpy tester handle high-volume testing?

A: Yes, its robust construction supports continuous, high-throughput testing, making it ideal for industrial labs requiring reliable performance over extended periods with minimal downtime.

Q: What standards does the Impact Testing Machine comply with?

A: It adheres to ASTM, ISO, and EN standards, ensuring global compatibility and reliable results for quality assurance in diverse industrial applications.

Q: How often should calibration be performed?

A: Annual calibration is recommended to maintain precision in impact testing of materials, ensuring consistent and accurate results for quality control and compliance with industry standards.