Instrument And Equipment Wholesale

Premium Semi-automatic Impact Testing Machine Manufacturer in China

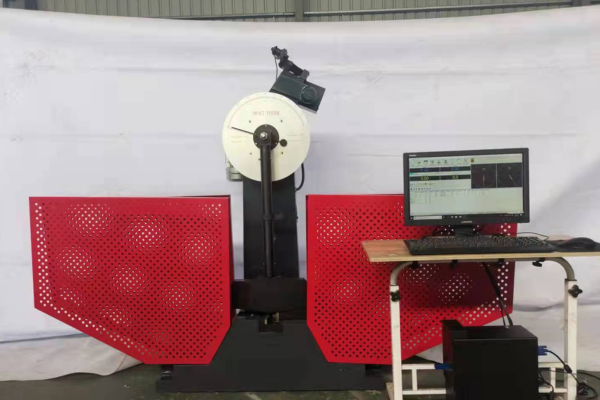

As China's leading manufacturer of semi-automatic impact test machines, we expertly design machines that meet ASTM and ISO standards. These machines are widely used in laboratories and the metallurgical and machinery industries due to their reliability and efficiency. Testing the material toughness of components efficiently under various dynamic loads is easy with their intuitive systems. A dependable partner for testing precision in industries and sectors that require stringent quality control.

What Is A Semi-automatic Impact Testing Machine

-

A semi-automatic impact testing machine evaluates material toughness by measuring energy absorbed during impacts, ensuring performance under dynamic loads for metals and ceramics.

-

These machines feature automated pendulum lifting, impact release, and resetting, along with precise digital displays, stable design, and protective enclosures for efficient and safe testing.

-

They calculate impact energy via gravitational energy differences before and after an impact, optimizing repeated testing through electrical automation for seamless and accurate results.

-

Widely used in metallurgy, manufacturing, and laboratories, these machines assess durability and quality in high-volume testing environments.

-

Compliant with ASTM, ISO, and GB/T standards, these machines meet global benchmarks, ensuring reliable, consistent testing methodologies across industries.

Main Features of Semi-automatic Impact Testing Machine

Semi-automatic Impact Testing Machine allows for detailed analysis of various materials and components under controlled conditions, providing critical data for research, development, and quality assurance.

Automated Mechanism

Features motorized pendulum lifting, impact release, and resetting, enhancing efficiency and reducing manual effort in repetitive tests.

Safety Features

Includes enclosures and safety pins to prevent operational hazards, ensuring a secure testing environment.

Precision Engineering

Equipped with digital displays and stable material construction for accurate energy measurements and impact resistance assessments.

Standards Compliance

Adheres to international standards like ASTM and ISO, assuring consistent, reliable material testing across industries.

Semi-automatic Impact Testing Machine For Sale

JB-500J Semi-automtic Metal Charpy Impact Tester

JB-300J Semi-automtic Metal Charpy Impact Tester

Precision and efficiency are critical to medium-capacity testing, which is offered by the JB-300J semi-automatic metal Charpy impact tester. The device is compliant with ASTM and ISO standards, making it possible to offer reliable and repeatable results while evaluating material toughness under dynamic loads.

JB-150J Semi-automtic Metal Charpy Impact Tester

The JB-150J semi-automatic metal impact tester provides accurate and efficient testing at a lower balance of performance. Energy standards such as ASTM and ISO certify the machine to assess material toughness, optimizing its use in dynamic load measuring across various applications.

Semi-automatic Impact Testing Machine Technical Specifications

| Parameter | Description |

|---|---|

| Load Capacity Range | Supports impact energy from 150J to 750J with precise calibration for different testing needs. |

| Testing Versatility | Applicable for metals, ceramics, and plastics in dynamic load conditions. |

| Accuracy and Precision | High accuracy with ±0.1° angular measurement; digital display for precise energy readings. |

| Environmental Conditions | Operates efficiently at temperatures between 10°C to 35°C; humidity ≤85%. |

| Software and Automation | Features PC control for automated pendulum lifting, release, and data analysis. |

| Speed Range | Offers impact speeds of up to 5.24 m/s for accurate material testing. |

| Crosshead Travel | Not applicable; pendulum-centered operation ensures uniform test dynamics. |

| Extensometer Integration | Non-relevant for impact machines; energy absorption measured directly through pendulum dynamics. |

| Power Supply Options | Compatible with three-phase 380V AC power supply; energy efficient. |

| Safety Features | Equipped with safety enclosures and pins to protect operators during tests. |

Application Industries of Semi-automatic Impact Testing Machine

Metallurgy: Analyzes the impact resistance of metals during production processes.

Automotive: Tests material durability for automotive structural components under stress.

Aerospace: Assesses material toughness vital for high-stress aerospace applications.

Construction: Examines materials used for bridges and high-strength infrastructure projects.

Manufacturing: Ensures quality control of components for industrial manufacturing needs.

Energy Sector: Tests materials for pipelines and energy transmission infrastructure.

Oil and Gas: Validates impact resistance in safety-critical equipment and machinery.

Research and Development: Supports innovative material research for better industrial applications.

Education: Assists in teaching material testing concepts in academic laboratories.

Defense: Evaluates material strength for critical military tools and equipment.

Request Information on Your Semi-automatic Testing Solution!

Boost your testing accuracy and efficiency today with our Semi-automatic Impact Testing Machine! Designed for precision and compliant with industry standards, it’s the ideal tool for reliable material assessments. Act now to upgrade your testing capabilities.

Frequently Ask Questions

Q: What is a Semi-automatic Impact Testing Machine?

A: It is a device used to evaluate material toughness under dynamic load conditions with automated features for efficiency.

Q: How does a Semi-automatic Impact Testing Machine work?

A: The machine uses controlled pendulum motion to impact a material, measuring its resistance to dynamic forces.

Q: What industries use Semi-automatic Impact Testing Machines?

A: Common industries include metallurgy, automotive, aerospace, construction, and manufacturing for material quality assurance.

Q: What materials can be tested with this machine?

A: It tests metals, plastics, and ceramics, ensuring their behavior under impact stress is evaluated.

Q: What are the key auto-functions in this machine?

A: Automated pendulum lifting, precise impact, and data recording enhance operational efficiency and accuracy.

Q: What is the typical energy range for these machines?

A: The machines handle impact energy from 150J to 750J, covering various testing needs.

Q: What standards do Semi-automatic Impact Testing Machines meet?

A: They comply with ASTM, ISO, and GB/T standards for consistent and reliable testing outcomes.

Q: Why choose a Semi-automatic Impact Testing Machine over manual?

A: It offers higher efficiency, precision, and compliance, reducing manual effort and improving repeatability in testing.