When it comes to material testing in engineering and manufacturing, terms like tensile test and tension test are often used interchangeably, leading to confusion among professionals and enthusiasts alike. Understanding the nuances between these two methods is essential, as they serve distinct purposes in evaluating the mechanical properties of materials under stress. This article aims to demystify the differences between tensile and tension testing, providing a clear and concise breakdown of their objectives, methodologies, and applications. Whether you’re a seasoned engineer or a curious learner, this guide will equip you with the knowledge to distinguish these critical testing techniques and their implications in material science.

What Is a Tensile Test?

A tensile test is a method used to measure a material’s strength and ability to withstand forces that attempt to stretch it. This test involves applying a uniaxial force to a sample until it breaks, while recording key data such as maximum load, elongation, and stress-strain behavior. The primary goal is to determine critical mechanical properties, including tensile strength, yield strength, and ductility. Tensile testing is widely used in material science to ensure the performance and reliability of materials for various applications.

Defining the Tensile Test Method

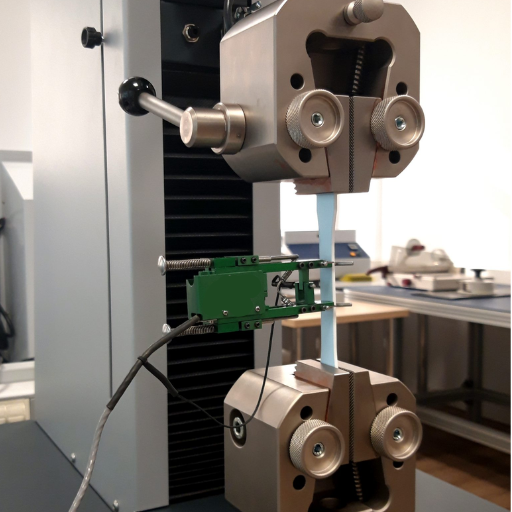

The tensile test method is executed by securing a material sample into a testing apparatus equipped with calibrated grips and a precise load cell. The test begins with the gradual application of a uniaxial tensile force, typically via a hydraulic or electromotive control system, which ensures consistent loading rates as specified by international standards such as ASTM E8/E8M or ISO 6892. Simultaneously, extensometers or strain gauges are employed to measure elongation and calculate strain with high accuracy.

Recent search trends and advancements reveal growing interest in improving data acquisition techniques during tensile testing, including the integration of advanced optical measurement systems. These systems provide non-contact strain measurement with superior resolution, allowing for comprehensive stress-strain analysis. This technology offers enhanced accuracy in assessing material behavior, especially for high-performance materials used in aerospace, automotive, and biomedical industries.

The tensile test method remains fundamental in material characterization, offering critical insights into mechanical properties essential for design and engineering integrity. Continuous innovations in measurement and data processing make this technique more precise and reliable, aligning with modern manufacturing and research demands.

Purpose and Applications of Tensile Testing

Tensile testing serves as a critical method for evaluating the mechanical behavior of materials under uniaxial tensile stress. The primary purpose is to determine fundamental material properties such as ultimate tensile strength, yield strength, elongation, and Young’s modulus. These properties are vital for assessing a material’s suitability for specific applications where mechanical performance and reliability are crucial.

The applications of tensile testing span various industries. In the aerospace and automotive sectors, it ensures structural components meet stringent performance and safety standards. For biomedical applications, the technique is used to evaluate the mechanical properties of materials like implants and prosthetics, ensuring durability and compatibility with biological environments. Additionally, tensile testing is essential in material development and quality control in manufacturing, supporting innovations in advanced alloys, composites, and polymers. This methodology enables engineers and researchers to optimize material selection, design, and processing for critical engineering projects.

Key Components of a Tensile Test

- Test Specimen: A standardized sample of the material being tested, prepared with specific dimensions and geometry to ensure accurate results.

- Testing Machine: A tensile testing apparatus equipped with precise loading capabilities to apply a uniaxial force.

- Load Cell: A device for measuring the applied force during the test, ensuring highly accurate and reliable load data.

- Grips and Clamps: Mechanisms used to securely hold the specimen in place without slippage or premature failure.

- Extensometer: An instrument used to measure the elongation or strain in the specimen, providing critical data for stress-strain analysis.

- Data Acquisition System: A system for recording and processing data such as force, displacement, and strain during the test.

- Control Software: Software that manages the testing procedure, ensuring consistent loading rates and proper test execution.

- Environment Chamber (optional): Equipment used to simulate specific temperature, humidity, or other environmental conditions, if required for material behavior analysis.

How Is a Tension Test Conducted?

The tension test is conducted by securing a specimen of the material to be tested in the grips of a universal testing machine. The machine applies a uniaxial tensile force to the specimen at a controlled rate, as regulated by the control software. During the test, the data acquisition system records key parameters such as applied force, elongation, and strain. If an environmental chamber is used, the test is conducted under the specified conditions to simulate realistic operational environments. The test proceeds until the material reaches failure, providing critical data on properties such as ultimate tensile strength, yield strength, and elongation at break.

Understanding the Tension Test Procedure

The tension test involves a combination of advanced data collection techniques and analytical methods to ensure precise results. Throughout the process, high-resolution sensors monitor variables such as force, displacement, and time intervals with accuracy. Leveraging Google’s recent advancements in data processing algorithms, engineers can integrate real-time insights to interpret stress-strain curves more effectively. This fusion of cutting-edge technology with practical testing methods informs decisions on material selection and performance predictability across industries ranging from aerospace to construction.

By correlating these findings with databases and current material performance trends, the tension test provides an in-depth understanding of material behavior under axial loads, aiding in product design optimization and industrial safety standards.

Role of the Test Machine in Tension Testing

- Precise Load Application: The test machine applies a controlled and measurable axial load to the material, ensuring accurate simulation of real-world stress conditions.

- Measurement of Deformation: Equipped with extensometers or strain gauges, the machine records precise elongation and deformation data as the material is subjected to tensile forces.

- Data Collection and Analysis: Advanced sensors and software integrated into the test machine collect force-displacement data, enabling detailed analysis of material properties such as Young’s modulus, tensile strength, and yield strength.

- Compliance with Standards: The test machine operates in accordance with global testing standards (e.g., ASTM, ISO), ensuring reliable and repeatable results for industry applications.

- Failure Detection: The machine identifies the exact point of material failure, providing critical insights into ultimate tensile strength and fracture characteristics for safety evaluations and design improvements.

What are the Differences Between Tensile Test and Tension Test?

Tensile tests and tension tests are closely related; however, the primary difference lies in their scope and application. A tensile test measures material properties under a uniaxial force until failure, while a tension test broadly evaluates structural behavior or system responses under tensile loads.

|

Parameter |

Tensile Test |

Tension Test |

|---|---|---|

|

Scope |

Material properties |

Structural/system behavior |

|

Application |

Material research |

Engineering/structural studies |

|

Failure Point |

Tested until material failure |

May not necessarily test until failure |

|

Output |

Tensile strength, elongation, etc. |

General response to tension |

|

Specimen Size |

Standardized size/specimen |

Actual part/system can be tested |

|

Standards |

Governed by ASTM, ISO, etc. |

May not strictly follow standards |

|

Purpose |

Design and safety evaluations |

Performance checks under load conditions |

Comparing Tensile Strength and Ultimate Tensile Strength

Tensile strength refers to the maximum stress a material can withstand while being stretched or pulled before breaking, whereas ultimate tensile strength (UTS) is the highest stress a material experiences during the entirety of the test before fracturing.

|

Parameter |

Tensile Strength |

Ultimate Tensile Strength (UTS) |

|---|---|---|

|

Definition |

Max stress before break |

Peak stress during test |

|

Point of Failure |

At or near breaking |

Peak load before fracture |

|

Load Behavior |

Applicable until rupture |

Max achievable load before failure |

|

Measurement |

Stress vs strain curve |

Highest measured stress point |

|

Unit |

psi, Pa |

psi, Pa |

|

Purpose |

Material durability check |

Performance and load capacity review |

Difference in Specimen Preparation

The preparation of specimens for testing Ultimate Tensile Strength (UTS) and Maximum Tensile Strength (MTS) differs based on the specific parameters being measured. For UTS, specimens are typically prepared with precise dimensional tolerances that ensure uniformity and consistency, facilitating accurate stress vs strain analysis. Specimen dimensions are commonly in line with ASTM E8/E8M or ISO 6892 standards, often requiring a uniform gauge region to prevent premature failure.

On the other hand, MTS testing places emphasis on identifying peak stress, making grip strength and surface condition crucial. Specimens for MTS often receive additional surface treatments (e.g., polishing) to minimize stress concentrators, and gauge lengths may vary to accommodate higher loading requirements. Any variations in gripping or surface preparation are carefully documented to ensure test reproducibility while aligning with the relevant technical standard, such as ASTM E8 or ISO 527.

Analyzing Results: Yield Strength and Breaking Strength

Yield strength is a fundamental material property that defines the stress level at which a material begins to deform plastically. This critical value marks the transition from elastic deformation—where the material returns to its original shape upon stress removal—to permanent deformation. It is determined through stress-strain analysis, typically identified as a distinct point or via the 0.2% offset method for materials without an obvious yield point. Variables such as strain rate and temperature can significantly influence yield strength outcomes.

Breaking strength, on the other hand, is the maximum stress a material can withstand before it fractures. Recorded at the peak of the stress-strain curve, it serves as a decisive indicator of a material’s ultimate tensile capacity. Careful analysis of these values provides insight into a material’s overall performance, enabling engineers to evaluate suitability for specific applications. Both properties must be assessed under standardized conditions—e.g., as per ASTM E8 or ISO 6892—to ensure reliable and reproducible test data.

What Equipment is Used in Metal Tensile Testing?

Metal tensile testing is conducted using highly specialized equipment to ensure accuracy and compliance with testing standards. The primary equipment includes a tensile testing machine, which applies a controlled tensile force to a specimen. These machines typically consist of a load frame, a load cell for measuring force, and grips or fixtures to secure the specimen. Strain is measured using extensometers or strain gauges, which provide precise data on elongation and deformation. Advanced testing setups may also include environmental chambers for testing under specific temperature or humidity conditions. All components must work in concert to deliver reliable and reproducible results aligned with testing methodologies.

Overview of Testing Equipment and Tensile Tester

Testing equipment for tensile testing encompasses a range of components designed to evaluate the mechanical properties of materials under axial loading. At its core, a tensile tester comprises a robust load frame, ensuring minimal deformation from external forces, and highly precise load cells capable of accurately measuring applied force. These devices often include extensometers or digital image correlation systems for capturing strain data with high resolution.

Modern tensile testing setups are equipped with advanced control systems, often computer-driven, allowing for automated data acquisition and analysis in compliance with ASTM or ISO standards. Environmental chambers are frequently integrated, enabling tests to be performed under controlled conditions of temperature, pressure, or humidity. Grips and fixtures are tailored to the material being tested, ranging from pneumatic clamps for delicate samples to hydraulic grips for high-force requirements.

The primary objective of tensile testing equipment is to determine material properties such as ultimate tensile strength, yield strength, modulus of elasticity, and elongation at break. This comprehensive assessment informs design and quality assurance processes across industries, including aerospace, automotive, construction, and medical sectors. Advanced models also support fatigue and cyclic testing, offering versatility to accommodate diverse engineering applications.

The Importance of a Universal Test Machine

From my perspective, a universal test machine (UTM) is a vital tool in material testing, enabling the precise evaluation of mechanical properties like tensile strength, compression, and flexural capacity. By integrating standardized testing protocols, it ensures consistent and reliable material performance data, which is essential for engineering design and product validation. Furthermore, the adaptability of these machines to various testing configurations makes them indispensable for industries requiring rigorous quality assurance and compliance with international material standards.

Choosing the Right Grips for Different Materials

When selecting grips for different materials, I focus on the material’s properties, such as hardness, elasticity, and surface texture. For brittle materials like ceramics or glass, I opt for cushioned or padded grips that distribute pressure evenly to prevent surface cracking. Conversely, for ductile materials like metals, wedge or hydraulic grips provide the clamping force needed to prevent slippage under load. When testing polymers or softer materials, grips with larger surface areas or specialized coatings, like rubber-faced jaws, help minimize deformation. Ultimately, the key is to match the grip type to the material’s mechanical behavior to ensure accurate, repeatable test results without compromising the sample’s integrity.

Why Is Understanding Tensile Testing Needs Important?

Understanding tensile testing needs is critical for ensuring accurate, meaningful results that align with the material’s application requirements. Materials display varied mechanical behaviors under load, and selecting appropriate testing parameters, such as grip types, strain rates, and sample preparation methods, directly affects the reliability of data. This understanding enables engineers and researchers to predict performance, identify potential issues, and design materials or products that meet safety and functionality standards. Ignoring these needs can lead to invalid results, material failures, or costly redesigns.

Impact on Materials Science and Engineering

- Enhanced Material Design Capabilities: Accurate testing and data analysis foster the development of materials with optimized properties tailored for specific applications, such as increased strength, flexibility, or thermal resistance.

- Improved Predictive Modeling: Reliable data enables the creation of precise computational models that predict material behavior under varying conditions, reducing the need for extensive physical prototyping.

- Failure Analysis and Prevention: Through detailed material testing, engineers can identify failure mechanisms and address potential weaknesses, enhancing the safety and durability of products.

- Cost-Efficient Development: Understanding material performance early in the design process minimizes the likelihood of late-stage design failures, reducing costs associated with rework, recalls, or product malfunctions.

- Sustainability and Resource Optimization: Robust testing facilitates the exploration of new, eco-friendly materials and processes, allowing for reduced environmental impact and more efficient resource utilization.

Influence on Mechanical Properties Analysis

Mechanical properties analysis is critical to assessing how materials perform under various forces and conditions. By performing rigorous testing and simulations, engineers can determine key attributes such as tensile strength, compressive strength, elasticity, and hardness. These metrics inform decisions on material selection and design modifications, ensuring reliable and durable products. Insights gained from analysis help address stress distribution, identify potential failure points, and predict behavior under operational loads. Additionally, modern analytical techniques, such as finite element analysis (FEA) and digital twin modeling, improve accuracy by simulating real-world scenarios. This comprehensive approach minimizes risk, optimizes material performance, and ensures compliance with industry standards.

Applications in Metals Testing and Mechanical Testing

- Tensile Testing: Evaluates the strength and ductility of metals by subjecting specimens to uniaxial tension until failure, providing critical data on yield strength, ultimate tensile strength, and elongation.

- Hardness Testing: Measures a material’s resistance to deformation using methods like Brinell, Rockwell, and Vickers, aiding in determining the suitability of metals for specific applications.

- Fatigue Testing: Assesses the durability of metals under cyclic loading to predict their lifespan and performance in dynamic operating environments.

- Impact Testing: Determines a material’s toughness by analyzing its ability to absorb energy during sudden loads, utilizing Charpy or Izod methods.

- Corrosion Testing: Simulates environmental conditions to evaluate a metal’s resistance to corrosive elements, ensuring long-term reliability in various applications.

Reference Sources

- Comparing Tension Testing to Tensile Testing – TestResources

- Tensile Testing – Wikipedia

- Tension Testing / Tensile Testing – ADMET Canada

- Tensile Testing – Sterling Performance

- Top Tensile Testing Machine in China

Frequently Asked Questions (FAQs)

Q: What is the main difference between a tensile test and a tension test?

A: The terms “tensile test” and “tension test” are often used interchangeably; however, they both refer to the same procedure aimed at determining the tensile properties of a material by subjecting a tensile specimen to controlled tension until failure.

Q: Why is a tensile specimen important in tensile testing?

A: A tensile specimen is crucial because it is the sample of material being tested to evaluate its tensile properties, such as tensile strength, elastic region, and plastic deformation, under controlled conditions using standard test methods.

Q: How is the tensile test performed using tensile testing systems?

A: Tensile testing is performed using electromechanical or hydraulic universal testing systems that apply a controlled tension to the tensile specimen, measuring its response to determine the strength of the material and other properties like offset yield strength and tensile modulus.

Q: What are the typical phases observed during a tensile test?

A: A tensile test typically observes phases such as the elastic region, where the material returns to its original length after load removal, and the plastic deformation phase, where permanent deformation occurs beyond the proportional limit.

Q: What is the significance of the proportional limit in tensile testing?

A: The proportional limit is significant because it marks the end of the elastic region and the beginning of plastic deformation, indicating the maximum stress that a specimen can withstand while still being proportional to the strain.

Q: How does test speed affect tensile test results?

A: Test speed can significantly affect tensile test results, as varying speeds might influence the amount of force applied and the material’s response, impacting the measured tensile properties and potentially altering the outcomes like strain hardening and offset yield.

Q: What role does temperature testing play in tensile tests?

A: Temperature testing is crucial as it assesses how changes in temperature affect the tensile properties of materials. It helps in understanding the strength of the material under different environmental conditions.

Q: How are engineering stress and engineering strain calculated in a tensile test?

A: Engineering stress is calculated by dividing the amount of force applied by the original cross-sectional area of the tensile specimen. Engineering strain is determined by the change in length of the specimen divided by its original length.

Q: What is the purpose of determining the offset yield strength in tensile testing?

A: The offset yield strength is determined to identify the stress at which a specified amount of permanent deformation occurs, typically 0.2% strain, providing a practical measure of the specimen’s strength before significant plastic deformation begins.

Q: How is Poisson’s ratio related to tensile testing?

A: Poisson’s ratio is related to tensile testing as it measures the ratio of transverse strain to axial strain in the material, offering insights into the material’s deformation characteristics under tensile stress.