Definition of Coefficient of Friction

The coefficient of friction is a unitless number used to denote the degree of resistance encountered between two interacting surfaces. It is determined as the ratio of the frictional force between the surfaces to the normal force pressing those surfaces together. The formula denoting COF is:

Material type, surface texture, and other conditions, such as lubrication and environmental factors, can cause variations in this parameter. It is classified into two main types: static coefficient of friction, which applies to surfaces at rest; and kinetic coefficient of friction, which applies to surfaces in motion. The coefficient of friction is used to predict and analyze surface behavior under various conditions, making it a crucial aspect in engineering, physics, and materials science.

What is the Coefficient of Friction?

The coefficient of friction is a scalar quantity relating the force of friction acting between two surfaces to the normal force pressing them together. Modern-day research and data indicate that the value of the coefficient of friction can vary significantly with the materials in contact with each other: say, rubber and dry asphalt with a COF of about 0.7 to 0.9, whereas ice on steel sides is extremely low, usually around 0.03.

There is a formula used for calculating the coefficient of friction:

Some other contemporary researches highlight the environmental and surface conditions, such as humidity or contamination, which may instantaneously alter the value of the coefficient of friction under study. These considerations are now taken by advanced analytical models that simultaneously utilize computational simulations and real-time data to solve the problem with maximal accuracy.

Types of Coefficients of Friction

The main types of coefficients of friction (COF) are static, kinetic, rolling, and fluid friction.

| Type | Definition | Key Factors | Range |

|---|---|---|---|

| Static | Friction between surfaces at rest | Surface texture, force | 0.1-1.0 |

| Kinetic | Friction during relative motion | Speed, material | 0.05-0.7 |

| Rolling | Resistance in rolling motion | Surface deformation | 0.001-0.2 |

| Fluid | Friction through liquids/gases | Viscosity, velocity | Variable |

Importance of Coefficient in Engineering

The coefficient of friction (COF) is a crucial parameter in engineering, measuring the resistance to motion between two interacting surfaces. This parameter has a direct impact on the design, operation, and safety of various mechanical systems across multiple industries. In mechanical engineering, COF must be understood when designing parts like bearings, clutches, or brakes, where friction needs to be controlled for performance. Likewise, in civil engineering, COF considers the frictional resistance between soil and foundation materials for the stability of a structure under various load conditions.

Materials and Their Impact on Friction

Materials inherently tend to affect the coefficient of friction between two adjacent surfaces due to their physical and chemical properties. For easily understandable examples, rough materials such as concrete or rubber would exhibit higher COF characteristics due to their greater surface asperities, which aid in mechanical interlock, resulting in higher friction. On the other hand, smooth surfaces of metal or Teflon would tend towards lowering the COF and thus reducing friction. Surface treatment, coatings, and lubrication can further enhance or mitigate frictional effects by modifying the cumulative surface energy and, consequently, the interaction characteristics. It is the study of such material influences that leads an engineer towards optimal friction in any application.

Common Materials Used in Friction Studies

General-purpose material for strength and versatility

Aerospace and automotive applications

Known for low frictional properties

High frictional properties with deformation

High temperature, low-friction applications

- Steel: The general-purpose material in friction studies due to its strength and versatility, and also because of its general use in engineering applications. The variations in surface roughness and treatments make it an excellent material for examining a variety of frictional behaviors.

- Aluminum is constantly tested due to its other properties; i.e., it is employed in industries where aerospace and automotive applications require excellent wear resistance and specific frictional characteristics.

- Teflon (PTFE): Known universally for its low frictional properties, it is extensively researched for applications where friction needs to be minimized, such as bearings and coatings.

- Rubber: It is an excellent material for studying its high frictional properties, which deform significantly under stress; thus, it is essential for studies of tires and sealing applications.

- Ceramics: The studies of ceramics are carried out in those applications, where high temperature and slight friction are in demand, such as in braking systems or cutting tools.

How Material Properties Affect Friction Coefficients

Friction coefficients are related to the physical and chemical features of the materials in contact. The primary aspects considered are surface roughness, hardness, lubrication, and chemical composition. The smoother the surfaces of the materials, the lower the coefficient of friction due to the decreased interlocking between asperities. Therefore, rougher surfaces create higher levels of friction, as irregularities engage more firmly.

Hardness also plays an important role; typically, harder materials tend to have less friction when dry, as they resist deformation more effectively than softer materials, which can increase friction through energy dissipation during deformation. The presence of lubricants alters the environment by introducing a boundary layer; therefore, direct contact between the surfaces will be minimal, thereby decreasing the coefficient of friction.

The chemical composition and atomic bonding determine the specific behavior of a material. For example, ceramics with strong ionic or covalent bonds resist wear under extreme temperature conditions and maintain low friction coefficients in real-world applications, such as those used in turbine blades. Based on the latest information gathered from Google research, a recent study revealed that specially designed material combinations, such as composites with nanostructured phases, provide a better way to manage friction coefficients; thereby allowing the engineered materials to be fine-tuned to optimize performance in various fields, including aerospace, automotive, and medical devices.

Complementing these interactions is instrumental in the design of materials, where such designs ultimately pursue targeted frictional performance, whether in static or dynamic applications.

Methods for Measuring Coefficient of Friction

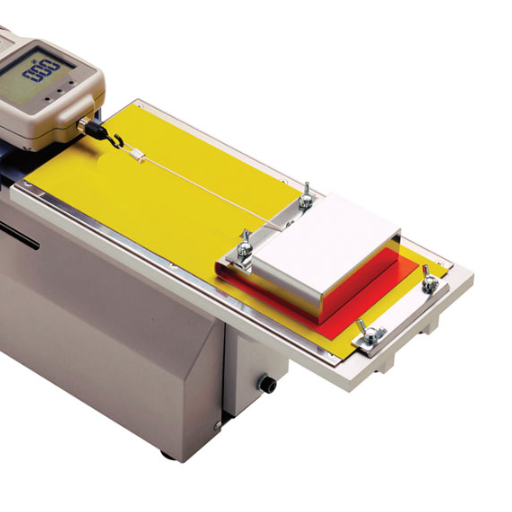

Various standard methods can measure the coefficient of friction, depending on the application and the kind of materials involved. Tribometers are frequently used as instruments designed to measure frictional forces. The pin-on-disk method consists in placing a piece of material (pin) in contact with a rotating disk under controlled conditions and measuring the frictional force.

One other popular option is the inclined plane method, whereby the material is laid on a surface of known inclination, which is increased until the object starts sliding, allowing calculation of the static CoF. Other methods, based on optics and lasers, include surface profilometry that addresses micro-scale interactions that contribute to friction. Accurate measurements are only possible when one maintains a constant temperature, humidity, and sliding velocity, thereby creating a situation that closely approximates real operating conditions.

Traditional Measurement Techniques

Traditional measuring techniques for friction typically involve relatively simple experimental setups to determine coefficients of friction (CoF) in a controlled environment. A standard method is to use a tribometer: two surfaces-one stationary and one moving-are brought into contact with a predetermined load, and the frictional force is directly measured. Another commonly used method is the incline plane test, with which one determines static CoF by slowly tilting the plane until the test object begins to slide, allowing for a simple calculation based on the critical sliding angle. Pin-on-disk tests also take priority in these techniques, wherein a pin is pressed against a rotating disk, and the resultant wear and frictional forces are analyzed. It implies that these techniques focus on simplicity and repeatability, although advanced calibration and environmental controls are typically prescribed to enhance the accuracy of the data further.

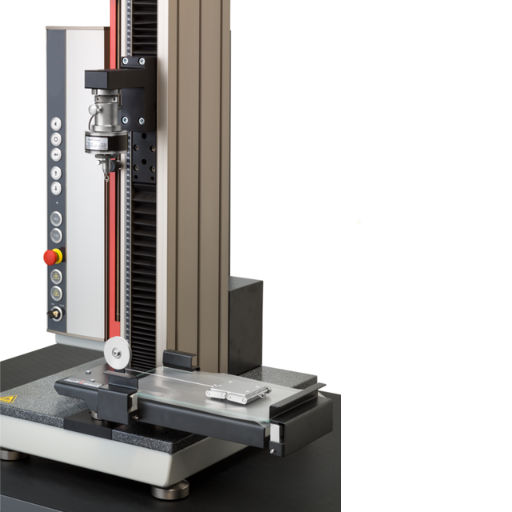

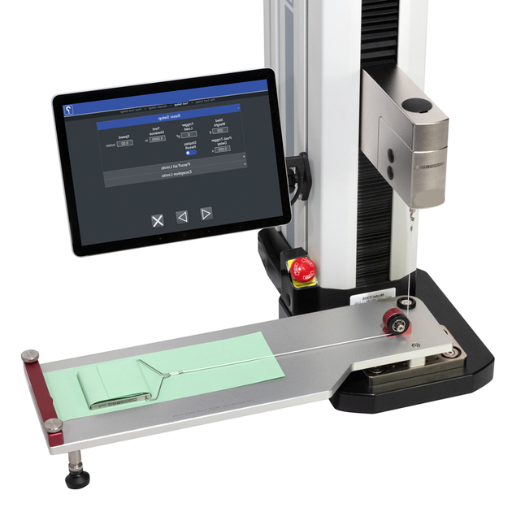

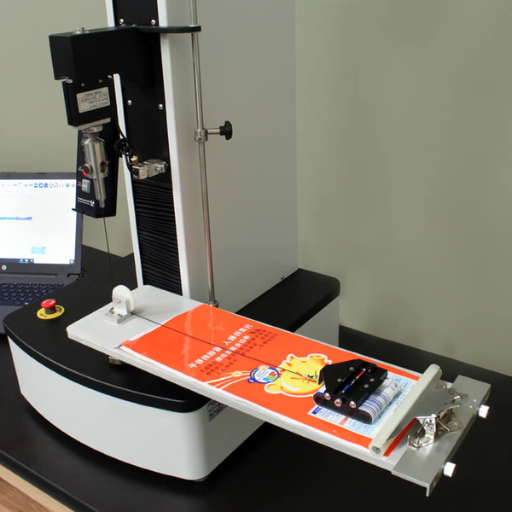

Modern Measurement Equipment and Technology

Modern friction and wear measurement holds some of the latest technological advances aiming at increasing the precision, efficiency, and repeatability of experiments. Tribometers (reciprocating and rotary types, typically equipped with integrated sensors for high-resolution data acquisition) are among the more recognizable tools, which enable real-time measurement of the frictional forces generated under various environmental conditions, such as temperature, humidity, and pressure.

Optical and laser-based techniques enable the measurement of surface roughness and wear characteristics through 3D surface profilometry and interferometry. Digital imaging systems further complement these analyses by capturing wear patterns for quantitative assessment of surface deformation. Computational tools, such as finite-element modeling (FEM), serve as a valuable complement to physical testing by simulating tribological interactions and reducing the burden of physical testing.

Integrated software and machine learning algorithms are now being incorporated into friction measurement processes, enabling data processing and predictive modeling on an entirely new scale. Such developments are enhancing wear mechanism analyses and the development of materials and lubricants that perform more effectively.

Comparative Analysis of Measurement Methods

Modern friction measurement methods include pin-on-disk, ball-on-flat, reciprocating tribometers, scratch testing, and micro-tribological techniques.

| Method | Key Feature | Application | Material Size | Load Range | Speed Range |

|---|---|---|---|---|---|

| Pin-on-Disk | Rotational | Bulk Materials | Varies | Low-High | Low-High |

| Ball-on-Flat | Stationary | Surface Tests | Small | Low-Medium | Low-Medium |

| Reciprocating Tribo | Oscillatory | Thin Films | Small | Low-High | Low-Medium |

| Scratch Testing | Linear Motion | Coating Durab. | Micro | Low | Static |

| Micro-Tribological | Nanoscale | Micro/Nano | Micro/Nano | Micro | Micro |

Measuring the Coefficient of Friction in a Lab Setting

Specific steps should be taken to determine a coefficient of friction in a laboratory setting, depending upon what test apparatus is being used and what materials are used in testing:

1. Pin-on-Disk Method

A disk is rotated against a pin under a controlled load and speed environment. The CoF is determined by measuring tangential and normal forces exerted during testing. It takes bulk materials and can vary widely in speed and load.

2. Ball-on-Flat Test

Here, a stationary flat sample is loaded against a ball, providing data to analyze surface interactions under low to medium forces and velocities, thus suitable for surface-level analysis.

3. Reciprocating Tribometer

This method of friction and wear simulation for thin films utilizes oscillatory motion, with the coefficient of friction estimated as the ratio of the applied load to the resistive force within each oscillatory cycle.

4. Scratch Testing

Mainly used for evaluating coatings’ durability, this method applies a controlled linear force while creating a scratch along which the CoF is determined by tracking the force resistance.

5. Micro-Tribological Testing

For nanoscale applications, this method is concerned with the micro/nano-scale materials, exploiting ultra-sensitive force measurement in precise CoF assessments.

All methods have specific advantages depending on the nature of the material, scale of contact, and test conditions for accurate and reproducible results.

Static vs. Kinetic Friction Measurements

Static vs. Kinetic friction measurements involve identifying the Coefficient of Friction (CoF) before motion starts (static) and during motion (kinetic).

Static COF

- Definition: Before motion

- Motion State: Stationary

- COF Value: Typically higher

- Force Type: Initial force

- Measurement: Peak resistance

- Application: Start of movement

Kinetic COF

- Definition: During motion

- Motion State: Moving

- COF Value: Typically lower

- Force Type: Continuous force

- Measurement: Dynamic resistance

- Application: Ongoing sliding

| Parameter | Static COF | Kinetic COF |

|---|---|---|

| Definition | Before motion | During motion |

| Motion State | Stationary | Moving |

| COF Value | Typically higher | Typically lower |

| Force Type | Initial force | Continuous force |

| Measurement | Peak resistance | Dynamic resistance |

| Application | Start of movement | Ongoing sliding |

Equipment Used for Testing

Accuracy in testing frictional forces requires instruments of the utmost precision to measure the static and kinetic coefficients of friction (CoF). Tribometers are the most common instruments used, as their environment can be tightly controlled while observing these forces. Popular configurations involve pin-and-disk and block-and-ring setups, wherein materials subjected to applied forces and velocity under strict control. High-resolution load cells are integrated into these instruments, along with force sensors and displacement monitors, to assure increased precision in measurements.

According to the latest information gathered, the leading manufacturers have equipped their advanced tribometers with data-logging and analysis systems that run on machine learning algorithms. This ensures that the measurements are as consistent as possible, reducing human errors and enhancing repeatability. Temperature sensors, followed by moisture control devices, ensure that suitable environmental conditions are met, allowing for a close simulation of real-life scenarios. A star product these days for manufacturers carrying out material testing, product development, and quality monitoring.

Calibration and Setup for Accurate Results

When striving for exact results, I calibrate all test equipment by the manufacturer’s specifications and relevant industry standards. This calibration involves using certified reference material and calibration tools to adjust the equipment to its best operating conditions. Then the equipment is set up according to very detailed setup procedures, including environmental adjustments—such that temperature and humidity levels are controlled for the test conditions. It is also common practice to apply periodic validation steps, such as base-level checks and performance-monitoring measures, to verify the system’s accuracy with minimal variation. Adherence to such procedures makes it possible to produce a specific output that meets all quality standards.

Applications of Coefficient of Friction in Various Industries

The coefficient of friction plays a vital role in industries as a parameter indicating the resistive force that exists between two surfaces. In manufacturing processes, it is essential to have materials handled with friction on machines, such as conveyors or robotic arms. The automotive sector utilizes the coefficient of friction to design tires with optimal grip on the road surface, thereby enhancing the stability and safety of vehicles. COF could also be used in construction to select materials for flooring and infrastructure that have some measure of resistance or traction. On the contrary, in the aerospace industry, it is used in an exact manner to design landing gear and braking systems, while packaging industries use it to ensure that materials stack up and transport well. Examining these examples provides insight into the broad application and significance of COF in enhancing efficiency and safety across various fields.

Manufacturing Processes

The coefficient of friction (COF) plays a crucial role in various manufacturing processes, enabling precise control over material handling, machinery performance, and the quality of the processed product. In machining, metal forming, and other operations, the COF influences the tool wear, heat generation, and surface finish, thereby ensuring the best efficiency and highest durability. Conveyors and automated assembly lines utilize COF to prevent slippage, maximize grip, and provide the smooth passage of materials and components. Additionally, the COF is crucial in selecting materials for molds, dies, and other surfaces in contact with materials, as their production consistency is at stake, not to mention the energy consumption. These methods above evidently confirm COF as indispensable in facilitating manufacturing efficiency and precision.

Engineering Solutions

The coefficient of friction (COF) is an essential factor in many engineering applications, particularly in cases where precise control of motion and force distribution is required, and material interaction occurs. One of the key applications is in braking systems in automotive and aerospace engineering. The COF is optimized to provide maximum stopping power, minimize wear, and meet performance levels under all environmental conditions. With advancements in materials science, brake pads made of composite or ceramic materials rely heavily on more precise information about the friction coefficient to strike a balance between safety and efficiency.

Additionally, in robotics, the COF plays a crucial role in gripping and manipulation mechanisms that require controlled interaction with objects, preventing slipping and allowing for the application of minimal force. This ensures reliability in automation systems even under dynamic loading. In civil engineering, COF values are used in conjunction with surface treatment processes to develop skid-resistant pavements, thereby enhancing traction and reducing the likelihood of accidents.

Modern engineering approaches, based on the most recent data, employ COF modeling as an integral part of computer simulations to allow prediction analysis and the design of new surfaces. Advanced coatings and surface texturing are now being engineered to customize COF for applications ranging from hydrophobic surfaces to decrease drag to lubricated interfaces to minimize wear in machinery. These innovative solutions provide a glimpse into how knowledge and the application of COF is used to improve operational efficiency, safety, and long-term durability across a diverse array of engineering disciplines.

Materials Science Innovations

The coefficient of friction is a crucial factor in materials science that affects the operation and efficiency of surfaces in various industries. For example, in automotive applications, the COF of tire compounds affects road grip, safety, and fuel performance. One more example pertains to aerospace, where the reduction of COF on external surfaces is aimed at reducing aerodynamic drag for better fuel performance. Another critical application is in biomedical devices, where the COF can be manipulated to a functional degree, allowing for prosthetics and joint replacements that function with minimal wear for enhanced longevity. The application and design of coatings, such as diamond-like carbon (DLC) or Teflon, utilize COF to meet specific performance requirements. This is evidence of how COF plays a significant and integrated role in engineering durable, high-performance systems for special environments.

Reference Sources

-

Xometry: Coefficient of Friction Testing: Procedure, Application, … – This source discusses the applications of friction coefficients in materials like rubbers and road surfaces, particularly for vehicle tires and aircraft landing gear.

-

PASCO Scientific: Coefficients Of Friction – Lab Experiments – A detailed lab experiment guide for determining static and kinetic friction coefficients using sensors.

-

University of Alabama Physics Lab: Friction Lab – A comprehensive lab manual exploring friction properties and methods to measure the coefficient of friction.

-

Rheology Lab: Coefficient of Friction Testing Service – Offers insights into friction testing services for static and kinetic coefficients, especially for plastic films and sheeting.

-

Pivot Interactives: Student Video Analysis: Friction Coefficient Lab – A resource for analyzing friction coefficients through video-based experiments and comparing measured values with published data.

Frequently Asked Questions (FAQs)

What materials are commonly employed in interacting with the lab coefficient of friction?

In the investigation of the lab coefficient of friction, common materials considered are rubber, wood, metals, and plastics. These materials are selected based on their distinct properties, allowing researchers to investigate how interactions occur between the surfaces under the specified conditions.

How do scientists make the determination of the coefficients of static friction for two working bodies of material?

The coefficients of static friction between two bodies of materials are determined by experiment; the two materials are placed in contact while a force is steadily applied to bring about the initiation of relative motion as one body moves on the other. A measurement is then taken consisting of the ratio of the maximum force of static friction to the normal force.

What kind of information can be extracted from the experiments on the lab coefficient of friction?

Experiments on the laboratory coefficient of friction provide valuable insights into the interaction of different materials, including the effects of surface roughness, composition, and environmental factors on frictional forces. Gathering such information can provide insights relevant to engineering, physics, and materials science.

Can different positions of materials change the lab coefficient of friction?

Yes, since the lab coefficient of friction depends on the area of surface contact and the degree of inclination, different positions of materials can alter the lab coefficient of friction. In this way, slight variations in one material’s ability to grip another can create different frictional outcomes.

How are the coefficients of static and kinetic friction differentiated and defined experimentally?

The coefficients of static or kinetic friction differ because they define two different states of motion. The static friction coefficient is the frictional force that has to be overcome to start moving an object, and the kinetic friction coefficient is the frictional force acting on an object in motion. Usually, the coefficient of static friction is greater than that of kinetic friction.

What are the common types of experiments used in the scientific studies of friction coefficients?

Experiment setups used in studying friction coefficients are the inclined plane, the horizontal plane with weights, and the dynamic test systems. This type of experimentation identifies the relative impact of various parameters, such as material type, surface texture, and force applied, on friction coefficients.