The assessment of adhesive bond strength and longevity is an essential factor in all industries, from aerospace to automotive engineering. This post will look at the two most recognized standards for lap shear testing: ASTM D1002 and ASTM D5868, which are the sources of information of the mechanical performance of adhesive joints during static load. If you are an engineer, a materials scientist or a manufacturer, it is a must for you to know the subtleties of these test methods because that is the way to make reliable and high-performing bonds. Come along as we unravel the procedure for these tests, what their outcomes are and the reason they are important in the examination of bond specimens.

Understanding the Lap Shear Test

Definition of Lap Shear Test

The lap-shear test is an accepted and widely used method for measuring the strength of the adhesive joints between two overlapping samples. It evaluates the performance of the adhesive joint when it is subjected to shear stress, which refers to the force that directs the sliding of one material layer past the other. Therefore, this test gives a reliable estimation of the adhesive’s stress performance in real-life applications.

In the course of the lap shear test, an overlap of two slides is done, and in the middle of the overlap, the adhesive to be tested is applied. The assembly is then subjected to a tensile load that is applied parallel to the bonded area until the joint fails. The peak load recorded during the test will determine the adhesive’s shear strength. This technique characterizes the adhesive’s structural integrity and its compatibility with the materials in question.

The lap shear test results play a vital role in deciding the adhesive’s fitness for different applications. The testing mimics real-world stress conditions so that the engineers and manufacturers can anticipate how the adhesive will perform under various circumstances. Thus, the right adhesive can be chosen that will not only be cost-effective but also be safe, durable, and efficient in the end product.

Lap Shear Tests: Adhesion’s Significance

Adhesion is the primary factor influencing lap shear tests as it basically defines the strength and the trustworthiness quality of the connecting between two materials. The testing purpose is to analyze the adhesive’s performance of holding the materials together under shear forces, which are assigned to represent the stress types occurring most commonly in practice. Strong adhesion makes it possible for the bonded materials to withstand operational stresses without loss of structural integrity.

Adhesion is the key to the product’s life, durability, and safety. An adhesive that passes a lap shear test can be trusted to uniformly distribute stress across the whole area of the joint, hence reducing the possibility of the joint failing, extending the product’s life, and allowing the product to perform consistently under varying conditions, like temperature changes, vibrations, or mechanical forces, that also includes those of less intensity.

Moreover, the lap shear tests give engineers a chance to test potential and get the most suitable adhesive for the specific applications. In this way, manufacturers will be able to make their choice of adhesive match the operational requirements and environmental conditions the product will face, thus ensuring safety, efficiency, and cost-effectiveness in the final design by testing the adhesive’s performance under controlled conditions.

Overview of Shear Strength Measurement

Shear strength measurement is an essential technique that determines the material or adhesive’s resistance to the forces that cause layers to slide over each other. This property is of prime consideration in assessing an adhesive’s performance in holding structures together during loads or stress. By shear strength evaluation, the engineers are able to forecast the materials’ behavior during the operation.

Standardized testing procedures, such as lap shear tests, are usually used for the measurement. In such tests, force is applied to the bonded materials until the adhesive gives way. This test yields data regarding the maximum stress a bond can take up to the point of failure. The factors that are of concern include the type of materials used and several other parameters that control the shear strength.

ASTM Standards for Lap Shear Testing

Method of Test ASTM D1002

The ASTM D1002 test method is a universally accepted procedure through which the shear strength of adhesives adhering to metal substrates is measured. Its performance evaluation of the adhesive under controlled conditions is done to a large extent. The test comprises of specimen preparation by fusing two metal adherends with the adhesive in question. After that, these specimens are subjected to an increasing tensile load until the adhesive bond is broken.

One of the main reasons for the ASTM D1002 test is the evaluation of the shear strength of the adhesive. This figure is arrived at by dividing the breaking force by the area of the specimen that was bonded. The value resulting from this process indicates the amount of stress that the adhesive can endure before it is broken, thus providing very important data for those situations where strong and reliable bonds are necessary.

Among the main factors that affect the results are the adhesive type, the adherends’ preparation, and the test conditions such as temperature and load rate. It is highly important that strict procedural guidelines are followed and that consistent specimen preparation is maintained in order to obtain results that are both accurate and reliable. This method continues to be a reference point for adhesive performance testing in a variety of industries, clearly demonstrating the product’s reliability in real-world usage.

ASTM D5868 Test Method

Importance of ASTM D5868 Test Method:

The ASTM D5868 test method is indispensable for testing the strength of adhesive composites in a structural context. It measures the lap shear strength of adhesives in exacting conditions applied to rigid substrates. The intactness of bulk and reliability of the adhesive in the specified conditions is thus guaranteed. Moreover, the method by recreating actual application scenarios gives the user important information on how the adhesive will act in the practical use.

Applications and Benefits:

ASTM D5868 is extensively used in various sectors like aerospace, automotive and construction. The unchanging procedure of this method allows manufacturers to validate and compare adhesive products besides optimizing the formulations to obtain strong and durable. The method also enables the early detection of such failures or incompatibilities of certain materials thus extending its benefits to support product development and quality control processes. Its dependability has turned it into a standard test method across the adhesive industry.

Clear Results for Practical Applications:

This test method stands out mainly by the reproducibility of the results it produces which can easily be translated into practical applications. Controlled conditions simulating stress are applied, and products are tested accordingly to the critical performance standards of the ASTM D5868 test. This process gives the consumer more confidence, as well as it being an assurance that structural adhesives are compliant with tough safety and operational criteria, thus benefiting both manufacturers and end users.

Comparison of ASTM Standards

The ASTM standards are universally accepted methods in the different fields to get uniformity, dependability, and materials as well as testing procedures’ safety. When it comes to comparing the standards, the first thing to do is to recognize their specific purposes and testing methods. To illustrate, ASTM D5868 is all about testing lap shear strength of the adhesives to be used for rigid substrate joining, and this is very important because it gives out an evaluation of the adhesive performance under stress. At the same time, ASTM D1002 looks into the shear strength of adhesives in single-lap bond joints, specifically metals, thus presenting a similar but narrower field of application.

The main difference between these standards resides in the type of materials and the testing arrangements. ASTM D5868 can deal with a wider variety of the rigid substrates that eventually lead to its use in industries other than metal bonding, for instance, composites or plastics. Conversely, ASTM D1002 is for metal-to-metal bonding only, making it the standard of choice for those who deal in metallurgical and need quite accurate performance data under conditions that are stable.

The two standards agree on the point that reproducibility has to be guaranteed and that no adhesion breakage occurs as a result of the adhesives’ being on the stricter safety and operational standards, but the appropriate standard is selected on the basis of the materials that are involved and the corresponding industry requirements. By being aware of the range and the applicability of each standard, the manufacturers can be sure that their products not only meet the high-quality requirements but also the best practices of testing and evaluation.

Methodologies for Conducting Lap Shear Tests

Preparation of Specimens

The preparation of specimens for lap shear tests requires meticulous attention to detail to achieve precise and reproducible results. The first step in this process is to choose suitable materials that not only correspond to the application aimed but also comply with the test standards. The substrates have to be cleaned, cut to the standard dimensions laid out in the testing protocol, and finally, checked for purity concerning contaminants. Cleaning by means of suitable solvents or cleaning agents not just removes dirt, oils, or residues but also ensures the creation of a flawless surface for adhesion.

As per the next step, adhesive is applied in compliance with the manufacturer’s suggestions and the test standard regulations. The application has to be uniform since that will prevent the variations in measurements of strength of the bond. A controlled layer of adhesive is usually spread over the designated area, and the substrates are pushed together under a certain pressure to eliminate air bubbles and to keep the bonding even. The joint is then cured under specified conditions which might include time, temperature, or humidity controls, depending on the type of adhesive being tested.

When the specimens are completely cured they undergo inspection for uniformity as well as defects. Any misaligned or poorly bonded specimens must be discarded to maintain the validity of the test. The proper preparation of specimens not only paves the way for accurate lap shear test results but also assists in perceiving the adhesive’s performance in its actual applications. Thus, following standardized methodologies not only guarantees reliability but also offers compatibility in comparison of the data collected across applications and industries.

Testing Procedures for Adhesively Bonded Joints

The procedure for testing adhesively bonded joints is very important in the assessment of adhesive performance, durability, and their reliability under different conditions. The main aim is to simulate the real stresses and environmental factors that the bonded joints may be subjected to. Below, the most common methods together with their main points are listed:

Lap Shear Test:

The adhesive bond’s shear strength is evaluated by this test. A typical universal testing machine pulls the bonded specimen at a fixed rate until it breaks. The ASTM D1002 or ISO 4587 industry standards guarantee that testing is done consistently. The important data includes the maximum shear strength (expressed in megapascals, MPa), failure mode (either adhesive or cohesive failure), and strain at break. To illustrate, a very strong adhesive for structural applications could have shear strengths of more than/around 25 MPa.

Peel Test:

Peel tests like T-peel or climbing drum peel, are used to measure the ability of an adhesive to withstand peeling forces. The peel strength is usually reported as force per unit width, for example, in N/mm, and this figure highlights the peeling resistance of the adhesive. This is of great significance in the case of flexible laminates, where peeling stresses are common. Soft adhesives, such as pressure-sensitive, may have a data range of 2 N/mm to 10 N/mm depending on their formulation, with the lower end being for less peeling resistance and the higher end for more resistant ones.

Environmental Exposure Tests:

As part of their assessment of durability, adhesively bonded joints are often exposed to the worst-case scenarios, environmental-wise, such as thermal cycling (-40°C to 85°C or greater), UV exposure, and high humidity conditions. A structural adhesive might, for instance, still have more than 90% of its original lap shear strength after 1,000 hours of exposure if subjected to alternating humidity and temperature conditions.

Fatigue Testing:

Fatigue testing gauges the performance of an adhesive when it is subjected to repeated loads during its lifetime. This is done by applying cyclic stresses, and the test represents long-term stresses on a joint. Usually, failure data is given in S-N curves, where N is the number of cycles a joint can hold for a certain stress level S.

Impact Testing:

An adhesive’s impact resistance is usually referred to as its ability to endure sudden shocks. The strength of the adhesive between the parts that are bonded is tested by dropping a weight (drop-weight test) that gives a certain energy hit and observing whether the joint is still good in dynamic loading.

Fracture Toughness Testing:

This test rates the administration of the adhesive bond to crack propagation. The strain energy release rate (G) is one of the parameters that provides knowledge on the bond’s toughness. Typically, high-performance adhesives show G-values above 1 kJ/m² for very difficult applications.

Through the application of both standardized and advanced testing methods, manufacturers are able to validate their adhesives for the automotive, aerospace, construction and other industries confidently. Thereby, these results also render the product safe, reliable, and with a long lifespan even in critical applications.

Factors Influencing Test Results

The results of lap shear tests analyzing adhesive performance can be influenced by multiple factors. One of the foremost issues is the surface preparation for the bonding of the materials. If the surfaces are cleaned and treated properly, better adhesion will be guaranteed and contaminants like oil, dirt or moisture will be prevented from affecting the bond’s strength. Surface roughness can also have a effect, as slightly roughened surfaces sometimes lead to more mechanical interlocking between the adhesive and substrate.

Another crucial factor is the test environment. Temperature, humidity, and exposure to the elements can all affect the properties of the glue. The adhesive can be weakened at high temperatures and made brittle at low temperatures. In the same way, adhesives under long-time humidity exposure can get degrade through moisture uptake, thus losing part of their holding strength.

The design and material of the lap joint are also very important. The lengths of the overlaps and the thicknesses of the bond lines affect the stress distribution during the tests and, hence, the results directly. In addition, the substrate material’s choice can hugely influence the test results as different materials will have different interactions with adhesives. By controlling these factors with precision, manufacturers can produce lap shear test results that are more consistent and reliable, thus providing very useful data for product performance assessment.

Applications of Lap Shear Tests

Use in Fiber Reinforced Plastics (FRP)

Lap shear test results are of utmost importance in the determination of the performance of the adhesives that are used for the bonding of fiber-reinforced plastics (FRP). The reason for this is that these plastic composites are, in fact, the lightest and most durable materials and are, therefore, widely used in industries like aerospace, automotive, and construction just because of their unique high strength-to-weight ratio. The test verifies that the adhesive will be able to withstand shear forces and also that the bonded FRP components will not lose their structural integrity during the various operational conditions.

The lap shear test gives us the exact data we need on the adhesive’s capacity to cope with long-term mechanical loads by applying controlled shear stress to the bonded FRP samples. This is essential as the FRP components are usually exposed to harsh environments with high temperature variations, humidity, and vibrations that can deteriorate adhesive bonds over time. The requirement that adhesives be able to resist these conditions is a matter of safety and performance.

As a result, the lap shear test results help the manufacturers to either select or develop adhesives that are specially made for the particular FRP applications. This, in turn, not only increases the durability of the final product but also improves its reliability in critical applications. Even though adhesive technology has made great strides, the lap shear test still stands as an indispensable viability tool for the modern engineering world to optimize the usage of FRP.

Applications in Aerospace and Automotive Industries

The lap shear test is one of the most important methods for the evaluation and optimization of adhesives used in the aerospace and automotive industries. These sectors require materials capable of resisting every extreme condition, ranging from stess to temperature and even chemical and environmental interactions. The lap shear test measures the adhesion strength across various substrates and thus guarantees that the adhesive used complies with the very rigorous performance and safety standards defined by the industry.

Although in aerospace the structural integrity of the components is the priority, both it and the latter have to do so from the point of view of safety first and, consequently, of their efficiency. Adhesives have to offer strong but at the same time lightweight bonding solutions for such dissimilar materials as fiber-reinforced polymers (FRPs), aluminum, and plastics. Lap shear tests can show whether these adhesives can cope with the overwhelming forces of aerodynamics and with the extremes of heat and cold that flights experience. Testing the strength of these bonds increases safety by lowering the chance of accidental failure as well as by contributing to the operational safety of the plant.

The auto makers have the same dependency as the aviation industry in lap shear tests for proof of bonding in automobile assembly and designing. The gradual change to lighter, more efficient materials usage, like FRPs and composites, makes it necessary that the adhesives are able to form bonds between disparate assemblies which are strong and permanent. Over time, lap shear tests will still help manufacturers in their selection of the right adhesives that can resist wear, that will still perform well under mechanical stress and that are also able to withstand environmental conditions such as moisture, temperature variations and vibrations, thus making the periodical inspection and repair of road vehicles less and, consequently, their durability and safety higher.

Role in Construction and Civil Engineering

One of the most significant ways that lap shear tests have impacted construction and civil engineering is through the assessment of the performance of adhesives that are used in structural applications. The testing process measures the shear strength of the bond between the materials, thus indicating the level of mechanical stress that the adhesive joint can tolerate without causing safety or functionality issues. This is very important in the case of bonded components subjected to long-term loads, e.g., in beams, panels, or reinforcements, where the adhesive layer is permanently stressed.

Construction projects often include a wide variety of materials such as metals, glass, and composites. lap shear testing aids engineers in selecting the best adhesive for these materials, and thus, results in strong and trustworthy joints. By getting a grip on the adhesion strength under various conditions, e.g., different temperatures or moisture exposure, the experts can make wise decisions for the structure’s durability.

In addition, lap shear tests are the mainstay for compliance with the industry standards and regulations. They present a reliable way to evaluate the longevity and performance of adhesives, which is a prerequisite for public safety. Hence, lap shear testing has become an unavoidably important technique in the modern construction and civil engineering realms, one that helps in the development of structures that are , besides being safe, also long-lasting and reliable.

Challenges and Limitations of Lap Shear Testing

Common Issues in Testing Procedures

Testing procedures might involve some common issues; for example, lap shear testing performed on inconsistent specimen bases is one such problem. Adhesive application, surface treatment, or alignment variations could be reasons for non-uniform stress distribution, thus resulting in inaccuracies in the test outcomes. It is therefore advisable to apply stringent measures in each stage of preparation of the specimens for testing in order to minimize variability and increase reliability.

The other problem is the environmental conditions that testing might face. Temperature, humidity, or exposure to contaminants are some of the factors that can dramatically change not only the performance of the adhesive but also the outcome of the tests. Therefore, it is necessary to carry out lap shear tests in a controlled environment under the conditions that reflect the intended application to produce data that is of significance.

In addition, equipment calibration and maintenance present an issue regarding test accuracy. Machines that are not properly calibrated or worn-out fixtures can produce results that are false, thereby creating doubt in the evaluation process. It is then essential to carry out regular calibrations and adhere to proper testing protocols for precision and consistency to be achieved and maintained in lap shear testing procedures.

Limitations of Adhesive Properties Measurement

The adhesive properties measurement, particularly the lap shear test, contains limitations that could compromise the accuracy of the results as well as their applicability. One notable limitation is the effect of substrate material and surface treatment. Surface texture differences, contamination, or varied cleaning methods could result in incorrect bonding strength evaluation, thus questioning the test’s dependability. The adhesive’s real capabilities may be concealed when such variables are not standardized.

Another limitation is the environmental factors that affect lap shear test results. Condition changes like temperature, humidity, and chemical agents could enhance the adhesive’s performance or reduction depending on the comparison between real-world and laboratory situations. Controlled lab conditions might not be able to imitate real-world dynamics, thus creating a disparity between the findings of the tests and the actual use instances.

Lastly, the lap shear testing setup and its dimensions may not be able to consider the awkward loading situations that are commonly encountered in the field. The lap shear test is designed to measure shear forces only, while the majority of bonded joints in real-world applications are under mixes of stresses for instance, peel, tensile or fatigue loads, making the test more limited in predicting adhesive performance under multi-directional or prolonged stress conditions. Therefore, more than one method of evaluation will be needed to support results from the lap shear test.

Potential for Misinterpretation of Results

The lap shear test is an important method for evaluating adhesives, but it can lead to misinterpretation of results if its limitations are not taken into account. One of the significant drawbacks of the test is that it only measures shear forces, which may not represent the entire spectrum of stresses that are present in actual applications. The adhesive joints are subjected to a variety of stresses, such as peel or tensile forces, which the lap shear test fails to simulate adequately. This may lead to overestimation or underestimation of the adhesive performance in complex structural situations.

Aside from this, factors like specimen shape, material characteristics, and loading rate play a significant role in determining the test results. Altering any of these factors may result in inconsistent and difficult comparisons between different adhesive products. If this is the case, results will just be indicative of the adhesive’s performance and not limitations in different application environments.

Moreover, relying solely on the lap shear test as the primary evaluation method might resort to erroneous design decisions. It is important to carry out other tests along with the shear test, such as peel tests or fatigue tests, in order to gain a full understanding of the adhesive performance. Misinterpretation of results can thus be avoided, and the selection and application of adhesives can be done more efficiently by using a combination of testing methods and taking into account the actual stress conditions in the field.

Frequently Asked Questions (FAQ)

Q: What is a lap shear test?

A: A lap shear test is basically the same as two bonded materials adhesive bond quality evaluation by means of shearing off the joint of the materials which is done by applying force to it until it fails.

Q: What is the difference between a single lap shear test and a double lap shear test?

A: To define it simply, a single lap shear test is regarding one pair of bonded interfaces subjected to a shear loading test, while a double lap shear test has two pairs of identical interfaces, allowing for better assessment of the shear strength of the bond.

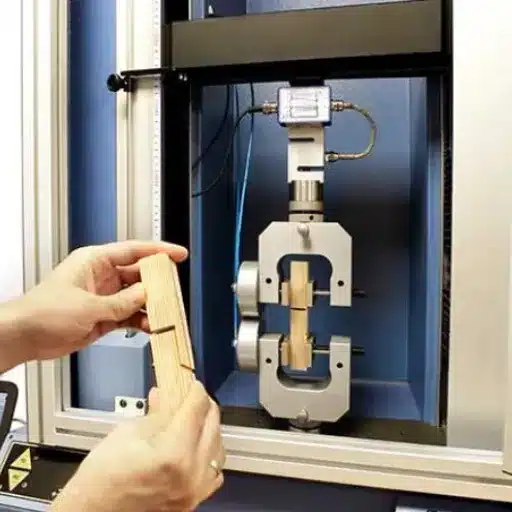

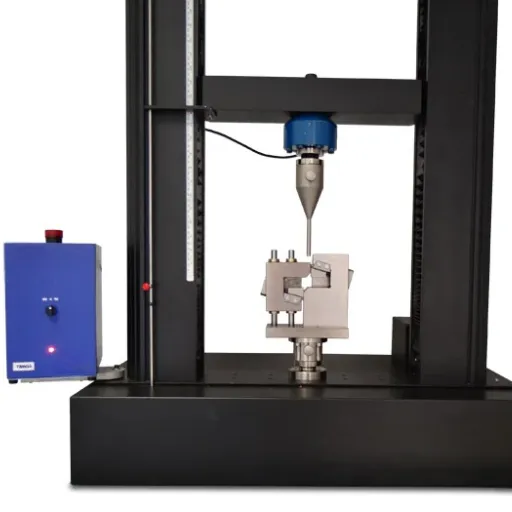

Q: What types of testing equipment are used for lap shear testing?

A: The lap shear testing equipment normally encompasses a universal tensile testing machine, which applies the force in a controlled manner to the specimen. The grips that will securely hold the specimen during the test, like wedge grips or self-aligning grips, are also a crucial part of the setup.

Q: What is the purpose of a lap shear strength test?

A: The purpose of a lap shear strength test is, first, to measure the ultimate shear load a bond can resist before it breaks and then, based on the measurement, to classify and assess adhesive performance.

Q: How is shear strength data obtained from a lap shear test?

A: Shear strength data is calculated by taking the maximum load applied in a lap shear test and dividing it by the bonded area of the adhesive layer. This is a direct quantitative measurement of the bond strength developed in the shear loading condition.

Q: What factors can affect the results of a lap shear test?

A: There is a list of factors that might affect the results of a lap shear test such as the thickness of the adherend, the thickness of the bondline, the geometry of the specimen, and the materials used for bonding. Additionally, the actual stress distribution in the shear test joint can be quite variable with respect to location and geometry, thus affecting the test results.

Q: Can the lap shear test be used on different substrates?

A: Absolutely, the lap shear test can be performed on various substrates which means the adhesive can be tested in conjunction with different materials. This is a very important test to evaluate adhesives, as it shows how they will perform when used to bond dissimilar materials.

Q: What is the role of compression in a lap shear test?

A: Compression plays a minor role in shear testing since the latter is the main focus of the testing process; however, in the case of multiaxial and non-uniform stress scenarios, compression becomes a factor that affects the overall loading conditions. In such cases, knowing the adhesive’s performance under both shear and compression will further describe the overall mechanical properties.

Q: What is the importance of the testing system in lap shear testing?

A: The testing system is a key player in lap shear testing because it guarantees the application of forces and conditions that are consistent with the standards throughout the test. The consistency is extremely important for producing reliable results which would further allow a precise evaluation of adhesive performance and bond quality across several tests.