Impact testing is one of the most crucial evaluations performed for confirming material durability and performance under extreme conditions, particularly in cold environments. Materials under stress must be thoroughly understood to ensure safety, performance, and compliance with engineering standards in aerospace, automotive, and construction industries.

This comprehensive guide explores the importance of low temperature impact testing machines in material assessments, highlighting methods and technologies that guarantee advanced accuracy and reliability in measuring results. Whether you’re an industry professional or researcher, this article provides essential knowledge about the testing process in material science to help you make informed choices for critical applications.

Introduction to Low Temperature Impact Testing

Low temperature impact testing evaluates the mechanical characteristics of materials under extreme cold conditions. It records and analyzes the impact of sudden forces on materials at low temperatures to simulate actual working conditions. By subjecting materials to controlled impact forces, engineers and scientists can:

- Assess material response to determine weak areas

- Certify performance against safety and quality standards

- Ensure reliability in harsh environments

- Prevent catastrophic failures in critical applications

This testing is particularly relevant for the aerospace, automotive, and energy industries, where materials must withstand harsh operating environments.

What is Low Temperature Impact Testing?

Low temperature impact testing is a specialized procedure for checking material toughness and resilient abilities at sub-ambient temperatures. This testing procedure is particularly relevant for materials destined for use in cold environments, where brittleness and loss of elasticity could hamper performance.

The test is typically conducted by striking a specimen with an impact force of a particular magnitude within a controlled environment that complies with standards such as:

- ASTM E23 – Standard Test Methods for Notched Bar Impact Testing

- ISO 148-1 – Metallic materials — Charpy pendulum impact test

Recent improvements in test equipment include digital monitoring and precision impact hammers, allowing researchers to focus more on studying fracture behavior. Industries related to cryogenic applications, energy transmission, and Arctic engineering increasingly depend on these tests to ensure material performance and prevent failures in critical applications.

Importance of Impact Testing in Various Industries

Impact testing serves as a key method for checking the competence and safety of materials used in critical applications across different industries:

Automotive Industry

These tests ensure that materials are crashworthy and can sustain high-energy impacts without catastrophic member failure. This is crucial for vehicle safety systems and structural components.

Construction Industry

Materials are impact tested to verify their ability to resist sudden shocks, such as those arising from earthquakes or extreme weather conditions.

Energy Sector

Testing minimizes the risk of leakages, fractures, or system malfunctions by ensuring materials used in pipelines and power plants can withstand varying temperatures and pressures.

With emerging technologies and evolving engineering requirements, industries are moving towards advanced impact testing techniques to strengthen material properties and comply with internationally recognized safety standards.

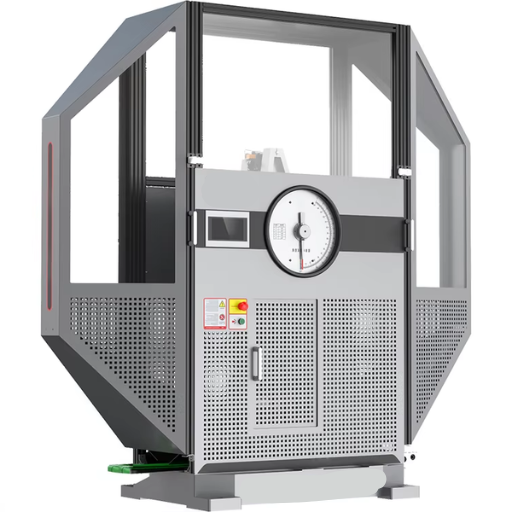

Overview of Testing Machines Used

Impact testing machines are specialized tools designed to test material behavior under impact force and specific environmental parameters. These instruments typically include:

- Pendulum impact testers – Used in Charpy and Izod methods

- Drop weight impact testers – Simulate high-energy impacts

- Universal testing machines – Versatile systems for multiple test types

Modern testing instruments incorporate advanced sensors for data collection linked to digital interfaces, ensuring higher precision, reliability, and strict adherence to international testing protocols.

Types of Impact Testing Machines

The following table outlines the primary types of impact testing machines and their characteristics:

| Type | Test Method | Material Focus | Strength Area | Energy Range |

|---|---|---|---|---|

| Charpy Tester | Pendulum | Metals, Plastics | Toughness | Low to High |

| Izod Tester | Pendulum | Plastics, Polymers | Brittleness | Low to Medium |

| Drop Weight | Drop Impact | Composites, Pipes | Resilience | High Energy |

| Universal | Multiple Tests | Diverse Materials | Versatility | Variable |

Charpy Impact Testing Machines

Charpy impact testing machines are specifically designed to test material toughness by subjecting them to sudden impact loading. The test involves a pendulum hammer striking a notched specimen, determining how much energy is absorbed during fracture.

Key benefits:

- Measures ductility and notch sensitivity of materials

- Especially effective for metals and plastics

- Vital for materials that must resist dynamic loads

- Complies with ASTM E23 and ISO 148 standards

Pendulum Impact Testers

Pendulum impact testers evaluate material toughness under dynamic loads, including notch sensitivity, ensuring compliance with ASTM E23 and ISO 148 standards. The machine operates by measuring energy absorption as a weighted pendulum strikes a notched specimen to cause fracture.

Modern systems feature high-precision sensors and digital interfaces, guaranteeing accuracy in data gathering for applications in aerospace, automotive, and construction industries.

Drop Weight Impact Testing Systems

Drop Weight Impact Testing Systems are designed to test material response under sudden, high-rate energy impacts. These systems operate by allowing a precisely weighted body to fall from a predetermined height onto the test sample.

Measured parameters include:

- Impact force

- Energy absorption

- Onset and propagation of fracture

Modern instruments incorporate state-of-the-art instrumentation with high-speed data acquisition units and sensors, providing maximum accuracy and reliability in result generation.

Applications of Low Temperature Impact Testing

Low temperature impact testing serves critical needs across industries exposed to hostile environments:

Key Applications

- Cryogenic systems – Material selection for ultra-low temperature applications

- Pipelines – Ensuring structural integrity in cold climates

- Offshore platforms – Materials for marine environments

- LNG storage and transport – Critical for energy sector safety

- Aerospace components – High-altitude and space applications

This testing helps identify materials capable of avoiding brittle fracture risk, which is paramount in aerospace, marine engineering, and energy sectors. It also supports the formulation of safety standards and ensures regulatory compliance for extreme applications.

Aerospace Industry Standards

The aerospace industry adheres to strict standards for materials regarding safety, reliability, and performance in extreme conditions:

- ASTM International – Including ASTM E1820 for fracture testing

- SAE International – AMS (Aerospace Material Specifications)

- ISO Standards – Such as ISO 2685 for fire resistance

Compliance ensures materials can withstand operational stresses including temperature variations, mechanical loads, and vibration while conforming to regulatory requirements.

Automotive Material Performance Analysis

Low-temperature impact testing ensures automotive materials can perform reliably in real-world applications. The testing measures material toughness and ductility under extremely cold conditions, simulating harsh automotive environments.

Critical components tested include:

- Structural frames

- Body panels

- Suspension systems

- Safety-critical components

Technical Aspects of Low Temperature Impact Testing Machines

Low temperature impact testing machines are equipped with specialized components to ensure precise and reliable operation under extreme conditions:

Key Components

- Cooling chamber – Maintains sub-zero temperatures using liquid nitrogen or refrigeration

- Pendulum assembly – Delivers controlled impact energy with high calibration standards

- Advanced sensors – Record force, displacement, and fracture behavior

- Digital data acquisition system – Real-time viewing and analysis of test results

All systems adhere to international standards like ASTM and ISO to ensure reliable and comparable results.

Design and Functionality of Impact Testers

Impact testers are designed to measure the energy required to break a material under high strain-rate conditions, providing crucial information about material ductility or brittleness.

Core components include:

- Pendulum or drop-weight assembly

- Precision specimen holders

- Sophisticated data acquisition system

Modern impact testers offer advanced features such as automatic specimen positioning, temperature-controlled measurements, and comprehensive software for graphing impact load versus time relationships.

Low Temperature Chambers and Control Systems

Low temperature chambers simulate sub-zero conditions required for testing material properties in extreme environments. They employ advanced temperature control techniques maintaining precise control typically in the range of -70°C to -196°C.

Advanced features include:

- Superior thermal insulation

- Programmable temperature cycles

- User-friendly interfaces

- Remote monitoring capabilities

- Compliance with ASTM and ISO standards

Refrigeration Technology in Testing Machines

Refrigeration technology enables precise environmental control for testing materials under extreme cold conditions:

- Cascade refrigeration – Achieves extreme temperatures efficiently

- Direct expansion systems – Widely adopted for moderate temperature cooling

- Integrated sensors and controls – Ensure accuracy in temperature regulation

This technology is vital in aerospace, electronics, and automotive sectors where materials undergo stringent qualification processes.

Choosing the Right Low Temperature Impact Testing Machine

Selecting the appropriate low temperature impact testing machine requires careful consideration of several factors to ensure optimal performance and compliance with testing standards.

Key Considerations for Selection

When evaluating testing equipment, consider these critical factors:

- Temperature Range

- Required minimum operating temperature

- Cooling efficiency and stability

- Temperature uniformity across the test chamber

- Standards Compliance

- ASTM E23 compliance for impact testing

- ISO 148 adherence for international compatibility

- Industry-specific standard requirements

- Automation Features

- Data acquisition systems

- Automated specimen handling

- Real-time monitoring capabilities

- Impact Energy Capacity

- Range suitable for your materials

- Precision and accuracy requirements

- Repeatability specifications

Evaluating Performance and Accuracy

Thorough evaluation of testing system performance requires analyzing key parameters:

- Precision in Measurement – Resolution and calibration accuracy verified against ASTM or ISO guidelines

- Repeatability – System’s ability to provide consistent results under identical conditions

- Reproducibility – Performance consistency across different operators and environmental conditions

- Response Time and Sensitivity – Equipment’s ability to react promptly to changes and provide accurate results

Durability and Reliability of Machines

Machine durability and reliability are crucial for sustained function and consistent performance:

- Durability – Ability to withstand wear, pressure, and damage over time

- Reliability – Probability of failure-free operation, measured by failure rate and MTBF (Mean Time Between Failures)

- Modern Engineering Features – Robust design, preventive maintenance plans, and quality components

Manufacturing Compliance and Safety

Low-temperature impact testing plays a critical role in ensuring manufacturing compliance and safety across various industries. By testing material behavior under impact at below-zero temperatures, manufacturers can ensure components meet requirements imposed by standards such as ASTM E23 and ISO 148.

Manufacturing Compliance Benefits

- Ensures materials retain structural integrity under temperature-induced stresses

- Helps manufacturers avoid regulatory fines and product recalls

- Prevents legal complications from material failures

- Supports quality assurance programs

Safety Considerations

- Prevents use of brittle materials in critical systems

- Reduces fracture risks that could expose systems to high-risk states

- Ensures durable, high-performing, and safe product development

- Protects human life and property in extreme conditions

Frequently Asked Questions (FAQ)

Q: What is the utility of an impact testing machine?

Q: How does low temperature testing differ from high temperature testing?

Q: What types of impact tests does the low temperature pendulum impact testing system perform?

Q: What instruments are used in low temperature impact testing?

Q: What is the function of a compressor in low temperature testing?

Q: Can impact testing machines be automated?

Q: What are the benefits of using a low temperature pendulum impact tester?

Q: How do drop weight impact tests compare to pendulum impact tests?

Conclusion

Low temperature impact testing machines are essential tools for ensuring material reliability and safety in extreme conditions. By understanding the various types of testing equipment, their applications, and selection criteria, industries can make informed decisions that protect both products and end users.

As technology continues to advance, these testing systems will play an increasingly important role in material science and engineering, ensuring that materials meet the demanding requirements of modern applications in aerospace, automotive, construction, and energy sectors.

Reference Sources

-

ZwickRoell – Impact Testers & Charpy Impact Testers: Provides details on pendulum impact testers for metals and plastics, as well as drop weight testers.

-

Instron – Pendulum Impact Testing Machine: Features the Instron CEAST 9050 impact pendulum for testing the resilience of plastics and composites.

-

JJ-Test – Hit-245x Low Temperature Pendulum Impact Testing Machine: Describes a low-temperature impact testing machine capable of testing as low as -50°C.

-

WMTR – Impact Testing: Discusses Charpy Impact Tests conducted on machines capable of measuring a wide range of impact energies at extremely low temperatures.