Instrument And Equipment Wholesale

Top Manhole Cover Testing Machine Manufacturer in China

As a premier manhole cover testing machine manufacturer in China, we delivers robust solutions for critical manhole cover load test and compression assessments. Our precise testing machines ensure your products meet stringent safety and quality standards. Trust our expertise for reliable material testing equipment designed to verify structural integrity and load-bearing capacity of various access covers.

What Is a Manhole Cover Testing Machine?

-

A specialized material testing equipment designed to determine the load-bearing capacity and structural integrity of manhole covers, gully tops, and gratings.

-

It primarily performs manhole cover load test and manhole cover compression testing machine operations to simulate real-world service conditions and stress.

-

Essential for manufacturers and civil engineers to ensure products meet safety standards (e.g., EN 124, BS 9124) and prevent premature failure in infrastructure.

-

The manhole testing machine typically utilizes hydraulic or electromechanical systems to apply controlled force, measuring deflection and ultimate strength.

-

Understanding the manhole cover testing machine working principle is key to verifying product quality and compliance before installation.

Essential Tests You Can Perform with a Manhole Cover Testing Machine

Elevate product quality with our versatile manhole cover testing machine. It performs crucial evaluations, ensuring your covers meet demanding specifications and deliver long-lasting performance. Essential for comprehensive manhole cover testing protocols and confident market placement.

Ultimate Load Capacity

Pinpoint the exact failure point or proof load. This vital manhole cover load test confirms structural strength, ensuring your products exceed safety margins for real-world use and build user confidence.

Permanent Set Evaluation

Verify long-term structural integrity. This test measures residual deformation after unloading, a critical indicator of resilience and the cover's ability to maintain its form and function effectively over time.

Deformation Analysis

Assess material response under pressure. Our advanced manhole cover compression testing machine precisely tracks deflection, providing key data for design optimization, material selection, and enhanced product durability.

Streamlined Test Procedures

Experience efficient quality control. Our machine design facilitates a clear manhole cover testing machine procedure, and for reinforced units, it complements checks like the cover meter test procedure for thorough assessment.

How to Choose the Right Manhole Cover Testing Machine?

- Assess the maximum load capacity required for your specific manhole cover designs and sizes.

- Verify the machine's capability to meet EN 124, AASHTO, or other relevant industry standards.

- Evaluate control precision, sensor accuracy, and the sophistication of its data acquisition system.

- Consider user-friendliness of the software, operational safety features, and overall machine ergonomics.

- Compare manhole cover compression testing machine price, after-sales support, and manufacturer reliability.

What are the uses of the Manhole Cover Testing Machine?

- To rigorously determine the ultimate load-bearing strength of various manhole cover types.

- Performing essential manhole cover load test procedures for quality assurance and safety compliance.

- Vital material testing equipment for R&D, helping optimize designs and material usage effectively.

- Used by manufacturers and labs to certify products against stringent international safety norms.

- Understanding the manhole cover testing machine working helps ensure consistent product quality.

Components of Manhole Cover Testing Machine

Discover the precision-engineered components that ensure reliable performance and accurate results from your manhole testing machine. Each part contributes to the robust manhole cover testing machine working principle.

View our Manhole Cover Testing Machine Price

Explore competitive manhole cover compression testing machine price options. Get top-value, high-performance testing machines inc solutions.

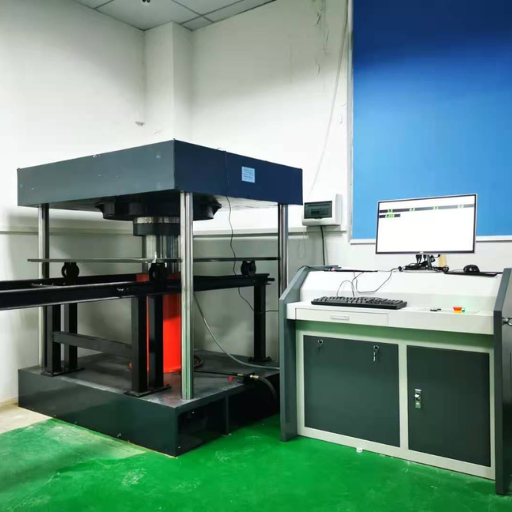

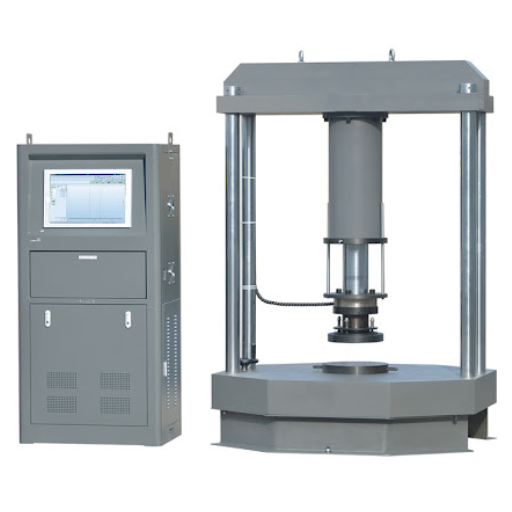

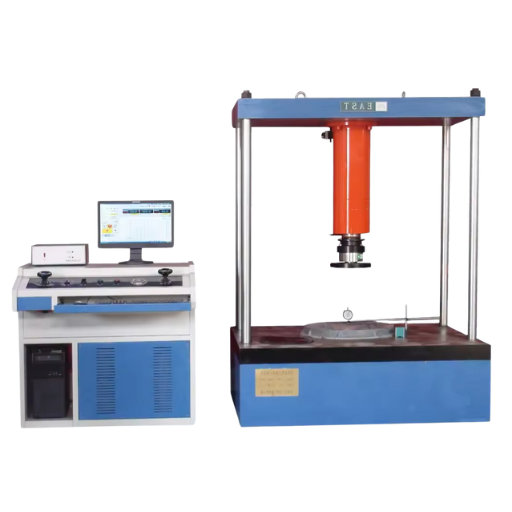

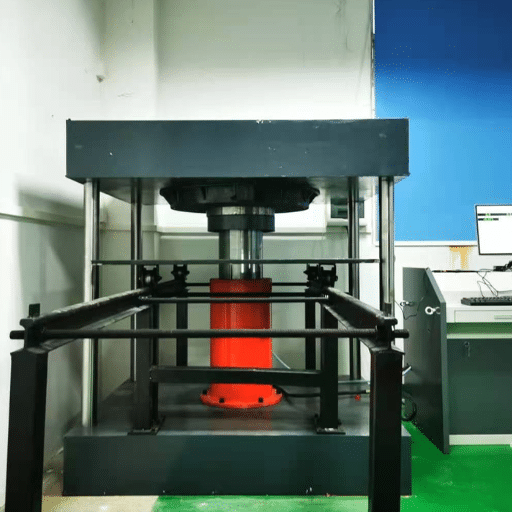

Hydrau-Cylinder Computerized Manhole Cover Compression Testing Machine

Discover our range of Hydrau-Cylinder Computerized Manhole Cover Compression Testing Machine. These systems offer powerful hydraulic force application combined with precise computer control, ideal for rigorous testing of manhole covers requiring high load capacities and detailed analysis.

Manhole Cover Testing Machine Data Overview

| Parameter | Details |

|---|---|

| Max. Load Capacity | 300kN to 2000kN typically; customizable options available. |

| Load Accuracy | Better than ±1% or ±0.5% of indicated value. |

| Control Mode | Computerized servo-hydraulic closed-loop; various control methods. |

| Effective Test Space | Accommodates various cover sizes; adjustable height. |

| Loading Speed Range | Adjustable, e.g., 0.5 - 75 mm/min, for diverse test needs. |

| Displacement Measurement | High-precision LVDT or encoder; typically ±0.5% FS accuracy. |

| Data Acquisition | Real-time curves, auto recording, analysis, and report generation. |

| Control System | PC-based software; intuitive interface for test setup and analysis. |

| Safety Features | Overload protection, emergency stop, safety guards, limit switches. |

| Frame Structure | High-stiffness 4-column or C-type frame for stability. |

| Power Supply | 380V, 50Hz, 3-phase or as per regional requirements. |

Why Choose Us as Your Manhole Cover Testing Machine Manufacturer?

With years of dedicated engineering and manufacturing expertise, we deliver testing solutions built for precision, durability, and consistent performance. Our equipment is crafted to empower your quality control processes, ensuring your products meet the most demanding industry standards and provide lasting safety. We are committed to innovation and reliability in every machine we build.

Our focus extends beyond the machinery itself; we aim to be your trusted partner. We offer comprehensive support, from initial consultation to after-sales service, ensuring you maximize the value and operational efficiency of your investment. Choose us for a partnership grounded in technical excellence and a shared commitment to achieving superior testing outcomes.

What Our Client Says

Understand from our clients what they say about doing business with us and the unique value addition we provide.

Expert Insights on Manhole Cover Testing Machine

Q: What is the manhole cover testing machine procedure?

A: The manhole cover testing machine procedure generally involves placing the cover on the test bed, setting test parameters (load, speed), applying a controlled force via the machine, and recording load versus deflection data until the specified load or failure point is reached, followed by result analysis.

Q: What is the purpose of manhole cover testing machine?

A: The primary purpose is to verify the load-bearing capacity and structural integrity of manhole covers, ensuring they meet safety standards (like EN 124), prevent failures in service, and assure product quality for infrastructure projects.

Q: How does a manhole cover testing machine work?

A: A manhole cover testing machine working principle involves a robust frame applying controlled compressive force, typically via a hydraulic or electromechanical actuator, onto the manhole cover. Sensors measure the applied load and the resulting deflection of the cover.

Q: What are the advantages of manhole cover testing machine?

A: Advantages include ensuring public safety, verifying compliance with international standards, improving product design and material efficiency, reducing liability from failures, and enhancing manufacturer reputation through consistent quality assurance.

Q: What is the standard for manhole cover testing machine?

A: Key standards include EN 124 (for gully tops and manhole tops for vehicular and pedestrian areas), AASHTO M306 (US standard), BS 9124, and various national standards like CJ/T (China). The machine itself must accurately perform tests according to these.

Q: What is the machine used for manhole cover testing machine?

A: The machine itself is a specialized type of material testing equipment, specifically a compression or universal testing machine configured with appropriate fixtures and load capacity for testing manhole covers, often referred to simply as a manhole testing machine.

Latest Blog Posts

Maintain Inventiveness by Following The Blog for the Latest Best Practices, Techniques, Innovations, and Insights in the Field.

The importance of manhole covers in the urbanization system is fundamental to safety management, accessibility, and protection inflicted on the […]

Manhole cover testing machines are essential in the modern era when technology has advanced all over the globe. Every day, […]

Manhole cover testing machines are critical tools designed to ensure the safety, durability, and compliance of manhole covers across various […]

Manhole covers are critical components of urban infrastructure, tasked with enduring immense loads and variable environmental conditions to maintain safety […]

Manhole cover testing machines and compressive testing machines serve critical yet distinct roles in material testing, often leaving professionals in […]

Manhole cover test machines play a pivotal role in ensuring the longevity, safety, and performance of infrastructure systems worldwide. These […]

Get a Quote for Manhole Cover Testing Machine Today

As a leading Manhole Cover Testing Machine Manufacturer in China, we ensure your product’s integrity. Our precision manhole testing machine guarantees compliance and safety. Boost your quality control with reliable, easy-to-use equipment. Contact us now for a personalized quote and expert advice. Elevate your standards with our trusted solutions!

Frequently Ask Questions

Q: What is the primary function of a manhole cover testing machine?

A: Its primary function is to determine the load-bearing capacity and structural integrity of manhole covers, gully tops, and similar access covers by applying controlled compressive forces.

Q: What international standards can these machines test to?

A: They are commonly designed to test according to standards like EN 124, AASHTO M306, BS 9124, and various national standards, ensuring global compliance for your products.

Q: What is the typical load capacity range for these testing machines?

A: Load capacities typically range from 300kN (approx. 30 tons) up to 2000kN (approx. 200 tons) or even higher, depending on the specific requirements and models.

Q: Can the manhole testing machine accommodate different sizes and shapes of covers?

A: Yes, most machines feature adjustable test beds or interchangeable fixtures to accommodate a wide variety of manhole cover sizes and shapes for versatile testing.

Q: How do I ensure I'm choosing the right machine for my needs?

A: Consider your maximum load requirements, the specific standards you need to meet, the sizes of covers you test, and the level of automation or data analysis features you require.

Q: What kind of after-sales support do reputable manhole cover testing machine manufacturers typically offer?

A: Reputable manufacturers usually offer installation support, operator training, calibration services, readily available spare parts, and ongoing technical assistance to ensure optimal machine performance.

Q: How often does a manhole cover testing machine require calibration?

A: Calibration frequency typically depends on usage and regulatory requirements, but an annual calibration by a certified technician is generally recommended to maintain accuracy.

Q: Are safety features integrated into the design of these machines?

A: Yes, standard safety features often include overload protection, emergency stop buttons, physical safety guards or enclosures, and limit switches to protect operators and the machine.