Instrument And Equipment Wholesale

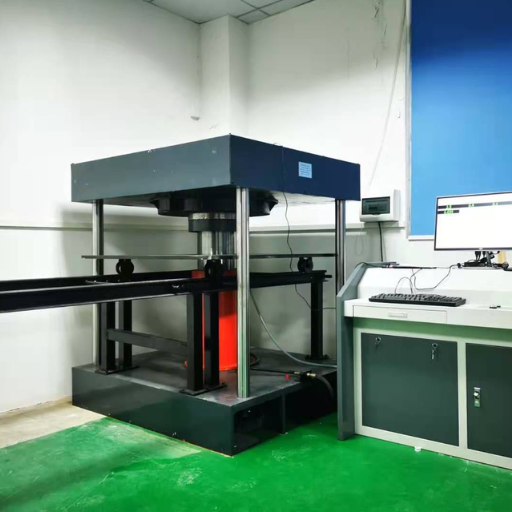

Advanced Hydrau-Cylinder Computerized Manhole Cover Compression Testing Machine Manufacturer in China

Experience ultimate precision with our Hydrau-Cylinder Computerized Manhole Cover Testing Machine. This advanced system from a leading China Manufacturer excels in demanding manhole cover compression testing, guaranteeing accurate manhole testing results every time for superior product validation.

What Is a Hydrau-Cylinder Computerized Manhole Cover Compression Testing Machine

-

A specialized testing machine utilizing a robust hydraulic cylinder for high-force application, precisely controlled by an advanced computer system.

-

Specifically designed for rigorous manhole cover compression testing, ensuring products like manhole covers and gully grates meet strength standards.

-

The computerized system enables automated test execution, real-time data acquisition, and detailed analysis of load-deflection characteristics.

-

Essential for manufacturers needing to verify product integrity and for accurate measure for a drain cover strength assessments.

-

This material testing equipment provides reliable data for quality control, R&D, and compliance with international safety regulations.

Hydrau-Cylinder Computerized Manhole Cover Compression Testing Machine Features

Unlock superior testing capabilities with our Hydrau-Cylinder system. This manhole cover testing machine combines immense power with intelligent control, offering unmatched accuracy and efficiency for all your manhole cover compression testing requirements.

High-Force Hydraulic Power

Experience exceptional force application with our robust hydraulic cylinder. It delivers consistent, high-capacity loading, perfect for testing the most demanding manhole covers and ensuring their ultimate strength.

Precision Computer Control

Achieve flawless test execution. The advanced computerized system provides precise control over loading rates and test parameters, capturing accurate data for reliable manhole testing and analysis.

Automated Test Cycles

Boost your lab's efficiency. Pre-programmable test cycles automate the entire testing process from start to finish, minimizing operator input and maximizing throughput for faster product validation.

Comprehensive Data Insights

Gain valuable insights with sophisticated software. It offers real-time graphing, detailed result analysis, and customizable reporting, making it an indispensable material tester for informed decisions.

Hydrau-Cylinder Computerized Manhole Cover Compression Testing Machine For Sale

JAW-1500KN Lower Hydrau-Cylinder Computerized Manhole Cover Compression Testing Machine

Our JAW-1500KN, with its lower hydraulic cylinder, delivers 1500kN for heavy-duty manhole cover compression testing. Computerized control ensures precise results for demanding applications and accurate measure for a drain cover strength validation.

JAW-1000KN Lower Hydrau-Cylinder Computerized Manhole Cover Compression Testing Machine

The JAW-1000KN provides 1000kN capacity via its robust lower hydraulic cylinder. Ideal for comprehensive manhole testing, it combines computerized precision with durable construction for consistent performance across various testing material types.

JAW-600KN Lower Hydrau-Cylinder Computerized Manhole Cover Compression Testing Machine

This JAW-600KN system offers 600kN force through an efficient lower hydraulic cylinder setup. A versatile manhole cover testing machine for standard needs, delivering computerized accuracy and ease of use for reliable quality control.

WTJ-600KN Computerized Manhole Cover Compression Testing Machine (Upper Hydrau-Cylinder)

Our WTJ-600KN utilizes an upper hydraulic cylinder design for a solid 600kN capacity. This computerized manhole testing solution provides accurate results and user-friendly operation, suitable for a wide range of common cover types.

WTJ-1000KN Computerized Manhole Cover Compression Testing Machine (Upper Hydrau-Cylinder)

The WTJ-1000KN model, featuring an upper hydraulic cylinder, provides 1000kN for precise manhole cover compression testing. Its computerized system offers advanced control and detailed data analysis, a powerful tool among modern testing machines.

WTJ-1500KN Computerized Manhole Cover Compression Testing Machine (Upper Hydrau-Cylinder)

Experience maximum testing force with the WTJ-1500KN upper cylinder model. Delivering 1500kN, this computerized manhole cover testing machine is built for the most rigorous strength and durability assessments of heavy-duty covers.

Hydrau-Cylinder Computerized Manhole Cover Compression Testing Machine Technical Specifications

| Parameter | Details |

|---|---|

| Model Series | JAW (Lower Cylinder), WTJ (Upper Cylinder) configurations available. |

| Max. Load Capacity | 600kN, 1000kN, 1500kN models |

| Load Frame Structure | High-stiffness 4-column or robust portal frame design. |

| Hydraulic System | Servo-controlled hydraulic power unit for precise force application. |

| Control System | Advanced computerized closed-loop control; PC & dedicated software. |

| Load Accuracy | Meets or exceeds ±1% (or ±0.5%) of indicated value. |

| Displacement Resolution | High-precision sensor, e.g., 0.001mm or better. |

| Test Speed Range | Adjustable, e.g., 0.5 - 75 mm/min (or as specified). |

| Effective Test Space | Accommodates various cover sizes; specific dimensions per model. |

| Data Output | Load-deflection curves, test reports, data export options. |

| Safety Features | Overload protection, limit switches, emergency stop, optional guards. |

| Power Requirements | Typically 380V, 50Hz, 3-Phase; customizable to local needs. |

Application Industries of Hydrau-Cylinder Computerized Manhole Cover Compression Testing Machine

- Municipal Engineering: Verifying manhole cover strength for urban infrastructure safety.

- Foundries & Manufacturing: Quality control for cast iron, ductile iron covers.

- Composite Material Production: Testing strength of polymer or composite manhole covers.

- Civil Construction: Ensuring road and pavement components meet load standards.

- Telecommunications: Validating access covers for underground utility vaults.

- Airport & Port Authorities: Testing heavy-duty covers for high-traffic areas.

- Testing Laboratories: Providing third-party certification and material research services.

- Quality Inspection Departments: Ensuring compliance with national and international standards.

Request Information on Your Manhole Testing Solution!

Ready to guarantee the strength and safety of your manhole covers? Our Hydrau-Cylinder Computerized Manhole Cover Compression Testing Machine offers unmatched hydraulic power and pinpoint digital accuracy. Elevate your quality control, ensure compliance, and gain complete confidence in your products. Contact our experts now for a personalized quote and discover the difference precision engineering makes!

Frequently Ask Questions

Q: What makes a hydrau-cylinder system ideal for manhole cover compression testing?

A: Hydraulic cylinders provide high, consistent force essential for testing the robust nature of manhole covers and accurately simulating real-world load conditions.

Q: How does the computerized control enhance the manhole testing process?

A: Computerized control allows for precise test parameter settings, automated execution of test cycles, real-time data logging, and sophisticated analysis of results.

Q: Can these machines test different classes of manhole covers?

A: Yes, by selecting a model with appropriate load capacity (e.g., 600kN, 1000kN, 1500kN), these machines can test the full range of manhole cover classes.

Q: What data is typically generated by this manhole cover testing machine?

A: It generates load vs. deflection curves, maximum load sustained, deformation values, and comprehensive test reports for quality assurance and certification.

Q: Is special training required to operate these machines?

A: While user-friendly, initial training is recommended and often provided by the manufacturer to ensure proper operation, safety, and understanding of the software.

Q: How does the "lower" vs "upper" hydrau-cylinder configuration affect testing?

A: The configuration mainly affects machine design, ergonomics, and sometimes the ease of sample loading, but both can achieve accurate testing if properly engineered.

Q: What maintenance is typically required for these testing machines?

A: Regular maintenance includes checking hydraulic fluid levels, ensuring sensor calibration, inspecting structural components, and keeping the software updated.

Q: Can this machine be used to measure for a drain cover's compliance with specific standards?

A: Absolutely, it’s designed to perform tests according to standards like EN 124, ensuring drain covers meet required load-bearing and deflection criteria.