Materials characteristics that describe a material’s properties include strength, durability, and performance under varied conditions. These are important for industries, be it manufacturing or construction, among others. Force testing comes into the picture during these evaluations to give the exact insight into the material’s behavior when placed under tension, compression, or in the presence of other mechanical forces. Equipped with state-of-the-art force testers to assess materials, major players finally certify the materials for quality and safety before the customers accept them. This article takes you through the basics of force and material testing, the functionality of a force tester, and how reliable measuring instruments, key in ushering innovation, maintain standards of excellence in the industry. Force testing is an arena that truly binds the possibilities of the present with the innovations of the future. So, for all engineers or curious individuals, this article will serve as a comprehensive guide to why force testing matters and shapes the modern world.

Understanding Force Tests

Definition of Force Testing

Force testing involves establishing forces acting on materials and components or upon a structure to impart strength, resistance, or durability. These forces can consist of tension, compression, shear, or torque, all acting as real stress that an object experiences in use. By quantifying these responses, the engineer or researcher can verify that the material or product satisfies the requirements for performance, safety, and reliability.

Force testing is significant in that it offers insight into critical material or product integrity. For instance, it may be used to determine breaking points, elasticity, and deformation as a result of the over-application of stress. Such tests are carried out in a variety of industries, including construction, automotive, aerospace, and medical device manufacturing, in which safety and performance are number one. Force testing ensures that the products can bear the stresses and strains of the proposed course of action without failure.

By understanding force test results, one will create innovation, control risks, and meet regulations. Force testing thus makes it possible to optimize design for durability, enhance longevity of materials, and instill confidence in consumers and manufacturers. It is an essential and inevitable process, as it is the critical step where theory meets practice, both in engineering and manufacturing.

Types of Force Tests

Force testing verifies the strength, durability, performance, etc., of materials or components under various conditions. A few major types of force tests include:

- Tensile Testing: Tensile testing measures the material’s response when it is stretched or pulled. This test identifies its tensile strength, elongation, and modulus of elasticity. Such a test determines the force that a particular material can resist before it either deforms or fractures.

- Compression Testing: analyzes the compression force is applied to a piece of material until it fails, testing for the ability of the material to resist crushing forces. It is important in testing columns, beams, or supports.

- Shear Testing: Shear Testing measures and analyzes the effect of forces on materials that tend to cause layers to slide against one another. Materials or joints susceptible to shear stresses, such as glues or fasteners, must be tested using this method.

- Flexural Testing: Also referred to as bending tests, the flexural test determines the strength and deformation of a material subjected to forces in bending. This is usually accepted for beams, slabs, and other structural elements.

Each one of these tests is critical to the choice of materials, product design, and quality testing. Selecting the proper force test will enable engineers and manufacturers to make sure that their materials and products meet the necessary safety requirements, perform accordingly, and withstand the stresses expected in actual applications.

Applications of Force Testing

Forces have remained at the heart of every testing procedure in different industries, assuring the reliability, safety, and longevity of materials, parts, and finished products: construction, automotive, aerospace, and manufacturing are some major sectors, with others also in line, like that of consumer goods. The passage of the tests, as in meeting standards, guarantees that a material or product can operate safely under the expected conditions.

A major application of force testing is product development. In this case, engineers test materials and prototypes for their structure and behavior under predicted working conditions purely as an exercise done before large-scale production. Tensile testing might be considered one such test, as it can indicate whether a material is capable of resisting tensile forces, whereas compression testing may be conducted to check its reaction to compressive loads. Thus, the selected materials are positively going to perform in actual use, whereas, with poor performance levels, the risk to human life is surely going to be high.

Another major application is in quality control and conformity. Manufacturers conduct force tests on finished products to ascertain that the products comply with regulatory requirements and customer specifications. This may entail either testing highly crucial components, such as airplane parts, to ascertain that they will resist anticipated stress or testing rather mundane items, such as household appliances, to ascertain if they are considered durable and reliable. The force testing gives conclusive results to establish whether or not the product meets certain standards, safeguards the interests of the end-user, and minimizes liability exposure.

Material Tests Overview

What is Material Testing?

Material testing is the examination of materials to determine their properties, performance, and suitability for their intended use. It subjects materials to different conditions so that some properties like tensile strength, durability, hardness, elasticity, and so on can be gauged. Material testing guarantees that materials have met certain safety and quality standards.

Testing of materials is done to ensure that they meet the design requirements and assure safety and quality. Test procedures vary depending on the type of materials to be tested as well as the properties of the materials. Such testing is carried out on metals and alloys, ceramics, composites, plastics, powders, and coatings. In some applications, materials are subjected to performance testing, i.e., under load and temperature or wear. Often materials have to be tested independently for certain properties, such as strength, hardness, or wear resistance. These testing laboratories are widely spread across many commercial and industrial sectors.

For any product, material testing means ultimate quality assurance and assurance of durability with very little risk associated with it. It ensures compliance with regulatory standards and reduces the likelihood of material failure, which could lead to safety hazards, costly repairs, or product recalls. With thorough testing at every stage, industries can remain very sure of high-quality production that leads to consumer confidence.

Different Types of Material Tests

Material testing means any technique for ascertaining sets of properties, performance, and operations of materials used in industries. Materials, by testing, should be ensured and should satisfy certain minimum criteria and should perform according to their intended use. Some commonly performed material tests may include:

- Mechanical Testing: Mechanical tests assess the strength, elasticity, and toughness of a material. These tests include tensile testing to establish a material’s strength against pulling forces, while compression testing studies its reaction to squeezing forces. Other mechanical tests, such as fatigue and impact testing, contribute towards gauging how a material will hold up against long-term endurance and resistance to prompt treatments.

- Chemical Testing: The chemical testing is crucial in determining the composition or activity of any matter. These tests include traces of contaminants or major compounds in the chemical constitution of the material and their degradation by particular impurities or chemicals. Commonly used techniques include spectroscopy or chromatography.

- Thermal Testing: Thermal testing evaluates the behavior of samples subjected to temperature changes. This would include, for instance, the testing of heat resistance, thermal conductivity, and rates of expansion. These tests are very important for materials that are used in any high-temperature environment, testing for their stability and performance so that they do not fail.

With these tests in place, industries establish faith in the materials used for manufacturing so that the end products will be safe, quality-oriented, and of design standards. Testing at regular intervals forms an essential part of ensuring reliable and productive manufacturing outcomes.

Importance of Material Tests in Various Industries

Material testing being essential in various industries ensures the safety and reliability with efficiency of the end products. By subjecting materials to processes under varied conditions to test their properties, the companies can detect the shortcomings and improve the quality of the final products. The absence of testing would expose industries to risks such as product failures, injury hazards, and non-conformity to prescribed regulations.

In construction, material testing is of utmost importance, as it certifies the strength and durability of fairly important constituents such as concrete, steel, and composites, in order that buildings, bridges, and other structures are able to resist environmental loading with the passage of time. Aerospace materials undergo the ultimate test so that they can be sure to withstand extreme weather, high temperatures, pressure, and mechanical stresses, all of which ensure passenger safety and operational integrity.

Meanwhile, material testing in the automobile and healthcare industries works toward ensuring that the products conform to high standards of performance and safety. In automotive testing, components such as tires or chassis materials are tested for their strength and resistance to wear and tear to prevent accident occurrences. In healthcare, materials used in medical devices or implants are tested and vetted so that there can be no possible failures that could endanger a life. Generally, the process of material testing is a must to ensure safety, quality, and reliability irrespective of industries.

Key Techniques in Force Measurement

Tensile Testing Methods

Understanding the mechanical properties is an array of tensile testing methods. This test provides for determining a material’s response to a force that tends to stretch the material; tensile strength, modulus of elasticity, elongation, and ultimate breaking point being considered. The results thus obtained are useful in determining whether the material will sustain the applied loads in the practical application.

The specimen has to be gripped between the jaws of a tensile testing machine. The tensile testing machine slowly applies a uniaxial tensile force while simultaneously recording parameters such as stress (force per unit area) and strain (deformation relative to original length). These factors are then used to plot a stress-strain curve, giving useful information on the behavior of the material under stress, such as yield strength, and the point at which it finally fails.

Each component of this unit is tested for tensile strength in different industries, such as construction, aerospace, or manufacturing, to ensure materials conform with safety and quality standards. By knowing the limits of a material in strength and bending capability, the engineer/designer is able to choose the best fit. This, in turn, enhances the reliability and safety of the end product.

Compression Testing Techniques

Compression testing determines how materials respond to compressive loads. The forces induced on the material exert crush and condensation; therefore, the agents offer the parameters of compressive strength, deformation, and elasticity. These tests are essential when the construction or manufacturing processes require materials to undergo compression forces without failing.

The sample material is placed between two compression plates, and the load is gradually increased. The results are documented and evaluated to define the maximum load capacity of the sample that the material can endure and the load at which it begins to deform or fails altogether. Usually, the experiments are carried out according to common test standards such as ASTM and ISO, which apply to parameters for results to be accurate and reliable.

With compression testing, one can determine the limits of materials in terms of strength and deformation among others and conscientiously design materials for different applications. This guarantees the structural integrity of the product while at the same time making it safe and efficient. Compression testing ensures the minimization of risks and promotes the use of sustainable designs in various industries.

Creep Testing: A Thorough Examination

Creep testing is a method of determining a material’s thermomechanical behavior over time under constant loads and constant temperature. Hence, it gives insights into the behavior of a material with respect to shape changes as that material sits under load and temperature over time. Creep-testing is very important when you want to utilize the materials in high-temperature work areas such as for aerospace, power-generating stations, and various types of industrial plants, wherein prolonged exposure to load causes the material to fail by other forms of deformation.

The test involves applying a given load to a specimen, maintaining it at a steady temperature. Once these conditions are established, the material sample is strained slowly, and measurements are taken, used to or against time. Creep test outputs are generally presented in the form of graphs where graphs depict the mechanical behavior of strain against time; from these, an engineer can single-check the big creep properties pertinent to primary, secondary, and tertiary strain. This offers a prediction that can be correlated with the service life and performance of the material.

Understanding the creep behavior of materials allows an engineer to make informed decisions with various aspects for material selection, design modifications, and safety checks. This ensures that a structure or component shall survive through operational demands without surprise failure, making the application reliable and efficient. Creep testing is one of the most important tools involved in the design of durable and safe systems for industries requiring high-performance materials.

Testing Equipment and Systems

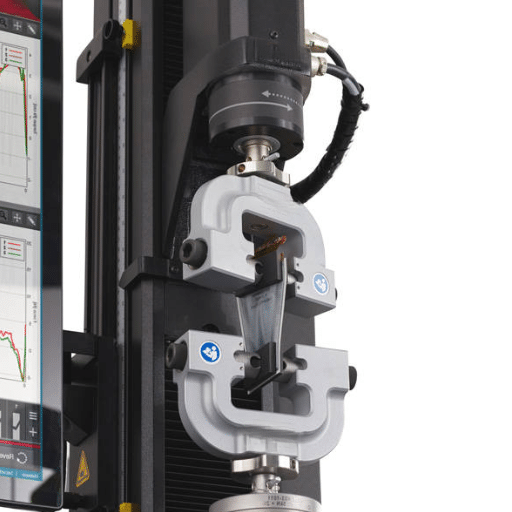

Overview of Testing Machines

Testing machines are instrumental to the evaluation of the mechanical properties that a material should possess for industrial application and testing. These machines are designed to carry out tests of applications tensile, compression, creep, fatigue, etc., in any chosen environmental conditions. That, and with good equipment and advances of sensors and software, modern machines can provide measures of accuracy and data analysis.

Types of Testing Machines:

Universal Testing Machines (UTM):

General-purpose machines are used for strength testing: tensile, compression, and bending tests. The measures for yield strength, ultimate tensile strength, elongation at break, etc. UTMs are usually rated from around 5 kN up to more than 2,000 kN, thereby testing a wide range of sample sizes and materials.

Creep Testing Machines:

Creep machines for testing: the machines are specifically designed to measure the deformation of materials under constant load and at a constant temperature over very long periods. The applications are widespread in the aerospace and power generation industries, where materials must withstand extreme conditions of stress and temperature.

Fatigue testing machines:

These machines serve to evaluate material durability by subjecting the material to cyclic loads over thousands of cycles. Reports on fatigue life serve an engineering purpose to predict the failure of components operating under repeated stress. These advanced fatigue-testing machines are capable of cycling loads from the thousands to millions, depending on the application.

Impact testing machines:

These impact testers test the toughness of a material when subjected to sudden force. Charpy and Izod impact tests are commonly conducted on these machines to measure the brittleness of the material.

By leveraging the capabilities of modern testing machines, industries can push the boundaries of material performance, design safer products, and ensure compliance with international quality standards.

Force Testing Systems: Types and Functions

Force-testing systems are vital determining tools for the mechanical properties of materials, components, and systems. These systems ascertain how a material reacts under various forces such as tension, compression, shear, and bending. The information thus gathered concerning performance, safety, and reliability is applied to materials in their various applications.

Tensile testing machines are one of the principal types of force-testing systems: As it names suggests, the machine tests the stretching of materials under tensile forces until they break. It is largely informative with respect to tensile strength, ductility, and elasticity. Another compressor or compressive force testing machine is applied by imposing the force which produces compression on the test material, and in such manner, one could measure parameters like compressive strength and rigidity. Universal testing machines can perform tensile, compression, and bending tests.

In this way, force testing systems apply controlled mechanical forces to the test specimen, noting its specific response under that force. These systems may rely on extremely sensitive measuring instruments to determine the precise readings needed, with software that watches for and analyzes the results. Understanding how materials behave enables force testing systems to help manufacturers in tuning designs, ensuring that the safety-related laws are met, and upholding the quality of the product.

Innovations in Testing Equipment

Recent innovations in testing equipment have revolutionized the way we understand material properties and performance. I’ve observed advancements such as automated systems with higher precision, integration of AI for predictive analysis, and the use of non-destructive testing techniques that preserve the integrity of materials. These innovations enhance efficiency, accuracy, and reliability in various industries.

Benefits of Accurate Force and Material Testing

Enhancing Product Quality

Precise force and material testing play a crucial role in improving product quality by ensuring that the materials meet specific performance parameters. Materials-testing procedures enable manufacturers to study inherent weaknesses or defects in materials, allowing production processes to be modified to produce better-quality products; thus, the end user enjoys durability, superior functioning, and safety.

The other key feature of accurate testing is being able to confidently innovate and develop new products. Designers and engineers use design insights to push the limits of materials by really knowing their properties and boundaries, thus enabling them to create better solutions or new ones altogether. Likewise, reliable test data enables teams to fast-track design verification and to minimize costly design errors.

Furthermore, accurate testing fosters trust between manufacturers and consumers. When products consistently meet the allotted standards of quality and safety, consumers will rely upon and remain loyal to the brand. This reputation for reliability strengthens relations with its customers and becomes a competitive edge where quality stands out as a major differentiator.

Improving Safety Standards

Force testing on materials is important in enhancing the safety standards across industries. By accurately measuring the force, durability, and performance of materials under all sorts of pressure conditions, materials are given safety requirements before incorporation into the final products. Testing will expose weak points or design flaws early enough during the course of the development to obviate failures that can result in accidents or hazards.

Reliability in material testing hence, ensures safer products for consumers and end-users. In construction, for instance, testing guarantees that materials such as steel or concrete or composites can, under environmental pressure and loads, give a state of safety. In the automotive and aerospace industries, the force testing ensures the structural integrity and provides delivery in case of mechanical failure.

Moreover, the implementation of testing methods under strict protocols warrants chief importance, as it provides for regulatory compliance and public confidence in product safety. Manufacturers that practice serious testing of materials contribute toward the creation of safety and responsibility within their industries, thereby decreasing risk and building the trust of consumers, professionals, and regulators.

Cost Efficiency through Testing

Material force testing is fundamental in improving cost efficiency for manufacturers by defining the performance limits of materials used during production. In this way, ensuring materials of high quality are used will reduce possible defects and cost liabilities allied with a recall of products or a failure. Once these limits are understood, companies can then optimize environmental usage and production processes, thus saving on waste and unnecessary expenses.

Material force testing can help avoid over-engineering, a problematic practice where companies overuse resources or produce unnecessarily strong designs. Knowing exactly how to balance performance against costs through material strength and durability data is something companies can apply in creating economically viable products. This, again, leads toward sustainability through efficient material usage and minimizing industrial waste.

Finally, through investing in elaborate, thorough material force testing, the basis for long-term savings is placed by extending product lifespan while adequately maintaining. Testing through the best-reliable methods, material testing companies should know how their materials will hold under real-life conditions, thus decreasing risks and costs for repair or replacement. This approach builds company assets while pleasing and rewarding customers with strong products that perform well.

Frequently Asked Questions (FAQ)

Q: What is material force testing?

A: Material force testing involves checks that are executed to find the strength and behavior of materials under exerted forces. This testing involves the following: tensile and compression testing, shear testing, and torque testing, which merely provide insight into the behavior of the material as it reacts to the time-honored methods of force measurement.

Q: Why does force capacity matter for material force testing?

A: Force capacity dictates the limit of force a material can endure before breaking. By knowing the force capacity, an engineer or designer can determine what material would be appropriate for an application wherein strength and durability are of importance, so that the material will hold under loads as expected.

Q: Testing for toughness: How is it done?

A: Toughness testing is performed to assess the capacity of a specific material to absorb energy and deform plastically before fracturing. Thus, before using a material in construction where impact resistance may be required, a complete insight must be gained into the attributes of the material.

Q: What materials do one use for force testing?

A: Most of the materials include metals, polymers, ceramics, and composites for force testing. Every type of material exhibits certain qualities and behaviors under force, so material testing analyses must be carried out specifically to the particular type of material toxic one wishes to test.

Q: What instruments does one use in material force testing?

A: Material force testing employs several instruments that include material testing machines, mechanical test stands, and motorized force-measuring devices. These instruments ensure an accurate measurement is all about the force in assessing the strength and durability of specimens of materials tested.

Q: Can you explain shear testing and applications?

A: Shear testing is about determining the resistance of a material against shear forces. These forces are applied when two opposing forces are applied parallel to the surface of the material. This testing is important in applications where materials are subjected to forces that can slide or shear off one another. For example, structural components or fasteners might experience shear forces during certain types of loading.

Q: How are material characterization and force testing related?

A: Material characterization consists of studying the properties of the material, such as modulus, tensile strength, and toughness, in an attempt to predict the material’s behavior under different environments. Force testing is a part of material characterization because it is used to impart loading upon a material and provide data for forcing predictions upon a material.

Q: Why is it important to measure the elongation of a material during force tests?

A: Material elongation during force tests provides a measure of the ductility of the material. This means how much a material can stretch before it ultimately breaks, and this is very important in applications where flexibility and resilience are requisite.

Q: And how do test applications vary from material to material?

A: Test applications vary greatly depending upon the material under evaluation as different materials have different properties and behave differently under force. Metals, for example, could be required to undergo tensile and compression testing, whereas polymers could undergo peel testing to measure the adhesion strength. Each method of testing is meant to provide insights relevant to the material under concern.

References

- Force Testing: Purpose, Importance, Types of Testing, and More – A comprehensive guide on the basics of force testing, its applications, and importance.

- Materials Testing by ZwickRoell – Information from a leading manufacturer of testing machines, covering various types of material testing.

- Materials Testers by Mark-10 – Details on force and compression measurement test stands for material strength testing.

- Top 10 Most Common ASTM Standards for Metal Testing – A resource on ASTM standards for tension and other material tests.

- Force Measurement is Fundamental in Material Testing – Insights into the role of force measurement in material testing, including applications like hardness and compression tests.