Instrument And Equipment Wholesale

Premium Material Testing Machine Manufacturer in China

China's best supplier of material testing machines provides businesses in construction, automotive, and aerospace with cutting-edge solutions for assessing material strength and quality with advanced technology. China’s best suppliers of Material testing machines guarantee extreme precision in every application. They deliver reliable machines tailored to diverse test requirements and are credited for exceptional product quality and expertise. Machine Materials Testing Machines provide unmatched performance for every application.

What Is A Material Testing Machine

-

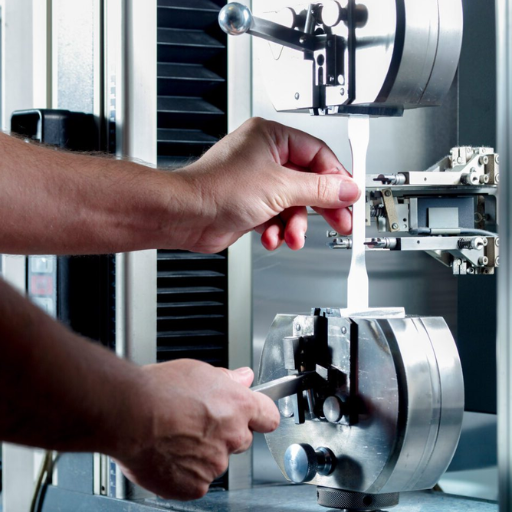

A material testing machine evaluates the physical and mechanical properties of materials, such as tensile strength, compressive strength, hardness, and ductility, under controlled conditions.

-

These machines are essential in industries like aerospace, automotive, construction, and manufacturing for quality control, research, and ensuring material reliability.

-

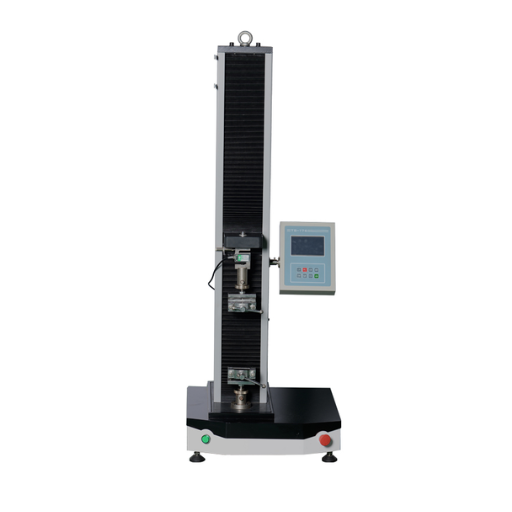

Common types include universal testing machines (UTMs), which perform tensile, compression, bending, and shear tests, and specialized machines for impact, fatigue, and torsion testing.

-

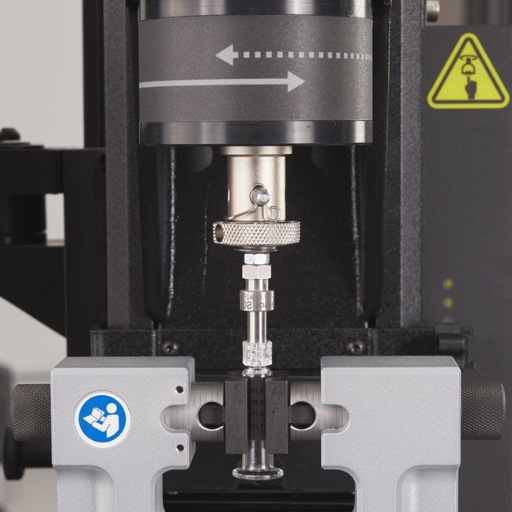

Key parts include a load frame, load cell, grips, extensometers, and software for data acquisition and analysis.

-

Testing machines and methods are standardized by organizations like ISO and ASTM to ensure consistent and reliable results across industries.

Essential Tests You Can Perform with a Material Testing Machine

Explore the comprehensive range of material characterization capabilities available with a Material Testing Machine. This versatile equipment allows for detailed analysis of various materials and components under controlled conditions, providing critical data for research, development, and quality assurance.

Versatile Testing Capabilities

Performs tensile, compression, bending, and shear tests to evaluate material properties like strength, elasticity, and ductility.

Robust and Adaptable Design

Features a rigid frame, customizable grips, and fixtures for testing various materials and applications.

Precision Measurement Tools

Equipped with load cells, extensometers, and software to measure force, displacement, and stress-strain relationships accurately.

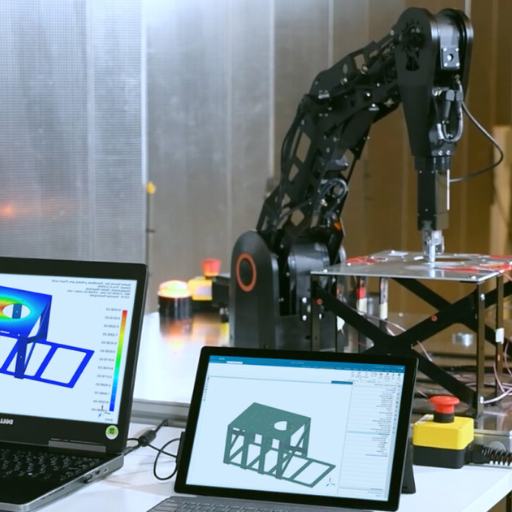

Data Analysis Integration

Includes software for real-time data recording, analysis, and visualization, aiding in quality control and material research.

What is the difference between UTM and CTM?

- UTM is versatile, performing tensile, compression, bending, and shear tests. CTM specializes in measuring compressive strength, mainly for materials like concrete.

- UTM is used across industries for diverse material testing. CTM is primarily used in construction to test concrete and bricks.

- UTM includes interchangeable grips and fixtures for various tests. CTM has a simpler design focused on applying compressive loads.

- UTM evaluates multiple mechanical properties, including elasticity and ductility. CTM focuses solely on compressive strength.

- UTM is adaptable for different materials and tests. CTM is a specialized subset of UTM, limited to compression testing.

What is the use of material testing machine?

- Measures tensile, compressive, and flexural strength, providing insights into material behavior under various forces.

- Ensures materials meet industry standards and specifications, enhancing product reliability and safety.

- Assists in developing new materials by analyzing properties like elasticity, ductility, and hardness.

- Identifies material weaknesses and failure points to improve design and performance.

- Widely used in construction, aerospace, automotive, and manufacturing for testing metals, plastics, and composites.

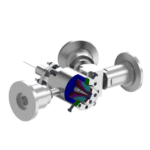

Components of Material Testing Machine

A material testing machine features a load frame, crosshead, load cell, grips, and extensometers, enabling precise force application, specimen holding, and deformation measurement for accurate material property analysis.

View our Material Testing Machine

Top Material Testing Machine tailored for you, our advanced technology provides reliable quality efficiently and professionally.

Glass And Tile Testing Machine

Equipped with waste management systems for glass splinters and testing systems for EN 1288, this machine does multifaceted testing on glass and tiles, checking their bending strength, durability, and surface quality.

Wood Plastic Testing Machine

Customizable to specific specimen sizes and shapes, this machine helps evaluate the tensile, flexural, and compressive strengths of composite materials for use in construction and furniture manufacturing.

Foam Sponge Testing Machine

This compact machine performs tests on the compression, durability, and resilience of foam and sponge materials. Its ease of use paired with its multifunctional abilities makes it ideal for quality control in the furniture, bedding, and packaging industries.

Daily Necessities Testing Machine

This wide ranging multifunction machine does tensile and compression tests on plastic, ceramics, as well as other household goods, measuring their safety, durability, and performance. Essential for manufacturers in consumer goods, this machine enhances product development while ensuring reliability in multi functional use.

Composite Material Testing Machine

This machine performs advanced composite material tests by measuring tensile, compressive, and flexural properties. It is suitable for aerospace, automotive, and construction industries and comes equipped with innovative software for data analysis.

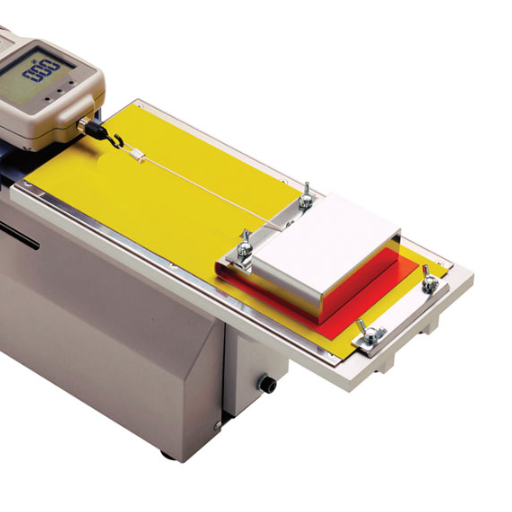

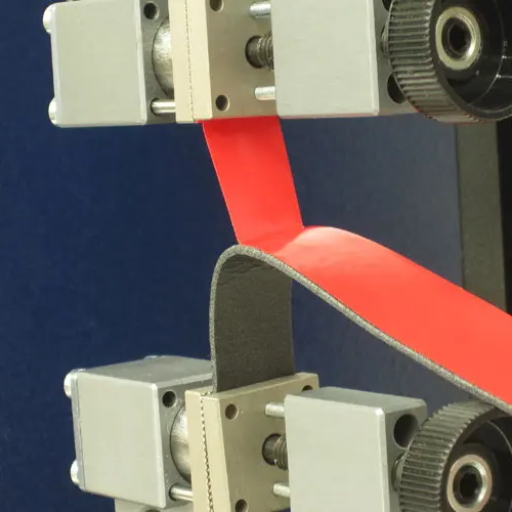

Film Tape Testing Machine

This machine performs tests to determine the adhesive strength, elongation, and durability of films and tapes. It is compact and well-suited for industrial and packaging purposes, thus enhancing quality and reliability.

Other Material Testing Machine

This machine is adaptable for various materials such as metals, ceramics, and polymers with customizable features to suit specific requirements. It is capable of performing tensile, compression, and impact tests for research and industrial purposes.

Material Testing Machine Data Overview

| Parameter | Description |

|---|---|

| Load Capacity Range | 1 kN - 10,000 kN, adaptable to various testing applications from light materials to heavy industrial components. |

| Testing Versatility | Supports tensile, compression, bending, impact, and shear tests across diverse materials like metals, composites, and ceramics. |

| Accuracy and Precision | ±0.5% or better, ensuring reliable and repeatable measurements for critical quality assurance processes. |

| Environmental Conditions | Operates under controlled conditions or in extremes (e.g., -10°C to 50°C) with optional environmental chambers. |

| Software and Automation | PC-controlled software for test design, data analysis, and automated reporting; supports real-time monitoring. |

| Speed Range | Adjustable between 0.001 mm/min to 500 mm/min for versatile testing requirements. |

| Crosshead Travel | Up to 1,500 mm, accommodating longer specimens and testing configurations. |

| Extensometer Integration | Compatible with clip-on and non-contact extensometers for precise strain measurement. |

| Power Supply Options | Operates on 220V/50Hz or 120V/60Hz, with optional battery backup for uninterrupted testing. |

| Safety Features | Includes emergency stop buttons, limit switches, and overload protection to ensure operator and machine safety. |

Why Choose Our Material Testing Machine Manufacturers

Our profound material testing machine specialists utilize advanced technologies enabling accuracy and reliability. Systems are adjustable and cater to a variety of Industries, fulfilling particular requirements. With certifications accepted all over the world, novel designs along with your rigorous performance expectations for high-demand testing, we are upbeat to standing your testing needs.

With unmatched backing as part of your partnership, don’t worry about unsatisfactory claims on aftersales or complicated workflows with our self-explanatory systems. Automated machine processes aided with sophisticated programs make the operations effortless while eliminating chances of data biases in the analytics. Do business with us if operational efficiency serves as a priority alongside quality in any set environment.

What Our Client Says

Understand from our clients what they say about doing business with us and the unique value addition we provide.

Expert Insights on Material Testing Machine

What is the main functionality of material testing machines?

Material testing machines measure the physical and mechanical properties of materials, such as tensile strength, compression, bending, and shear. These machines ensure that materials meet performance standards across industries like construction, aerospace, and manufacturing.

What industries commonly use material testing machines?

Material testing machines are widely used in industries like construction for testing building materials, automotive for component durability, aerospace for composite analysis, and packaging for quality control of films and adhesives.

What are the key benefits of using advanced material testing machines?

These machines offer high precision, real-time data analysis, and customizable capabilities. They ensure compliance with industry standards, reduce product failures, improve quality assurance, and support innovative material development processes.

How can regular maintenance improve the lifespan of a material testing machine?

Routine maintenance, such as calibrating loads, cleaning components, and updating software, ensures machine accuracy and prevents unexpected breakdowns. Manufacturer-recommended service intervals help maintain optimal performance and extend the machine’s lifespan.

What role does software integration play in material testing machines?

Integrated software allows for automated testing, data collection, and analysis. It enables real-time monitoring, generates detailed reports, and ensures seamless operation, enhancing productivity and accuracy in testing processes.

How do material testing machines align with industry standards?

These machines are designed to comply with global standards like ASTM, ISO, and EN. They offer test configurations and reports that meet specific certification requirements, ensuring end-user confidence and regulatory compliance.

Latest Blog Posts

Maintain Inventiveness by Following The Blog for the Latest Best Practices, Techniques, Innovations, and Insights in the Field.

Understanding the friction coefficient is fundamental among professionals from various fields, including engineering and materials science. Being a relatively rarefied […]

Adhesive performance is a crucial consideration for industries such as automotive, aerospace, packaging, and construction. Testing the bonded materials for […]

Material testing deformation is a vital field in the study of various materials under different mechanical stresses. It helps to […]

With durability and fatigue simulation being in the spotlight today in engineering, there is a possibility of inventing ingenious and […]

Torsion testing is crucial for determining the mechanical properties that materials exhibit under twisting forces, thereby enabling the performance and […]

Material testing is the core of design and manufacturing, where one guarantees that each component or product meets quality, safety, […]

Get a Quote for Your Material Testing Machine Today

Elevate your evaluation processes with state-of-the-art material testing machines with unparalleled accuracy. These engineering-grade devices serve multiple industries whilst ensuring worldwide conformity and unrivaled dependability. Place an order today and refine your quality assurance workflows. With unparalleled precision technology, these devices will transform your operation efficiency. Improve your business processes now!

Frequently Ask Questions

Q: What are material testing machines used for?

A: Material testing machines are used to evaluate the mechanical and physical properties of materials. They measure attributes like tensile strength, compression, bending, and shear to ensure materials meet performance and safety standards.

Q: What industries rely on material testing machines?

A: Material testing machines support industries such as construction, aerospace, automotive, packaging, and research labs, where material durability, reliability, and compliance are critical.

Q: What are the advantages of using a material testing machine?

A: These machines enhance precision, provide real-time data, and ensure compliance with industry standards. They reduce product failures, improve quality assurance, and make material development more efficient.

Q: How do you maintain a material testing machine?

A: Regular maintenance includes calibrating loads, cleaning moving parts, inspecting safety features, and updating software. Following manufacturer-recommended service schedules helps maintain long-term accuracy and performance.

Q: Can material testing machines be customized?

A: Yes, many material testing machines are customizable to meet specific testing needs, such as different load capacities, testing speeds, or environmental conditions. Customization ensures compatibility with unique applications.

Q: Do material testing machines comply with international standards?

A: Most modern machines adhere to major global standards like ASTM, ISO, and EN. This compliance ensures consistency, reliability, and acceptance across international markets.

Q: How important is software integration in these machines?

A: Software integration streamlines the testing process, offering features like automated testing, real-time monitoring, detailed data tracking, and easy report generation. This enhances productivity and minimizes human error.

Q: What safety features are included in material testing machines?

A: Safety features often include emergency stop buttons, overload protection, and limit switches to prevent equipment damage and operator injuries. These features promote safe and efficient operation.