Instrument And Equipment Wholesale

Premium Foam Sponge Testing Machine Manufacturer in China

As China’s leading Foam Sponge Testing Machines supplier, they provide accurate and dependable solutions for foam testing. Their machinery guarantees precision evaluation of foam resilience, hardness, and durability owing to their outstanding fabrication reputation, stringent quality control processes, and modern technology. Their products are ideal for laboratories and industrial uses and meet international standards of tests and calibrations. Get your Foam Sponge Testing Machines today and experience unmatched quality!

What Is A Foam Sponge Testing Machine

-

It evaluates foam materials' resilience, hardness, and durability under compression and fatigue conditions.

-

Used in industries like furniture, automotive, and packaging to ensure material quality.

-

Complies with global standards like ASTM D3574 and ISO 3385 for accurate results.

-

Equipped with precision sensors, adjustable settings, and digital displays for detailed analysis.

-

Tests are conducted on foam specimens of specific dimensions, ensuring consistency and reliability.

Main Features of Foam Sponge Testing Machine

Foam Sponge Testing Machine allows for detailed analysis of various materials and components under controlled conditions, providing critical data for research, development, and quality assurance.

Precision Sensors

Equipped with high-accuracy pressure sensors for reliable and consistent measurement of foam indentation and resilience.

Versatile Standards Compliance

Supports global standards like ASTM D3574, ISO 3385, and JIS, ensuring compatibility with diverse testing requirements.

Automated Testing

Features automatic counting and indentation cycles, ensuring efficient and repeatable testing processes.

User-Friendly Interface

Includes LCD touch screens and computer integration for easy operation, data visualization, and result printing.

Foam Sponge Testing Machine For Sale

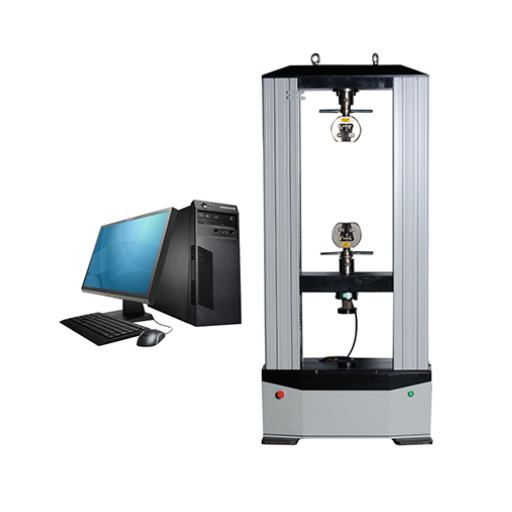

Computerized Sponge Compression Strength Testing Machine

The Computerized Sponge Compression Strength Testing Machine provides fully automated workflows for testing sponge durability and indentation hardness, incorporating quality control automation for automotive, furniture, and material research industries.

Foam Pressure Tester

The Measuring Model FPT-04A Foam Pressure Tester makes estimating foam resistance and strength easy. Thus, it serves firms in the manufacturing, automotive, and furniture industries that need effective quality control mechanisms to increase performance reliability.

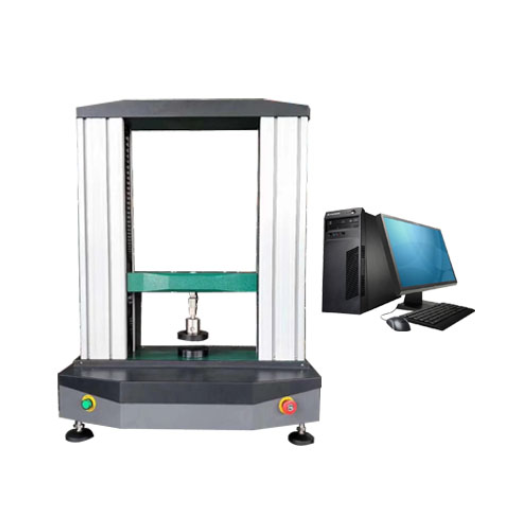

Computerized Latex And Polyurethane Foams Compression Testing Machine

The Computerized Latex and Polyurethane Foams Compression Testing Machine guarantees accurate foam strength analysis, which ensures material quality, precision performance, and safety for rigorous research demands in the automotive, furniture, and medical industries.

Computerized Flexible Cellular Polymeric Materials Tensile Tester

The Computerized Flexible Cellular Polymeric Materials Tensile Tester aids industries like automotive, aerospace, and research to enhance innovation-driven projects by providing exact tensile strength evaluations, improving performance, reliability, and quality with cutting-edge materials.

Foam Sponge Testing Machine Technical Specifications

| Parameter | Description |

|---|---|

| Load Capacity Range | 0–200 kg, adjustable for various testing needs. |

| Testing Versatility | Supports multiple test types: compression, fatigue, and hardness. |

| Accuracy and Precision | Equipped with precision load cells and digital display for accurate results. |

| Environmental Conditions | Operates under standard lab conditions; optional temperature control available. |

| Software and Automation | Touchscreen control with automated cycle adjustments and data logging. |

| Speed Range | 100 ± 20 mm/min, configurable for different test requirements. |

| Crosshead Travel | Maximum stroke of 200 mm for diverse sample sizes. |

| Extensometer Integration | Compatible with extensometers for detailed strain analysis. |

| Power Supply Options | Single-phase 220V, 50/60Hz, suitable for global use. |

| Safety Features | Emergency stop, overload protection, and stable base for secure operation. |

Application Industries of Foam Sponge Testing Machine

Furniture Manufacturing: Tests foam quality for sofas, mattresses, and chairs.

Automotive: Ensures seat cushioning and interior foam durability.

Aerospace: Ensures foam reliability in aircraft seating and insulation.

Construction: Evaluates insulation and soundproofing foam materials.

Packaging Industry: Assesses protective foam for shipping and storage.

Medical Equipment: Verifies foam used in medical mattresses and supports.

Consumer Goods: Evaluates foam in toys, sponges, and household items.

Sports and Recreation: Tests foam for helmets, padding, and sports gear.

Electronics Industry: Tests foam for shock absorption in electronic packaging.

Marine Applications: Verifies buoyancy and durability of foam in marine equipment.

Request Information on Your Foam Sponge Testing Solution!

Improve your product quality and accuracy with the Foam Sponge Testing Machine. It provides assurance on durability, precision, and reliability in the furniture, automotive, and packaging industries. Achieve Foam Sponge Testing Machine now and deliver superior performance, surpassing industry standards on your crafted products. Call us right now and get a Foam Sponge Testing Machine for a tailored, innovative Foam Sponge Testing Machine that solves your business problems.

Frequently Ask Questions

Q: What is a Foam Sponge Testing Machine?

A: A device used to evaluate foam’s durability, compression, and tensile properties.

Q: What industries use Foam Sponge Testing Machines?

A: Commonly used in automotive, furniture, packaging, and medical sectors.

Q: What tests can be performed on foam?

A: Compression, tensile strength, tear resistance, and fatigue tests.

Q: What standards are followed for foam testing?

A: Standards like ASTM D3574 and ISO 2439 are widely used.

Q: How does a Foam Sponge Testing Machine work?

A: It applies controlled forces to foam samples to measure performance metrics.

Q: What types of foam can be tested?

A: Flexible, rigid, polyurethane, memory foam, and more.

Q: What are the key features of these machines?

A: Precision load cells, automated controls, and versatile testing capabilities.

Q: Why is foam testing important?

A: Ensures product quality, safety, and compliance with industry standards.