The very first thing that can actually make or break any project in manufacturing or construction is the quality and the durability of the materials. Material testing purports to nail down that components weighing in on your reliability are guaranteed as per strict industry standards for safety, performance, and longevity. This guide will explore the fundamental practices, methods, and tools of material testing to help you make an informed decision regarding your materials. This post will arm you with the know-how of testing techniques and assessing quality metrics required to uphold the highest standard. Do keep reading to understand why paying a good price for testing materials guarantees the best results for any project.

Understanding Material Testing

What is Material Testing?

Material testing analyzes and evaluates materials to determine their properties, performance, and aptness for certain applications; this acts as an assurance that materials conform to required standards and perform expectedly under varying conditions. Such a practice is vital to sectors like construction, manufacturing, and aerospace, where reliability and safety matter most to materials.

The basic goals of materials testing are to reveal mechanical properties such as strength, elasticity, or hardness and physical properties like density or thermal conductivity. The tests may also look at whether a material will remain durable: NRC can check the wear on one hand, or corrosion on the other, while another might be concerned with impact. Knowing such attributes can guide engineers and manufacturers to choose materials just right, conduct quality control, or ensure conformity to standards.

Key Insight: Broadly speaking, material testing methods fall into two categories: nondestructive and destructive. Destructive testing exposes materials to conditions that force them to fail, allowing for detailed insight into limits like tensile strength and fracture behavior. Conversely, nondestructive testing methods allow for evaluation without damaging the sample, calling for applications on components in use or those requiring preservation. In combination, these approaches assure that the tested materials are safe, efficient, and capable of fulfilling the demanding applications for which they are intended.

Importance of Material Testing in Various Industries

Material testing is critical with regard to safety, reliability, and performance for several product domains. It ensures that the material meets the standards or specifications before using in any application to avoid failure and to assure efficiency. When properties of a material, such as strength, durability, and impedance, are known, engineers and manufacturers select materials suitable for their project.

Construction Industry

Material testing paves way for the assurance that key components such as steel, concrete, and composites can withstand anticipated loads and environmental conditions. Testing might very well reveal if materials in construction can take the stress of an earthquake, high winds, or any other severe condition, thereby assuring great safety for the buildings and infrastructure.

Aerospace & Automotive

Material testing in aerospace and automotive industries ensure that the parts can resist extremely high pressures, temperatures and dynamic forces, thus guaranteeing performance and safety to their passengers.

Healthcare

Health care is making best use of material testing for manufacturing medical devices and implants. Testing of materials for biocompatibility and durability ensures safety in medical tools and implants for use in humans.

Material testing across all industries encourages innovations in developing new and better materials and ensures adherence to regulatory requirements, underscoring that it returns to being a vital mark in modern manufacturing and engineering.

Overview of Different Types of Material Testing

Material testing refers to a set of techniques used to evaluate the properties and performance of materials for various applications. These tests are necessary to certify that materials fulfill requirements of safety and quality, along with regulatory standards. Different types of material tests belong to mechanical testing, chemical testing, and non-destructive testing.

| Testing Category | Purpose | Common Methods | Applications |

|---|---|---|---|

| Mechanical Testing | Evaluates behavior under forces like tension, compression, and shear | Tensile strength, hardness testing, impact testing | Building and manufacturing industries |

| Chemical Testing | Determines composition and assesses contaminants | Spectroscopy, chromatography | Pharmaceuticals and electronics |

| Non-Destructive Testing | Examines materials without causing damage | Magnetic particle inspection, ultrasonic testing, radiographic testing | Aerospace, automotive, and energy sectors |

Using these different processes, testing of materials ensures the reliability, performance, and safety of products and infrastructures, thus making material testing an absolute necessity in present-day engineering and manufacturing.

Types of Material Testing

Tensile Testing

Tensile testing is a fundamental process to analyze the strength of a material and assess its ability to withstand pulling forces on it. A tensile test subjects the specimen to a uniaxial tensile load, measuring the behavior of the specimen under stress. Quantities such as tensile strength, elongation at break, and Young’s modulus are determined in this way, and all provide information about the mechanical behavior of the material.

The testing is usually done according to a particular standard that ensures consistency and accuracy of results. Placing a sample in the tensile testing machine will allow it to be pulled up to fracture. Depending on the force applied and the elongation of the sample during the test, sensors record such measurements. By plotting these data in a stress-strain curve, we can understand how the material behaves. Through this curve, one can find whether the material withstands all the criteria required for its actual use.

Tensile testing finds its application in many industries, ranging from construction, automobile, and aerospace to testing materials such as metals, polymers, and composites. Knowing material behavior under stresses enables engineers and designers to make sound decisions in selecting materials, designing products, and considering safety measures.

Compression Testing

Compression testing is an essential method to establish how materials react to saw compressive forces. The test looks at compressive strength, yield strength, or behavior relative to deformation. During the process, the sample undergoes a progressively increased load in compression until it fails or meets some pre-established limit. The results give an indication of its ability to maintain structural integrity under such stresses.

Its prominent use in compression testing is to ensure that materials can behave under compressive loads; hence coordination is crucial with construction and packaging. For example, concrete is famous for its compressive strength, being a primary consideration in the design of buildings and bridges. In contrast, foam and cardboard are checked for crushing resistance in the protective packaging design.

Data derived from compression tests allow the selection of materials and hence identification of inadequate properties in structures or products by engineers. Results from compression tests are likewise based on decisions regarding the manufacturing processes and material formulations to achieve the best possible solution under actual conditions. In essence, compression testing is a fundamental step in material testing and safety assurance in various fields.

Hardness Testing

Hardness testing may plausibly be referred to as a way of studying that mechanical property whereby a material resists deformation, considering specifically its capacity for surface indentation or scratching. This property is of great importance in ascertaining the durability and efficiency of the material under varying conditions. In general, there are three hardness testing methods commonly used, the Brinell test, the Rockwell test, and the Vickers test, each with its own tool or apparatus and testing procedures.

Brinell Test

Uses a hardened steel ball indenter

Rockwell Test

Measures depth of penetration

Vickers Test

Uses diamond pyramid indenter

The use of hardness testing has several applications. It tests if a material fits the requisite standard for a use such as resistance to wearing, abrasion, or penetration. Hardness testing is classically used in industrial fields like construction, manufacturing, and designing materials for environmental and operational type stresses. It may be used for quality control purposes wherein consistent hardness maintains the uniformity of properties in batches of production.

Information regarding hardness from test results may help in studying the overall mechanical properties of the material, including the strength, ductility, and wear resistance. For example, a very high hardness value generally suggests that the material can resist deformation when stresses are applied, while a low hardness value indicates a material that could easily be bent or squeezed out of shape. Having knowledge of those properties gives an engineer or manufacturer a choice of possibility to improve the performance, reliability, and cost-efficiency of the product.

Fatigue Testing

Fatigue testing is an important process performing various functions according to the subject it deals with. It determines the behavior of materials under tensile and compressive loading under repeated or cyclic loading. It tells the flexibility and limit of the material under fluctuating stresses that are below the ultimate tensile strength. Prediction of failure could be the prominent task assigned to this test that deals with components undergoing varying loads during their service life, such as automotive, aerospace, and structural domains.

The specimen is subjected to controlled cyclic stresses that may be tensile, compressive, or a combination of the two while fatigue testing is conducted. The number of cycles the material can sustain before the appearance of cracks, plastic deformation, or complete failure is counted. Very useful knowledge about material behavior under real-life situations is generated so that they are meeting the set standards for safety and performances. They are normally conducted taking either stress control or strain control approach, thus they have their unique advantage on a case-to-case basis.

Fatigue testing is used to provide the knowledge that the engineer might apply for the choice of materials and design changes. By utilizing their knowledge of fatigue limits or endurance limits, manufacturers can create components with much greater reliability and cost reduction. Thus, these methods contribute to reducing the chances of sudden failure and the advancement of the modified, safer, and highly-scalable products in different sectors.

Material Testing Equipment and Techniques

Overview of Material Testing Equipment

Material testing equipment refers to all those instruments and machines that find use in testing or measuring material properties, particularly physical and mechanical properties. These tests ascertain whether the materials conform to the requirements for various applications in industries like civil, automotive, aerospace, and manufacturing. The equipment will test properties such as strength, hardness, durability, ductility, and resistance to environmental effects, such as temperature and corrosion.

Essential Testing Equipment Types

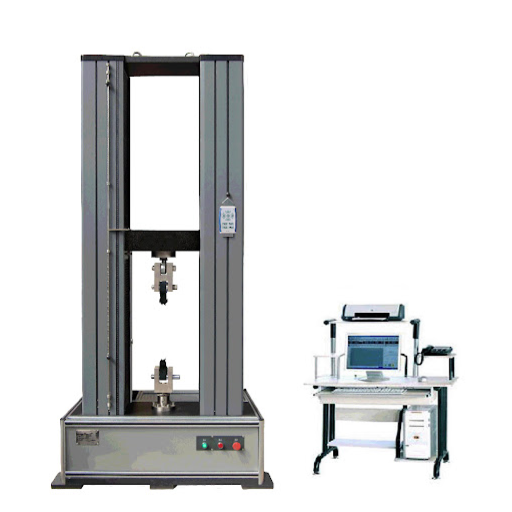

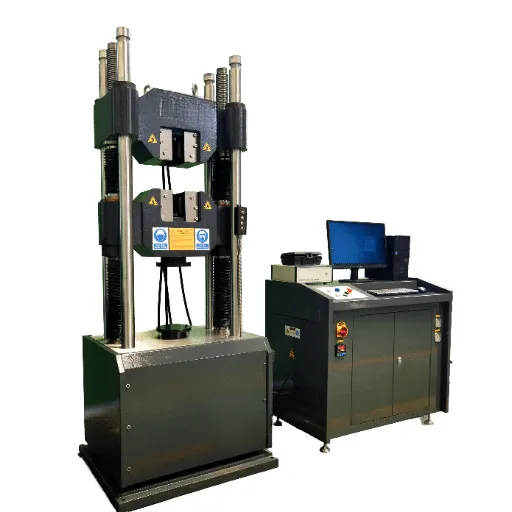

Universal Testing Machines (UTM)

Versatile machines that test materials in tension, compression, and bending

Hardness Testing Machines

Including Brinell, Rockwell, and Vickers methods

Impact Testing Machines

Measure material’s ability to resist impacts and energy absorption

In addition, there are thermal testing instruments, used in evaluating the material under extreme temperatures, and nondestructive testing (NDT) tools, which assess the integrity without damaging the material. Some NDT methods are ultrasonic testing and radiographic testing, both useful in discovering hidden defects to ensure high safety and reliability. Working together, all these testing machines give necessary information on material performance, allowing different industries to optimize design, thereby enhancing service life and safety.

Role of Advanced Technologies in Material Testing

Ever-evolving into new forms with technology and the need for more precision and efficiency, the innovative techniques in testing materials include Digital Image Correlation (DIC): a technique using high-speed camera(s) to measure strain and deformation by using the surface texture of the material under stress. It is a non-contact technique that provides extensive details and can give real-time feedback so that industries can study materials’ behavior under different conditions very accurately.

- Nanotechnology Applications: With devices like the nanoindenter, researchers are able to characterize materials for mechanical properties at the nanoscale level, including hardness, elasticity, and behavior of thin films. Such precision is of paramount importance in applications such as aerospace, biomedical engineering, and microelectronics.

- Machine Learning & Data Analytics: Using big data from test methods, these technologies predict material performance or failure trends. Detecting patterns and anomalous behaviors through machine learning tools adds value to decision-making and aids in streamlining testing processes.

These new-solving techniques are selling fast to become standards for testing materials and ensuring future applications with more durable and reliable materials.

Role of Proctor Tests in Material Evaluation

In materials testing, Proctor tests are a major aspect of soil testing for compaction characteristics. The tests aim to determine the maximum dry density of a soil and its optimum moisture content, both contributing to the stability and durability of roads, foundations, and earthworks. The tests simulate actual field conditions so that engineers can predict the behavior of soil upon compaction efforts in the field during the construction stage, thereby reducing the chances of structural failures.

In the test procedure, the soil is compacted with varying moisture contents in a standard mold, and the densities are measured. This process determines the moisture content at which a soil attains its maximum dry density. This relationship must be well understood, especially for construction requiring soil stability and load-bearing capacity. Soils that are compacted properly reduce the problems of settlement, erosion, or water seepage that may lead to jeopardizing the performance in the long run.

Due to their ease of use and great effectiveness, Proctor tests have been accepted by many industries. Besides, they form the backbone of a rational approach to assessing soil properties essential to the success of construction projects. These tests have also enhanced sustainability by promoting efficient use of soil and materials for safer and dependable infrastructure development.

Applications of Material Testing

Construction Industry Applications

Materials testing is an important aspect of construction, as it ensures that materials used in projects meet certain standards for safety, durability, and performance. It assesses the physical and mechanical properties of materials such as concrete, steel, asphalt, or soil. Materials testing measures strength, elasticity, load-bearing capacity, and that eventually aid the engineers in selecting appropriate materials for construction projects.

Primary Applications in Construction

- Quality Assurance: Every material must be strongly tested to guarantee compliance with design requirements and regulatory guidelines before being used in any structure.

- Concrete Testing: Concrete undergoes testing for compressive strength to determine if it can sustain the anticipated loads.

- Soil Analysis: Testing assesses soil stability and capability to bear building foundations, certifying that the groundwork is sound.

It also keeps in view the safety and sustainability of construction projects over a longer period. Testing materials prove the working of materials under varying environmental conditions, which contributes to the design of resilient and resource-efficient structures; this way, materials testing reduces chances of structural failures and helps optimize the use of available resources. Hence, materials testing contributes to the successful completion of a project while promoting responsible and sustainable construction practices within the industry at large.

Key Aerospace Material Testing Practices

Aerospace material testing is required to ascertain that materials meet standards of utmost safety and performance rigor imposed by the aviation or space industry. These practices measure the strength, durability, and reliability of materials through the extreme conditions of high temperatures, pressure variations, corrosive environments, and more. Testing of materials under tensile forces, fatigue, and thermal resistance are some of the known conditions in the evaluation of materials. All these tests confirm that materials can resist enormous loads during flight and sustain long hours of operations.

Non-Destructive Testing (NDT)

Methods such as ultrasonic testing, radiographic testing, magnetic particle inspection identify flaws or defects without compromising material quality, maintaining integrity while offering valuable failure analysis information.

Environmental Simulations

Materials are tested under extreme heat, cold, and humidity conditions for resistance evaluation. These tests provide insights into long-term durability and suitability for specific applications, helping develop lightweight, high-performance components.

Yet environmental simulations constitute an important aspect in aerospace material testing. Materials are supplied with a mixture of environments, such as extreme heat, cold, and humidity, and are tested for their resistance to these environments. These tests shed much light on the long-term durability of a material and possible suitability for a particular application, hence helping in the development of lightweight, high-performance components that fulfill the latest industry requirements. In summary, the procedures for aerospace material testing assure the strict regulatory and safety requirements applied to every component in an emerging production project and further promote the development of reliable and sustainable aerospace technologies.

Automotive Industry Standards and Tests

Materials testing in the automotive industry occurs to ensure that the components comply with safety, durability, and performance standards. Various parameters that these tests evaluate include the mechanical, chemical, and physical properties that a material constitutes for use in vehicle manufacture: strength, corrosion resistance, heat tolerance, to name a few. By conducting tests according to their standards of the industry, manufacturers establish that the material shall be suitable for usage under various operating conditions.

Key Automotive Material Tests

| Test Type | Purpose | Application |

|---|---|---|

| Tensile Tests | Measure material strength under tension | Body panels, chassis components |

| Impact Tests | Check ability to absorb shocks | Safety systems, bumpers |

| Fatigue Tests | Assess behavior under repeated stress | Engine components, suspension |

| Environmental Testing | Confirm resistance to temperature, humidity, chemicals | All vehicle components |

Some key automotive material tests include tensile tests that measure the strength of a material under tension, impact tests to check its ability to absorb shocks, and fatigue tests to ascertain how it behaves when subjected to repeated stress. Environmental testing is equally essential so as to confirm that materials sustain very high or very low temperature, humidity, and chemical processes presented during a vehicle’s lifecycle. Compliance with such tests aggravates material integrity failures; their proper observance mean a really great reckoning of vehicle safety and reliability.

By complying with set industry standards such as ISO and ASTM, automotive manufacturers can increase efficiency in quality assurance and remain compliant with laws. They provide less space for interpretation as to methods and requirements for performance tests for various materials and for final products from the production batches. With materials testing performed on a large scale, the automotive industry can thus continue its pursuit of developing stronger, lighter, and more efficient components for modern vehicles, with the utmost regard for passenger safety and environmental sustainability.

Recent Innovations and Trends in Material Testing

Emerging Technologies in Material Testing

With new technologies being brought into play for greater accuracy, efficiency, and sustainability, material testing has seen tremendous evolution. An evident innovation is the use of Machine Learning and Artificial Intelligence (AI) processes within the testing framework. These tools allow intricate analyses of material properties, swift defect identification, and predictions of material behavior under various conditions. AI has become a game changer as it eliminates human errors when interpreting data and in the manner materials are presently tested across industries.

Revolutionary Technologies Transforming Material Testing

AI & Machine Learning

Intricate analyses of material properties, swift defect identification, and predictions of material behavior under various conditions. Eliminates human errors in data interpretation.

Non-Destructive Testing (NDT)

Ultrasonic testing and digital radiography permit inspection without material damage. Vital for aerospace and construction where structural integrity is key.

Green Testing Processes

Less energy consumption and waste creation during testing operations. Recyclable and green materials employed to satisfy sustainable solution demands.

Disrupting trends have turned attitudes away from traditional destructive testing toward nondestructive testing (NDT). Some of these assessments include ultrasonic testing and digital radiography, which permit inspection of materials from all angles without inflicting any harm. Domain of NDT finds vital application in industries wherein integrity of the structure is key, such as aerospace and construction. A new generation of NDT sensors and imaging systems ensures more capable and reliable safety assessments.

In present-day material testing, sustainability has thus ascended to a position of utmost importance. Green testing processes are an example wherein less energy consumption and creation of waste is attempted during testing operations. In addition, there are recyclable and green materials that are being employed in test procedures, too, to satisfy the demand for sustainable solutions. Altogether, all of these emerging technologies are molding the future of testing materials in such a way that it does a great deal of close-working as a theme of innovation and progress in industries.

The Importance of Sustainable Materials in Materials Testing

Sustainable materials are essential to minimize the environmental impact of materials testing. These materials must be so constructed as to limit waste generation and energy consumption-the very environment issues covered in global initiatives attempting to tackle climate change and resource depletion. With the use of materials in testing processes that can be recycled or biodegrade, industry would limit its ecological footprint while keeping high standards of operational efficiency and precision.

Benefits of Sustainable Materials in Testing

- Environmental Impact Reduction: Limit waste generation and energy consumption during testing processes

- Resource Conservation: Use of recyclable or biodegradable materials reduces ecological footprint

- Innovation Driver: Elevates market demand for greener alternatives like renewable polymers and lightweight composites

- Regulatory Compliance: Helps industries align with changing environmental policies and societal concerns

Testing of materials usually concerns the inhibition of materials for maintenance of durability, strength, or performance that is to satisfy a given set of criteria. Thereby raising sustainable materials into the conversation elevates market demand for greener alternatives: materials such as polymers derived from renewable sources or lightweight composites that need less energy in their testing. These efforts assist in sustainability while fulfilling the demand for green solutions in manufacturing, construction, and product development from the eco-friendly side.

The use of sustainable materials in testing will help safeguard industries by conforming to changing environmental policies and societal concerns. With rising attention to the environment, many sectors are aligning themselves with the concept of green practices, wherein sustainable materials testing is one of the steps. By focusing on greener approaches, companies will be able to innovate and become part of the realization of a more sustainable and efficient future in all industries.

Future Directions for Testing Services

Materials testing is undergoing a paradigm shift due to advances in technology and ever-shifting industrial demands. One of such directions has been the increasing dependence on non-destructive testing (NDT) methods. These methods allow materials to be checked for their properties or integrity without damaging the product. Their use has become highly appreciated in various industries such as aerospace, construction, and manufacturing. NDT increases sustainability as contaminants from damaged products are reduced, giving importance to the longevity of such critical components.

Digital Technologies Integration

AI and ML tools analyze huge amounts of test data with unprecedented accuracy and speed, leading to better decision-making and predictive maintenance. Digitalization enables real-time monitoring and remote testing capabilities.

Circular Economy Principles

Testing guidelines focus on recyclability and environmental impact, ensuring materials can be reused with minimal environmental damage. Industries increasingly commit to green initiatives while maintaining safety and performance standards.

The next in line is applying digital technologies at an advanced level, such as AI and ML, into materials testing. AI tools analyze huge amounts of data from tests with never-before accuracy and speed, leading to lucidity in decision-making and predictive maintenance of critical systems. This digitalization of materials testing also allows materials to be monitored in real-time, promoting merit in, among other things, remote testing as well!

Last but not least, avenues that lean into eco-friendly approaches supporting circular economy principles stand firm as likely candidates for the materials-testing program. Testing guidelines are being developed toward recyclability and environmental impact so that materials may be reused with minimum damage on the environment. This indicates that industrial sectors are increasingly committing to green initiatives and thus alleviating environmental concerns while ensuring that safety and performance never fall below set standards.

Frequently Asked Questions (FAQ)

What are the types of material testing?

A few examples of material testing are tensile tests, compression tests, bend tests, and shear strength tests. Each of these methods measures certain mechanical characteristics of materials: ductility in the case of tensile testing, compressive strength in the case of compression testing, and tensile strength in the case of shear strength testing.

What is the importance of material testing?

Material testing is concerned with evaluating mechanical properties and assuring the suitability of materials for specific applications. It includes the determination of strength, deformation, and whether or not materials will withstand the effects of the intended environment.

How can mechanical tests be conducted on materials?

Mechanical tests involve the use of the “universal test machine” and other specialized equipments, which apply load to test specimens in a controlled manner. Hence all material responses to stress and deformation are fully understood and analyzed with data.

What is the meaning of a compression test?

It is a test to check the behavior of a material when subjected to compressive loads. It determines the compressive strength of the material and how it deforms under compression. Construction and aerospace industries need this information for proper application.

What are the types of equipment used for material testing?

In common usage, equipment for material testing includes universal testing machines, extensometers, hydraulic test machines, and special systems for creep testing. These equipments provide the capability to measure diverse parameters of material properties accurately.

Where are extensometers used in material testing?

Extensometers are used during tensile and compression tests to measure the elongation and deformation of materials. These data set gives important information regarding the ductility and strain behavior of the material under test.

Which standards are applicable to materials testing?

ASTM or International Standards Organization standards and parties aim to guide testing procedures. Testing in accordance to these standards would assist in fulfilling certain quality requirements and would ensure that test results from different materials and industries may reliably be inter-compared.

What is the articulation of ductility in material testing?

DUCTILITY is important because it defines the capability of a material to undergo deformation under tensile stress without being ruptured. Highly ductile materials can absorb energy and resist impact; hence, they become ideal for a wide range of applications.

References

- ZwickRoell – Materials Testing

Information on destructive testing methods such as tensile, compression, fatigue, and impact tests. - Photron – Material Testing

A guide to typical testing methods like tensile testing, drop testing, and crush resistance. - ASTM – Physical Testing Standards and Mechanical Testing Standards

Standards for physical and mechanical testing procedures and guidelines. - Barrus Testing – Material Testing Standards

A resource on material testing standards according to EN, ISO, and ASTM, covering procedures and evaluation methods.