Ceramics have been highly regarded for their diverse applications and durability, making these materials paramount in construction and advanced technologies. This blog post will delve into the exciting world of ceramics with a special focus on their mechanical and materials properties that established them as a separate class of materials. If it is about peculiar strength or resisting extreme conditions, or maybe in applications like aerospace and electronics, then this piece shall be your one-stop guide. Join us as we look into the intrinsic properties of ceramics and see how they influence performance, thus opening avenues for innovative applications in manifold fields.

Introduction to Ceramics and Their Properties

Definition and Overview of Ceramic Materials

Ceramic materials are inorganic and non-metallic solids that either derive from natural raw materials or synthetic compounds. They are usually made by heating and cooling. Ceramics are usually hard and brittle, and materials found in this category include porcelain, glass, or engineering ceramics for very specific uses.

Ceramics are extremely hard, strong in compression, and wear-resistant. Being brittle, they fail in a very limited deformation due to charges with their highly rigid atomic structure. Hence, there are good wear-resistant applications, applications of ceramics against high loads, and applications that are to withstand sudden impacts and tensile forces.

The other defining ceramic properties come into consideration in terms of chemical stability, thermal resistance, and so on. Ceramics are proficient only in certain conditions when extreme temperatures or corrosive environments come into the picture. Ceramics find uses in aerospace, electronics, and also in the medical profession. By providing technological solutions to industrial problems through the balancing of their mechanical and material properties, ceramics find revolutionary applications.

Importance of Mechanical Properties in Ceramics

The mechanical properties of ceramics are of prime importance primarily due to their effects on material performance under differing stresses and working conditions. Ceramics exhibit hardness, high compressive strength, and resistance to wear or deformation. Apart from these qualities, other considerations will be the hardest to resist cutting tools, armor, and wear-resistant surfaces that must endure with wearability and resilience.

It is their weakness too, in that ceramics are brittle and hence have limitations. Instantly under tensile stress or an impact, ceramics may shatter because of a lack of ductility-this limits their applications in certain domains. Technologists and researchers look for optimizing mechanical properties like toughness or resistance to fracture to widen the applications of ceramics. One might thus say the development of composite ceramics has brought about materials able to keep their hardness but endowed with greater flexibility and strength.

Hardness and toughness are key mechanical properties, but the potential HAZARDS coming from thermal conductivity, chemical resistance, and lightweight attributes must, in turn, be balanced. These balances are at the extremes in the field, i.e., aerospace and electronics. The versatility of ceramics lies in this very interesting relationship between mechanical and material properties: an interplay with which ceramics still remain at the forefront of modern engineering solutions.

Applications of Ceramics Across Various Industries

Aerospace Industry

Ceramics have found their way into diverse industries with great impunity owing to superior mechanical and material traits. One of the most important applications lies in aerospace, given ceramics’ lightweight nature and extreme heat resistance. This consideration has invited ceramics to be used in ceramic tiles, engine components, and structural components of spacecraft and aircraft. It is in such high-stress conditions that they prove to be very reliable.

Electronics Sector

Another important domain involving ceramics is electronics due to its need for superior electric insulators and thermal conductivity. To this effect, they would be used in semiconductors, capacitors, and circuit boards that allow devices to function under electrical or thermal stress; the chemical characteristic of the ceramics also ensures immense service life under complex electronic systems.

Medical Applications

The medical field, while in aerospace and electronics, relies on ceramics for bio-compatibility and durability. Advanced ceramic materials find their use for dental implants, joint replacement, and prosthetic application so that they maintain structural integrity along with being compatible with biological tissues. This versatility, with their mechanical strength and adjustable material properties, keeps ceramics in the forefront of innovative engineering and technological solutions in varied industries.

Fundamental Mechanical Properties of Ceramic Materials

Hardness: Measurement and Significance

The hardness of ceramics is a decisive property as the latter are considered to resist deformation, scratching, or abrasion. The hardness of ceramics was caused by atomic bonds with high strength, which are either ionic or covalent bonds, thus offering a high resistance to wear. Hence, surface conditions that suffer repeated impacts or friction will require ceramics for applications.

The capacity of the material to resist either indention or surface scratching is measured by any of the various standardizing methods: Vickers’ method and Mohs’ scale. For instance, many ceramic materials obtain high scores, thereby indicating their ability to resist deformation caused by mechanical forces. This is an advantage in the industry, as durable and trustworthy materials are always required for tools and machine parts.

Hardness defines materials from the mechanical viewpoint, but it has to be balanced with certain other properties such as brittleness or toughness for end-use applications. Ceramic materials might be truly hard, yet under heavy loading, they can go for a brittle failure. Hence, a well-combined selection of mechanical and other material properties assures successful performance in arduous environments.

Brittleness: Causes and Implications

Brittleness is generally a property acquired by materials due to an inability to withstand plastic deformation before fracturing. It is usually due to the microstructure of the material that forcibly restricts the dislocations from accomplishing deformation. Ceramics are typically considered brittle since their atomic structure develops strong, localized bonds resisting flexing upon the application of stress. External considerations like fast cooling processes, impurity atoms, or defects in the lattice structures, sometimes contribute to increasing brittleness.

In many applications, brittleness is of far more significance. While hard and wear-resistant, brittle materials can fail suddenly in a catastrophic fashion when subjected to sharp impacts or tensile stress. This is unlike tough materials which absorb energy and, while deforming, ultimately break under the respective load. In the case of designing components of which the brittle nature of the material is paramount; an engineer will have to ensure that the material is not subjected to premature failure in a harsh operational environment. For instance, ceramic components are utilized in scenarios in which compressive stress dominates since ceramics operate excellently in compression but not in tension.

Driven by brittleness and mechanical property balance, an engineer selects material or modifies the processing technique depending on the application. Fiber or toughening agent reinforcement can bolster ceramic toughness without lessening its hardness. Inventing composite materials or coatings to overcome brittleness while maintaining other desired properties like hardness or thermal resistance is also an option. These procedures highlight the need to comprehend mechanical properties as well as material properties for application with the best performance.

Elasticity and Compressive Strength in Ceramics

By its very nature, compressive strength pertains to a load that diminishes the size of a material, and ceramics, on account of their rigid crystalline structure, are supremely adapted for dealing with such forces. Elasticity, conversely, is invariably feeble for a ceramic material, for once the deformations enter the domain of elastic ones, the material shows considerable flexing, instead of either snapping or cracking. Such a property makes ceramics useful for applying in a setting where high compressive loads come into play, as building materials or as protective coatings.

Ceramics have a huge distinction between mechanical properties and material properties. The mechanical properties, such as elasticity or compressive strength, therefore describe how different forces or stresses act on the ceramic, such as tension, compression, or bending. Material properties stand for inherent characteristics such as hardness, density, and thermal conductivity. To this effect, these two properties correlate while they differ since mechanical performance usually depends on the inorganic material’s inherent composition or microstructure.

Having a full grasp of the roles of mechanical properties and materials over each other assures the correct choice of ceramics for a given application. Theoretical compressive strengths are generally considered by engineers with respect to structural applications, whereas the ceramic’s low elasticity and catastrophic nature may make the material fail under sudden and uneven loads. All ceramic compositions, additives, or internal structure can be tailored by engineers according to the application requirements as a compromise of performance.

Testing Methods for Mechanical Properties

Overview of Testing Machines and Equipment

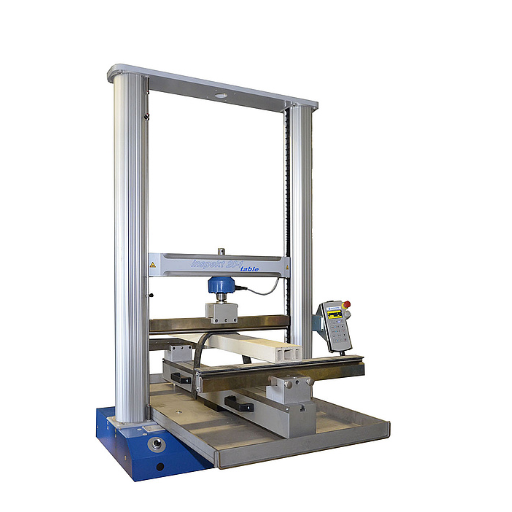

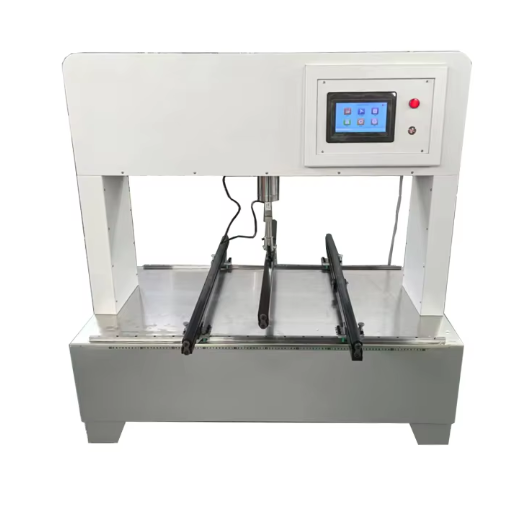

Ceramic mechanical testing needs accurate and robust equipment to test the special properties in question, such as compressive strength, tensile strength, and fracture toughness. Specially designed testing machines for brittle materials are used by engineers to ensure results are consistent. Among the commonly used equipment include universal testing machines (UTMs), nanoindenters, and impact testers.

- Universal Testing Machines (UTMs): UTMs measure tensile, compressive, and bending properties accordingly. The modern UTM load cell has the utmost sensitivity and is supported with software that controls load or displacement either by feedback of closed-loop systems or event signals for instructing data acquisition. For ceramics, special grips or fixtures are used to prevent premature failure. Lately, strain measurement was automated via improved digital image correlation (DIC) systems.

- Nanoindenters: These instruments characterize hardness and elastic modulus at micro- or nanoscale levels. They are of primary importance to ceramics because of the fine-scale structure of these materials. The nanoindenter uses a diamond tip to apply a very controlled force, while it measures how much is penetrated and the resulting geometry of the contact to characterize material properties like hardness and elasticity.

- Impact Testers: Ceramics are generally known to be brittle to impact and sudden loading; hence, impact testers are crucial. These machines determine the amount of energy absorbed by a specimen subjected to high-speed load-taking. Drop weight impact testers and Charpy impact testers are quite popular, exerting the ability to know how ceramics behave under dynamic conditions.

Standard Testing Procedures for Hardness and Strength

Before getting into ceramics, one should realise there are proper test methods of hardness and strength to be specified for measuring concrete mechanical properties. Thus, materials get tested for hardness to know their resistance to an indentation via different specified methods of hardness tests. Indentation resistance data becomes significant where whenever the application demands surface durability. The method applies an indenter under a controlled force to press onto the surface of ceramic materials, thereby providing a measure for resistance to a localised deformation.

Strength analyzing for ceramics commonly includes compressive or tensile strength testing. Ceramics perform excellently under very high compressive loads due to their inherent brittleness. The compressive strength test machine steadily applies force on the material until it finally fractures. Tensile strength tests are less common for ceramics because; their extremely low tensile strength causes them to fail rapidly when subjected to stretching forces. To achieve a good result, samples must be handled with care during these tests since even the faintest flaw or improper preparation can bring the entire accuracy of the test into question.

The relevant mechanical properties that determine applications of ceramics are hardness and strength. The high resistances of ceramic materials do not come on the cheap; in fact, they are very brittle and highly flaw sensitive. Engineers and designers use such standardized tests to obtain reliable and reproducible performance results of ceramics under real-time conditions to use the results to help make design decisions and select proper materials for the product under consideration. This means matching material properties with mechanical performance requirements to produce the best engineering solutions.

Innovations in Testing Techniques for Advanced Ceramics

Testing innovations in advanced ceramics aim to evaluate tests reaching mechanical property parameters through consideration of the particularities of such material systems. Along with hardness, wear resistance, and temperature stability, the brittleness of these materials and their sensitivity towards flaws warrant the need for accurate testing. New test techniques such as laser interferometry and acoustic emission allow for non-destructive examination of microscopic flaws and stress distribution and hence are necessary tests that materials must meet for a critical threshold in their performances.

Further, multi-axial testing methods have emerged to preclude the mismatch between lab and real-world settings. The conventional uniaxial tests seldom capture the complexity of simultaneous stresses that ceramics bear. Engineers now have the benefit of measuring strength, deformation, and failure points under multi-axial stresses, which provide them with the full picture of the practical behavior of these materials.

There is an essential facet that also comprises computer-aided design modeling and testing of simulations. These programs work with both mechanical and material properties while filling in the gap between theoretical designs and actual performances. Using learning data from physical tests in simulation software, designers or developers can simulate the ceramic response to respective conditions; hence an efficient and reliable application of ceramics toward engineering solutions with critical importance is achieved. Together, these improvements push beyond ceramic decision-making and optimization.

Limitations and Challenges in Ceramics

Susceptibility to Fracture Under Tensile Stress

Since these materials are brittle, because of how nature has made them, they are cushioned against tensile stress by means of being liable to fracture. The exact reason for such tortures lies within the atomic structure-a structure that forbids the particles to move or deform under the applied stress. Unlike metals-which can be plastically deformed-ceramics suddenly crack when their E-ultimate tensile strength has been exceeded. This characteristic can prove disadvantageous when flexibility or resistance to tensile failure is required.

Mechanical properties such as tensile strength and toughness are influenced by material properties of ceramics. Porosity, size of grain, microcracks, etc., tend to affect the mechanical behavior of ceramics. Ceramic materials with higher porosity tend to show less tensile strength because the pores develop into stress concentration sites that promote crack growth. By improving the microstructure of ceramic materials, their mechanical behavior can be influenced and, therefore, reduce the chances of fracture when tensile stress is applied.

Limitations on the fracture resistance of brittle materials can be overcome by product formulations. Ceramics are hard and wear-resistant, but they are also brittle and need to be counterbalanced. Placing ceramic elements in a polymer matrix may improve its durability and reduce its chances of catastrophic failure under tensile stresses. Such methods have been successful where strength, durability, and reliability are of extreme importance in engineering solutions.

Comparative Weaknesses Against Metals and Polymers

Being ceramics, they have their strengths yet rather more weaknesses than metals and polymers. One consideration is that ceramics are brittle under the typical circumstances and are generally not so good under tensile stresses. They will also be very prone to cracking under sudden impacts or shock. Unlike metals that can plastically deform and absorb energy, ceramics do not have such an option and hence always remain brittle. This property restricts their application where flexibility or impact resistance is needed.

This is quite another comparative drawback of ceramics: manufacturing and processing problems. Ceramic parts often demand high temperatures coupled with an exacting control environment, raising their relative cost and complexity when measured against metals or polymers. Metals, for one, are easily machined, welded, and reshaped, whereas polymers offer a degree of freedom in molding and fabrication. Hence, ceramics tend to be favored for high-end applications rather than for general use.

If anything, the thermal and electrical conductivities of ceramics are much lower than those of metals, limiting their application where quick energy transfer is necessary. Ceramics, because of their stability at high temperatures, can be perfectly used in thermal insulation-above all other applications. In contrast, these properties prohibit ceramics from competing with metals or polymer composites in applications like electrical engineering and heat exchange. These constraints emphasize the careful selection and design considerations needed when working with ceramics in engineering applications.

Cost and Manufacturing Challenges

Since ceramics require processing at high temperatures and with specialized tools, it often becomes an extremely expensive manufacturing business. Thus, ceramic materials are rendered more expensive as opposed to metals or polymers. Besides, being time-consuming, the ceramics manufacturing process goes through preparation of powders, shaping, drying, and sintering, all under precise conditions. It is this complexity that leads to high costs in manufacturing at an industrial scale.

Brittleness is another major drawback to ceramics. While ceramics are known for hardness and thermal resistance, too much brittleness will often mean handling and manipulation difficulties during manufacturing. Higher manufacturing costs and complexities need to be accounted for through design processes and methods so that the end product meets its needs.

In spite of the challenges, the professions retain ceramics as a competitor where its superior mechanical and material properties outweigh these disadvantages. Corrosion resistance, wear resistance, and resistance to extreme temperatures are some that make ceramics ideal for particular industries such as aerospace and medical devices. Over time, by improving production quality and integrating advanced engineering solutions, the cost of ceramics and manufacturing barriers may be eroded, allowing their applications to spread further.

Comparative Analysis: Ceramics vs. Other Materials

Strengths and Weaknesses Compared to Metals

| Property | Ceramics | Metals |

|---|---|---|

| Hardness | Extremely high | Variable, generally lower |

| Wear Resistance | Excellent | Good to moderate |

| Ductility | Very low (brittle) | High |

| Tensile Strength | Low | High |

| Weight | Lightweight | Generally heavier |

| Thermal Stability | Excellent | Variable |

Ceramics offer several mechanical advantages over metals, largely concerning hardness and wear resistance. They are highly abrasive-resistant and also retain their property under stiff conditions such as elevated temperature or corrosive atmosphere. In contrast with metals, ceramics do not bend much when force is applied or when heated, and so the ceramics make for hard cutting tools or are used in applications where heat intensities are very high.

But in terms of ductility and toughness, ceramics lack. When metals are hit with certain forces, they often do not shatter or break, but ceramics, being brittle, will probably crack or fragment under high stress, or sudden impact. This makes them less suitable for use in applications involving movement or impact. Metals are also generally higher in tensile strength, which increases their capability in structural and load-bearing assignments.

Theyighthing for application of material properties, ceramics weigh less than metals peculiar to aerospace purposes and other industries endeavoring for so-called weight reduction. They were considered much better than metals for electrical insulation and thermal stability; hence their use is ever-willing in electronics and higher temperature environments. Nonetheless, the high cost and relative inability to be reshaped hamper application, in a number of sectors. Otherwise, each material, in a way, bears its particular strength and value, so that the use of the material chiefly depends on the requirements of the industry or project given in question.

Performance Differentials with Polymers

Upon evaluating ceramics versus polymers, one will find stark differences between their mechanical characteristics. Ceramic materials are brittle but offer phenomenal hardness, resistance to compression, and resistance to abrasion. These properties are primarily suited for applications requiring durability under extreme pressure and harsh environments. Given such properties, many ceramics, because of maximum brittleness, will barely tolerate any tensile stresses and thus will rarely find applications in dynamic or impact-heavy situations.

On the other hand, polymers serve well in the realms of flexibility and processability. Compared with ceramics, polymers exhibit less hardness and heat endurance, and yet their strength-to-weight ratio and flexibility secure their place in the realm of lightweight deformation. Polymers, unlike ceramics, can sustain tensile strain to some extent and rarely break under moderate stress, paving way for a huge number of engineering applications that ceramics cannot possibly provide.

Ultimately, the mechanical properties of ceramics and polymers must be considered concerning the particular needs of the project under discussion. Ceramics perform well in applications where thermal stability and wear resistance are essentials, while polymers enjoy versatility and adaptation opportunities. In and of itself, the preference of a material would depend on the consideration of strength, weight, durability, and environmental conditions specific to the end use.

Composite Materials: Integrating Ceramics with Other Substances

Composite materials integrating ceramics with other materials offer unique advantages by combining the strengths of two materials. With high thermal stability and wear resistance being the attributes for which ceramics are famous, they are often combined with metals or polymers to provide mechanical properties such as toughening and flexibility. Composites are able to combine the best of both: compensating for features of ceramics, such as brittleness, with other characteristics from a different material.

Ceramics, from a mechanical viewpoint, having hardness and compressive strength, are employed to resist deformation and abrasion under heavy loads. On the contrary, ceramics tend to crack under tensile stresses or sudden impacts due to their low ductility. By joining such materials in composites, these weaknesses can be better balanced to enhance toughness without degrading the thermal or chemical durability provided by ceramics.

Material properties such as thermal conductivity, density, and environmental stability were enhanced through composite manufacturing. For instance, ceramics combined with lightweight polymers reduce the overall weight of the material while being resistant to heat, thereby finding applications in aerospace and automotive industries. Designing the ceramic blend with various other materials opens up an entire palette of solutions which may be developed according to need and applied innovatively to yield performance across numerous applications.

Frequently Asked Questions (FAQ)

Q: What are the mechanical properties of ceramic materials?

A: They are high hardness, flexural strength, and thermal stability. Based on such properties, ceramics find applications for many purposes where strength and durability are involved. Additionally, ceramics have low thermal expansion coefficients and high thermal shock resistance, properties that are essential for the performance of ceramics in harsh conditions.

Q: How does grain size affect the mechanical properties of ceramics?

A: Grain size is very important in influencing the mechanical properties of ceramic materials. Usually, a smaller grain-size leads to higher strength and toughness through the mechanism of grain boundary strengthening, whereas larger grains may reduce fracture toughness and increase brittleness, thereby influencing the hardiness of the material. The disposition is to affect durability.

Q: What do advanced technical ceramics comprise, and what are their advantages?

A: Advanced technical ceramics are engineered materials possessing great mechanical or electrical properties as compared with a traditional ceramic. The strength must be elevated, especially in the fracture toughness, the thermal shock resistance must be very high- all subjected to enhance the property profiling of materials for their applications in aerospace, electronics, and medical fields.

Q: How do zirconia ceramics compare with other ceramic materials?

A: Magnesium zirconate-in-ceramic system exhibits the best mechanical properties: high strength and toughness. They also show better thermal shock resistance, being used in dental applications and industrial settings. Their specific properties make them better than other ceramics in some applications, mainly in cases where reliability is a significant factor.

Q: What are ceramic composites and their advantages?

A: Ceramic composites manufacture materials by combining ceramics with other materials to optimize the mechanical properties and thermal stability. Such composites become beneficial for fracture toughness, strength, and resistance to thermal shock so that they must be used in the harsh working environment where common ceramics would try to fail.

Q: What role do electrical properties play in ceramic materials?

A: Electrical properties of ceramic materials, such as electrical resistance, are considered important in applications, especially for electronics and insulation. Certain ceramics, including glass ceramics and advanced technical ceramics, are intentionally designed to exhibit defined electrical and thermal properties and are thereby widely used in almost all modern electronic devices.

Q: What are the usual applications related to ceramic materials according to their properties?

A: Ceramics being a fine category of materials find applications depending on special properties. Made of ceramics are cutting tools, dental implants, some electronics, and some aerospace components. The mechanical properties, among them hardness and chemical resistance, make ceramics suitable for hostile environments in industries that demand reliability and performance.

References

-

Precision Ceramics – Ceramic Material Properties

A detailed overview of advanced ceramic materials and their mechanical strength characteristics. -

CoorsTek – Mechanical Properties of Technical Ceramics

Information on the high-performance mechanical strengths of technical ceramics, including hardness and fracture toughness. -

The American Ceramic Society – Structure and Properties of Ceramics

A guide to typical ceramic properties such as high hardness, wear resistance, and dimensional stability. -

Ceramic Industry – Ceramic Materials Properties Charts

Charts detailing the mechanical, thermal, and electrical properties of ceramic materials.