Metals & Metal Products Testing is one of the very important stages in all of the industries as it enhances the assurance, longevity and the security of the materials made in that particular industry building and other industries. The discussion of the post here will focus on the basic approach and the sophisticated techniques used in the determination of the mechanical, chemical and physical characteristics of metals. Tensile, hardness and and spectrometric analysis is imperative for managing quality; and meeting compliance requirements. At the end of this article, you should understand and appreciate the main theories governing testing techniques, the significant instruments which guide the development of material science and assist with use of the materials available in your work.

Introduction to Metal Testing

Metals & Metal Products Testing makes use of various techniques to assess the physical, mechanical, and chemical properties of intrinsically metallic matters. The aim of these tests is to ascertain the various parameters like the strength, hardness, ability to withstand corrosion and the chemical composition, thus ensuring that the material will perform up to the expected standards and safety regulations. Various methods like tensile strength tests for toughness, hardness tests for strength and spectroscopy/ spectrometry for chemical analysis are commonly employed. Metal testing, inclined towards innovation, is quite critical in construction, automobile, and even the aviation industries, to look at the dependability of products and their compliance with clear regulations.

Importance of Testing in the Metal Industry

In the metal sector, tests figure predominantly for guaranteeing safety, enhancing performance, and increasing the life span of the materials used in the process. Further, tests are there to confirm that metals adhere to the various industry standards and will operate effectively despite mechanical, thermal, and other operational stressors associated with use. For instance, in the construction industry, metals are usually tested to ensure their strength for building purposes so that the erected structures or bridges are not prone to structural damages. Also, in other sectors like automobiles or aircraft, it helps to ensure that some of the parts still work under harsh conditions such as very high heat or chronic mechanical strain. Where testing is not adopted or even properly standardized, products lose out on the quality in materials which are used and which creates a risk of causing any damage, illnesses, or bancruptcy to customers. This is the major reason why proper procedures of testing are extended to all the sectors in the economy and regulatory measures are put in place.

Overview of Materials Testing

The testing of materials is a procedure for the determination of the physical, chemical, and mechanical qualities of the materials to ascertain that they conform to certain functional and safety obligations. Some of these methods include tensile tests, hardness tests, fatigue tests, as well as impact tests, which are designed to determine the strength, elasticity, durability, and resistance of the material to failure tension. Basically, the purpose of this activity is to assess the ability of a particular material to be employed for a specific application, whether it be in building, engineering or aerospace manufacturing or vehicles. Advanced methods and international regulations of materials testing effectively reduce hazards, enhance efficiency of products and provide for adherence to regulations.

Key Terminologies in Metal Testing

1.Tensile Strength – Tensile strength of a material, especially metallic materials, is the maximum stress a material can withstand under tension loading without fracture. This measure is very important as it entails the ability of such a material to withstand the forces exerted on it.

2.Yield Strength – The yield strength of a material refers to the stress beyond which it cannot recover from plastic deformation. If the metal is strained below this point, it will fully revert to its original shape once the stress is withdrawn therefore this property is very important in many structural materials.

3.Hardness – The hardness of the material is the ability of the material to withstand deforming forces, predominantly when such forces are applied through a press. Hardness is measured based on different tests such as Brinell, Rockwell and Vickers, which arguably provide an indication of the wear resistance or durability of a metal.

4.Fatigue Limit – Fatigue limit is defined as the stress level below which a material can withstand repetitive stresses without failure for an infinite number of cycles. This property is particularly important in cases where components are subjected to repetitive loads such as in the case of aircrafts or machinery.

5.Elastic Modulus – Also referred to as Young’s modulus, it is the ratio of stress resultant to strain at no (zero) permanent deformation of a material. Young’s modulus is a crucial factor for understanding the stifness of any material and how it will perform once loads are applied to it.

6.Impact Toughness – As the name suggests, it is the energy a material takes in during its failure in a form of strain rate which is mostly as an impact. It is valuable property since it is used to measure how metals perform when exposed to sudden forces or shocks.

7.Corrosion Resistance – On the other hand, corrosion resistance is the ability of a material to resist corrosive attack from the surrounding elements (water; involving salt, chemicals). This characteristic cannot be overstated particularly for the marine, industrial and structural application.

Each of these terminologies plays an important part in evaluating the behavior of the metal when working under more or less normal working condition. These principles are essential in ensuring that metal testing is conducted according to the requirements of the industry as well as the clientele.

Common Metal Testing Methods

Common metal testing methods include tensile testing, hardness testing, impact testing, corrosion testing, fatigue testing, and nondestructive testing (NDT).

|

Method |

Purpose |

Key Points |

Tools Used |

Common Use |

|---|---|---|---|---|

|

Tensile Testing |

Measure strength |

Stress, strain |

Tensile tester |

Structural materials |

|

Hardness Testing |

Test surface res. |

Indentation |

Hardness tester |

Machinery components |

|

Impact Testing |

Assess toughness |

Energy, fracture |

Charpy tester |

Safety-critical parts |

|

Corrosion Testing |

Analyze durability |

Rust, oxidation |

Salt spray |

Marine environments |

|

Fatigue Testing |

Evaluate lifespan |

Cycles, cracks |

Fatigue machine |

Aircraft components |

|

NDT |

Detect defects |

Ultrasonic, X-ray |

NDT equipment |

Pipelines, welding |

Destructive vs. Non-Destructive Testing

Destructive testing evaluates material properties through methods that physically damage the sample, while non-destructive testing (NDT) identifies defects or properties without causing damage to the material.

|

Aspect |

Destructive Testing |

Non-Destructive Testing |

|---|---|---|

|

Purpose |

Strength analysis |

Defect detection |

|

Sample State |

Damaged |

Intact |

|

Methods |

Tensile test, impact |

Ultrasonic, X-ray |

|

Cost |

Higher (due to sample loss) |

Moderate |

|

Applications |

Quality control, failure |

Maintenance, safety checks |

|

Equipment |

Hardness tester, fatigue |

Ultrasonic, radiography |

|

Accuracy |

High for material limits |

High for defect location |

|

Suitability |

New designs or standards |

Maintenance, in-service |

|

Limitations |

Sample destruction |

Limited surface exposure |

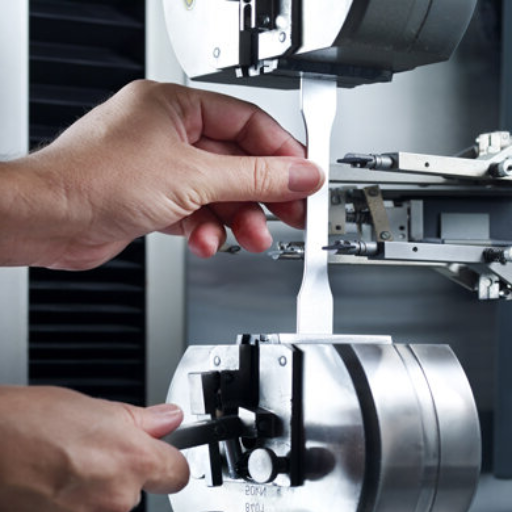

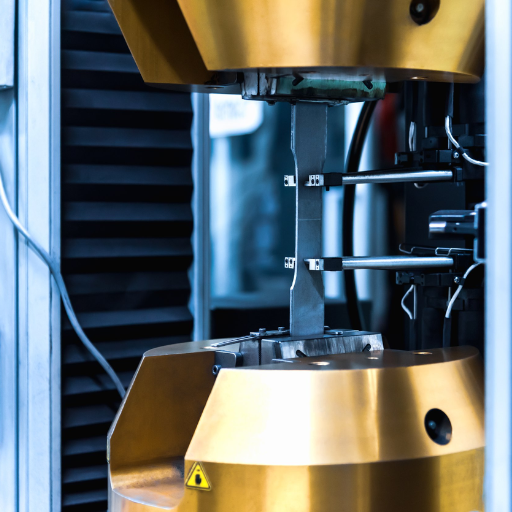

Tensile and Compression Testing

Material behavior towards mechanical forces has been explored through tensile and compression tests which are the principal test methods. In contrast, compression testing examines the extent and strength of failure when the sample is under a compressive force. It helps to see how a certain material works when under different kinds of loading and it is also used to check whether the information obtained is consistent with the design expectation.

In general tensile tests start with a sample that is subjected to tension until failure and such testing describes a material’s ability to stretch to accommodate tensile forces. On the other hand, while doing compression testing the object is put under tensile loads until it deforms or breaks. This is a basic test for materials that are why. In both these processes mechanical devices more specifically machines called universal testing devices are needed and standard procedures of testing (like ASTM, ISO) need to be followed. These find use for development of the material all the way to assurance/confirmation of performance and thus have their place in the aerospace, automotive and construction industries, amongst others.

Shear and Peel Testing Techniques

There are other important techniques for assessing adhesion and cohesion properties of materials across bonded interfaces. These are primarily shear and peel tests. Shear testing determines the capacity of material to withstand the stresses caused by the relative motion of the surfaces or layers. Evaluations of shear strength with regards to plastics and assemblies adhesives are performed by the elongation test. The focus of peel testing, however, is on the separation of surfaces and testing the force required to do so, emergence of resistance to peeling, stabilization of bond lines.

These also call for other equipment, for example, tensile testers supplemented with fixtures for shear and peel testing for the purpose of accuracy in results. Usually, such tests are conducted according to standard practices such as ASTM D1002 test for pin or shear joined capsule adhesives and standard ASTM D1876 for 180 degree peel. Testing of the shear and peel stresses helps in characterizing robust structural bonding and safety and quality assurance in industries such as packaging, electronics, materials, aerospace, etc.

Testing Standards for Metals

Metal testing standards are developed to assess the mechanical properties, chemical composition and functional performance of metals under different circumstances. Some of commonly used standards are ASTM E8/E8M that deals with tensile testing, ASTM E23 that is for Charpy impact testing and ASTM E18 that include hardness testing. Such standards help in quality assessments on parameters like strength, ductility, hardness and impact resistance by providing specific ways to characterise each parameter to avoid any form of failure in usage of the material for safety purposes and to guarantee the qualitative performance of the material for function.

ASTM Standards for Metal Testing

The built-in managerial protocol is the advance of ASTM in the testing of materials, results, and documentation. The most obvious example of this is ASTM E8/ E8M tensile testing. While it looks so simple at the first glance, there are very strict requirements when performing e8/e8m method to determine yield strength, tensile strength or even elongation. In the same way, ASTM E23 offers very rigid procedures when assessing toughness using Charpy impact Test. Lastly, ASTM E18 deals with hardness testing, reinforcing steps to carry out deformation resistance tests. Such standards are applied not only for obtaining results but also to ensure that in industrial practice such outputs are also within such products.

ISO Standards and Their Importance

ISO standards are universally accepted structures, which promote quality, safety, efficiency and compatibility in different sectors. These particular standards are standards which are made by the International Organization for Standardization, (ISO) and they specify combinations of standards and techniques which are meant to satisfy both the regulatory controls as well as the needs expressed by the consumers. An example of such a standard is ISO 9001 which lays out the principles for quality management systems to encourage effectiveness and continuous improvement. Furthermore, ISO 14001 concerns environmental management such that businesses are able to reduce the adverse effects on the environment while capitalizing on growth opportunities. Similarly, ISO/IEC 27001 includes controls for managing the security of information in the organization. Companies that follow these ISO norms can make their footing in the market more effective and gain consumer, stakeholder, and community confidence.

Common Testing Certifications

Common testing certifications for metals include ASTM, ISO, EN, DIN, JIS, and GB standards.

|

Parameter |

Description |

|---|---|

|

ASTM |

US standards for testing and materials. |

|

ISO |

Global standards for quality consistency. |

|

EN |

European Union testing norms. |

|

DIN |

German industrial standards. |

|

JIS |

Japanese standards for industrial use. |

|

GB |

Chinese national standards. |

Essential Equipment for Metal Testing

To achieve the best precision and dependability of metal testing, it is imperative to utilize proper equipment in the related processes. An obligatory device is a hardness tester for checking a surface’s resistance to indentation whereas a spectrometer is required to identify elements in alloys to know the round composition of an alloy in question. Besides, it is beyond any doubt that a tensile testing machine is crucial for checking the fracture strength of metals and the ultrasonic tester’s role as a non-destructive method for the detection of voids becomes quite apparent. Microscopes, and scanning electron microscopes (SEM) in particular, very often are used in surface and microstructure analysis. All of these give a proper and complete kit for metal property, quality, and performance analysis.

Overview of Testing Machines

In any given precision-driven field such as Material Science and Engineering, the testing machinery is required to help ensure the credibility of the materials free of adverse conditions. e.g. Tensile testing machine for unaxial tension current is used to determine the parameters such as strength, ductility elongation in metals etc which in other words refers to mechanical properties which are of course very useful in understanding the behavior of the material. Ultrasonic testing machine uses high frequency sound for evaluation purposes without any destruction which in turn helps to detect internal flaws like cracks and voids in materials. SEMs (Scanning Electron Microscopes) come in handy in this regard as they aid in microstructure analysis and facilitate the observation of the surface or the material making of a particular concern. All of these advancements in equipment allow the scientists or the manufacturers engaged in an assimilating and managing the performance of materials throughout the capacity of a complex processes involved in different businesses.

Types of Test Systems Used

Metal testing utilizes systems such as tensile testing, hardness testing, impact testing, fatigue testing, non-destructive testing (NDT), and spectroscopic analysis.

|

Test Type |

Purpose |

Key Methods |

Parameters |

|---|---|---|---|

|

Tensile Testing |

Measure strength |

Tensile machines |

UTS, strain |

|

Hardness Testing |

Determine hardness |

Brinell, Rockwell |

HRC, HBW |

|

Impact Testing |

Test toughness |

Charpy, Izod |

Energy absorbed |

|

Fatigue Testing |

Assess durability |

Cyclic loading |

Fatigue limit |

|

NDT |

Detect defects |

Ultrasonic, X-ray |

Cracks, voids |

|

Spectroscopy |

Analyze elements |

Optical, XRF |

Composition |

Advanced Non-Destructive Testing Equipment

Metals & Metal Products Testing requires the application of state-of-the-art, highly specialized equipment to ensure efficient, robust and non-destructive testing procedures. Methods like ultrasonic testing (UT), which helps to locate slight indications of cracks or erosions in the body, x-ray radiography and eddy current inspections are used to examine physical characteristics of materials being processed without causing damage. Efficient defect imagery is possible from a multi beam (PAUT) system and digital X-ray detector system addresses the need for a quality image in such place. There are currently very compact scanner devices and robots for use in NDT, busy rooms, and difficult environments. This is because such methods are essential, especially in the areas of aviation, power generation as well as building, and any other industry that has to ensure the safety and serviceability of its operations.

Applications and Suitability of Metal Testing

Ultrasound Solutions stands for a multitude of work and efforts by various people across the world that is aimed at providing certain pressure and flickr. It follows that the industries dealing with metals and metal products uses the relevant metals or alloys. The processes available in NDT include but not limited to ultrasonic testing, liquid penetrant, methyl alcohol, gamma radiography and particle testing. In case of the sector defined as aviation, these methods are applied for the validation of components exposed to high loads. Especially in building, welding strength and any other deformations are assessed to determine for example if the house is strong enough. Conveyed advanced techniques are among in portable 3D scanning and are well suited for the purposes of measurements of complex geometries objects. At the end of the day, however, the metal testing methodology will be dictated by the industry in question, the material in use, and what defect or discrepancy is put up for correction.

Metal Identification Testing

Different materials and the insufficiencies for some additions of other elements have made it necessary to create ways on how two determine the element composition and properties of a given metallic material of interest to a particular application in order. Typical examples of such techniques comprise of spectrochraomehltry, xrays fluorescent techniques, and sclerometry. Spectrometry deals with assessing fraction characteristics of atoms in an element by either absorption or emission of light or other forms of radiant energy, thus making it a very effective method where one wants to identify an element in details. X-Ray Fluorescence is used for quick and non-destructive analysis of the elements on the surface of materials using the method of high-energy x-rays. Some mechanical properties, for instance, strength and wear resistance and many more, can be evaluated by using hardness tests like the Rockwell or Brinell tests. Following there are some pertinent issues that need nevertheless to be addressed; such as the specific accuracy required, the nature of the material to be tested as well as the environment in which the test is to be conducted. For that reason manufacturing, testing departments and many demanding industries use them because they are essentials to have.

Testing for Common Metals: Aluminum and Stainless Steel

With aluminum, various mechanical property tests like Hardness test (Brinell or Rockwell) among others is usually done while conducting a test for hardness and strength of aluminum. Aluminium is a soft, light-weight metal, hence most of these methods are preferred as they do not damage the metal but rather serve to ascertain its performance potential in some industries as in aerospace or automobile. Non-destructive tests applicable for aluminum alloy are possible for stainless steel but require more advanced methods in particular hardness tests for stainless steel can include such techniques as Vickers, since the alloy is hard and difficult to wear. Furthermore, when it comes to testing how functional stainless steel is, controlling the level of corrosion through conducting salt sprays, or evaluating the degree of corrosion through electrochemical experiments was part of positive industry standards.

Rebar and Elemental Composition Testing

Reinforcement bars testers usually include mechanical tests as well as chemical tests to meet the structural requirements and certain safety standards. On the mechanical aspect, a series of tests such as tensile strength, yield strength, elongation, and the capability of bending are done to determine the level of support that is flexible under pressure. Elemental composition testing on the other hand is based on various methods and techniques such as spectroscopy or X-ray fluorescence (XRF) in order to precisely characterize the rebar in terms of its chemical constituents and most importantly carbon, manganese, and silicon are of fansa. The purpose for these examinations is to assure that the rebar has the desired characteristics and conforms to the requirements as laid out in building codes and within the industry.

Reference Sources

- ZwickRoell Group – Provides insights into standardized metal testing methods and reliable testing machines.

- IMR Test Labs – Offers details on chemical analysis methods like ICP, OES, and XRF for metals.

- Verichek Technical Services – Features a variety of metal testing equipment, including Optical Emission Spectrometers and X-ray Fluorescence machines.

Frequently Asked Questions (FAQs)

Q: What are the popular methods of testing for metal materials?

A: There are certain test methods that are used for checking the response of metals to different conditions. In tension tests, the fullness of a metal in stretch or tension is evaluated. Fracture toughness tests measure the degree of protection that a material possesses against cracks or fractures. These tests are performed to judge and classify metals in terms of standard specifications particularly including but not limited to ISO 6892-1 & ISO 6892-2. Such testing practices use additional methods to ensure the reason performance of the metallic products under the given applications.

Q: Why is the weld in metal products important during testing?

A: Welding grossly affects the integrity of most metallic constructions. During structural testing, welds can be subjected to both tensile and impact tests for checking their strength and resistance to cracking. Testing laboratories scope welds for any dread points and also fix the level of excellence there should be for those welds more in the level of application such as oil and gas or any other functional industry.

Q: Why are the results of the tests important in application testing?

A: The results of the tests are very important in an application testing as these are basically based on the analysis of how the metal specimen performs in specific conditions. These results help manufacturers determine whether their metal products would be suitable for consumers and injuring or hurting people if used.

Q: What part does fracture toughness play in metals testing?

A: Fracture toughness refers to the capacity of a material without causing tears or cracks. In metals, testing for fracture toughness is indispensable to determine the capability of metal products in relation to stress. Therefore, it is why the use of E8 standard tests performed by testing laboratories to determine the fracture toughness of metals is significant in cases where the consequences of failure may be catastrophic.

Q: What are some standards such as ISO 6892-1 used for and how are they applied regarding metal tests?

A: Some standards, such as stand ISO 6892-1, come with a set of procedures about how tensile tests on metals should be conducted so that any single test drafted anywhere in any laboratory may be compared to the tests in other laboratories without any bias notions. Further, these standards describe the testing methods suitable for ensuring that repeated sets of results produced by the same person and equipment conducted on different occasions are in line with the expectations of the industry.

Q: What are the facilities available for the testing of wires and cables in the laboratories?

A: The laboratories offer quite a number of testing facilities for wires cables and other metallic products. These tests include but are not limited to: tensile strength test, elongations test, electrical conductivity test. These tests are necessary for the protection of metallic material used in electrical applications to ensure that its safety and functional performance is dependable at different conditions.

Q: Is it significant to do elemental analysis in metals and metals products testing?

A: Compositional analysis is extremely important to be carried out in range of metal materials. The compositional analysis provides a better understanding of the characteristics of the material and its useful applications. Testing laboratories usually carry out compositional analysis to ensure that metal products are as per the desired standard and other requirements.

Q: In relation with metals testing, what is the importance of r and n values?

A: For characterization of the plasticity of sheets in deformations, r-value and n-value are the parameters which measure this plasticity. These values are very important in metals testing because they help engineers in understanding the behavior of metal products in various loading conditions.