Material testing is the core of design and manufacturing, where one guarantees that each component or product meets quality, safety, and performance standards. Amongst the several important tools for this are material testing machines, which enable one to measure accurately and assess the properties of a material under varying atmospheres.

Key Takeaway: Material testing machines act as yardsticks that check the feasibility of various innovations, helping advanced materials science and ensuring superior, reliable materials in modern industrial applications.

Introduction to Material Testing Machines

Material testing machines are precision instruments designed to test physical and mechanical properties of materials—namely, tensile strength, hardness, compression, and flexibility. They are important so that materials can be regarded as those meeting standards and being capable of performing functionally under certain situations.

These sophisticated instruments subject materials to the stresses and forces that would be experienced in practical application, thereby providing manufacturers, alongside their researchers, with valuable information to redesign their products for safety or comply with industry regulations.

Industries That Rely on Material Testing

- Construction: Ensuring structural integrity and safety

- Automotive: Testing components for durability and performance

- Aerospace: Verifying materials can withstand extreme conditions

- Healthcare: Ensuring biocompatibility and reliability of medical devices

What is a Material Testing Machine?

Material testing equipment is very specialized and is mainly employed to determine the mechanical properties and behavior of materials in various conditions involving stresses, strains, and forces. They perform detailed testing when forces are applied under very controlled conditions.

Key Properties Measured

- Tensile and compressive strengths

- Shear stresses

- Elasticity and ductility

- Hardness and durability

Today’s material testing machines often employ advanced techniques such as:

- Digital sensors for precise measurements

- Computer-aided controllers for automation

- Software applications for improved accuracy and data acquisition

The Importance of Testing Systems in Quality Assurance

Testing systems must be taken care of to guarantee the integrity, durability, and reliability of materials as required by different industries. By systematically testing and evaluating materials, manufacturers can:

- Identify defects before products reach the market

- Improve performance through data-driven insights

- Reduce incidents of product failures

- Ensure compliance with documented frameworks like ASTM and ISO

- Spur innovation in product lifecycle management

Overview of Different Types of Material Testing Equipment

Material testing equipment ranges from individual machines to comprehensive systems that evaluate mechanical, physical, thermal, and chemical properties of materials. Here are the main categories:

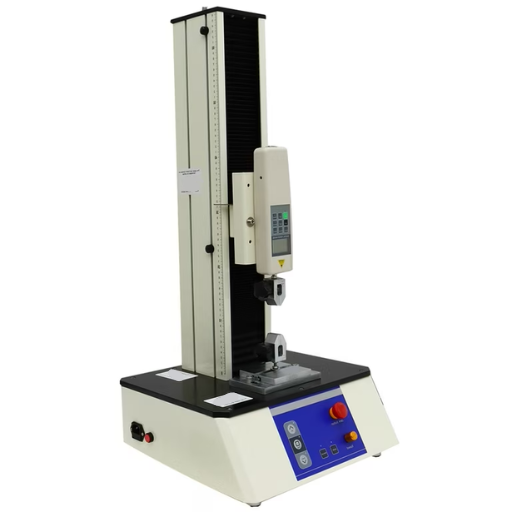

1. Universal Testing Machines (UTMs)

These are highly versatile machines used for tensile, compression, and bending tests. They check material strength and deformation resistance and can accommodate a wide array of attachments and testing methods.

2. Hardness Testers

These devices measure hardness utilizing methods like Rockwell, Brinell, and Vickers. They test a material’s resistance against indentation, providing a measure of durability and wear resistance.

3. Impact Testers

These machines apply sudden forces or shocks to evaluate material resistance, usually through Charpy or Izod tests that assess toughness and energy absorption capabilities.

4. Thermal Analyzers

Instruments such as DSCs and TGAs investigate material properties under temperature changes, offering data on thermal stability and transition points.

5. Spectrometers

These carry out analyses for the chemical composition of materials, usually through XRF or spectrophotometric techniques, to guarantee quality control and conformity with industry standards.

Types of Testing Machines and Their Applications

The main types of testing machines include tensile testers, compression testers, hardness testers, impact testers, fatigue testers, and universal testing machines, each applied to assess specific material properties.

| Machine Type | Application | Key Measurements |

|---|---|---|

| Tensile Tester | Measures tension resistance | Force, Elongation |

| Compression Tester | Measures compressive strength | Pressure, Load capacity |

| Hardness Tester | Tests surface hardness | Indentation, Scale values |

| Impact Tester | Checks material impact toughness | Energy absorption, Break resistance |

| Fatigue Tester | Evaluates cyclic load response | Stress cycles, Endurance limits |

| Universal Tester | Multiple tests in one device | Flexibility, Broad range testing |

Universal Testing Machines (UTMs)

Universal Testing Machines serve as versatile material testing facilities that provide tension, compression, flexure, and shear tests, among others. They are highly essential for determining:

- Tensile strength

- Compressive strength

- Elasticity and flexibility

- Material deformation characteristics

Advanced Universal Testing Machines feature state-of-the-art electronics that interface with software packages for detailed analysis of test data and measurement according to international standards such as ASTM or ISO.

Tensile and Compression Testing Machines

Tensile and compression testing machines are essential for measuring the mechanical properties of materials under uniaxial tensile or compressive loads.

Key Components

- Load frame: Provides structural support

- Load cell: Measures applied forces accurately

- Grips or fixtures: Hold specimens securely

- Electronic control system: Ensures precise measurements

Testing Standards

- ASTM D638: Standard for tensile tests

- ASTM D695: Standard for compressive tests

Fatigue Testing Machines and Their Uses

Fatigue testing machines accommodate testing for cyclic load discipline on materials. They simulate operational conditions by subjecting substances to repeated stress or strain until failure, thus determining the fatigue life of the item.

Key Applications

- Aerospace: Testing aircraft components for repeated stress cycles

- Automotive: Evaluating engine components and chassis parts

- Biomedical: Testing implants and medical devices for long-term reliability

Key Features of Material Testing Machines

Modern material testing machines come equipped with advanced features for precise and reliable testing:

Essential Components

- High-resolution load cells: Accurately measure applied forces

- Extensometers: Precisely measure strain and deformation

- Advanced software: Program testing parameters and process data

- Robust frames: Handle high loads and provide consistent performance

- Multiple testing capabilities: Support various testing methods

Understanding Grip and Fixture Options

Grips and fixtures form the foundation of reliable material testing processes. These components prevent specimen movement during testing, ensuring accurate and repeatable results.

Common Grip Types

- Wedge grips: Ideal for tensile testing applications

- Pneumatic grips: Provide consistent clamping force

- Vice grips: Best suited for harder materials

Specialized Fixtures

- Three-point bending fixtures: For flexural strength tests

- Compression platens: For compression load tests

- Custom fixtures: Designed for specific testing requirements

Torsion and Flexural Testing Capabilities

Torsion Testing

This test pertains to twisting forces and their effects on materials. Key measurements include:

- Shear modulus

- Torsional stiffness

- Ultimate shear strength

Flexural Testing

The flexural testing method applies force to achieve material deformation using three- or four-point bending methods. Essential data points include:

- Flexural strength

- Flexural modulus

- Strain characteristics

Hardness Testing Machines Explained

Hardness testing machines measure a material’s ability to resist deformation, penetration, or indentation under applied force. This helps study and rank different materials according to durability and resistance to wear.

Common Hardness Testing Methods

| Method | Application | Material Types |

|---|---|---|

| Brinell | Soft to medium hard materials | Metals, alloys |

| Rockwell | Wide range of materials | Metals, plastics, ceramics |

| Vickers | Precise measurements | Thin materials, coatings |

Industry Applications of Material Testing

Material testing ensures mechanical strength, wear ability, and suitability of materials for critical applications across different industries.

Manufacturing Sector Applications

- Component validation: Tensile and hardness testing before assembly

- Quality assurance: Ensuring specifications are met

- Non-destructive testing: Detecting internal flaws without damage

- Thermal analysis: Evaluating performance under temperature variations

Construction Industry Applications

- Concrete testing: Compressive strength verification

- Steel testing: Load-bearing capacity assessment

- Material certification: Compliance with building codes

Aerospace and Automotive Applications

Both industries demand advanced materials and testing techniques to meet stringent safety and performance standards:

Aerospace Industry

- Composite materials testing for weight reduction

- Titanium alloy evaluation for structural integrity

- NDT methods for microscopic defect detection

- High-temperature and pressure testing

Automotive Industry

- Aluminum alloys for fuel efficiency

- Carbon fiber-reinforced plastics for crashworthiness

- Weld quality evaluation

- Engine component durability testing

Role in Research and Development

In research and development, material testing plays a crucial role in:

- Material characterization: Understanding mechanical, thermal, and chemical properties

- Performance optimization: Developing high-performance materials for specific applications

- Innovation support: Enabling development of lighter, more durable solutions

- Standard compliance: Ensuring materials meet industrial requirements

Emerging Technologies in Material Testing

Emerging technologies are revolutionizing material testing by improving accuracy, efficiency, and expanding testing capabilities:

Advanced Non-Destructive Evaluation (NDE)

- Advanced ultrasonic imaging: Complete internal sample evaluation

- X-ray CT scanning: 3D internal structure analysis

- Maintaining material integrity: Testing without damage

Machine Learning Integration

- Enhanced data analysis capabilities

- Pattern recognition in material behavior

- Predictive testing outcomes

Nanoindentation Advancements

- Nanoscale mechanical property measurement

- Greater precision in small-scale testing

- Advanced material characterization

Automated Testing Systems and Their Advantages

Automated testing systems are revolutionizing quality assurance processes in engineering and manufacturing industries. These systems utilize sophisticated software and equipment to perform complex testing activities with exceptional precision.

Key Benefits

| Advantage | Description | Impact |

|---|---|---|

| Reduced Human Error | Automated processes eliminate manual mistakes | Higher accuracy and reliability |

| Increased Speed | Faster testing cycles and data processing | Improved productivity |

| Real-time Monitoring | Continuous data collection and analysis | Immediate quality feedback |

| Scalability | Adaptable to different protocols and volumes | Flexible operations |

| Cost Reduction | Lower operational costs over time | Better ROI |

Integration of Testing Software with Equipment

The integration of testing software with equipment ensures seamless communication between hardware and software components, providing several advantages:

- Real-time data acquisition: Immediate capture and processing of test results

- Automated control: Reduced need for manual intervention

- Accurate analysis: Enhanced precision in data interpretation

- Interoperability: APIs and middleware enable system compatibility

- Remote monitoring: Access to testing data from multiple locations

Impact Testing Machines: New Innovations

Recent developments in impact testing machines focus on accuracy, adaptability, and digital integration:

Latest Innovations

- Automated data acquisition: Eliminates human errors and provides real-time feedback

- Advanced analytics software: Enables predictive performance modeling

- Modular designs: Facilitate upgrades and reduce downtime

- Energy-efficient systems: Support sustainability goals in manufacturing

Frequently Asked Questions (FAQ)

What is a material testing machine used for?

What types of testing systems exist for mechanical testing?

How does a tensile tester work?

What is melt flow index testing?

What are test fixtures, and why are they important?

How do I determine what type of testing equipment to choose for my needs?

What is Vicat softening temperature used for?

Reference Sources

-

Instron – Materials Testing Systems: A trusted provider of testing equipment with detailed information on their systems and applications.

-

ZwickRoell – Materials Testing: A leading manufacturer of testing machines, offering insights into their reliability, accuracy, and applications.

-

Top Universal Testing Machine Manufacturers: A comprehensive list of trusted manufacturers, including details about their systems and features.

-

Universal Testing Machines: A Comprehensive Overview: An article covering the basics, components, and applications of universal testing machines.