The performance of papers, including packaging papers as well as consumer and technical papers, can make or break several industries. Suitable testing; aimed at assessing the physical, chemical, and functional properties of these materials, is an integral aspect of quality assurance in such cases. This blog post will explain every detail regarding the key testing services as well as techniques in relation to testing of paper and its products in an interesting manner. It is hoped as if none of the readers will be disappointed whether they manufacture paper and need to ensure that the quality of their products is acceptable in the regime imposed by various sectors or they are simply familiarizing themselves with some of the engineering challenges involved here. There are methods of examining and assessing paper products and this article is expected to assist in understanding these methods from the perspective of astronomers.

Introduction to Paper Testing

Testing is an evaluative procedure for paper and paper-based products in which the physical, chemical, and performance characteristics of the said items are determined and measured. For successful inspection, several parameters may be applied such as checking strength, fiber quality, water proofness and gloss of the paper. The inspection is possible as it is at this stage that the production of the product is verified against set standards, production processes are enhanced, and customers’ needs fully met. Moreover, such consistency is only possible because of the development of standard methods and sophisticated instrumentation for paper testing.

Importance of Paper Testing in the Industry

In order to meet the demands of the stakeholders in the industry and the end users’ requirements with regards to the different types of paper products, the functions of to ensure the quality and performance of paper are crucial. All key parameters, such as tensile strength, tear resistance, thickness and smoothness, can be measured to eliminate error, enhance the efficiency of the process of making the product, and increase the reliability of the manufacture. For instance, burst strength is sourcing for packaging materials; then if the paper is meant for graphic purposes, printability strength is expected. Thanks to standardized procedures, it is much easier to comply with international standards, and at the same time, new papers are manufactured for diverse sites such as packaging, printing, and sanitary purposes—all because standardized testing exists. Thus, comprehensive testing of paper is needed in order to sustain high quality in the market and encourage sustainability in the sector.

Overview of TAPPI Standards

The purview of TAPPI Standards encompasses a broad range of accepted international practises that allow one to assess chemical, structural, and physical characteristics of any kind of paper material, along with pulp and anything related. The paper and packaging industry almost invariably– will apply these standards to development work, quality assurance, as well as conformance testing. The TAPPI Standards address several aspects such as strength testing, light reflectance, sorption amount, and even the physical thickness of tested samples and so on clear performance expectations. Following them ensures that companies achieve and surpass all the performance requirements associated with taking products to market, while also underwriting the production of novel products via robust test methods.

Types of Paper Products and Their Testing Needs

Paper products include printing paper, tissue paper, packaging materials, specialty papers, and recycled paper, each with distinct testing requirements to ensure quality and performance.

|

Paper Type |

Key Testing Needs |

Parameters |

|---|---|---|

|

Printing Paper |

Brightness, Smoothness |

Weight, Gloss |

|

Tissue Paper |

Softness, Absorbency |

Thickness, Tensile |

|

Packaging Materials |

Strength, Durability |

Burst, Tear |

|

Specialty Papers |

Custom Properties |

Finish, pH |

|

Recycled Paper |

Purity, Strength |

Fiber, Moisture |

Types of Testing Equipment for Paper and Pulp

The primary types of testing equipment for paper and pulp include tensile testers, bursting strength testers, basis weight testers, brightness testers, moisture analyzers, tear testers, thickness gauges, and visual inspection tools.

|

Equipment |

Key Use |

Key Parameter |

|---|---|---|

|

Tensile Testers |

Measure strength |

Tensile |

|

Bursting Strength Testers |

Assess durability |

Burst |

|

Basis Weight Testers |

Check weight |

Weight |

|

Brightness Testers |

Evaluate light |

Brightness |

|

Moisture Analyzers |

Detect water |

Moisture |

|

Tear Testers |

Test resistance |

Tear |

|

Thickness Gauges |

Measure width |

Thickness |

|

Visual Inspection Tools |

Assess finish |

Texture |

Essential Laboratory Testing Equipment

Tools for investigating resistance of materials on an atomic level have been developed to be configured by or precision measurements and testing along different dimensions and performance. The equipment is aptly described as thus:

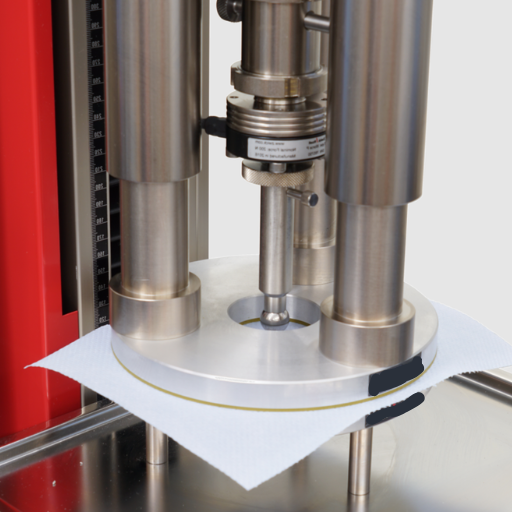

1.Tensile Testers Hell tensile tools are the testing machines with which the principle of tensile test is applied i.e. the object so is pulled in opposite directions till it fractures using the said test machine. Hence they can subject a sample to a tensile stress above the safety otherwise the limit for the material strength as well as the material quality by the help of the testers.

2.Bursting Strength Testers, otherwise known as ‘Popper’s’ work by assessing the strength of materials, especially overpackaging or textile equipment that can withstand some force before they tear.

3.The Basis Weight Tester which measures the weight of any particular material that has surfaces over areas helps assure the customers that the industry is within their weight specifications as far for example as with paper and textile industries which industries require unification of weight.

In short, the things mentioned in the above text help to make clear that the materials can be functionalized with all specifications regarding quality, resistance and production meeting the standards.

Advanced Machinery for Pulp Testing

Enhanced equipment for pulp monitoring is crucial in order to ensure both the quality and efficiency of the paper making process. Some of the major apparatus includes Freeness Testers. These claims measure the desired amenity level of the pulp in order to determine whether or not it can be used in the manufacture of paper. Fiber Morphology Analyzers, on the contrary, delivers a comprehensive analysis of the fibers such as dimensions and other properties that help determining the quality of the raw materials. Aside from that, the Burst Testers determine and measure the bursting or rupture strength of the paper and pulp so that the end trust product is maintained. These latest innovations help the manufacturers to enhance their performance in manufacturing the products and maintain the high standards required out of them by the industry.

Packaging Testing Equipment

Packaging tests equipment is a vital aspect that helps in determining the operational ability, durability and safety of any materials that are used in packaging in different industries. They are tailored In a way to mimic the real effects and pressures that any packaging systems have to go through in order to be considered efficient. One of the most commonly used devices is a Compression Tester, which allows to test products’ packaging material for ability to withstand static or dynamic loads to ensure that the structure does not collapse and is strong enough for storage and transportation. Drop Testers simulate free fall impact in order to check whether the packaging is durable enough to handle shock hazards. In addition, there are tensile strength testers that provide information on the packaging material ability to resist tears, elongation or breaking. Versatility of such test devices assures not only compliant with international norms, protects pressing issues like safety improvements, but also raises the mixture of satisfaction rates over the products.

Common Paper Testing Methods

Common paper testing methods include tensile strength testing, tear resistance testing, burst strength testing, thickness measurement, moisture analysis, smoothness testing, and basis weight measurement.

|

Method |

Purpose |

Key Points |

|---|---|---|

|

Tensile Test |

Measure stretchability |

Force, Elongation |

|

Tear Test |

Assess tear resistance |

Tear, Durability |

|

Burst Test |

Measure rupture force |

Pressure, Rupture |

|

Thickness Test |

Evaluate paper thickness |

Uniformity, Caliper |

|

Moisture Test |

Analyze water content |

Content, Stability |

|

Smoothness Test |

Measure surface finish |

Friction, Texture |

|

Basis Weight |

Check paper weight |

Mass, Standard |

Physical Testing Methods

Description of various methods of testing of materials, in this instance paper, each are important to such extent that they make the products tests better:

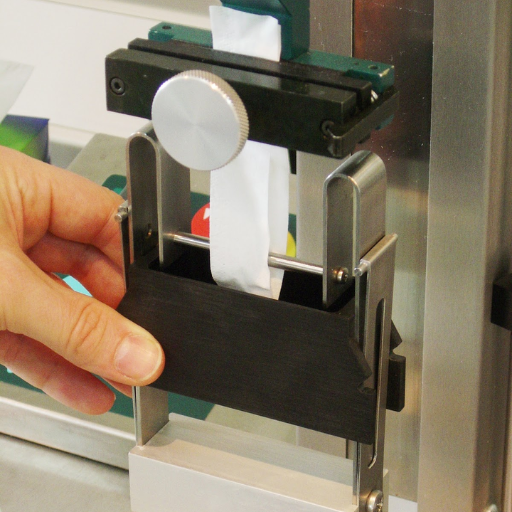

1.Tensile Test: tensile test measures[tension] the paper in order to determine the stretch of the paper as the force applied increases until a break occurs. Such an analysis tends to be extremely important in examining and evaluating the strength and the stretchability of the materials in question.

2.tear test: the durability of a material is measured using a tear test. This test looks at the characteristics of the material when subjected to a tearing force just to ensure that the material is within the toughness desired.

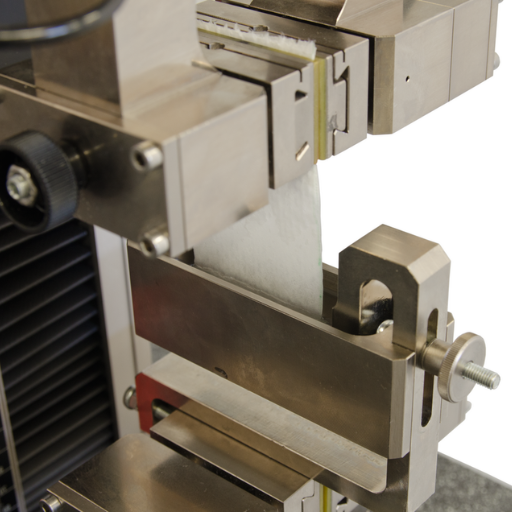

3.Burst test: To evaluate what force will rupture the paper, the paper is compressed within some limits until it breaks. The reason this task is pivotal is because it helps assess the load and harndlings which such paper is capable of sustaining.

Such tests which are based on accepted standards and procedures help to produce accurate and reliable quality products by measuring the suitability of the materials for their intended uses.

Analytical Testing Techniques

The range of analytical techniques in testing application is vast and includes many methods for precise measurement of materials’ properties and their sustainment in various environments. Meaning for example that in case of the heat resistance evaluation of certain material data and its usage, relevance use of data on common or new norms in real time allows one to address necessary changes in weave test settings. Such practice ensures the correction of testing not to only assumptions or core principles but also made towards current classless and purposes of usage thereby improving material usability and enhancing creativity.

Intertek Testing Equipment Overview

Testing equipment provided by Intertek emphasizes accuracy, expandability and quick adaptation to the needs of the different industrial sectors. Utilizing a sophisticated infrastructure and incorporating state of the art devices such as spectrometers, tensile testers and thermal analyzers, Intertek is able to satisfy existing and developing R&D requirements. Furthermore, if one considers the enormous amount of information filtering through Google’s search engine, then it can be seen that this equipment not only adheres to the international norms, but it also relocates itself in the new prevailing conditions. For example, a pattern of increased searching for information on eco development and ecological testing of materials alerts and develops trends in methodological approaches. This process enables the utilization of Intertek resources for testing purposes that are pragmatic with the constraints of today and the aspirations for the future.

Packaging Testing in the Paper Industry

When testing the systems that paper mills use in making their packages, a lot goes into ensuring that these factors are not compromised in any way. Such a process has to consider factors such as a material’s ability to resist forces like expansion, applying pressure, or retaining water over time without too much wear, and finally whether or not the material is ecologically friendly. New procedures for package testing will focus on specific aspects of performance related to the shipping, storage and use of a product. This helps limit and incorporate immediate environmental problems as much as possible.

Significance of Packaging Testing

Reasons of testing are common knowledge. However, as we delve into more detail, we can see that during the manufacturing process, the purpose of testing involves knowing the regulatory demand, ensuring the safety of the product and the final user, environmental protection, among others in general terms. Even so, it’s specific by allowing the producer to deploy the packaging constraint test, that is, testing those conditions in which packages are going to the market with materials put in them or to other destinations and simulating transport, storage or weather conditions e.g drop test compression test weather test respectively making it possible to conclude if the packages are strong enough to keep the contents secure against any mechanical or atmospheric conditions.

Moreover, it is an opportunity to find out whether the products comply with the international requirements specifically set in world standards like ISO, ASTM, ISTA, among others which in turn enhances further global acceptance and applicability of the products. This process goes a long way to aiding in the process of minimizing waste by defining the efficient utilization of material as well as developing designs that can be recycled and that make use of minimum resources as possible. By investigating potential weaknesses in packaging, businesses aid in reducing supply chain costs and improvement of their service delivery leading to customer satisfaction whilst ensuring that their green strategy targets are met.

Innovations in Packaging Testing Methods

The innovation regarding packaging testing methods is advanced and modern enough to change, primarily for better accuracy, performance and quality’s perspectives.

Today automation and predictive analytics combine to play a lot of these roles. In other words, artificial intelligence must be applied to packaging data in real time or even in a forecast manner using big data analytics. With the growing concern of environmental issues, science has made the testing of packaging possible with the use of sustainable materials and greener energy methods. There is also physical simulation using advanced computers to assess the performance of the design package under very high pressure operations not using any physically created model. Application of these modern technologies is drastic for it shortens the time and expenses for the production and also the advantages of efficient machining processes are very visible.

Industry Standards for Packaging Products

It is important to take note of all of the requisites needed in maintaining the safety, operation, and the growth of packaging products. As the industry grows with the size of business, some organizations like ISO, ASTM along with certain regional regulations set up standards for obtaining the highest possible quality. Take the ISO 18601 series as an example, it is a comprehensive set of standards for sustainable packaging, while ASTM D 4169 deals with simulated performance testing protocols and methods for diverse material types. Most times, to ensure the ability of the package to withstand these conditions as well as the regulations, manufacturers will seek out compliance with these standards. Products are made to last as per the approved specifications and pattern therein and the effects on the natural environment are minimised in coherence with the recycling discourse.

Future Trends in Paper and Pulp Testing

The paper and pulp industry growth is shifting towards advanced data driven methodologies to improve testing accuracy and workload. Automation and artificial intelligence are also expected in laboratory workflow optimization, utilization in process monitoring to control and expectation on material properties in a proactive way and enhance the laboratory processes. Besides, additional developments in testing techniques without effective alteration on examined objects are more prevalent now, thus making it possible to increase the quality of assessment without ruining a tested sample. Furthermore, development of testing methodologies for the new eco-friendly and bio based plastic and new recyclable materials is becoming more noticeable in the industry. All these tendencies are aimed overall at improving testing processes, facilitating the industries to adhere with regulations and boosting the development of green materials.

Innovations in Testing Technology

One of the greatest testing innovations involves deploying sophisticated automation and AI based analytics to increase both levels of accuracy and performance. Non-destructive testing techniques such as ultrasonic inspection and X-ray imagining are being employed more for effective information acquisition without any degradation of the sample. Also, advancement in sensor systems facilitates application with real time measurement and monitoring thereby increasing motivation for production quality control. This, along with fine-tuning sustainability concepts, accounts for most of the proactive measures as far as testing is concerned.

Sustainability and Testing in the Paper Industry

The resolution to sustainable healthy operating in the paper industry is mainly focused on activities such as clever handling of raw materials, lowering the water and energy use, recycling, among others. By precision while retaining the product attributes, the technological advancement in testing benefits this idea as well. For example, fiber morphology and pulp testing determine the suitability and longevity of a material thus eliminating extravagant use of raw materials. Moreover, environmental tests check for release of pollutants and discharges as per the process, and are very useful for maintaining environmental compliance during production.

The Impact of Digitalization on Testing Services

One of the effects of digitalisation on testing services is that automation is achieved in real time. Digital technologies have transformed the concept of testing, allowing faster, simpler and more efficient paradigms. Such systems already exist, for instance data acquisition accompanied by analysis systems that help in easy recognition of issues while improving accuracy in decision making. Additionally, the use of digital platforms in managing test papers helps to centralize work and also improves the process of traceability of tests and their conformance to industry norms. With this change, testing cycles become shorter and a better quality of the product is achieved alongside the regulatory compliance and sustainability in the production.

Reference Sources

-

Stable Micro Systems – Paper and Cardboard Testing Methods: Covers various testing methods like Box Crush Test, Flexural Stiffness Test, and more.

-

ZwickRoell – Paper Testing Methods: Provides insights into ISO and TAPPI standards for paper testing and specialized devices.

-

Applied Paper Technology – Paper Testing E-Book: Discusses resistance testing for paper and paperboard surfaces, including abrasion tests.

-

Fogra – Paper Testing & Specifications: Details testing processes like tearing force measurement and other specifications.

-

Measurlabs – Laboratory Testing Services for Paper and Board: Offers accredited lab tests for evaluating paper’s suitability for various applications, including food and medical packaging.

Frequently Asked Questions (FAQs)

Q:What is the role of a testing lab in paper and paper products testing?

A: A testing lab plays a crucial role in the paper and paper products testing process by conducting various assessments to ensure quality and compliance with industry standards. These labs utilize advanced techniques and equipment to perform physical and analytical testing, including evaluating properties such as tensile strength, water absorption, and the effects of humidity on paper materials. They provide reliable test results that help manufacturers and consumers make informed decisions regarding paper technology and performance.

Q:How does pulp and paper testing impact product quality?

A: Pulp and paper testing significantly impacts product quality by identifying the physical and chemical properties of paper materials. Through tests like SGS-IPS testing and TAPPI paper testing, manufacturers can assess aspects such as fiber composition, adhesive strength, and compressive strength of paper. This data helps ensure that the final products meet quality standards and performance expectations, leading to greater customer satisfaction and reduced waste.

Q:What types of technical associations are involved in paper testing?

A: Numerous technical associations are involved in paper testing, providing guidelines, standards, and resources for testing procedures. Organizations like TAPPI (Technical Association of the Pulp and Paper Industry) develop testing methods that ensure the reproducibility and accuracy of test results. These associations also offer training and certification for testing experts, helping them stay updated on the latest advancements in paper technology and testing methodologies.

Q:What are the common physical properties tested in paper and cardboard materials?

A: Common physical properties tested in paper and cardboard materials include tensile strength, bending stiffness, compressive strength, and water absorption. These tests are essential for evaluating the performance of materials, particularly for applications like corrugated board, which requires a balance of strength and flexibility. Additionally, tests for optical properties, such as brightness and opacity, are conducted to ensure the aesthetic quality of paper products.

Q:How is humidity controlled during paper testing?

A: Humidity is controlled during paper testing to simulate real-world conditions and evaluate the performance of paper products under various environmental factors. Testing labs often use controlled environments to maintain relative humidity (RH) levels at specified values, typically around 23°C and 50% RH. This ensures that test results accurately reflect how paper materials will behave in different humidity scenarios, impacting their usability and durability.

Q:What is the significance of migration testing in paper products?

A: Migration testing is significant in paper products as it assesses the safety and compliance of materials that may come into contact with food or sensitive applications. This testing evaluates the potential transfer of chemicals, such as heavy metals or additives, from paper and cardboard materials into the product they are packaging. By conducting migration tests, manufacturers can ensure that their products meet safety regulations and do not pose health risks to consumers.

Q:What specific tests are included in TAPPI paper testing?

A: TAPPI paper testing includes a variety of specific tests designed to measure the physical and chemical properties of paper products. These tests cover aspects such as tensile strength, tear resistance, thickness, and brightness. Additionally, TAPPI tests may involve evaluating the water absorption capacity and fold endurance of paper, providing a comprehensive view of a material’s quality and functionality in its intended application.

Q:How do testing capabilities vary among different testing labs?

A: Testing capabilities can vary significantly among different testing labs, depending on their equipment, expertise, and accreditation. Some labs may specialize in physical testing of paper, while others might focus on chemical analysis or migration testing. The range of tests offered, the precision of the apparatus used, and the lab’s adherence to industry standards play crucial roles in determining the quality of test results and the reliability of the data produced.