Introduction to the Plastic Index Test

The Plastic Index Test is a basic soil mechanics procedure to ascertain the plasticity of a soil by considering the difference between its liquid limit and plastic limit. These limits are the moisture contents at which soil states change: from a liquid state to a plastic state, and then from a plastic state to a semi-solid one. The plasticity index presents a quantitative expression of the soil’s ability to undergo deformation without cracking or crumbling, which is very critical for ascertaining the suitability of soils for construction and geotechnical purposes. This test affords engineers the opportunity to design more stable structures by considering the behavior of the soil with changes in moisture content.

What is the Plastic Index Test?

The Plastic Index test is basically a geotechnical test to determine the range of moisture content for which a soil will remain plastic. Plastic in this context refers to that condition of the soil which allows it to be molded without breaking into pieces, thus giving an indirect measure of the cohesive strength and behavior of the soil under applied forces. Saying technically, the Plastic Index is the mathematical difference of the liquid limit and the plastic limit of a soil sample determined using the Atterberg limits as standardized measurements.

With incoming research and extremely recent information, the Plastic Index Test has proven itself an essential instrument in current engineering practices. For example, it has been ascertained that it plays a major role in the recognition of clay soils that impart volume changes of magnitudes as the condition of the clay changes with the moisture content. This swelling and shrinking of the clays are adversely affecting the stability of the foundation of buildings, roads, etc. With correct PI value, engineers grade soils for particular applications, determine their shrink-swell potential, and work out suitable remedial measures to counteract the harmful behavior of problematic soil. It speaks volumes for the test that it has helped in good geotechnical investigations and further in ensuring safer and more durable infrastructure.

Importance of Plasticity Index in Soil Analysis

The Plasticity Index (PI) is an important parameter in soil analysis, offering clues about the make-up of a soil and its potential engineering behavior. The PI is derived from the difference between the liquid limit and the plastic limit; it defines the cohesiveness of a soil and its ability to deform when exposed to changes in moisture. Soils having very high PI values are largely expansive clays composed of silts and can swell up considerably with moisture, while soils with low values are relatively non-plastic and hence more stable. These factors are important in judging the suitability of the soil in construction work such as foundations, road pavements, and earth dams, and in the design of suitable stabilizing methods for unstable soils. With data on PI at their disposal, engineering professionals can ensure safer and more durable works in a number of geotechnical applications.

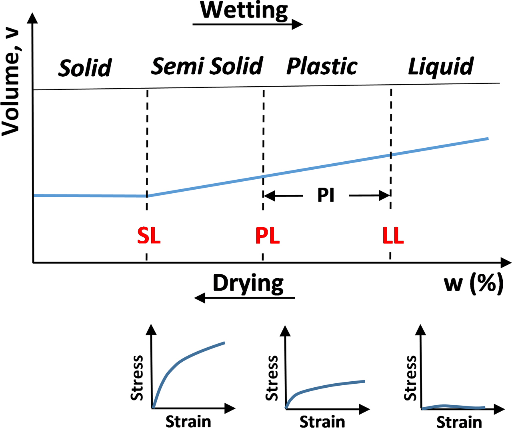

Overview of Atterberg Limits

Atterberg limits refer to three extremely important threshold points: shrinkage limit (SL), plastic limit (PL), and liquid limit (LL). The paid ones transiting from one state to another represent changes in fine-grained soils with their moisture content. These given limits are generally determined by testing, which, in turn, gives us an insight into plasticity and workability of the soil.

A liquid limit (LL) describes the moisture content above which soils behave like liquids, determined either by Casagrande’s cup method or by the fall cone test. Plastic limit (PL) defines the lowest moisture contents at which the soils gain sufficient plasticity to be recorded as a test with standard procedures: the soil is rolled into threads of 3mm diameter, which begin to crumble. It also numbers the plastic index (PI) that details the range of soil moisture service as plastic (PI = LL – PL).

Test Methods for Liquid Limit and Plastic Limit

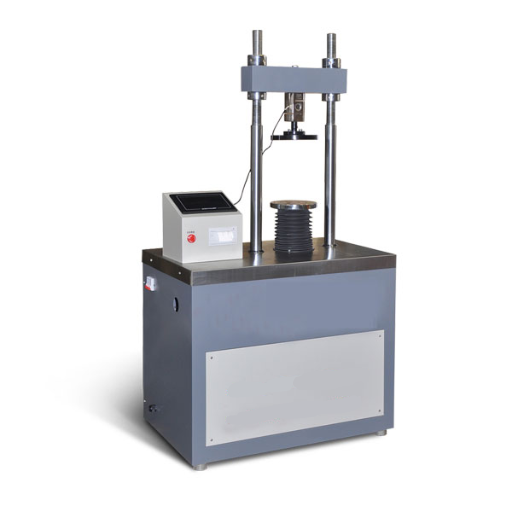

Liquid limit measurement involves two primary methods. First, a grooved brass cup holding a soil paste is struck to effect a separation. The cup is dropped from 10-mm height repeatedly until the groove, of standard length 12.7 mm, closes. The number of blows required to close the groove is recorded and extrapolated to 25 blows to get the LL from a flow curve. Second, the fall cone test penetrates a standard cone into the soil paste under a specific load and time, with LL depending on the penetration depth.

The plastic limit (PL) consists of rolling a soil sample into threads on a flat, smooth desk. The procedure consists of lowering the moisture content until the soil threads start to crumble at 3 mm diameter. This critical moisture level, at which the soil goes from plastic to semi-solid behavior, is recorded as the PL. These methods would give consistent and reliable data toward classification and analysis of soils.

Standard Test Methods for Liquid Limit

Soil liquid limits are determined through a series of standardized tests such as ASTM D4318 or the modifications thereof. One generally applied method involves the Casagrande cup in which a soil sample is placed under it and a groove is cut through the center of the sample. The cup is lifted and dropped thence from a fixed height while recording the number of blows it takes for the groove to close a distance of 0.5 mm. The moisture content at which the groove closes with exactly 25 drops is termed liquid limit; however, the cone penetrometer test at contrasting moisture levels has also been used to determine the LL by measuring the penetration depth of the cone into the soil. Both procedures are widely accepted because of their reliability in determining soil consistency and behavior with changing moisture content and, hence, are of utmost importance in geotechnical analyses.

Conducting the AASHTO T90 Test

The AASHTO T90 test is known as the standard test that determines the plastic limit and plasticity index of soils by subjecting fine-grained soils to systematic and precise steps based on their characteristics. The soil sample is air-dried and sieved through the No. 40 sieve for a uniform sample of fine soil particles. A minuscule portion of the sample is slowly wetted with distilled water until it is in a plastic state.

To determine the plastic limit, a one-eighth of an inch diameter thread is rolled from the soil sample on a flat surface. The plastic limit is the water content at which the soil thread crumbles when rolled. For the plasticity index, the numerical difference between the liquid limit (LL) and plastic limit (PL) is determined to give a measurement of the range of plasticity of a soil.

Performing the AASHTO T90 test with accuracy is paramount when distinguishing soil behavior for engineering purposes in a myriad of applications. The data generated are used in assessing soil stability, working characteristics, and acceptability as construction materials in providing crucial input into geotechnical design and decision-making.

Step-by-Step Procedure for Plastic Limit Testing

- Soil Sample Preparation: Obtain a representative soil sample that passes through the No. 40 (425 µm) sieve. Be sure that the sample is devoid of extraneous matter such as organic materials or debris.

- Moisture Adjustment: In case the sample is dry, a few drops of distilled water need to be added. Then the soil needs to be mixed thoroughly until moldable and at the same time not sticky.

- Making Soil Threads: A portion of the prepared soil is taken, transformed into an elliptical shape, and rolled between the palms of the hands or on a rolling board to generate a thread approximately 3 mm (1/8 inch) in diameter.

- Rolling and Observing for Cracking: Continue rolling the thread until crack appears or it begins to crumble. In an all-too-contradictory situation, when the thread fails to crack at the set diameter, the test is halted to allow the soil to dry out slightly before reasserting itself in the rolling process.

- Thread Condition: At the moment the soil thread commences to come on cracks, the soil thread is measured. Portions of the crumbled threads are collected for the determination of moisture content.

- Retesting: Repeat rolling with other portions of soil for confirmation. At least three trials should be made and the results found to be within close range of each other.

- Determination of Moisture Content: The failed soil threads are gathered and transferred to pre-weighed moisture content cans, which are dried in an oven at 110 ± 5°C until constant mass is attained.

- Calculate the Plastic Limit: Measure the moisture content of the dried soil sample. The plastic limit marks the moisture content where soil ceases being plastic and begins to be semi-solid.

- Report the results: The moisture content values from all trials are averaged, and the final plastic limit value is reported nearest to an integer for use in soil classification and analysis.

Significance of the Plasticity Index in Various Industries

The plasticity index is an important parameter in dealing with soil behavior and its applications. In construction and geotechnical engineering, the PI along with other parameters has been studied to specify whether a soil will wash out, compact nicely, or if opening a water channel through it will be unheroic to… all of which finally affects the decision of foundation design. For agriculture, it would give the potential for working the soil or the drainage capacity of the soil, a prerequisite for crop management and land use planning. For the transportation industry, although PI checks the deformability of soil over which road or pavement constrains are designed. This index is utilized in soil-type classification and hence to predict soil behavior when mechanical loadings act under varying conditions.

Construction & Geotechnical Engineering

Determines soil suitability for foundations, assesses compaction potential, and guides foundation design decisions.

Agriculture

Evaluates soil workability and drainage capacity, essential for crop management and land use planning.

Transportation

Assesses soil deformability for road and pavement design, ensuring structural integrity under varying loads.

Applications in Manufacturing

This Plasticity Index (PI) is of paramount importance in the industries of ceramics, construction materials, and metalworking. In ceramics, the PI determines the workability of clays, ensuring that materials may be suitably shaped without cracking or fracture into drying and firing. Similarly, with construction materials such as bricks and tiles, the index ensures the optimum compositions so that the material shall be consistent and durable. For metalworking lubricants and adhesives, the index enables them to perform optimally under various conditions. Hence, it is a measurable index guaranteeing confidence in processes where material deformation characteristics are key.

Role in Construction Projects

The Plasticity Index, or the PI, is an important factor in the assessment of the property’s suitability for a construction. It is basically a measurement of the workability, stability, and form-retaining ability of an earth material under varying moisture conditions. A very low PI value means the soil is basically more granular in nature with almost nil possibilities of expansion or shrinkage; hence, such soil is considered suitable for laying foundations and doing load-bearing construction on it. Conversely, a very high PI signifies the soil with clayey nature that may adversely affect shrink-swell behavior, thus requiring detailed stabilization techniques. Of course, engineers further use the PI to judge soil compaction, foresee settlement-related problems, or tailor the blending of materials to enable a firm mass with sound construction leading to structural integrity and life.

Impact on Packaging Materials

The Plasticity Index (PI) tends to get alongsidefor the selection and performance of the packaging materials especially in industries demanding stable and reliable resistance to environmental conditions. A lower PI value mostly means that the soil, being granular or sandy in nature, exhibits minimized risks of retaining moisture and undergoing deformation. This trait is favorable for packaging materials within contexts wherein dimensional stability and rigidity are required, such as shipping containers or structural protective layers.

In contrast, materials with a high-plasticity index, usually corresponding to high-clay content, tend to show much shrink-swell behavior due to moisture variations. This can expose the packaging to cracking, warping, and moisture damage, thereby reducing the effectiveness and lifespan of the packaging. Hence, plastics and polymers for packaging should be modified with additives or formulated as composites to counteract any adverse characteristic arising from high plasticity. Through accurate testing and adjustments to the material, manufacturers are able to resist structural and moisture degradation impingement, therefore upholding packaging specifications under assorted environmental conditions.

Benefits of the Plastic Index Test

Plastic Index test gives vital data about the deformation characterization and flow pattern under stress, an information required by manufacturers to consider a given material to be suitable for some applications. Through analyzing the plasticity range, the plastic index test helps in better performance of the product, in minimizing mechanical failures, and in optimizing material formulation. In addition, it helps with the enforcement of acceptable industrial standards, durability of packages, and the creation of more environmentally sound and good quality packaging alternatives.

Improving Material Quality

A Plastic Index tests several critical properties of materials to improve material quality. The test precisely assesses the performance characteristics of a particular material under a variety of conditions so that it may be deemed more durable and reliable. Defect reductions based on optimal processing parameters are thus less likely to occur, resulting in improved product consistency regarding brittleness or warpage. It should assist manufacturers in assuring that their products conform to regulatory standards and specifications, encourage innovation in material formulating, and decrease wastage during their manufacturing process, thereby making manufacturers greener and more efficient.

Ensuring Compliance with Industry Standards

In the past, as well as today, companies must have been ensuring compliance set forth by the industry standards in their manufacturing operations and materials. This also covers quality checks, especially as defined by standardized tests such as ISO, ASTM, or other methods applicable to the process, with proper documentation of the tested procedure. These work practices demonstrate to an organization its conformity with environmental, safety, and performance standards, thereby cementing stakeholder relations and eliminating other sources of brand risk. Meanwhile, knowledge of new standards ensures opportunities for further improvement and keeping pace with the industry’s advancement.

Minimizing Waste in Production Processes

This test measures the flow properties of a plastic with great accuracy, a fact that allows it to be used by manufacturers for process optimization and waste reduction. The melt flow rate or melt index is a consideration in this test in order that accurate choices may be made with respect to specific materials, with regard to consistent production quality and requirements for particular manufacturing operations. It also detects changes in material properties early in the process, so that costly mistakes such as producing an excess or rejecting the material may be avoided.

Implementing the Plastic Index Test conceptually provides for the diminution of raw material consumption by optimizing operational parameters like temperature and pressure. To the end that we use our resources efficiently, fine-tuning operations not only accounts for energy conservation but also helps in marshalling environmental protection. Data outputs from these tests may be used further down the line in recycling to determine whether recycled polymers are fit-for-use or not. In general, the Plastic Index Test helps fray into the production workflows for guaranteeing better control over quality, resource optimization, and waste reduction are all measures that economically sustain environmental sustainability.

Advancing Material Science through Plastic Index Testing

Plastic Index Test works as an edge to the advancing material science that deals with constituting precise measurement of properties of polymers like melt flow rate, density, tensile strength, etc. These properties help hence the researchers and the manufacturer to check the performance of the materials better, optimize the formulations, and enhance final research into novel ones and sustainable polymers. Working with tests of this nature in material science creates the possibility for industries to institute solutions to polymer technology intervention both on technical and environmental fronts, hence promoting the advancement of the polymer technology industry.

Fostering Innovation in Material Properties

Before focusing on its uses for determining the consistency of material and its processing characteristics, I wish to indicate some of the treatment polishes used in explanation of their importance-giving. Analyzing material properties involving viscosity and elasticity changes and consequently changes in the flow behavior will correspondingly give substantive information for processing and polymer tailoring for a particular application. Application of material property is a new approach taken seriously and considered for the polymer production and characterization purposes. Keeping in safety control check with the flow test will ensure utmost precision in their engineering and thereby laying down the materials that are in contrast to all other existing high-performance environmentally conscious plastics.

Promoting Sustainability in Industries

Being an important test contributes to sustaining industries by allowing correct material evaluation and selection for applications. This test measures important parameters such as melt flow index (MFI), which is related to the rate at which a given polymer flows under specified conditions. By establishing rheological properties of plastics, the test ensures that correct materials are chosen for applications where durability, recyclability, or energy efficiency are of concern. It also helps manufacturers by minimizing the wastage of materials, maximizing efficiency in production, and making products that pose less harm to the environment. The plastic index test assists in checking plastics for their consistent quality and correlated development into the right kind of materials for sustainable plastic solutions so that actions of industries become in harmony with the worldwide ecological goals.

The Future of Plasticity Index Research

The present-day plasticity index research is anticipated to be directed toward innovations that increase precision and applicability in different industries. New tools and techniques have come up to measure the plasticity index more precisely so that scientists can develop their materials for peculiar applications. Machine learning and artificial intelligence are increasingly being used to analyze large datasets to predict the behaviors of materials more efficiently and streamline the research process. At the same time, there is a trend toward incorporating green technology, such as the assessment of the plasticity index of biodegradable and recycled materials, onto sustainability platforms.

The creation of new standards and testing methods is being driven by joint research activities conducted by academic institutions, industry leaders, and government agencies. These intentional efforts are to expand the utility of plasticity index testing to other industries in new-wage specializations such as advanced robotics and energy storage. By promoting such activities, plasticity index research constantly evolves, furnishing solutions aligned with scientific and environmental values.

Reference Sources

-

Plasticity Index – Soil Performance Guide

This guide explains the plasticity index and its significance in soil performance. -

D4318 Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils

This standard provides detailed test methods for determining the plasticity index of soils. -

Atterberg Limits: A Quick Reference Guide

A quick reference guide to Atterberg limits, including the plasticity index and its calculation. -

Plasticity Index of Soil

This source provides a detailed explanation of the plasticity index and its calculation. -

Atterberg Limits – Wikipedia

A comprehensive overview of Atterberg limits, including the plasticity index and its role in soil mechanics.