Instrument And Equipment Wholesale

Premium Plastic Testing Equipment Manufacturer in China

Explore our High-Performance Plastic Testing Equipment, crafted by a leading manufacturer in China renowned for innovation and reliability. This advanced machinery is engineered to perform precise tensile strength, impact resistance, and thermal stability tests, ensuring compliance with international plastic industry standards. Built with eco-friendly materials and cutting-edge technology, it offers customized solutions to meet diverse testing needs.

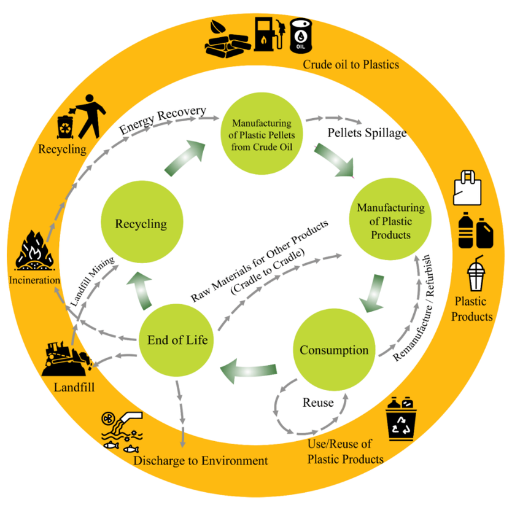

What Is A Plastic Testing Equipment?

-

Evaluates the strength and quality of plastic materials by simulating real-world stress conditions, ensuring durability and performance under various environmental factors.

-

Tests critical properties such as tensile strength, impact resistance, hardness, and thermal stability, providing comprehensive data for material analysis.

-

Utilized in the plastic manufacturing industry for quality assurance, product development, and adherence to safety and regulatory standards.

-

Equipped with advanced sensors and software for precise measurements, detailed data recording, and in-depth analysis of plastic properties.

-

Available in multiple configurations to test diverse plastic products, from packaging materials to industrial components, ensuring versatility.

Essential Tests You Can Perform With A Plastic Testing Equipment

Discover the comprehensive testing capabilities of Plastic Testing Equipment. This advanced machinery ensures precise evaluation of plastic properties under controlled conditions, providing critical data for development, design, and quality control.

Tensile Strength Test

Assess the plastic’s ability to withstand pulling forces by stretching it until it breaks. This test measures the material’s maximum load capacity and elongation, ensuring it meets durability standards for various applications.

Thermal Stability Test

Measure the plastic’s performance under extreme temperatures by exposing it to heat and cold cycles. This test ensures the material maintains its integrity and functionality in diverse environmental conditions.

Impact Resistance Test

Evaluate how well the plastic endures sudden forces by subjecting it to high-impact strikes. This test determines the material’s toughness and ability to resist cracking or breaking under stress.

Hardness Test

Determine the plastic’s resistance to surface deformation by applying controlled pressure. This test provides insights into the material’s durability and suitability for applications requiring high wear resistance.

How to Choose the Right Plastic Testing Equipment?

- Identify the specific tests required for your plastic materials or products (e.g., tensile, impact, thermal stability, hardness).

- Ensure the equipment includes the necessary features and attachments to perform these tests on various plastic types.

- Verify that the machine’s test parameters (load, speed, temperature range) match the properties of the plastics you’ll test.

- Choose equipment that complies with international plastic testing standards (e.g., ASTM, ISO) for reliable and consistent results.

- Consider the machine’s durability, precision, and the manufacturer’s reputation for support and calibration services.

What are the Uses of Plastic Testing Equipment?

- Plastic Manufacturing: Tests the tensile strength, impact resistance, and flexibility of raw materials to ensure production quality.

- Packaging Industry: Evaluates the durability, tear resistance, and thermal stability of plastic films for safe packaging solutions.

- Automotive Parts: Assesses impact strength, hardness, and heat resistance of plastic components for safety and performance.

- Material Development: Used to test the physical properties of new plastic compounds for innovative applications and improvements.

- Quality Assurance: Employed by labs to perform standard tests (e.g., ASTM, ISO) on finished plastic products for certification.

Components Of Plastic Testing Equipment

Discover a comprehensive selection of precision-engineered components, including parts, fixtures, sensors, and more, all crafted to conduct thousands of industry-standard plastic tests. When you're ready to customize your setup, connect with our experts who will work with you to tailor the system to your specific testing requirements and budget.

View Our Plastic Testing Equipment Price

Top plastic testing equipment crafted for your needs, our cutting-edge technology ensures reliable quality efficiently.

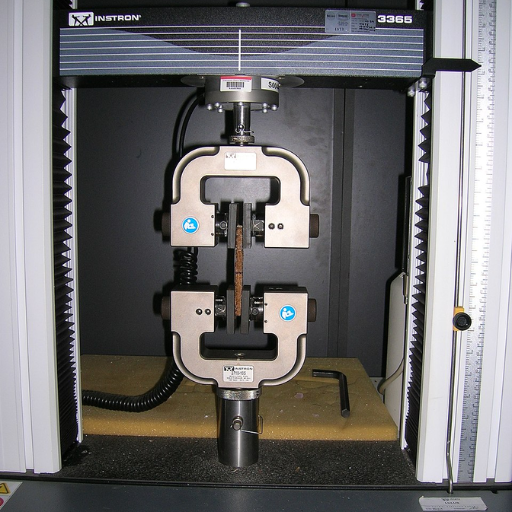

Plastic testing machine

Discover our advanced Plastic Testing Machine, designed for precise tensile, impact, and thermal tests. Ensures quality with cutting-edge sensors. Ideal for labs.

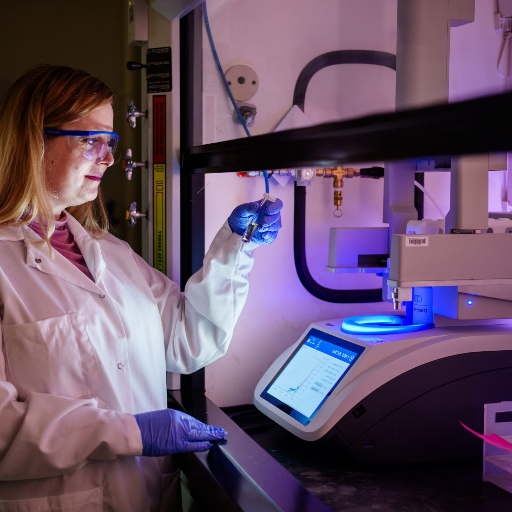

Other plastic testing equipment

Explore our range of Plastic Testing Equipment, including a test chamber and measuring instruments. Built for durability and accuracy in material analysis.

Plastic Testing Equipment Data Overview

| Parameter | Details |

|---|---|

| Load Capacity Range | Ranges from 0.05 N for light testing to 80 kN for heavy-duty applications. |

| Testing Versatility | Supports tensile, impact, hardness, and thermal stability tests. |

| Accuracy and Precision | Features high-precision sensors with ±0.5% accuracy and digital controls. |

| Environmental Conditions | Operates from -20°C to 60°C and 10% to 85% RH for real-world simulation. |

| Software and Automation | Includes intuitive software with automated data logging and analysis. |

| Speed Range | Adjustable from 1 mm/min to 500 mm/min for precise testing control. |

| Crosshead Travel | Offers up to 400 mm displacement for flexible specimen testing. |

| Extensometer Integration | Supports integrated or external extensometers for accurate strain data. |

| Power Supply Options | Compatible with 110V/60Hz or 230V/50Hz, depending on regional needs. |

| Safety Features | Equipped with overload protection, safety guards, and emergency stop. |

Why Choose Our Plastic Testing Equipment Manufacturers

We are committed to providing high-quality Plastic Testing Equipment with unmatched precision and reliability. Whether for research or production, we offer tailored solutions to fit your requirements.

As industry leaders in plastic testing, we leverage years of expertise to deliver robust equipment. Our designs ensure accurate tensile, impact, and thermal tests, using advanced technology and durable materials for consistent performance.

What Our Client Says

Understand from our clients what they say about doing business with us and the unique value addition we provide.

Expert Insights on Plastic Testing Equipment

How do you test for plastic?

Universal testing machines evaluate plastic by performing tensile, compression, and flexural tests. Samples are subjected to controlled forces to measure strength, elongation, and deformation, ensuring the material meets performance and durability standards for its intended use.

What tools are used to measure plastic?

Tools include universal testing machines for tensile and compressive strength, hardness testers like Shore or Rockwell, impact testers for toughness, and thermal analyzers for melting points. Extensometers and strain gauges measure deformation accurately.

What is the identification test for plastics?

Identification tests for plastics involve methods like the burn test to observe flame color and odor, density testing by flotation, and FTIR spectroscopy to analyze molecular structure. These help determine the type of plastic, such as PE, PP, or PVC.

What is the plastic analysis method?

Plastic analysis methods include mechanical testing (tensile, impact), thermal analysis (DSC, TGA for melting and decomposition), and spectroscopy (FTIR, NMR) for composition. These methods assess physical properties, chemical makeup, and performance under stress.

How to check plastic grade?

To check plastic grade, perform mechanical tests like tensile strength and hardness, and use spectroscopy (FTIR) for chemical composition. Compare results with standards like ASTM or ISO, which define grades based on properties like durability and heat resistance.

What is the test standard for plastics?

Common test standards for plastics include ASTM D638 for tensile properties, ISO 178 for flexural strength, and ASTM D256 for impact resistance. These standards ensure consistent, reliable testing for quality control and compliance in various industries.

Latest Blog Posts

Maintain Inventiveness by Following The Blog for the Latest Best Practices, Techniques, Innovations, and Insights in the Field.

The behavior of soil under some conditions is a critical consideration in civil-works and geotechnical projects. Plastic Limit and Plasticity […]

Modern societies cannot exist without plastics, being the linchpin of innumerable industrial activities: packaging, automotive, medical, and consumer goods among […]

In the scope of plasticity tests, the plastic limit test is one of the simplest in dry-sample texturing. It provides […]

Top Böhme Abrasion Tester in China. Costs, effectiveness, versatility, and durability are only a few reasons why PVC (Polyvinyl Chloride) plastic […]

Top Böhme Abrasion Tester in China. The field that bridges the world of materials science and engineering is perhaps one of […]

Top Böhme Abrasion Tester in China. From manufacturing to construction and from packaging to product design, almost every industry greatly relies […]

Elevate Your Plastic Quality with Our Testing Equipment

Enhance your plastic manufacturing with our cutting-edge Plastic Testing Equipment. Designed for precision, it conducts tensile, impact, and thermal tests, ensuring durability and compliance with global standards like ASTM and ISO. Built with advanced sensors and durable materials, our machines offer tailored solutions to boost production reliability and efficiency. Contact us today to explore customized options and elevate your quality control.

Frequently Ask Questions

Q: What are the common plastic testing methods?

A: Plastic testing methods include tensile testing to measure strength, impact testing for toughness, hardness testing for surface durability, and thermal analysis for heat resistance. These methods assess mechanical, thermal, and chemical properties to ensure quality and performance.

Q: What is the equipment testing procedure?

A: The equipment testing procedure involves calibrating the machine, preparing standardized plastic samples, setting test parameters (e.g., speed, load), conducting the test, and analyzing data. Regular maintenance ensures accuracy and reliability of results.

Q: What is plastic bottle testing equipment?

A: Plastic bottle testing equipment includes pressure testers for burst strength, wall thickness gauges for structural integrity, and drop testers for impact resistance. These tools ensure bottles meet safety and durability standards for packaging.

Q: What is a plastic tester?

A: A plastic tester is a specialized device, like a universal testing machine, used to evaluate plastic properties such as tensile strength, elongation, and hardness. It helps in quality control and material selection for various applications.

Q: What is plastic lab testing equipment?

A: Plastic lab testing equipment includes universal testers, melt flow indexers, and environmental chambers. These tools are used in controlled settings to analyze mechanical, thermal, and environmental performance of plastic materials.

Q: Who are the testing equipment manufacturers?

A: Manufacturers like Qualitest, Instron, and Presto Group produce plastic testing equipment. They offer a range of devices for tensile, impact, and thermal tests, ensuring compliance with international standards like ASTM and ISO.

Q: What does testing of plastics involve?

A: Testing of plastics involves evaluating tensile strength, impact resistance, hardness, and thermal stability. It ensures materials meet industry standards, supporting quality control, product development, and safety compliance.

Q: What equipment is used for plastic bottle testing?

A: Equipment for plastic bottle testing includes hydrostatic pressure testers, drop weight impact testers, and thickness gauges. These assess pressure resistance, impact durability, and structural integrity for safe packaging solutions.