Instrument And Equipment Wholesale

High Quality Plastic Testing Machine Manufacturer in China

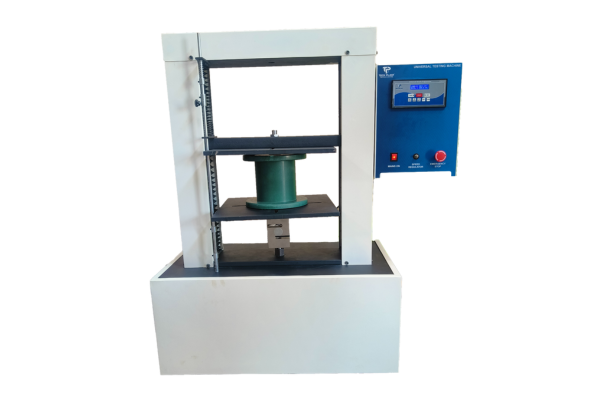

Introducing our advanced Plastic Testing Machine, a precision-engineered solution designed for accurate evaluation of plastic materials. This cutting-edge system assesses critical properties like tensile strength, impact resistance, and thermal stability, ensuring compliance with global standards. It’s ideal for quality control and research in the plastics industry.

What Is A Plastic Testing Machine?

-

A Plastic Testing Machine is a precision device used to assess the mechanical properties of plastics, such as tensile strength and impact resistance.

-

It operates by applying controlled forces to plastic samples, measuring deformation, strength, and durability under various conditions.

-

The machine provides detailed data on elongation, hardness, and thermal stability to ensure material quality.

-

This testing is standardized (e.g., ASTM D638, ISO 527) and supports quality control in manufacturing and research.

-

Equipped with advanced sensors and software, it delivers reliable results for material development and compliance testing.

Main Features of Plastic Testing Machine

Plastic Testing Machine enables detailed analysis of materials under controlled conditions, providing critical data for research, development, and quality assurance.

Tensile Strength Test

Accurately measures the force required to stretch plastic samples, evaluating their maximum load capacity and elongation for reliable performance data.

Thermal Stability Test

Quantifies the plastic’s performance under varying temperatures, ensuring stability and integrity for applications in diverse environments.

Impact Resistance Test

Assesses the ability of plastic to withstand sudden forces, determining toughness and durability under controlled impact conditions.

Hardness Evaluation Test

Measures the plastic’s resistance to surface indentation, providing insights into durability and suitability for demanding applications.

Plastic Testing Machine For Sale

Digital Cantilever Beam Impact Tester

Measure plastic impact strength with precision using this digital tester. Compliant with ASTM D256, it ensures reliable Charpy and Izod tests.

Drop Hammer Impact Tester

Assess plastic durability with this tester, simulating real-world drops. Features adjustable heights and weights for accurate impact resistance data.

Simple Support Beam Charpy Impact Tester

Evaluate plastic toughness with this Charpy tester. Designed for simple support beam tests, it meets ISO 179 standards for consistent results.

Horizontal Vertical Burning Tester

Test plastic flammability with this versatile burning tester. Supports horizontal and vertical tests per UL 94 standards for safety compliance.

Plastic Testing Machine Technical Specifications

| Parameter | Details |

|---|---|

| Applicable Materials | Suitable for testing thermoplastics, composites, films, and rigid plastics. |

| Standards Compliance | Designed to meet global standards (e.g., ASTM D733, ISO 527, EN 10002). |

| Load Application | Features adjustable force application from 0.1 N to 100 kN for testing. |

| Test Speed & Control | Includes precise speed settings from 1 mm/min to 500 mm/min for accuracy. |

| Measurement Method | Allows evaluation of tensile strength, elongation, and hardness precisely. |

| Sample Compatibility | Accommodates various sample sizes and shapes per testing requirements. |

| Automation Features | Offers programmable test sequences and automatic data logging for ease. |

| Data Output | Provides detailed reports on stress, strain, and thermal properties. |

| Safety Features | Includes overload protection, emergency stop, and safety interlocks. |

| Environmental Range | Operates in temperatures from -20°C to 60°C and 10% to 90% humidity levels. |

Application Industries of Plastic Testing Machine

Plastic Manufacturing: Quality control and assurance for raw materials (polymers, additives), in-process checks, and final product testing to meet specifications and standards.

Automotive Industry: Testing plastic components like dashboards, bumpers, interior trims, and under-the-hood parts for strength, impact resistance, aging, and environmental factors.

Packaging Industry: Assessing the mechanical properties (tensile strength, tear resistance), barrier properties, and durability of plastic films, bottles, and containers for food, beverages, and other products.

Consumer Goods: Evaluating the physical and mechanical properties of plastic parts used in appliances, toys, electronics, and household items to ensure safety, durability, and performance.

Research and Development: Characterizing the properties of new polymers, blends, and composites to understand their behavior under various conditions and develop innovative plastic materials.

Request Information on Plastic Testing Machines!

Ensure the quality and performance of your plastic materials and products. Discover our range of Plastic Testing Machines designed for precise analysis of strength, durability, impact, and more. Meet industry standards and enhance your quality control process. Contact us today for details and a customized solution for your testing needs!

Frequently Ask Questions

Q: Why is testing plastic important?

A: Testing plastic is crucial for ensuring product quality, safety, and reliability. It helps manufacturers verify that materials meet specifications, predict performance in real-world applications, optimize designs, reduce failures, and comply with industry regulations.

Q: What types of properties can be measured?

A: These machines can measure various properties, including tensile strength, elongation, flexural strength (bending), impact resistance (toughness), hardness, melt flow index (MFI), density, thermal properties (like Vicat softening point or HDT), abrasion resistance, and more.

Q: What are the common types of Plastic Testing Machines?

A: Common types include Universal Testing Machines (for tensile, compression, flexural), Impact Testers (Izod, Charpy), Hardness Testers (Shore, Rockwell), Melt Flow Indexers, HDT/Vicat Testers, Density Testers, and specialized machines for specific tests like abrasion or tear resistance.

Q: What types of plastic materials and products can be tested?

A: A wide range of plastic materials can be tested, including thermoplastics, thermosets, elastomers, composites, films, fibers, foams, molded parts, sheets, pipes, and packaging materials in various forms (granules, pellets, finished goods).

Q: What industry standards are relevant for plastic testing?

A: Plastic testing adheres to numerous international and national standards, primarily from organizations like ASTM (American Society for Testing and Materials), ISO (International Organization for Standardization), and DIN (Deutsches Institut für Normung). Specific test methods are defined by these standards.

Q: How do I choose the right Plastic Testing Machine for my application?

A: Choosing the right machine depends on the specific material to be tested, the properties you need to measure, the relevant industry standards you must comply with, your sample dimensions, testing volume, required accuracy, and budget.

Q: Are Plastic Testing Machines difficult to operate or maintain?

A: Modern plastic testing machines are often designed with user-friendly software and interfaces. While basic operation is typically straightforward, proper training is essential for accurate testing. Regular calibration and routine maintenance are necessary to ensure reliable and consistent results.

Q: What industries commonly use Plastic Testing Machines?

A: Industries such as plastic manufacturing, automotive, packaging, consumer goods, electronics, medical devices, aerospace, textiles, and construction heavily rely on plastic testing to ensure product integrity and performance.