Modern societies cannot exist without plastics, being the linchpin of innumerable industrial activities: packaging, automotive, medical, and consumer goods among others. In truth, however, with the widespread use of polymer materials comes the duty of making sure that the same are of quality and durable while being safe. That is when plastics testing comes into play as a key process. Plastics testing enables manufacturers to gauge the performance of polymer materials under conditions of actual use, thereby complying with regulations and creating trust among consumers. This blog post will discuss the reasons why plastics testing is important, including the methods and standards as well as recent developments that keep the industry up to speed. Whether you are a manufacturer, a product designer, or a sustainability advocate, working knowledge of these practices is essential in today’s convoluted landscape of plastology production and application.

The Importance of Plastic Testing

Plastic testing is necessary to ascertain the life and safety of any plastic materials and items. In the testing of plastics using standardized methods, manufacturers test a sample of their material for properties such as toughness, flexibility, resistance to chemicals, and thermal stability. These are to ensure compliance with regulatory standards, to ensure against product failure, and to check more suitable materials for certain applications. Testing keeps sustainability in mind by ensuring that materials are recyclable and thus contribute favorably to environmental aspects. A good plastic testing procedure stands as a sign of consumer confidence and longevity of plastic components under actual usage conditions.

Understanding Plastic and Polymer Materials

Plastics and polymers are materials that stand at the crossroads of versatility and myriad applications. Polymers are gigantic molecules consisting of many repeated units called monomers. They can be either natural or synthetic. Plastics, a class of synthetic polymers, are developed to exhibit those properties of durability, lightweight, and malleability needed for industries such as packaging, automotive, construction, and health care. A polymer scientist currently strives to further specialize plastics-an area that includes both thermoplastics and thermosets-to meet various specific application requirements. The science of plastic materials involves studying the mechanical properties, thermal properties, and chemical resistance of the plastics to ensure compatibility with environmental and regulatory criteria.

Critical Role of Testing Services in Quality Assurance

Testing services are critical to working with and assuring that plastic materials used by different industries for their applications are reliable, safe, and compliant. Manufacturers can use standardized methods such as tensile, impact, and thermal degradation tests to analyze mechanical strength, durability, and performance of plastics over long periods in their areas of application. Analytical methods such as spectroscopy and chromatography render information about chemical composition and degradation characteristics of the material to ensure regulatory and environmental conformity of the material. Besides, accelerated aging tests and environmental simulations enable the prediction of the behavior of the material under adverse situations, which helps industries find possible points of failure and thereby optimize product design. In essence, these tests serve the interest of consumer safety; minimize operating risk; and guarantee uniformity in product quality when put to use under tough conditions.

Industry Standards and Regulatory Requirements

Regarding industry standards and regulatory requirements, it is of uttermost importance to know and understand the major frameworks governing our field. First, complying with ISO measures such as ISO 9001 for Quality Management Systems prompts the implementation of standardized processes put to use for increasing the consistency and reliability of their products. Secondly, complying with several regulatory requirements like the OSHA guidelines or any region-specific regulations ensure safety at work and thus provide an additional level of accountability for their operations. Thirdly, staying on top of the legal requirements and testing procedures as set forth by authorities such as the FDA, EPA, or their international collaborators allow us to curb and confine those risks within the bounds that do not hinder our market credibility. Subsequently, we put these frameworks into their strategic considerations so that we remain consistently partnered with global and regional standards and they become a matter of trust and credibility in working together.

Techniques and Methods in Polymer Testing

Polymer testing incorporates methods such as spectroscopy, chromatography, thermal analysis, rheology, mechanical testing, microscopy, and chemical analysis.

|

Method |

Key Points |

Parameters |

|---|---|---|

|

Spectroscopy |

Identifies structure |

FTIR, NMR |

|

Chromatography |

Analyzes composition |

HPLC, GPC |

|

Thermal Analysis |

Examines stability |

DSC, TGA |

|

Rheology |

Measures flow |

Viscosity, modulus |

|

Mechanical Testing |

Tests strength |

Tensile, impact |

|

Microscopy |

Studies morphology |

SEM, TEM |

|

Chemical Analysis |

Assesses reactivity |

pH, titration |

Mechanical Testing: Tensile and Impact Resistance

The strength in tension and impact is one of the principal means by which polymers are characterized mechanically. The tensile test measures a material resistance to stress that attempts to tear it apart, while important tensile strength, elongation, and Young’s modulus properties determined specify the polymer behavior under stress and its ability to withstand stresses. Resistance to impact tests is a determination of the capacity of a material to absorb sudden forces or shocks without framework damage. Most of the tests used for resistance to impact are Charpy and Izod impact tests, which measure the energy absorbed by the specimen during fracture. By studying both resistance to tension and impact, the manufacturer ensures testing of polymers for demanding purposes where there is a compromise of strength or flexibility as per given operational requirements.

Thermal Analysis and Aging Tests

Thermal analysis and age testing are used to characterize temperature-induced behaviors and durability factors of polymeric materials. The Differential Scanning Calorimetry (DSC), and Thermogravimetric Analysis (TGA) are among the most common techniques. DSC measures heat flow associated with phase transitions such as melting or glass transition, allowing an understanding of thermal stability and processing parameters; on the other hand, TGA records weight changes as a function of temperature, describing the extent of thermal decomposition and degradation of materials. The aging tests, namely accelerated environmental aging involving exposure to heat, UV, and humidity, provide a forecast from a durability viewpoint over the assumed service life of the polymer. In combination, these methods serve as a guide in material selection-related issues and consequently promote reliability in performance over different application scenarios.

Flammability and Combustion Testing

Flammability and combustion testing analyze how materials react to fire and how likely they are to propagate flames. These tests usually analyze various critical parameters, including resistance to ignition, heat release rate, smoke density, and production of toxic gases. Other commonly used standardized test methods include ASTM E84 (Surface Burning Characteristics of Building Materials), UL 94 (Tests for Flammability of Plastic Materials), and cone calorimeter, which evaluates heat and smoke emissions generated during combustion. Such tests will provide vital information for the implementation of fire safety legislations, ensuring materials conform to tightened safety standards for various industrial applications. Knowing this information allows engineers to optimize material formulations and increase overall safety and performance of the end products in settings where fires are common.

Applications of Plastic Testing in Various Industries

Plastic testing plays a very important role across a range of industries since testing ensures that materials conform to performance and safety qualifications. In the automobile sector, testing is done to analyze heat-resistance and durability properties of plasties that go into interior and exterior components; thus, the disposition of these tests about balancing vehicle reliability and passenger safety. Construction-related testing treats plastic and other materials for insulation, structural integrity, and fire-retardancy to ensure compliance with building codes. The other major field of testing is medical, where tests are required to ensure that polymers in devices and packaging are biocompatible, sterile, and durable. The electronics industry assesses plastics in devices for thermal stability properties and electrical insulation properties; this ensures that the devices perform well and remain safe for use. Thus, testing of plastics can allow the manufacturer to attain optimum performance for his materials and comply with regulatory standards.

Packaging Industry: Durability and Sustainability

There has been a growing emphasis on packaging durability and sustainability to meet consumer demands and regulatory requirements. Durability ensures that packaging materials protect the product until it reaches the end user through transit, handling, and storage. Advanced material testing involves analyzing tensile strength, impact efficiency, barrier characters, and so on. In the meantime, sustainability emphasizes reducing the environmental footprint by promoting recyclable, biodegradable, and lightweight materials. Other highly desired innovations include bioplastics and eco-design, so support global efforts to decrease waste and carbon footprint.An excellent and workable synergy can be created out of the two competing approaches.

Automotive Sector: Safety and Performance Testing

Safety and performance testing during automotive development ensure compliance with regulatory standards while providing reliable, high-performing systems. Emphasis is put on conducting a variety of harsh tests that include crash tests, rollover tests, and structural integrity tests to study occupant safety. More advanced test processes consist of computer-aided simulations and real-world validations to analyze the performance of vehicles in extreme temps and high-speed impacts among other conditions. The testing also looks into emissions control, brake systems, and aerodynamics so that energy consumption might be optimized to meet environmental standards. The emergence of new technologies in testing, such as machine learning techniques, sensor-based monitoring, etc., has made the whole process of testing faster and accurate, thereby enabling manufacturers to enforce safety protocols rigorously while adapting to ever-changing industry standards.

Medical Applications: Compliance and Precision

Medical technology advances find foremost reliance on compliance to regulatory standards and the preciseness of instrumentation. Accurate diagnostic tools, including imaging systems and laboratory equipment, are designed under constrictive guidelines from agencies, including the FDA or ISO, to ensure patient safety. Compliance processes include reasonably stringent testing to confirm its performance requirements under specified conditions, reliability, and accuracy. The precision of these instruments is ensured by a rigorous process of calibration and maintenance that allows clinicians to arrive at useful decisions and to promote direct improvement of patient care.”

Latest Advancements in Plastics Testing

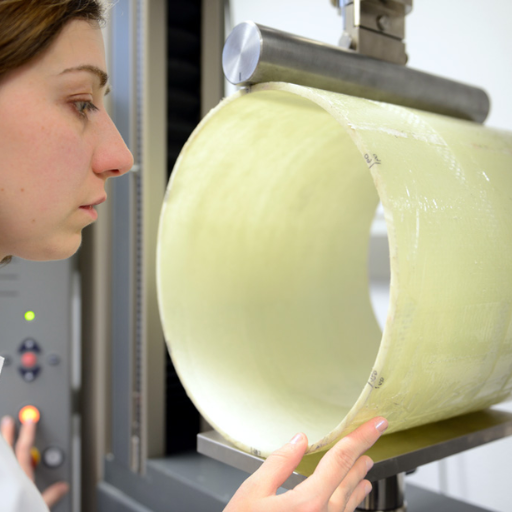

Due to the recent advancements in advancements, the measuring of plastics has become more accurate and efficient in terms of material properties. Very commonly, spectroscopic types of analyses, thermal tests, and mechanical tests are integrated with automation and AI. With these new systems, one can truly monitor variations in tensile strength, impact resistance, thermal behavior, and chemical composition all in one go. NDT methods such as ultrasonic and X-rays form are being used for complete tests without destroying the sample itself. It optimizes the production process while remaining within regulatory specifications, making the entire plastics testing more reliable and cost-efficient.

Emerging Trends in Testing Methods

By my research, I can identify certain emphasizing trends that guide the future of testing methods. One has been a big emphasis on automation and artificial intelligence (AI) to maximize accuracy and efficiency first. AI systems are used to manage huge amounts of data, recognize anomalies, and predict how a material will perform, all with minimum human interference. Second, continuous real-time data collection is possible through the integration of advanced sensor technologies into testing equipment which helps in identifying problems early, leading to lesser downtime. Finally, sustainability is actually on the rise, with attention being directed toward testing processes that don’t use a lot of resources and aren’t damaging to the environment. Tests such as recyclability testing and tests for green materials are carving the way for green initiatives within the testing industry. These trends enhance operational efficiency and customer compliance in tune with changing regulations and environmental concerns.

Innovations in Material Development and Testing

With the technical background in the field, we understand that the driving forces towards changes in material development and testing are automation, computational modeling, and sustainable practice. Automation moves material testing forward by deploying robotics and machine-learning-type algorithms that enable rapid and precise results. Computational methods simulate detailed behavior of materials under complex conditions, thus reducing the degree of actual material testing. And lastly, a particular emphasis on sustainability gives rise to the search for recyclable materials and environmentally friendly testing protocols to realize the environmental goals set forth, while at the same time satisfying industrial performance criteria. Such innovations in material science allow us to work more effectively and in a way that adapts to the challenges of this day.

Rheological Testing and Its Importance

Rheological testing enters critical processes by which the flow and deformation of materials under varying conditions are measured. In an excellent way, it is capable of characterizing viscosity, elasticity, and plasticity with immense precision and provides profound information on materials’ reaction to applied forces. This turns out to be important in manufacturing industries, pharmaceuticals, food processing, and polymer industries, where the knowledge of materials behavior is directly translated to enhanced performance and product uniformity. Equipped with state-of-the-art rheometers, and under simulated actual conditions, tests allow scrutinization of parameters like shear rate, temperature, and stress, which are indispensable when it comes to predicting performance of materials, modification of formulation processes, and cutting production inefficiencies through material development; hence, driving material development toward innovation and quality control.

Best Practices for Effective Polymer Testing

1.Clearly Define Testing Objectives

There can be several parameters to test; these may include tensile strength, thermal stability, or viscosity, ensuring that the testing really puts the polymer under conditions aiming at end-use applications.

2.Use Appropriate Testing Equipment

Always select the best instrument for the specific analysis, calibrated for measuring properties for the polymer under examination, e.g., dynamic mechanical analyzers (DMAs) for viscoelastic properties and rheometers for flow behavior.

3.Simulate Real-Life Conditions

Perform tests under conditions simulating those that would actually exist in the application environment, including temperature fluctuations, humidity, mechanical stress, etc.

4.Ensure Sample Preparation Consistency

Samples are to be prepared similarly in all cases to avoid variability among tests and improve reliability of the results.

5.Calibration and Maintenance

Ensure the proper maintenance of testing equipment and calibration at frequent intervals to uphold data integrity and guarantee it complies with standards.

6.Adopt International Standards

Testing standards like ASTM, ISO, or such other relevant testing standards should be adhered to in order to validate results for comparison industry-wide.

Successful application of these best practices leads to better quality of data, reproducibility, and ultimate insight into the polymer’s behavior, thereby assisting in sound decision-making in material innovation.

Developing a Robust Testing Protocol

To develop a robust testing protocol, I begin by clearly laying out the specific objectives and performance criteria required of the polymer material for the application at hand. This would involve determining critical properties like tensile strength, thermal conductivity, or chemical resistance on the basis of the operational environment and potential regulatory constraints. Preference would be given to the use of internationally accepted standards such as ASTM, ISO to design the test, so as to provide for uniformity and comparability of the results in their various applications. Calibration and periodic maintenance of testing equipment would be ensured to remove any variations due to mechanical inaccuracies in the testing devices. Stringent documentation relating to conditions, methodologies, and results of tests would be maintained so that recording of data or results can lead to reproducibility or weighing decisions in any further development of the material.

Specimen Production and Preparation Techniques

Specimen production and preparation are crucial activities to enable accurate and reliable testing results. Standard procedures may call for the machining or molding of the materials into specific geometries conforming to an applicable governing standard like ASTM or ISO. Usually, specimens are prepared using precision measuring tools and methods to the required dimensions and surface finish, all of which help reduce variation in the test results. The orientation, thickness, and environmental conditions under which specimen preparation is done are all controlled factors to minimize defects and ensure uniformity. Proper labeling and storage are also imperative in preserving specimen integrity until testing. All these factors go into ensuring the validity and repeatability of the experimental data.

Choosing the Right Testing Services and Facilities

With selecting suitable testing services and facilities, I keep three main factors in mind: accreditation, expertise, and equipment. First of all, I verify that the facility carries accreditations such as ISO/IEC 17025, which actually prove their capability to carry out tests reliably. Second, I consider how capable they are in terms of technological know-how and specialization in my own industry to ensure relevant and precise results. Third, I would appraise the quality and sophistication of their testing equipment in order to ensure the tests adhere to current standards and methodologies. Taking into consideration these factors makes one able to choose a provider capable of delivering accurate and consistent data.

Reference Sources

-

Handbook of Plastics Testing and Failure Analysis – A comprehensive guide on testing methodologies and failure analysis in plastics.

-

Plastics Testing (Handbook of Materials Selection) – Discusses high-performance applications and testing methods for plastics.

-

Reliability of Proficiency Test Results for Metals and Phthalates in Plastics – Explores the reliability of test results and challenges in standardization.

-

Testing and Evaluation of Plastics – A reference book focusing on the applied aspects of polymer and plastic materials science.

-

Certifications and Testing Methods for Biodegradable Plastics – Reviews international standards and certification criteria for biodegradable plastics.

Frequently Asked Questions (FAQs)

Q:What is plastics materials testing, and why is it important?

A:Plastics material testing is evaluating properties and performance of different plastic compounds to ensure they comply with industry standards and specifications. This testing is important for compliance and in developing products, as it enables the manufacturer to know how his material behaves under different conditions-plastic materials under thermal aging, weather, or the like.

Q:How do testing and certification services assure the quality of recycled plastics?

A:They test the recycled plastics by very stringent testing regimes for tensile properties, chemical resistance, and ASTM conformity. Therefore, the testing and certification service, by ensuring the performance level of recycled material, improves sustainability of the plastics industry.

Q:How is a polymer testing laboratory involved in product development?

A:Polymer testing laboratories provide testing services significant for the development of products and processes of plastic materials. Polymer testing labs measure some analytical features such as melt flow rate (MFR) and heat deflection temperature (HDT) of plastic compounds regarding the performance of plastic compounds vis-à-vis the requirements of OEMs.

Q:What are some common testing methods used in the plastics industry?

A:Tensile testing, thermal aging, Vicat softening point, and chemical analysis are only some of the different methods commonly used to dynamize the plastics industries. Each testing method imparts information about the physical and chemical properties of plastic materials, thus assisting the manufacturers in optimizing their materials for manufacture or in meeting industry standards.

Q:How does Intertek help in plastics testing and certification?

A:Intertek is a world leader in providing testing and certification services to the plastics industry. They have set up a very comprehensive testing program in conjunction with their international customers to evaluate the performance of plastic materials as per the requirements of international standards including UL 746A. This allows their customers to be assured of the safety and reliability of their products in various applications.

Q:Why is the melt volume rate (MVR) important in plastics testing?

A:The melt volume rate (MVR) is one of the key indicators of polymer melts’ flow characteristics in plastics testing. It stands useful to one’s determination of processing conditions or the suitability of a plastic material for a particular application. The testing for MVR is a very important part in maintaining consistency with product quality.

Q:What is the influence of thermal aging on plastic materials?

A:Plastic materials undergo a major change under thermal aging in that they lose their mechanical strength, end flexibility, and overal. Testing for thermal aging assists in predicting how long the products will stand up under elevated temperatures, making them durable and reliable for end-user application.

Q:What about weather resistance on plastics testing?

A:Weather resistance is particularly important in plastics testing for plastics that get exposed to the outdoors. The plastics being tested are checked as to their durability when exposed to UV radiation, moisture, and extreme temperature changes. This ensures that the products retain their performance and stability through time, which is vital for practical applications such as aerospace.

Q:What kind of plastic testing specimens are usually employed?

A:Plastic testing specimens may differ in their shape and size depending upon exactly what test is being conducted. Some of the specimens are in the form of dumbbells for tensile tests while thin films are used for flexural tests. The chosen test specimen must represent the material being tested adequately.