The glue test demands precision and reliability. The Peel Adhesion Test-according to PSTC 101 standards-is a yardstick based on which adhesive materials are evaluated for strength and durability. In this blog post, we will look at the essential equipment needed for peel adhesion testing and thereby unravel the complex testing procedures necessary to ascertain the true level of adhesion performance. As a manufacturing, quality control, or product development professional, you need to know the tools and the methodology behind PSTC 101 for product integrity and standards. Fasten your seatbelt as we delve into the dimensions of peeled adhesion testing and understand why it is a pillar of the adhesive realm.

Introduction to PSTC and Adhesion Testing

According to the standards of PSTC, peel adhesion essentially assesses the adhesive bond strength between the material and substrate. The force is exerted against the adhesive at a controlled angle and speed to measure the free peel of the material in purely adhesion terms. Whenever tested by a recognized standard such as PSTC 101, which is the most widely accepted, adhesion test methods developed must ensure repeatability and reliable application of results. This is extremely relevant in any industry where the expected product function depends on adhesive quality in terms of measurement and predictability of durability, consistency, and suitability for application.

What is PSTC?

PSTC is an acronym for the Pressure Sensitive Tape Council, an industry association that sets international technical standards for pressure-sensitive adhesive (PSA) tapes. These standards aim to provide a reference for tape characterization methods ensuring uniformity of test results and consistency in industry use, be it packaging, automotive, building, or healthcare. The organization draws up a vast array of test methods for tape properties such as adhesion, shear strength, and tack-the most well-known of which is PSTC 101. Besides developing and maintaining these standards for the advancement of adhesive technology, the PSTC also undertakes educational initiatives and fosters innovation within the PSA tape industry. Their standards lay down the development and testing of an adhesive product to ensure it meets critical application-related requirements.

Importance of Adhesion Testing

Adhesion tests were important in assessing the capability of pressure-sensitive adhesive (PSA) tapes to perform and ensure reliability in their respective application environments. In the adhesion testing field, one ensures each adhesive product meets the required standards for strength of bond in endurance, carried on under certain, more or less actual conditions and situations of use. Peel adhesion, shear strength, and tack are parameters tested for that provide applicable data on product quality and appropriateness for a given use. This service is necessary for the safety, field efficiency, and failure minimization in those application areas where one, for instance, cannot compromise on healthcare, matters of automotive, and construction.

Overview of PSTC 101 Standards

PSTC 101 is a highly recognized standard developed by the Pressure Sensitive Tape Council (PSTC) to test rigorously the peel adhesion performance of pressure-sensitive tapes. The method of test objectively measures the force required to remove a given tape specimen from a smooth surface under specified conditions of angle and speed, thereby obtaining results which are reliable, consistent, and reproducible. This standard is all the more important from a manufacturer’s point of view because it enables him to compare the performance of various products against one another and also to study the effect of variations in the formula of his own products. The industries of packaging, automotive, and electronics, by endorsing the use of PSA tapes tested with this standard, may be assured that the assessment of tape performance is according to the best possible methods in relation to their own requirements.

PSTC 101: Key Concepts and Methods

The Practical standards in Technical Committee 101 (pstc-101) sets out the basic and key procedures on how the characteristics of an adhesive tape should behave after production. This is called adhesion in general terms and refers to the degree to which a tape would be expected to wet out various surfaces. The next aspect is within certain laden boundaries, that is, how good the tape holds a certain weight or force without sliding down. At the same time, this sort of focuses on the level of busting some myths for practicality. The standard describes these procedures of testing-Few thickness of coating is increased yet kept under strict control, and comes as (say) 180 or 90 degrees of peel ‘temper’ experienced so called as the peel strength. The shear test on the other hand tests that if the tape some friction is present, while the tact test checks the bond of the tape instantly. It is important to note that these methods are well practiced and standardised so as to have data that is repeatable and used extensively for setting benchmarks and quality control them to ensure illustrative effectiveness of tapes in all cross and horizontal market sectors.

Understanding Peel Test Standards

”Peel tests” are used to evaluate the strength of adhesives based on the force needed to place an object within the testing scenario, allowing one to obtain certain comparative measures. Some of these variables are the angle of peeling, usually set at 90° or 180°, and the peeling rate, which is mostly given in mm or inches per minute. If these variables change, it is no wonder that the results would be so far-fetched which, in turn, calls for strict adherence to otherwise abstract standards, such as ISO 29862 or ASTM D3330. They describe the aspects of preparation and conditioning of samples in regard to their treatment and their measurements in order to insure reliability of the results as well as interventions which could impair other people’s work. Peel tests imply the potential usage of peel strength values in the completion of packaging constructions or in intervention strategies for example in diagnosis worksheets, some medical devices and other relevant applications and hence such values are very necessary in most of the cases.

Common Test Methods in PSTC 101

The common test methods in PSTC 101 include shear, peel adhesion, tack, rolling ball, release liner, and substrate testing.

|

Test Type |

Purpose |

Key Parameters |

Outcome |

|---|---|---|---|

|

Shear |

Test holding strength |

Temp, time |

Load capacity |

|

Peel Adhesion |

Assess adhesive strength |

Angle, speed |

Peel adhesion |

|

Tack |

Measure initial stickiness |

Force, area |

Tack value |

|

Rolling Ball |

Evaluate quick stick |

Ball size |

Distance |

|

Release Liner |

Analyze release force |

Peel speed |

Force needed |

|

Substrate Test |

Assess adhesion on materials |

Material, type |

Compatibility |

Role of Testing Equipment in Adhesion Assessment

Testing instruments are essential in making a correct assessment of the adhesive characteristics and their behavior in different environments. I employ the use of special instruments to determine some of the major adhesion characteristics such as shear adhesion, peel adhesion, and tack. As an example, with shear testing, the bonding ability of an adhesive can be timed for long periods in different temperatures. This means it is very useful when assessing the long-term reliability of adhesives. Peel adhesion testing involves pulling the adhesive at certain angles and velocities so that one can measure the adhesive on the substrate in question. On the other hand, tack tests are carried out to measure how well an adhesive sticks onto the surface by evaluating the pull-off force. Advanced equipment is used in every one of these tests to ensure consistency in terms of performance and this aspect is important in coming up with more specialized adhesives and their respective materials of pstc-101 concern.

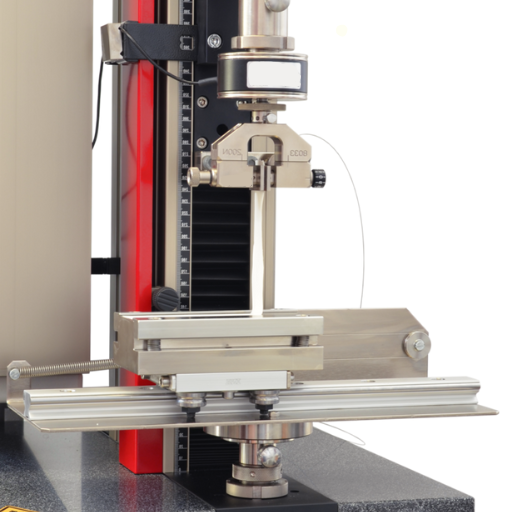

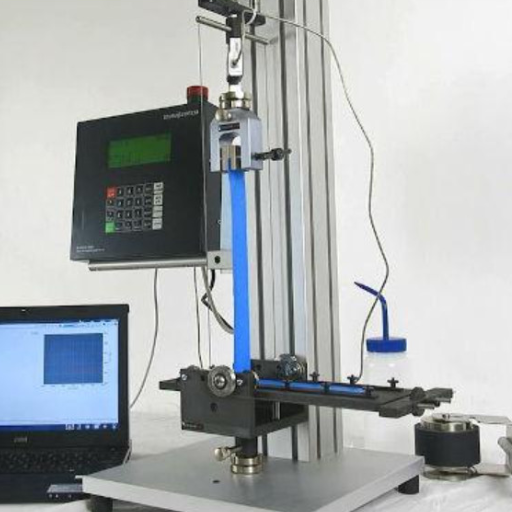

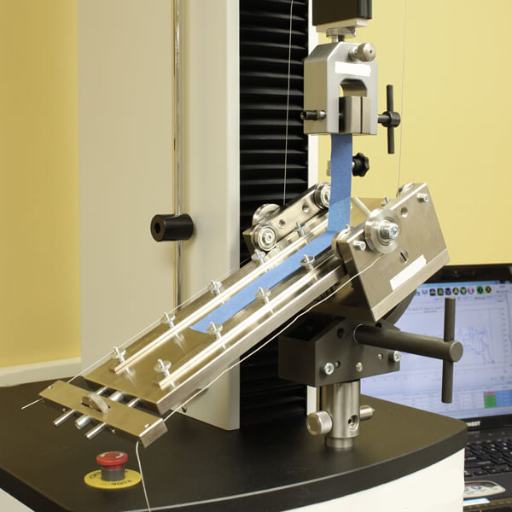

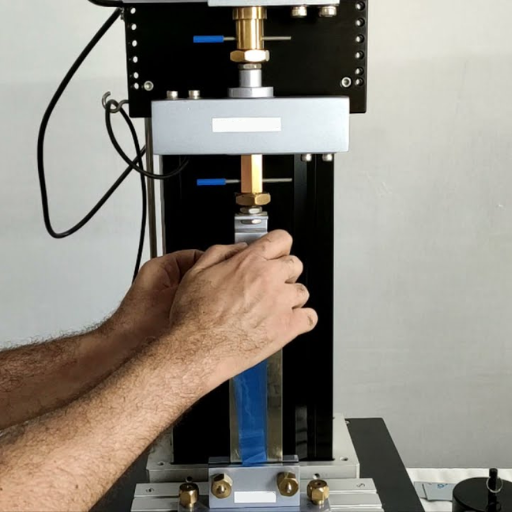

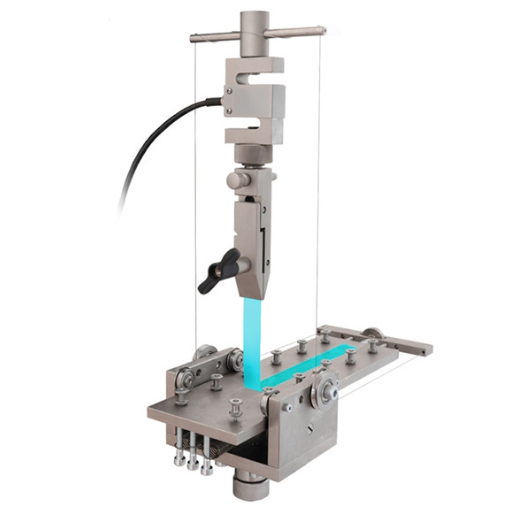

Peel Adhesion Test Equipment

Adhesion strength testers or adhesion peel testers normally include a Universal Testing machine together with a peel test fixture to evaluate the adhesives. Such equipment measures the strength necessary to peel the adhesive off the substrate at specific conditions; pre-set angles and speed – 90 and 180 degrees are most common. Measurements of the force exerted during the process of pulling the surfaces apart are obtained from load cells contained within the instrument. The equipment also provides the flexibility of presetting the distance from the sample to the jaw and the jaw displacement speed while ensuring conformance with standards such as PSTC-101 and ISO 2288. The benefits of the versatile equipment extend adhesion evaluations.

Types of Peel Adhesion Testers

Peel adhesion testers can be broadly categorized into manual, motorized, and automated systems.

|

Type |

Key Features |

Use Case |

Control |

Accuracy |

Max Load |

|---|---|---|---|---|---|

|

Manual |

Basic operation |

Field testing |

Hand-driven |

Moderate |

Limited |

|

Motorized |

Controlled speed |

Lab analysis |

Motor-driven |

High |

Medium |

|

Automated |

Programmable |

R&D, QA/QC |

Software |

Very High |

High |

Choosing the Right Equipment for Your Needs

The choice of the adhesion tester for use should be guided by parameters such as the nature of the testing environment, the need for accuracy, and the range of the application. In most field works, handheld testers can be used due to their portability and ease of use although the accuracy obtained is fairly good. In addition, motorized systems are preferred in the lab due to their controlled speeds and precision. These automated systems are bound to be superior in terms of accuracy and programmability which are highly applicable during extensive research, development, and strict quality checking. Understanding well how the tester can work and your objective requirements prevents some successive gaps in effectiveness.

Calibration and Maintenance of Testing Equipment

In everything that I carry out, routine, and calibration of all test equipment that I work with or I am assigned to be in charge of, is a must. Pstc-101 states that calibration is only done after a specified period of time that could be either in accordance with the fabricator’s instruction or out as stated in the standard by enhancing the instrument’s accuracy – measuring application accuracy. Surveillance constitutes to: evaluating parts of a system, verifying critical elements, replacing used-up parts, making some repairs or etc., in order to avoid any functional failures. In maintaining capacity building in a systematic way and in accordance with the worldwide best available practices, I avoid equipment giving faulty or deviating results which is vital for quality processes and regulatory adherence.

Applications of PSTC 101 in Industry

PSTC-101 standard is known as a standard base and its applications can be found in almost every industry including quality management and product testing. These rules essentially contribute to the better usage and reliability of pressure-sensitive elements such as adhesives or coatings in regards of using them in the packaging or auto industry, health care, construction etc. In the packaging example PSTC 101 makes sure that the fixing capability of the tapes to hold the contents within is enough. In the same vein, the standard is also concerned with assessing the medical adhesive’s capacity to do no harm to the patient when adhering to the body or a device. Therefore, by using the PSTC 101, there is no room for deviation as it provides the necessary means to achieve effective performance, and fills the void when it comes to customer assurance.

Use Cases for Adhesion Testing in Manufacturing

Testing the adhesion or bond strength is crucial to many industries because failure to do so may result in the production of sub-standard products. This is especially true in the aerospace industry and the automotive industry where it is necessary to test the adhesion of paints and sealants, in addition to the materials joined, in how they withstand harsh conditions. Likewise, in the sector dealing with electronics, these tests check how well adhesives, which include conductive cements, coatings, and protecting envelopes adhere to their supporting structure. Moreover, in the construction industry, such tests being carried out afford paints, sealants and flooring materials to be adhered and failure averted. Such a detailed quality check increases durability of the product, follows industry regulations, and helps prevent expensive recalls or damage.

Impact on Product Development and Quality Control

Adhesion testing provides great value in product design and development by allowing materials and bonding techniques to be selected as appropriate to the design. Engineering design provides the means to design specifically for adhesion via the controlled material choice and techniques of bonding in the metal fabrication details, in order to adhere between the bodies to the desired coated performance level under random boundaries. This helps designers manage user expectations on adopting a technology as well taking care of the barriers beforehand thereby shortening the cycle up to a release and the following support. Additionally, safe performance of end use items through specification of adhesion requirements is a function of the adhesion test in quality control, hence ensuring that the products are of the highest quality downside is that it enhances product support a cross promotional issue every manufacturer strives to diminish. The range of various tests for a quality of adhesion, including peel, tensile, and shear stresses, distinguishes such methods from other production tests and assists in the provision of the maximum possible level of quality controlling any product corresponding to the existing laws on safety requirements.

Real-World Examples of PSTC 101 Applications

Applications of pstc-101 standards are evident across many sectors to incorporate qualitative and dependable adhesive solutions. For Example, in the automotive Industry, ‘Tape adhesive Test’ is crucial for holding together various components including trim, gaskets and others. Such a property is very important for the durability of the material, even in such extreme conditions as temperature and vibration. In the same way, in the groundworks, adhesives are also used in joining surfaces, and such applications are subjected to intense tests, as they are considered safety or structural components. Finally, such tests are also implemented in the electronics manufacturing sector wherein exact placement of bonded fragile pieces is confirmed, extending the shelf life of the product and increasing its functional performance, with the customer’s interests protected. These uses clarify the importance of pstc-101 approaches to enhance creativity, ensure protection, and concern with tastes in various sectors.

Conclusion and Future Trends in Adhesion Testing

The evolution of adhesion testing, headed primarily by the PSTC 101, bears testimony to the importance placed on quality, safety, and function across industries. Based on this premise, with the advancement of technology, the emergence of highly precision automated testing systems and artificial intelligence for better analysis of adhesion performance may be the future trends of this field. On the other hand, the increasing demand for sustainable and environmentally friendly materials may also boost the development of testing methods that rationalize the new adhesives and substrates for uniform standards in the new areas of application.

Innovations in Adhesion Testing Technology

From the late ’90s up till the early 2000s, advancements in adhesion-testing techniques were targeting increased accuracy and more efficient utilization in different fields. An automated adhesion testing system provides precise force measurement and repeatability while minimizing human intervention [Washburn, 1980]. Robots are being used in loading systems, combined with sensors to maintain consistent loads during the duration of the test while recording real-time performance data. A further advancement in AI includes test result analysis, AI prediction of adhesive performances under possible conditions, and optimization of product formulation with large amounts of data.

Sustainability has also been pushed to the forefront, allowing for creativity in testing procedures for environmentally pure adhesives and substrates, such as bio-based or recyclable materials. Newer standards and methodologies are ensuring that the materials meet the performance requirements without putting much weight on the environmental benefits. NDT methods, including acoustic emissions and infrared thermography, are also gaining traction in the adhesives world. They allow the evaluation of adhesion without destroying the materials, which is vitally important when consideration is given to sectors such as aerospace and electronics where testing resources lack. As these advances progress, they help build a more robust adhesion test suitable for modern-day applications.

Looking Ahead: The Future of PSTC Standards

A future PSTC would foster innovation and adapt to evolving technological needs, in my mind. With the general introduction of sustainable materials and newer testing technologies, the standards will tend toward getting more precise and environmentally oriented in the adhesive performance evaluation. Collaborating across industries, the standards will stay indeed relevant when applications in several industries such as healthcare, electronics, and aerospace demand stronger and greener solutions. When PSTC remains in tune with these global trends, it will continue to foster quality and reliability.

Reference Sources

-

TestResources – PSTC-101 Peel Adhesion Test Equipment: Provides details on high-quality test equipment for precise peel adhesion testing.

-

Industrial Physics – PSTC 101 Testing: Explains the international PSTC 101 standard for determining peel adhesion properties of pressure-sensitive tapes.

-

Thwing-Albert – PSTC Quality Standards Testing: Offers insights into pressure-sensitive tape testing for accuracy and reliability.

-

Thwing-Albert – PSTC 101 Peel Adhesion Test Equipment: Features testing equipment that meets PSTC 101 standards for peel adhesion.

-

YouTube – ASTM D3330 Test Method for Peel Adhesion: A video explaining ASTM D3330, a related standard for peel adhesion testing of pressure-sensitive tapes.

Frequently Asked Questions (FAQ)

What is PSTC 101 peel test?

The PSTC 101 peel test is a standardized method used to evaluate the adherence strength of pressure-sensitive tapes. This test measures the force required to peel the tape from a surface, such as a standard steel panel, at a specific angle, usually 90 degrees or 180 degrees.

How is the strength of pressure-sensitive tape measured?

The strength of pressure-sensitive tape is measured through various methods, including methods A through F as outlined in PSTC 101. These methods give a measure of adherence based on the force applied and the angle of peel, allowing for an assessment of the tape’s performance under different conditions.

What types of surfaces can be used in PSTC 101 testing?

PSTC 101 testing can be performed on a variety of surfaces, including standard steel panels and other rigid surfaces. The choice of surface is crucial as it can affect the measure of adherence, influencing the results of the peel tests.

How does the angle of peel affect the test results?

The angle of peel significantly impacts the results of the PSTC 101 peel test. Testing at angles such as 90 degrees or 180 degrees provides different insights into the adherence properties of the tape, with each angle offering a unique measure of the tape’s performance and strength.

What is the significance of the release liner in PSTC 101?

The release liner plays a critical role in the adherence of adhesive transfer tapes and double-coated tapes. The adherence of the release liner to the adhesive must be evaluated to ensure that the tape performs effectively when applied to the surface of interest.

Can PSTC 101 be applied to both single and double-coated tapes?

Yes, PSTC 101 can be applied to both single and double-coated tapes. The testing methods provide a comprehensive measure of adherence for various tape types, ensuring that manufacturers can assess the performance of their products accurately.

What equipment is needed for PSTC 101 testing?

Testing equipment for PSTC 101 typically includes a testing machine capable of applying a controlled force to peel the tape from the surface at specified angles. This equipment must be calibrated to ensure accurate measurement of the adherence and strength of the tape being tested.

How does PSTC 101 comply with international standards?

PSTC 101 is developed under the auspices of ISO, ensuring that the methods and practices meet international standards for testing pressure-sensitive tapes. Compliance with these standards helps in maintaining consistency and reliability in the measurement of tape performance across different applications.

What factors can influence the performance of pressure-sensitive tapes in testing?

Several factors can influence the performance of pressure-sensitive tapes during testing, including the type of adhesive used, the surface texture of the material, environmental conditions, and the method of application of the tape. Understanding these factors is crucial for accurate assessment of tape strength and adherence.