Materials such as rubber and elastomers are essential to metals, ceramics, and plastics. When assessing such materials, one has to keep in mind the quality, durability, and overall performance because of the multitude of environments they will be subjected to. This article takes a look at the world of tests for rubber and elastomers, looking at creative test techniques, consideration of standards and the enlarging of the boundaries of the testing scope due to the evolution of the present advanced techniques. This article serves as a one-stop resource for anyone including even a metallurgist, an engineer or deputed auditor required for everything about rubber and elastomers insofar as R & D is concerned today. Don’t price yourself out of the market – stick around for some interesting tips that you might find useful in increasing effectiveness problems, cutting costs and going green.

Introduction to Rubber and Elastomer Testing

The evaluation physical, mechanical, and chemical properties of elastomers and rubber is a crucial process; it determines their use in different uses, reliability, and performance. These aspects include tensile strength, elasticity, hardness, and heat resistance and chemical resistance among others. With the help of testing that is done in particular ways, manufacturers, as well as researchers, can confirm conformity to the standards in force, optimize material compositions, and estimate the effective longevity of goods. It, therefore, finds relevance in areas such as the automotive industry, aerospace industry, consumer products, and even healthcare products and devices where the performance of the material is of utmost importance for the safety and proper functioning of the product.

Importance of Testing in Rubber and Elastomer Applications

Testing the use of rubber and elastomeric substances plays a critical role in assessing and optimizing product performance to a specific set of use patterns. It is a key enabling activity that helps engineers assess the properties of materials including but not limited to tensile strength, shear resistance, flexibility and temperatures resistance.For example, in the automotive as well as aerospace industry, the use of high performance elastomers lightweight oriented material has increased hence leading to the need of harsh thermal ageing including application ozone resistance. In the case of medical device sector, biocompatibility tests asses the patient safety; while regulations such as ISO 10993 embrace their cases as well. Technologies in place are not only favourable from the point of view of adequacy of materials in relation to its function but also decrease the dependence on materials, build in faults and improve form. That is why, without exaggeration, this kind of analysis brought about the innovation in numerous economic spheres.

Overview of Rubber and Elastomeric Materials

Elastomers – Rubber and similar materials are polymers with high expansion rate under stress that can return to their initial state after the stress release. This rather simple property of materials is peculiar due to a certain structure of the arrangement of molecules giving rise to excessive loading upon stretching of such materials. There are two broad classes of these materials: natural rubber derived from the latex of Hevea brasiliensis and synthetic elastomers which are produced from petroleum derivatives by procedurial polymerizations. Major synthetic types comprise butadiene rubber (BR), nitrile rubber (NBR) and silicon rubber among others, each designed for a specific industrial and commercial purpose. Such characteristics are utilized in a wide variety of industries e.g. automotive (including the making of tires and sealing elements), healthcare (such as gloves and implant rubbers), among others (such as gaskets and vibration isolators). As the need for specific characteristics in elastomers is required, there are components and mixtures that can be created which will act within these required modifications, therefore allowing them to retain importance in prosperous industries.

Key Terminology in Elastomer Testing

In most cases, the evaluation of the properties of a material under particular conditions requires understanding of certain terminologies related to rubber testing. Such concepts are explained, however, in order to remedy this:

1.Ultimate Tensile Strength: This is the peak amount of load that an elastomer material can withstand before failing while being extended. It is expressed in newtons per square meter, centimeters, or inches, and it is vitally important in judging the performance of a material in tension mode.

2.Elongation at Break: This represents how much an elastomer is stretched until it breaks in relevant percent. The more the values, the more deformability and compliance is indicated.

3.Compression Set: The extent to which the recovery ability of an elastomer after a long period of compression is referred to as the compression set. It is one of the most important barometers for evaluation of elastic and durable material for seals.

4.Hardness (Shore A or D): Hardness calculates how resistant an elastomer is to indentation on its surface- mostly in Shore units. Shore A scale is for relatively soft rubbers but Shore D is useful whenever handling hard materials.

5.Tear Strength: This testing defines how a material becomes resistant to external impact of dynamic stress and puncture. In circumstances where there are cyclic loading fatigue or sharp objects present, such a tough tear property has to be satisfied.

6.Thermal Precision: The capacity of an elastomer that maintains its shape or chemical composition is termed as thermal stability. Thermal stability ensures that the outer boundaries of the test sample perform within reasonable limits under extreme temperatures.

7.Reduced Aging: The attribute of an elastomer where it does not deteriorate much even after long storage or exposure of external factors such as ultraviolet rays, oxygen, ozone etc. is known as reduction in aging.

These definitions overall provide a better picture of the properties of elastomers that are usually characterized in order to provide assistance in selection and control.

Testing Methods for Rubber and Elastomers

Common testing methods for rubber and elastomers include tensile testing, hardness testing, compression set testing, aging tests, abrasion resistance testing, and thermal analysis.

|

Test Type |

Purpose |

Key Parameter |

|---|---|---|

|

Tensile Testing |

Measures elasticity |

Tensile strength |

|

Hardness Testing |

Assesses surface |

Shore hardness |

|

Compression Test |

Evaluates shape loss |

Compression set |

|

Aging Tests |

Studies durability |

Aging resistance |

|

Abrasion Testing |

Tests wear resistance |

Abrasion rate |

|

Thermal Analysis |

Analyzes stability |

Thermal behavior |

Tensile Testing: ASTM D412 and Its Significance

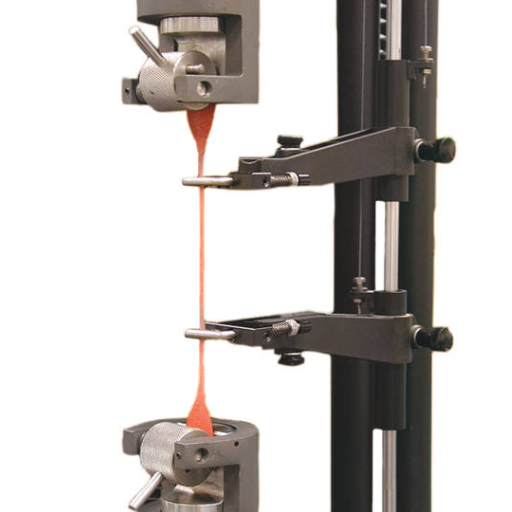

ASTM D412 is a common testing protocol aimed at determining the tensile properties of elastomers, thermoplastic elastomers, as well as other soft pliable materials. Tensile strength, ultimate elongation, and the load at a specified elongation are the important parameters measured by this test. Loads generated by elongating a material are vital in evaluating the potential of a material for critical application. The examination process consists in elongating a test sample at a chosen rate until fracture strength is reached, and recording the length and force at every point. This helps companies and scientists in fine-tuning the processing parameters of materials and products for specific applications before putting out a product into the market.

There are different industries such as the automotive, aerospace, and construction that often use elastomer parts which undergo high stresses. Thus, there is an increased relevance of ASTM D412 for these industries. This helps in enhancing the development of stable and functional materials which are however specific to the task and conforming to the requisite norms.

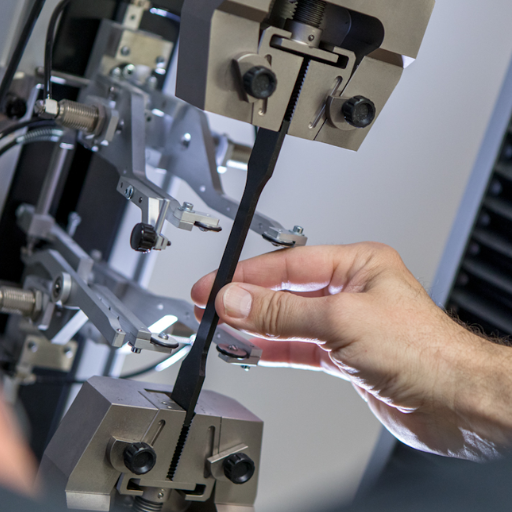

Tear Strength Testing: ASTM D624 Overview

A widespread test procedure that is used for testing the tear properties of flexible materials such as elastic polymers or rubber is ASTM D624. This is important for the applications where the components face such forces which tend to tear them. The process entails molding the samples in a set shape (e.g., die C or trouser) and then applying a constant force on the sample till it fails by tearing. The tear strength is expressed in terms of length per unit force, for instance, kN/m, and aids in understanding the resistance of the material to tear propagation, making it relevant for components subjected to highly operational demands.

With the introduction of dynamic analysis of structural materials, tear strength data from ASTM D624 tests is being used increasingly in predictive analysis. Using relevant machine learning techniques, engineers have started using large amounts of data to model the life and performance of the material under different conditions of use. Test results coupled with present-day data science techniques enable manufacturers to assess the functional risks of products even before they are designed and replace them with safer options. The fusion of conventional testing methods with the extended computing power allows manufacturers to produce materials that more than meet the requirements of today’s industries.

Compression Testing and Compression Set Analysis

Compression testing is an essential part of material testing that evaluates a test material’s response and behavior when subjected to compressive loading or deformation. In simple terms, it finds out stress strain relations, yield strength and elastic characteristics. On the other hand, compression set analysis measures the recovery in thickness of a sample indented for a given period of time and temperature. This is a significant feature for those who deal with products such as seals, gaskets, cushions and the like, which are expected to keep their shapes and especially functionalities after durable usage.

We can use compression testing and set analysis in conjunction with data analytics to forecast the future behavior of materials, which offers the possibility of modifying materials with strict industry requirements. These methods not only enable organisations to meet global regulatory standards such as ASTM D395 but also explore the existing designs for improvements thereby improving the longevity and performance in various products.

Industry Standards and Compliance Requirements

Every industry has its own set of norms and conformity rules that governs the production and distribution of goods accordingly with the maintenance of Abate this yields quality control and efficiency of produced or would be produced goods at all outcomes. Several regulations, for example ASTM International, the International Standard Organization, and the SAE provide limits on the material characteristics, all its tests and processing methods. Regulation invites compliance because companies are able to trade efficiently worldwide and can satisfy the needs of the consumers plus government requirements. Regulation is also a dynamic platform of which formats change with time hence the need to always update the systems; this will enable the firm to remain in the certified form, boost the products and mitigate any legal aim risks that can arise as a result, thus building a healthy firm’s position in the competitive market.

ASTM Standards for Rubber Testing

ASTM standards for rubber testing are aimed at providing the scope of all the possible physical, mechanical and chemical properties evaluation of rubbers irrespective of the application scope. The most commonly used standards included in this category are ASTM D412 (tensile strength), ASTM D2240 (durometer hardness) and ASTM D573 (resistance to aging). Those techniques turn out to be irreproducible and even in case of standartization some heat distortion of the samples will occur. These standards help both manufacturers and researchers in checking quality, enhancing formulations and also doing some ‘compulsory requirements’ within industries and among states. In line with the ASTM standards the products’ validity and work of the material will be guaranteed under a variety of user applications.

Global Testing Standards for Elastomeric Materials

The international standards set for elastomeric materials relate to measuring their mechanical, thermal and chemical properties in given conditions. Internationally approved norms have been established by certain bodies that include the ASTM International (American Society for Testing and Materials), ISO (International Organization for Standardization), as well as DIN (Deutsches Institut für Normung), providing reliability and assuring consistency in almost every sector. For example, ASTM D412 provides the guidelines on measurement of tensile properties while ISO 37 aspires to achieve the same restrictions in the world at large, whereas DIN 53504 is already used within Europe.

Some Parameters such as tensile strength, elongation at break, tear resistance, compression set, hardness among other parameters are examined. The test conditions are closely monitored as parameters like temperature, humidity and strain rate affect the performance considerably. Plus it also includes the use of the specimens in composites, after chemical treatment and measurements in solution for assessing chemical resistance, (eg., ISO 1817) to test curing systems for elastomers that have to resist oils, fuels, or any other harsh chemicals used in the industry and in turn our immune system must be able to cope with.

Due to this uniform legal documentation ill doled such a substantial amount of elastomer components for manufacturing and give the possibility to produce these materials for medical instruments, automotive gaskets, aviation elements, and more despite high mechanical or severe climatic loads. Moreover, these tablets help to ensure hastle free entry into global market range of a given product due to their respective license.

Importance of Compliance in Automotive and Aerospace Industries

Very important steps of compliance in automotive as well as aerospace industries are the rigid safety, performance and environment standards. The internationally certified specifications such as ISO and SAE specifications are essential in ensuring that all the materials and components meet the regulatory specifications. This also ensures that the product does not fail at extreme conditions and also enables entry into other markets. For instance, all elastomer components used in these sectors experience mechanical tensile and compressive loading, high temperatures, or chemicals which would hinder their usage function in these industries. Strategies that focus on compliance reduce risks, maximize performance, and retain confidence in the use of applications associated with significant exposure to risk such as air travel, and cars overall safety.

Recent Advancements in Testing Technologies

There have been some notable growth in the field of testing methods that has enabled more precise and efficient evaluation of materials in an opposing manner. The non destructive testing or NDT methods such as the one involving ultrasound or x-rays have all progressed giving detailed assessment of material structural integrity without employing the test items. Moreover, the modern remarkleting system has incorporated neuro-systems for analyzing rather than predicting how a defect appears or how the system will function much decreasing the errors done by the operator. Advanced environmental chambers with capabilities of recreating extreme operational conditions with accuracy to test performance in top gear are also available. It expedites the entire testing process while effectively using resources and assure meeting the highest requirements of the sector industries.

AI-Driven Testing Methods in Rubber and Elastomer Testing

One of the AI-driven approaches to testing rubber and other elastomer materials comprises harnessing high performance machine learning ML techniques and data analytics to improve mechanical, thermal warm, and chemical properties evaluations. These perform computations to process enormous amounts of experimental data and help in understanding how it was generated or what kinds of relationships exist which are too complicated for humans to find. With the help of such predictive algorithms, even the stresses and strains of materials can be calculated with inordinate details thanks to AI.

As an illustration, tasks related to the design and development of the compound for optimal performance of the rubber in different scenarios such as some extreme conditions or even during mechanical stress for long periods can be performed by this AI assisted software. Also, in-built AI computer vision systems discriminately detect baffled micro defects like surface cracks or air void in defective components in real-time thereby eliminating dependence on traditional inspection techniques. Moreover, it is even more beneficial in context with long-term properties forecasting for the materials which makes compliance with safety and assurance requirements less burdensome.

They enable more rapid actions, reduces development expenditures, and ensures Rubber and Elastomer products are reliable within applications from automotive to aerospace and even healthcare. The addition of AI in material testing processes increases accuracy levels as well as safeguarding products for market use under conditions of use and conformity within the mandatory legal limits.

Automation in Material Testing Systems

In material testing systems, automation is achieved using various technologies that include robotic operation, software applications that connect different technologies in a fo-ur-with-one-bioactivity and real time data about the process. The risk of human error is virtually eliminated through the use of this system, which improves the overall repeatability of the experiments as well as their precision. Hence the automatic systems can perform high volume testing of samples in a sense that many samples may be processed at any one time thereby speeding up the timelines of the product development cycle. Moreover, predictive tools and machine learning protocols embedded in these systems are able to perform a quick assessment of results of materials with a view of material formulation and generation of new materials. By employing automation testing processes, industries are able to ascertain that the necessary regulations are followed even though there is a restrict ion imposed on the operational costs due to the expense involved in the use of human tests.

Challenges and Opportunities in Modern Testing Approaches

As I see it, the challenges of contemporary testing paradigms do not lie in the tests themselves but concern the use of rapidly changing technological systems as well as the data that is produced and stored in various formats within the network. Given the trend of increased automation and AI based instruments, connecting systems with poles on both poles of the spectrum is often a challenging task. Moreover, to meet the changes in regulations and assure data protection in more complex test environments is no easy feat as well.

At the same time, there are advantages to all these drudgery activities. Automation and use of subsequently analysis facilitate the processes, remove barriers of human error and replace one more cycle with another within weeks. In other words, employing artificial intelligence leads to an enhancement of accuracy during analysis performance which includes assessment of historical trends and evaluation of options. If such modern means are used more extensively and appropriately, it will conference efficiency, increase innovations, and also avoid high cost while providing the needed regulation. Its about thinking of challenges in testing methodologies as opportunities of change and improvement.

Quality Control in Rubber and Elastomer Applications

Rubber and Elastomer materials are used across a range of applications where failure can result in compromise in performance, durability, or safety which is why quality assurance measures need to be fulfilled. A system of testing sample elasticity, hardness, temperature exposure and how it affects the material, and other procedures, helps remove nonconformities and controls quality of materials’ properties. Spectrometry, viscosity measurements, and other analytical methods are used for evaluating performance and composition at fine details for different situations. In relation to manufacturing standards, efforts in reducing failures enhance performance and system effectiveness enabling the firm also to achieve the specific regulatory requirements possible.

Role of Quality Control in Manufacturing Processes

Quality control is a component of the manufacturing process and one of the main objectives for manufacturing companies is to deliver a standard product to the customer. Including, various techniques as inspection, process control, and statistical tools during all the processes, in order to find and correct any problems. The modern approach to quality control uses highly sophisticated systems, for example, mechanical systems incorporating architectures of artificial intelligence that make the processes more efficient. The focus on Quality Control eventually helps the manufacturer by reducing wastage and enhancing the productivity, staying within the law, and also customer loyalty increases with time.

Impact of Quality on Rubber Products Performance

Rubber products and quality have a direct correlation; durability, usage, and even performance in various sectors are all affected by the quality of rubber products. The use of good quality materials reduces variations in properties and the chances of flaws which can be helped with enough controls in the manufacturing processes to promote dimensional tolerance and reputation under strain. For instance, low-quality rubber usually encourages quicker wear, breaks, and cracks especially in areas more prone to heat, chemicals, or moving parts. Also, strict adherence to high standards of craftsmanship promotes anti-aging qualities and increased tolerance to other elements thereby helping to prolong the use of the product and reducing replacement costs. Appropriate measures that incorporate enhanced testing methods, such as tensile, compression, and temperature aging tests, are necessary in order to validate parameters and support or create the necessary certifications. Manufacturers are able to improve not only the efficiency of the products but also the safety members of the society appreciate those efforts and also improve the level of trust.

Case Studies: Quality Control in Automotive and Aerospace Sectors

Key case studies include defect detection techniques, material testing advancements, precision manufacturing audits, and supply chain quality integration within the automotive and aerospace sectors.

|

Case Study |

Key Points |

Summary |

|---|---|---|

|

Defect Detection |

Visual/CT Scans |

Use of advanced imaging for identifying issues. |

|

Material Testing |

Tensile Tests |

Ensures material durability under stress. |

|

Precision Audits |

Tolerance Checks |

Verifies manufacturing adherence to specifications. |

|

Supply Chain Quality |

Supplier Audits |

Focuses on supplier compliance and reliability. |

Reference Sources

-

ASTM Testing Methods for Elastomers – A detailed overview of ASTM standards for elastomer testing, including tensile, tear resistance, and compression set tests.

-

Understanding Rubber Testing Methods – A comprehensive guide to various rubber and elastomer testing methods.

-

ASTM Test Standards for Typical Physical Properties – Focuses on ASTM standards like D2240 for evaluating rubber hardness.

-

Innovations in Testing Material Applied to Elastomer Crack Propagation – Discusses new methodologies for testing elastomer resistance to tearing and crack propagation.

-

Elastomer Technology Trends to Watch for in 2025 – Explores innovations in elastomer technology, including self-repairing materials.

Frequently Asked Questions (FAQs)

Q:Why is adhesion important in the rubber and thermoplastic elastomers?

A:Adhesion is a property that enhances the ability of rubber and thermoplastic elastomers to interact with materials and is most important where the formation of a bond becomes pertinent. This means that the materials can be used in manufactured products that are for automotive, industrial and consumer applications. Poor quality adhesion will reduce the durability and reliability of elastomer products and for that, it is essential to test it and optimize it.

Q:Which types of rubber is usually test for its tear resistance?

A:some types of rubber are tested for tear resistance more than others e.g.natural rubber,syntheric rubber and vulacnised rubber. In each case, the rubber has properties and the level of tear resistance which makes them more or less appropriate for these applications. Tear resistance tests are way to help manufacturers determine which kind of rubber is best for exact functional needs

Q:How is tear testing of elastomer materials done?

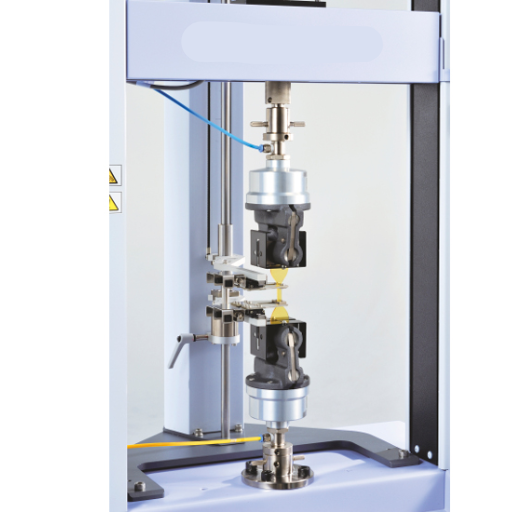

A:For tear resistance testing, a tensile testing machine with pneumatic grips is used most often. It involves applying load to a rubber unit until it fails, reading off the load required for the crack to start and or extend. This helps in measurement of the properties of the rubber and in understanding the potential use of the elastomer products in particular cases.

Q:What is the relevance of vulcanized rubbers and thermoplastic in testing?

A:They are important because they have improved mechanical properties and heat stability thus testing these materials is useful. This is important to determine an adequate compliance of these materials which will withstand specific stresses “internal and external” without failure. It also allows creating new and improved compositions of the rubbers.

Q:Which standard test method is used by ASTM for rubber and elastomer testing?

A:The use of ASTM standard test methods such as the ASTM D412 for tensile properties or ASTM D297 for rubber identification for the testing of rubber and elastomers is most common. These test methods contain procedures that specify how the tests should be carried out and establish the modalities in which the tests should be performed, so that the results can be thoroughly assessed and interpreted in a concise and coherent manner. Adherence to these standards is very important towards the overall quality of the industry.

Q:Why is the modulus of elasticity a factor in rubber testing?

A:The modulus of elasticity is an important consideration that should be taken into account on the results of testing any rubber material. This measures the extent to which a material can be stretched without breaking. A flatter curve means that the rubber is difficult to break which can be in favor or against certain applications. The modulus of elasticity enables the prediction of the test outcomes of a particular rubber sample for different performance test conditions such as tensile tests, tear tests and so forth.

Q:What is the equipment for universal rubber & elastomer testing?

A:There is a vast, universal range of equipment for these specialized tests that exist including rheology tests. This machine allows to evaluate or perform a variety of tests, such as tension, compression, and tear. Different grips such as pneumatic grips can be used and tests speeds are adjustable which makes the testing efficient and accurate as compared to other models where only limited types of grips or test speeds could be used.

Q:What needs to be evaluated in rubber testing?

A:Evaluation of the most common characteristics of rubber include tensile strength, elongation at break, tear resistance, hardness, and resilience. This information will be useful in understanding how the material works under different conditions and whether the material will be useful for any particular purpose. Correct evaluation helps in satisfactory performance of rubber to the functions intended as well as ensuring compliance to recommended specifications.