Instrument And Equipment Wholesale

High Quality Rubber Testing Equipment Manufacturer in China

Introducing our High-Quality Rubber Testing Equipment, crafted by a leading factory in China renowned for precision engineering and innovative design. This reliable equipment performs accurate hardness, tensile, and abrasion tests, ideal for diverse industrial applications. Built with durable materials and advanced technology, it offers extensive customization options to meet specific needs. Trusted for reliability and superior performance, it’s the top choice for quality control and rubber material testing.

What Is A Rubber Testing Equipment

-

Evaluates the physical properties of rubber under controlled conditions.

-

Capable of conducting tests to assess tensile strength, hardness, and elasticity.

-

Utilized across industries like manufacturing, automotive, and quality control to ensure material durability.

-

Often integrates with data logging systems and software for accurate control and detailed test analysis.

-

Available in various designs and capacities to suit different sample sizes and testing needs.

Essential Tests You Can Perform With Rubber Testing Equipment

Explore the comprehensive range of material characterization capabilities available with Rubber Testing Equipment. This versatile equipment allows for detailed analysis of rubber samples under controlled conditions, providing critical data for research, development, and quality assurance.

Vulcanization Test

Assesses the curing process of rubber to enhance its strength and elasticity. By applying heat and pressure, you can measure the cross-linking properties. Understanding how rubber vulcanizes ensures optimal performance in applications like tires and seals where durability is essential.

Compression Test

Measures a rubber sample’s ability to withstand compressive forces without deforming. This test determines the compressive strength and elastic recovery. It’s vital for rubber used in gaskets, seals, and shock absorbers, ensuring they maintain integrity under pressure.

Grinding Test

Evaluates a rubber sample’s resistance to abrasive wear through grinding forces. This test simulates surface degradation under mechanical stress. It reveals the material’s abrasion resistance, crucial for products like conveyor belts and footwear soles that face constant friction.

Tensile Test

Analyzes a rubber sample’s behavior under stretching forces to determine its tensile strength. By pulling the material, you can measure elongation, breaking point, and elasticity. This is key for rubber in belts, hoses, and elastic bands, where stretching resistance is critical.

How to Choose the Right Rubber Testing Equipment?

- Determine the specific types of tests required (tensile strength, tear resistance, compression set, hardness, etc.).

- Consider the sample dimensions and the availability of appropriate grips and fixtures for rubber samples.

- Evaluate the need for environmental chambers to conduct tests at specific temperatures or humidity levels.

- Ensure the machine complies with relevant rubber testing standards (e.g., ASTM D412, ISO 37, etc.).

- Assess the software's ability to analyze specific rubber properties like stress-strain curves, modulus, and hysteresis.

What are the uses of Rubber Testing Equipment?

- Tire Manufacturing: Tests rubber compounds for durability, abrasion resistance, and grip under varying conditions.

- Automotive Components: Tests rubber parts like seals, hoses, and mounts for elasticity, tensile strength, and resistance to fluids and temperature.

- Footwear Industry: Evaluates rubber soles for flexibility, durability, and resistance to wear and tear.

- Industrial Belting: Tests rubber belts for tensile strength, elongation, and resistance to fatigue and abrasion.

- Medical Rubber Devices: Assesses rubber or elastomer materials for strength, flexibility, and biocompatibility in medical applications.

Components of Rubber Testing Equipment

Choose from a variety of controller packages, grips, fixtures, chambers, extensometers, and more, all designed to perform thousands of ASTM, ISO, EN, DIN, and JEDEC industry-standard test methods. When you are ready to complete your system, contact us, and an application expert will help you optimize it for your testing requirements and budget.

View our Rubber Testing Equipment Price

Top rubber tester equipment tailored for you, our advanced technology provides reliable quality efficiently and professionally.

Vulcanizing Machine

Laboratory presses cure raw rubber samples under precise heat and pressure, essential for preparing specimens for post-cure property testing according to standards.

Grinding Test Machine

Measures the resistance of rubber to abrasive wear by controlled friction against a grinding surface, evaluating durability in dynamic applications.

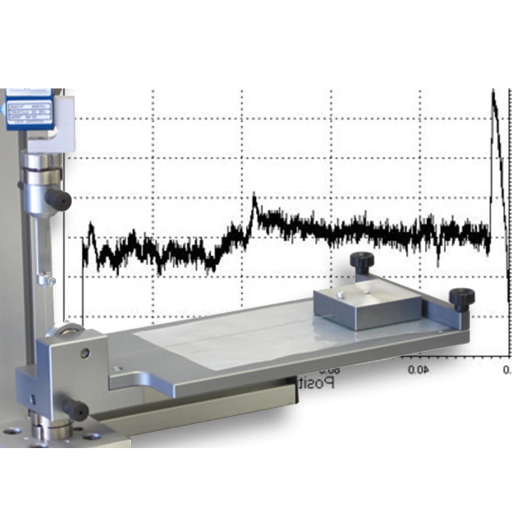

Wear Testing Machine

Evaluates the surface durability and abrasion resistance of rubber materials by simulating wear conditions, critical for performance in tires, footwear, and industrial parts.

Functional Testing Machine

Tests finished rubber products or components under simulated real-world stress, cycles, or environmental conditions to assess performance, lifespan, and reliability.

Other Rubber Testing Equipment

A broad category including specialized testers for properties like hardness, viscosity, elasticity, density, or environmental aging.

Rubber Testing Equipment Data Overview

| Parameter | Details |

|---|---|

| Testing Capabilities | Supports tests like tensile strength, elongation, compression set, tear, hardness, abrasion. |

| Load Capacity Range | Specifies the maximum force the machine can apply, suited for various rubber applications. |

| Strain Measurement | Ability to accurately measure the deformation or elongation of the rubber sample. |

| Testing Speed Control | Allows adjustment of the test rate for different rubber types and standards. |

| Environmental Control | Option to perform tests at controlled temperatures, humidity, or specific atmospheres (e.g., ozone). |

| Sample Fixturing | Availability of grips and fixtures specifically designed for testing rubber specimens without slippage. |

| Accuracy | Indicates the precision of force and displacement measurements for reliable results. |

| Software Features | User interface for test setup, data collection, analysis, and reporting of rubber properties. |

| Standards Compliance | Adherence to relevant international and national testing standards (e.g., ASTM, ISO, DIN). |

| Durability & Build | Quality of construction ensuring long-term performance and reliability under repeated use. |

Why Choose Our Rubber Testing Equipment Manufacturers

We are committed to providing top-tier Rubber Testing Equipment with unmatched precision and reliability. Whether you need advanced testing solutions for compound development, quality control, or finished product assessment, we offer equipment tailored to your specific rubber testing requirements.

We specialize as expert rubber testing equipment manufacturers, leveraging years of experience to deliver high-performance machines. Our designs ensure accurate results for vital tests like tensile strength, elongation, tear resistance, compression set, and hardness, while prioritizing durability through robust materials and advanced technology.

What Our Client Says

Understand from our clients what they say about doing business with us and the unique value addition we provide.

Expert Insights on Rubber Testing Equipment

How do you test rubber material?

Rubber material is tested by subjecting samples to specific forces or conditions using various testing machines. Common tests evaluate properties like tensile strength, elongation, tear resistance, compression set, hardness, abrasion resistance, and performance under environmental stresses such as heat or fluid exposure. Universal testing machines perform many mechanical tests, while specialized equipment is used for others like hardness or viscosity.

What is the standard test method for rubber?

There is no single standard test method for all rubber properties. Standard test methods are defined by organizations like ASTM International (e.g., ASTM D412 for tensile properties, ASTM D2240 for hardness), ISO (International Organization for Standardization), and DIN (Deutsches Institut für Normung). The specific method depends on the material type, intended application, and the property being evaluated.

How do you test the hardness of rubber?

The hardness of rubber is typically tested using a Durometer. This instrument measures the depth of indentation of a specific shaped indenter under a prescribed force into the rubber surface. Different scales exist (most commonly Shore A for softer rubbers and Shore D for harder rubbers), and the resulting number indicates the material’s resistance to permanent indentation.

What is the viscosity test for rubber?

The viscosity test, often performed using a Mooney Viscometer, measures the flow characteristics and processing behavior of unvulcanized or mixed rubber compounds. It evaluates the resistance of the rubber to shear deformation under heat and pressure, providing critical data for controlling mixing, molding, and extrusion processes, as well as predicting scorch time (premature curing).

What is tensile strength test of rubber?

The tensile strength test measures the maximum stress (force per unit area) a rubber sample can withstand before it breaks when pulled in tension. A dumbbell-shaped specimen is stretched at a constant speed on a universal testing machine, and the force and elongation are recorded throughout the test. This test is crucial for determining material strength and elasticity.

What are the parameters for rubber testing?

Key parameters for rubber testing include mechanical properties such as tensile strength, elongation at break, modulus (stiffness), tear strength, compression set (permanent deformation after compression), hardness, and abrasion resistance. Other important parameters include density, resilience, specific gravity, and resistance to environmental factors like temperature, aging, fluids, and ozone.

Latest Blog Posts

Maintain Inventiveness by Following The Blog for the Latest Best Practices, Techniques, Innovations, and Insights in the Field.

For any industrial application, safety engineering, and material science, the knowledge of the coefficient of friction between two materials is […]

Functional testing of equipment plays a vital role in ensuring that a machine, system, or device actually works for the […]

Rubber is considered to be one of the all-around materials, from the automotive and aerospace industries to healthcare and consumer […]

It is rather difficult to overestimate the role of rubber testing equipment in providing the compliance, stability, and performance of […]

Materials such as rubber and elastomers are essential to metals, ceramics, and plastics. When assessing such materials, one has to […]

From healthcare to the automotive and aerospace industries, rubber has become a fundamental material due to its unique elasticity. Caring […]

Get Quote for Reliable Rubber Testing Equipment Today

Ensure the quality and performance of your rubber materials and products with our specialized testing solutions. We offer precise equipment for crucial tests like tensile strength, elongation, tear resistance, compression set, and hardness, helping you meet strict industry standards and predict material lifespan. Partner with a trusted manufacturer delivering durable, accurate machines tailored to your specific requirements. Contact us now for a personalized quote!

Frequently Ask Questions

Q: What is rubber testing and why is it important?

A: Rubber testing involves evaluating various physical and mechanical properties of rubber materials and products. This rubber testing is crucial to ensure quality, safety, and performance, confirming that the rubber meets specified standards for its intended application, whether in automotive, medical, or industrial sectors.

Q: What kinds of rubber tester equipment are commonly used?

A: A range of rubber tester equipment is utilized, including Universal Testing Machines (UTMs) for tensile, compression, and tear tests, Durometers for hardness, Mooney Viscometers for viscosity, abrasion testers, aging ovens, and specialized machines for fatigue or environmental resistance.

Q: What are some standard rubber testing methods?

A: Common rubber testing methods include tensile strength and elongation (ASTM D412/ISO 37), compression set (ASTM D395/ISO 815), tear resistance (ASTM D624/ISO 34), hardness (ASTM D2240/ISO 868), and abrasion resistance (various standards like DIN, Akron). These methods define how tests are performed.

Q: Can you describe a basic equipment testing procedure for rubber?

A: A typical equipment testing procedure for rubber starts with preparing samples to standard dimensions. The sample is then mounted in the appropriate grips or fixtures on the testing machine. The test parameters (speed, temperature, etc.) are set according to the standard, and the test is run while the machine records force, displacement, and other data until the test condition is met (e.g., break, specific deformation).

Q: What are the main types of rubber testing?

A: The types of rubber testing cover various material properties, including mechanical properties (tensile, tear, compression), physical properties (hardness, density, resilience), thermal properties (heat aging, low-temperature flexibility), electrical properties, and environmental resistance (ozone, fluid, UV).

Q: What is needed for rubber glove testing equipment?

A: Specific rubber glove testing equipment is used to evaluate properties crucial for safety and performance. This often includes machines for measuring burst strength (simulating puncture resistance), tensile strength, and elongation (to assess stretch and durability) according to medical and industrial standards.

Q: How does rubber hardness testing equipment work?

A: Rubber hardness testing equipment, typically a Durometer, works by pressing an indenter into the rubber surface under a specific force or spring pressure. The depth of the indentation correlates to the hardness. Different indenter shapes and forces are used for different hardness scales (like Shore A or Shore D).

Q: Besides UTMs, what other rubber testing instruments are essential?

A: Essential rubber testing instruments besides universal testing machines include Mooney Viscometers for processing behavior, Rheometers (like MDR or ODR) for curing characteristics, abrasion testers, density meters, and environmental chambers or ovens for accelerated aging or testing under extreme conditions.