Instrument And Equipment Wholesale

Premium Rubber Functional Testing Machine Manufacturer in China

Introducing advanced systems for evaluating rubber performance, engineered to provide accurate and comprehensive analysis. These instruments are designed to measure key operational properties, helping to ensure material quality, product durability, and compliance with industry standards for a variety of testing needs.

What Is A Rubber Functional Testing Machine

-

A Rubber Functional Testing Machine employs advanced electronic controls to assess rubber performance under applied forces.

-

It determines key properties like elasticity, resilience, and tear strength from test specimens.

-

These machines are widely used in industries for research, development, and quality control of rubber products.

-

Equipped with sophisticated data systems, it provides real-time data, automated testing, and detailed reporting.

-

Available in various models and capacities, it can be configured with tools to test different rubber types and standards.

Main Features of Rubber Functional Testing Machine

Rubber Functional Testing Machine enables detailed evaluation of diverse rubber materials and components under controlled conditions, delivering essential data for research, development, and quality assurance.

Precise Rubber Control

Our Rubber Functional Testing Machine utilizes advanced control systems and sensors for highly accurate application and monitoring of deformation forces on rubber samples, ensuring reliable performance testing.

Real-Time Data Acquisition

Features sophisticated digital systems that collect, process, and display real-time data from sensors, providing high-resolution insights into rubber performance for precise quality assessments.

Flexible Testing Options

Capable of performing a wide range of mechanical tests, including flexibility, hardness, and tear strength, our machine accommodates various rubber materials and components, offering versatile testing capabilities.

Intuitive Software Support

Integrates with powerful software for easy test setup, automated execution, real-time monitoring, and in-depth analysis, generating professional reports to enhance rubber testing efficiency and documentation.

Rubber Functional Testing Machine For Sale

Rubber Flaker

Process rubber into thin flakes with this efficient Rubber Flaker, ideal for recycling and compounding, ensuring uniform thickness with adjustable settings.

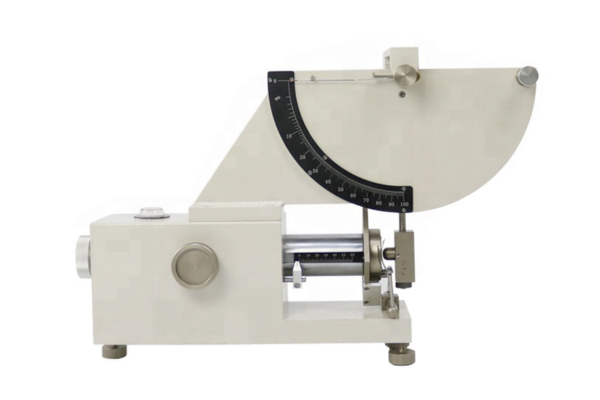

Rubber Rebound Tester

Measure rubber resilience with this Rubber Rebound Tester, compliant with ISO 4662, offering precise rebound height data for quality control.

Rubber Crack Fatigue Testing Machine

Test rubber durability with this Crack Fatigue Testing Machine, simulating cyclic stress to assess crack growth per ASTM D813, with digital controls.

Manual Puncher for Tensile Test Specimen Preparing

Prepare tensile test specimens with this Manual Puncher, ensuring accurate shapes for rubber samples, meeting ASTM D638 standards, easy to use.

Pneumatic Punching Machine

Cut precise rubber specimens with this Pneumatic Punching Machine, offering high-speed operation and consistency for tensile testing, ASTM-compliant.

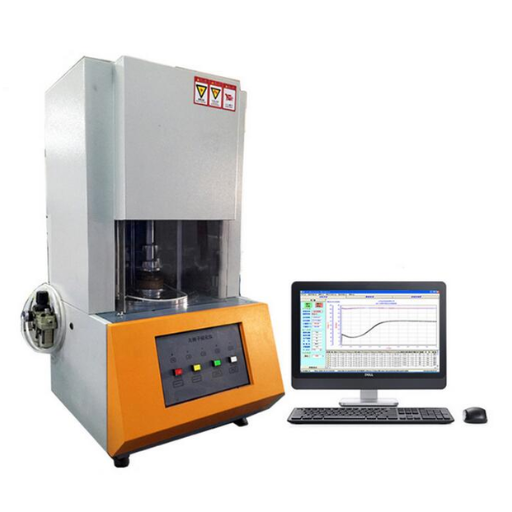

Mooney Viscosity Testing Machine

Assess rubber viscosity with this Mooney Viscosity Testing Machine, meeting ASTM D1646, featuring digital display and automated testing for accuracy.

Low-Temperature Brittleness Impact Tester for Rubber

Evaluate rubber brittleness with this Low-Temperature Impact Tester, testing at -70°C per ASTM D2137, ensuring material performance in cold conditions.

Rubber Functional Testing Machine Technical Specifications

| Parameter | Details |

|---|---|

| Test Types Supported | Tensile, Compression, Flexural, Tear, Adhesion, Cycling, Hardness. |

| Load Capacity | Maximum force the machine can apply or measure (e.g., 10kN, 50kN). |

| Speed Control | Range of test speeds and precision of control (e.g., 0.1 mm/min to 500 mm/min). |

| Displacement/Stroke | Total range of movement of the crosshead or testing mechanism. |

| Data Acquisition Rate | How frequently data points (load, displacement, time) are recorded. |

| Temperature Range | Environmental chamber capabilities for testing at different temperatures. |

| Specimen Gripping | Types of grips available and compatibility with various rubber samples. |

| Software Capabilities | Data analysis, graphing, reporting, automation, standard test methods. |

| Accuracy & Repeatability | Precision of measurements (load, displacement) and consistency of results. |

| Compliance Standards | Adherence to industry standards like ASTM, ISO, DIN for specific tests. |

| Safety Features | Emergency stop, overload protection, safety interlocks. |

| Dimensions & Footprint | Physical size of the machine and space required for operation. |

Application Industries of Rubber Functional Testing Machine

Automotive Components: Testing rubber parts like tires, hoses, seals, and vibration isolators for performance and durability.

Tire Manufacturing: Evaluating rubber compounds for strength, abrasion, fatigue, and dynamic properties.

Footwear Production: Assessing the flexibility, wear resistance, and traction of rubber soles and shoe components.

Industrial Hoses and Belts: Testing tensile strength, elongation, bending fatigue, and pressure resistance of rubber hoses and power transmission belts.

Sealing Solutions: Measuring the compression set, environmental resistance, and sealing effectiveness of rubber gaskets and seals.

Medical Devices: Evaluating the flexibility, strength, and biocompatibility of elastomeric components used in medical equipment.

Consumer Goods: Testing rubber parts in appliances, tools, toys, and other products for durability and functionality.

Discover Advanced Rubber Testing Solutions!

Seeking precise rubber testing? Explore our advanced Functional Testing Machines. Accurately evaluate tensile, tear, compression, and other key properties for quality control, R&D, and compliance. Ensure product performance and reliability. Contact us today for details and a custom consultation!

Frequently Ask Questions

Q: What types of tests can a Rubber Functional Testing Machine perform?

A: These machines are versatile and can perform a range of mechanical tests including tensile strength, elongation, tear resistance, compression set, flexural testing, peel strength, adhesion testing, and cyclic fatigue tests.

Q: Why is functional testing important for rubber products?

A: Functional testing is crucial to ensure rubber products meet performance specifications, durability requirements, and safety standards. It helps verify material properties, predict lifespan under various conditions, and maintain product quality control.

Q: What are the key features to consider when choosing a machine?

A: Important features include load capacity range, speed control precision, crosshead travel or stroke length, available gripping options for different specimens, environmental testing capabilities (temperature/humidity), and user-friendly software with robust data analysis.

Q: Can these machines test rubber at different temperatures or environmental conditions?

A: Yes, many Rubber Functional Testing Machines can be integrated with environmental chambers to perform tests at specified temperatures (hot or cold) and humidity levels to simulate real-world operating conditions.

Q: What range of load capacities is typically available?

A: Rubber testing machines come in various load capacities, from low force units for testing thin films or small components (e.g., in Newtons) to high force systems for large industrial parts or finished products (e.g., in KiloNewtons).

Q: What industries commonly use Rubber Functional Testing Machines?

A: These machines are widely used across industries such as automotive (tires, hoses, seals), medical devices, consumer goods, footwear, textiles, adhesives, and general manufacturing for quality control and research & development.

Q: How does the machine ensure accurate and reliable results?

A: Accuracy is typically achieved through high-precision load cells, accurate displacement measurement systems, robust digital controls, and calibration procedures. Reliable results depend on proper specimen preparation, test setup, and standardized testing methods.

Q: Does the machine comply with industry testing standards?

A: Reputable Rubber Functional Testing Machines are designed to comply with various international and national standards relevant to rubber and polymer testing, such as those published by ASTM, ISO, DIN, and others, depending on the specific test method.