Instrument And Equipment Wholesale

Premium Grinding Test Machine Manufacturer in China

Introducing the Grinding Test Machine, a specialized instrument engineered for precisely evaluating the abrasive wear resistance of various materials. This advanced system utilizes controlled grinding action to simulate real-world wear conditions, accurately measuring material loss. It's ideal for assessing the durability of surfaces, coatings, and solid materials in applications where resistance to abrasion is critical.

What Is A Grinding Test Machine

-

A Grinding Test Machine is a specialized piece of equipment designed to evaluate the abrasive wear resistance of materials by subjecting them to controlled grinding action.

-

It typically uses a rotating grinding surface (like an abrasive wheel or disc) and applies a specific load to the test sample, simulating wear conditions found in real-world applications.

-

The machine measures the material loss (either by weight, volume, or thickness reduction) after a set number of grinding cycles, quantifying its resistance to abrasive forces.

-

These machines are widely used in industries testing materials like rubber, plastics, coatings, metals, ceramics, and textiles to assess their durability and predict performance under abrasive environments.

-

Available in various types depending on the material and standard (e.g., Akron, DIN, Taber), Grinding Test Machines provide critical data for quality control, material selection, and product development.

Main Features of Grinding Test Machine

The Grinding Test Machine allows for detailed analysis of how materials resist surface wear when subjected to controlled abrasive forces. Operating under specific parameters, this instrument provides critical data on abrasion resistance, essential for research, development, and quality assurance of materials.

Precise Wear Measurement

Accurately quantifies material loss due to abrasion by applying controlled grinding force and cycles, providing objective data on durability and resistance to surface wear.

Simulates Real-World Abrasion

Utilizes various abrasive media and controlled parameters like load and speed to simulate the wear conditions materials face in actual applications, offering practical performance insights.

Standardized Test Execution

Designed to perform tests according to specific industry standards (e.g., for rubber, coatings, or textiles), ensuring consistent procedures and comparable results accepted within quality control and R&D.

Versatile Material Testing

Adaptable for testing a wide range of materials susceptible to abrasive wear, including rubber, plastics, coatings, textiles, and composites, making it a valuable tool across multiple industries.

Grinding Test Machine For Sale

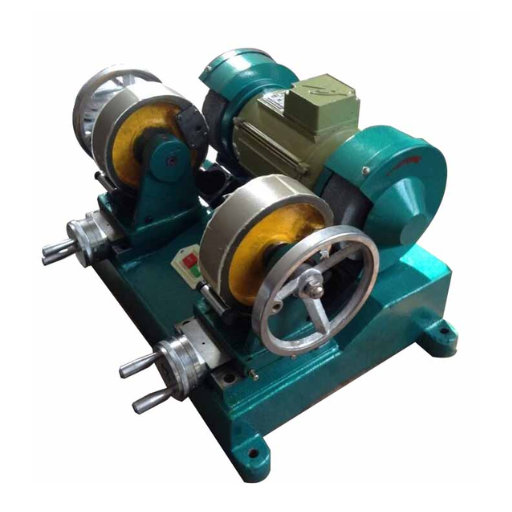

Double-Head Grinding Test Machine

Measures wear resistance with two testing stations for efficient, standardized abrasion testing of rubber, coatings, textiles, and more, quantifying material loss precisely.

Small Drum Mill

Laboratory-scale rotating mill for grinding, crushing, and mixing small quantities of materials with grinding media, commonly used for sample preparation in labs.

Grinding Test Machine Technical Specifications

| Parameter | Details |

|---|---|

| Clamping Force Capacity | Specifies the maximum pressure (e.g., tons or kN) the press can exert on the mold. |

| Platen Size | Dimensions of the heated plates, determining the maximum sample/mold size that can be accommodated. |

| Number of Layers/Platens | Single or multiple layers for curing one or more sets of samples simultaneously. |

| Temperature Range | Operating temperature limits (°C or °F) for curing various rubber compounds. |

| Temperature Uniformity | Consistency of temperature distribution across the platens for even curing. |

| Pressure Control | Ability to set and maintain precise pressure during the vulcanization cycle for repeatable results. |

| Heating/Cooling System | Method and efficiency of heating and cooling the platens. |

| Timer Control | Programmable timing functions for accurate control of curing duration. |

| Daylight Opening | The maximum vertical distance between platens, important for mold handling. |

| Automation Options | Level of automation for cycle control, pressure hold, and alarms. |

Application Industries of Grinding Test Machine

Rubber Manufacturing: Evaluating wear resistance of tires, belts, soles, and other rubber products.

Plastics & Polymers: Assessing surface durability for flooring, films, coatings, and molded parts.

Textile Industry: Testing fabrics, yarns, and upholstery for abrasion resistance and pilling.

Coatings & Paints: Measuring the resistance of surface finishes to abrasive wear.

Footwear: Evaluating sole and upper materials for durability against grinding and scuffing.

Leather Industry: Testing leather for resistance to surface damage and abrasion.

Flooring Industry: Characterizing the wear performance of various floor covering materials.

Wood & Furniture: Assessing the durability of wood surfaces and finishes to abrasion.

Request Information on Your Grinding Test Solution!

Seeking reliable assessment of material durability against abrasive wear? Discover our advanced Grinding Test Machine, engineered for precise and consistent abrasion resistance evaluation. Ideal for diverse materials like rubber, plastics, coatings, and textiles, it offers accurate measurement of wear loss under controlled conditions. Connect with us today for details and a custom consultation!

Frequently Ask Questions

Q: What is a Grinding Test Machine used for?

A: A Grinding Test Machine is used to evaluate the resistance of materials to abrasive wear. It measures how much material is lost or damaged when a sample is rubbed against an abrasive surface under controlled conditions, simulating real-world wear scenarios.

Q: Why is abrasion testing important for materials?

A: Abrasion testing is crucial for predicting the lifespan and performance of materials used in applications where they are subjected to friction and rubbing. It helps manufacturers select appropriate materials, ensure product durability, and meet quality standards for components like tires, flooring, coatings, and textiles.

Q: How does this wear testing machine measure material durability?

A: This wear testing machine typically applies a specific load to a material sample while an abrasive element (like a grinding wheel or abrasive paper) rotates or moves against it. The amount of material lost (by weight, volume, or thickness reduction) after a set number of cycles indicates the material’s resistance to wear.

Q: What types of materials can be tested using a Grinding Test Machine?

A: Abrasion resistance testing machines can test a wide range of materials including rubber, plastics, polymers, textiles, leather, coatings, paints, and certain types of wood or laminates, depending on the specific machine design and standard used.

Q: Are there specific standards for using a Grinding Test Machine?

A: Yes, there are numerous national and international standards that govern the use of these machines, such as various ASTM, ISO, and DIN standards (e.g., DIN 53516 for rubber, ASTM D4060 for coatings using a Taber Abraser). The relevant standard depends on the material being tested.

Q: What kind of results can I expect from abrasion testing?

A: Results from abrasion testing quantify the material’s wear performance. This is often expressed as material loss (mg or mm³), volume loss, depth of wear, or an abrasion resistance index compared to a reference material, allowing for direct comparison between different samples.

Q: Are all abrasion testing machines the same?to specific standards?

A: No, different abrasion testing machine types exist, designed for specific materials and standards. Examples include Taber abrasers (rotating wheel on flat sample), DIN/Akron abrasers (rotating sample on abrasive surface at an angle), and Martindale testers (circular rubbing motion for textiles).

Q: How do I choose the right abrasion resistance testing machine for my needs?

A: Selecting the correct abrasion resistance testing machine depends on the material you need to test, the specific industry standards you must comply with, and the nature of the abrasive wear encountered in your product’s application. Consider sample size, test loads, and available abrasive media.