When it comes to packaging products, the integrity and reliability of flexible barrier materials must be ensured—especially when it comes to the food, pharmaceutical, and medical device industries where safety and performance are non-negotiable. A leading method in package testing is ASTM F88, a standardized procedure for determining seal strength in flexible packages. But what exactly makes seal strength so important, and how does ASTM F88 evaluate it? This blog post delves into the basics of seal strength testing: its significance, the ASTM F88 method, and ways in which one can ensure packaging is compliant with the highest industry levels. If packaging is your field of interest, either as an engineer or in quality control, or if you have any curiosity for how packaging stays together, continue on for some critical insights regarding this process.

Introduction to Seal Strength

Definition of Seal Strength

Seal strength is a measure of the ability of the package seal to maintain its integrity under stress. Being a critical factor in packaging, it ensures that the contents are protected from outside effects such as contamination, physical damage, or perhaps even environmental influences during storage and transport. Seal strength depends on such factors as material properties, seal design, and quality of the sealing process.

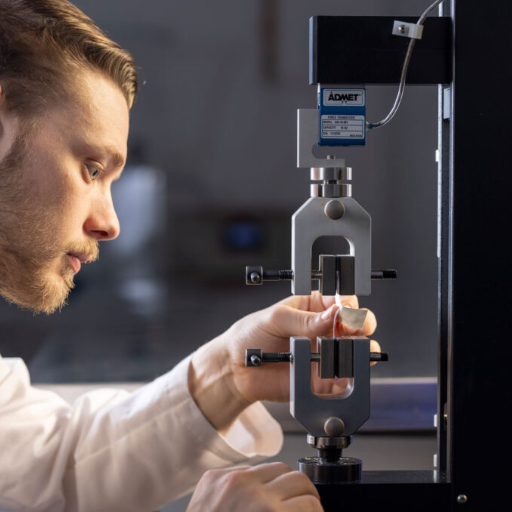

ASTM F88, Standard Test Method for Seal Strength of Flexible Barrier Materials, is an acceptable method of evaluating the strengths of package seals using a tensile test to measure the force required to pull apart a sealed material. During testing, a sample of the seal is held at both ends, away from the melon, and force is applied until the seal fails. The recorded maximum force required to break the seal is the direct measure of its strength. Testing guarantees that the seal withstands any handling and mechanical stresses in the real world.

Seal strength testing per ASTM F88 is an essential factor for having operational industry acceptance and for auditorial review. It could raise some issues in the production processes for the operator’s consideration, such as weak seals or incorrect sealing techniques, which may adversely affect package performance. On the other hand, having good sealing strength should keep product quality from deterioration, along with waste reduction and customer satisfaction. This testing procedure, therefore, helps in data accumulation for the bettering of package design so that it will always be acceptable with the highest standards in the industry.

Importance of Seal Strength in Packaging

Seal testing is essential to human safety and product reliability. By checking the strength of any preparation, a manufacturer assures that the product will retain integrity through storage, handling, and transport. Containment in any form keeps the product inside away from contamination, spoilage, or damage-again, that is to say, one-time quality until it reaches its end user. The strength of well-tested seals is mainly used in food, pharmaceutical, and medical device industries wherein flimsy packaging could pose an excellent health risk or contravene regulatory standards.

Seal strength testing can be conducted, providing manufacturers with data on weaknesses within the materials or into the methods of sealing. Ill-strengthened seals may come from weak adhesives, temperature treatments, or abnormalities in pressure application during the sealing process. Having identified problems with these tests, companies then undertake corrective measures in their packaging procedures to bring them into compliance, thereby assuring consistency to sealing and avoid costly product recalls or failures. Reliable seal performance creates customer confidence, which is also a trade standard.

Testing of seal strength is a primary contributor to the efforts toward sustainability. Providing durability to seals offers a solution to various packaging wastes because of different failures, leaks, or damages thereby impacting the environment. It helps manufacturers to optimize their materials and procedures without compromising the integrity of the package. There are several other types of testing that focus on product safety, quality, and eventually support efficiency, sustainability, and environmental responsibility in packaging operations.

Overview of Flexible Barrier Materials

Seal strength testing is vital for evaluating flexible barrier materials used in packaging in terms of functionality and integrity. Such materials keep contents safe from external influences such as moisture, oxygen, light, and contaminants, while product safety is assured. The seals on such materials need to be strong and durable to prevent leaks that lead to a loss in shelf life and product quality.

The tested method is that forces are applied under specific conditions to test seal strength, and the equipment usually measures peak force when the seal breaks and peak consistency of the packaging. Factors like seal temperature, pressure applied to the seal, and dwell time during package sealing will most influence seal strength. Regular seal strength testing programs will support confirming that packages can endure any handling, transport, or storage that may threaten their integrity.

From a seal-strength perspective, the overall reliability of packaging is considered in order to make it more sustainable. Strong seals could very well make waste due to product leakage or even contamination a thing of the past. Hence, this is a viable environmentally responsible measure. When doing applications that include seal strength testing, it will fall under the entire umbrella of quality assurance and, thereby, help in keeping up with regulatory criteria, allow consumers to trust the brand and make it a truly commercially viable sustainable packaging endeavor.

Understanding ASTM F88 Seal Strength Testing

What is ASTM F88?

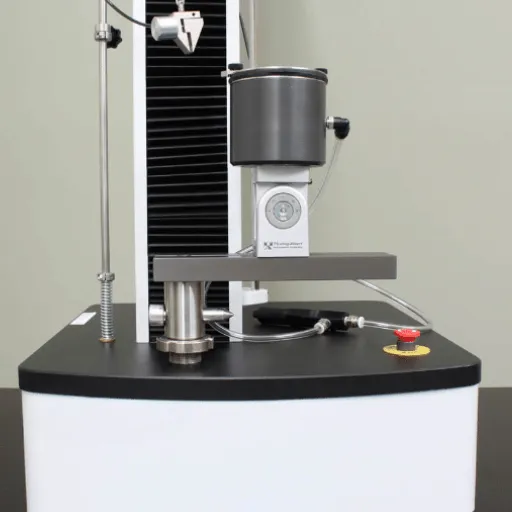

ASTM F88 is a standard test method that is used in measuring the seal strength of flexible packaging materials. This method enjoys widespread recognition, for it is used in determining the integrity and durability of package seals. Bringing a tensile testing machine into the picture, the seal is put under a controlled force until failure, and the results can be used by the manufacturers in analyzing the seal strength and the uniformity. The results determine how the package maintains product safety and integrity during storage, transportation, and usage.

This test method stands critical to quality assurance in industries wherein sealing security is a must, such as in foods, pharmaceuticals, and medical appliances. Therefore, ASTM F88 seal strength testing will help identify any defects in the seals or weakened seals that may adversely affect product shelf life or may allow contamination. It will also make sure that the packaging passed the highest regulatory standards, allowing manufacturers and consumers to be detracted with confidence concerning the product.

ASTM F88 required tests were typically conducted in three sealing orientations, based on a manufacturer’s need: unsupported (seal only), supported (seal with adjacent packaging); both supported and unsupported. The analysis guarantees a thorough understanding of seal performance under different conditions. The ASTM F88 would link companies to better packaging processes with minimal waste and better product quality-as they do together with responsible and sustainable packaging.

Significance of ASTM F88 in Package Testing

ASTM F88 plays a crucial role in determining the seal strength of flexible packaging to ensure that the materials used are durable, reliable, and suitable for the protection of the product. It aims to evaluate the resistance of package seals against forces encountered during handling, storage, and transportation and thereby affects the package’s ability to keep the product intact. Any weakness or inconsistency in the sealing procedure can be detected by ASTM F88, and companies can ensure better quality packaging until the product doesn’t get contaminated or spoiled due to packaging failure.

Seal strength testing as per ASTM F88 is very important because it ensures packaging conforms to safety requirements needed in specific applications. Sterility or shelf life is maintained through flexible packaging in food, pharmaceutical, and medical products. Therefore, regular seal strength testing allows manufacturers of flexible packaging materials to improve their materials and sealing processes, potentially eliminating failures guaranteed under performance in various environmental conditions.

In addition, seal strength tests in accordance with ASTM F88 are implications to costs and sustainability. By detecting a packaging defect in the early stages of production, manufacturers reduce waste and convert materials into products. Accordingly, they save materials, including those which, upon packaging failure, lead to product recall. Following ASTM F88 also helps manufacturers gain consumer confidence since it shows that a company meets the values of quality and sustainability in production, including safe packaging design.

Overview of the Test Method for Seal Strength

ASTM F88 is a highly accepted terminology that describes the test method to establish seal strength for flexible barrier materials. This test method works by pulling a sealed material with force to separate it, essentially testing the integrity of packaging employed in different industries. For ensuring the quality of a product while preventing contamination and satisfying sanitary and durability criteria, this test method becomes very important.

The seal strength of materials comprised of thin films is measured by a tensile testing machine. In the test, the equipment holds the specimen firmly by the grips, applies a steady increase in force to the seal of the specimen until September forces and finally records the strength of the specimen. One means of describing the results is to calculate the number of force units applied to fracture the seal divided by the width of the seal. This helps the manufacturers to determine if their packaging fulfills quality requirements as well as withstands conditions of handling and transportation.

Testing seal strength thus provides an evaluation for the packaging performance to gauge the seals for durability and functionality. When sealing and packaging are tested regularly, such potential weaknesses in the materials and in the processes can be identified, leading to improvement before problems arise. Moreover, it is a method of complying with industrial standards and regulations, assuring consumers of product safety and packaging quality.

Determining Seal Strength of Flexible Barrier Materials

Factors Affecting Seal Strength

Seal force is influenced by several factors, which describe the performance of flexible barrier packaging materials. Materials selected, temperature, pressure, and dwell time during heat sealing are the key factors. These factors combine to ensure a strong seal; any variation may seriously affect the seal integrity.

Another seal strength factor that plays an indispensable role is material selection. Different types of polymers and barrier materials fare differently as far as compatibility and sealing properties are concerned. Cohesive properties (when the same material) or adhesive properties (when materials differ) of a material define its ability to bond upon being subjected to heat and pressure. Materials are, therefore, selected to ensure optimum performance depending on product and packaging requirements.

During the sealing process, temperature, pressure, and dwell time are all equally significant. The balance must be precise to avoid an underseal, which produces a weak bond, or an overseal that would damage the product in some cases. Regular testing of seal strength application enables adjustment of said parameters when necessary. Tensile or peel strength tests can be employed to determine whether the seals meet given specifications, thereby improving packaging and safety.

Methods for Measuring Seal Strength

Seal strength measurement methods are generally applied as a means of guaranteeing the marketability and safety of packaging. The most commonly employed methods include tensile, or force, and peel tests, all of which check the strength of the seams under the influence of a given force. The tensile test gives the maximum force needed to separate a seal-applying the meaning to the test being conducted directly as a definition. The peel test measures the force required for peeling one surface from another, and this test customarily is applied for peelable seals in consumer packaging.

Another dependable method is burst testing, wherein pressure inside the package is gradually increased till the seal succumbs to failure. This test basically establishes the seal’s ability to resist certain pressures that are met by it during hazardous external stresses while transportation or storage of the package. Likewise, vacuum decay testing is performed, whereby a reduced pressure is applied and any increase in that pressure is observed to notice an apparent leak in the seal that may not be evident through simply visual inspection.

Integrity of seal can also be tested through dye penetrant tests in a way that may help in introducing the dye across the device to check for faults. In all, these approaches ensure a strong composite for testing and analyzing the sealing force to further ensure the packaging to perform well as per standards, thereby strengthening the quality assurance programs, which will in turn secure the packaged products while conforming to industry standards.

Comparative Study of Different Seal Strength Testing Methods

The testing of seal strength is important for testing the integrity of packaging to see if it will stand against the stresses of the environment and keep the product safe. Among the various test methods available, tensile, burst, and vacuum decay tests are mostly employed. Each procedure has advantages and disadvantages depending on the application it is used for and the desired outcome.

| Testing Method | Description | Advantages | Limitations |

|---|---|---|---|

| Tensile Test | Defines the amount of force exerted on a seal to separate it | Precise quantification of seal strength; Useful in detecting weak points | Requires good sample preparation; Concentrates on small isolated seal areas |

| Burst Testing | Determines pressure a sealed package can withstand before failure | Evaluates overall package strength; Tests ability to withstand internal pressure | Does not reveal specific defects along the seal line |

| Vacuum Decay Testing | Finds leaks by detecting pressure fluctuations in a vacuum chamber | Non-destructive testing; Tests whole package integrity | Less efficient when measuring mechanical strength of seal |

Each method gives a worthy data contribution to the testing for seal strength. The more methods are combined into a quality assurance program, the more thorough the program will be, testing multiple facets of package integrity, in turn assuring conformity to industry standards, and guaranteeing the best safety for the product.

Practical Applications of Seal Strength Testing

Case Studies in the Industry

Case Study One: Pharmaceutical Packaging

A leading pharmaceutical company has employed burst testing in measuring the seal strength of foil packages containing medicines to ensure that during the transportation, the packaging is able to withstand pressure and, thereby, maintain the product. Modifications to the heat-sealing temperature improved the consistency of the seal integrity, which led to a noticeable decrease in product recalls due to compromises in packaging.

Case Study Two: Food Industry Standards

A worldwide food manufacturer determined tensile forces in order to test the strength of vacuum sealing of processed meats. The test measured the force necessary to peel a seal so as to ascertain that the packaging was maintained during storage and transportation. The results, in fact, necessitated a reduction in the amount of adhesive used, which in turn increased seal strength and improved consumer safety.

Case Study Three: Medical Device Packaging

Creep tests were used by a medical device manufacturer to evaluate seal strength of sterile barrier systems. These tests measured seal performance under long-term stresses at conditions given as “worst case scenarios,” such as long storage and late handling. According to the results of these tests, optimal pack materials were developed to withstand environmental fluctuations and ensure suitability for maintaining sterility along with being regulatory compliant.

Hands-On Demonstrations of Testing Procedures

It is important to conduct demonstrations of procedures for testing seal strength so that people may gain insight into the ways used in assessing sterile barrier systems. Such demonstrations usually include several major techniques measuring the degree of perfection and durability of packaging seals subjected to simulated real-world stresses. Usually, we will employ methods such as tensile testing, burst testing, and creep testing, each one testing—from a somewhat different perspective—the results that can occur on seals with pressure changes, mechanical stresses, and environmental changes.

The tensile test attempts to determine the force needed to rupture a seal under tension. Such a test highlights the strength of the seal and assures that the packaging does not come apart prematurely during handling or transportation. Conversely, burst testing evaluates the seal’s ability to withstand an ever-increasing positive internal pressure until exploding. This testing proves particularly valuable for packages subjected to down-pressure, such as cases in air transit. Creep testing examines the maintenance or retention of strength of seals under a constant load or repeated stress over time for long-term strength.

These procedures are performed with precision instruments to ensure consistency and adherence to regulatory standards. Each method provides critical insights into the materials and configurations that optimize seal performance while maintaining sterility. By observing the demonstrations, the stakeholders will better appreciate how seal strength is assessed, thus ensuring that the systems conform to the requirements set by the industry for safe and effective packaging of medical products.

Actionable Examples of Improving Seal Strength

- Optimize Material Selection: First, set to design and check for materials that are compatible with seal application. Those sealants and substrates must be of a high grade with proven seal integrity to strengthen the overall seal. Heat sealable laminates, for example, with consistent thickness can prevent weak spots.

- Refine Sealing Parameters: Optimize and validate sealing process parameters such as temperature, pressure, and dwell time. Trials should be carried out to find the best set of parameters for an even sealing without over exposure or under processing of the material. For example, allow the heat or pressure to not fluctuate during operation as it is its fluctuation during testing that causes the seal to fail.

- Conduct Routine Seal Strength Testing: Seal strength tests include tensile strength testing and burst testing to test how well the seal performs when put under stress. These tests simulate real-life situations and highlight areas that may require further attention. Having these tests incorporated into quality assurance procedures will greatly contribute to the maintenance of sterility and safety standards.

Through continuous observation, use of improved materials, and tested parameter application, stakeholders can facilitate the improvement of seal strength, along with ensuring regulation compliance.

Compliance and Industry Standards

Regulatory Requirements for Seal Strength

Seal strength regulations are in place to allow integrity tests of sealed packages for applications in the medical, pharmaceutical, or food sectors. Agencies such as the FDA and ISO specify standards for the testing of standards intended to diminish potential contamination of products and guarantee protection of product integrity.

Seal strength testing generally includes testing a seal’s ability to resist forces encountered in storage, handling, and transportation. These may include tensile pull testing, peel strength testing, or burst testing, each of which mechanizes some kind of evaluation of the performance of the sealed edge. Following these tests ensures that regulatory expectations are met and that the product is well protected through its life cycle. Hence, organization must study and implement tests and procedures used to verify and attest the seal quality to standards for safety and reliability of the product.

Location-wise and with respect to seal strength requirements, documentation and validation processes need to be stipulated as part of the regulatory requirements. The manufacturers are required to keep records of test results, the methods used, and the calibration procedures of the testing instrument. Traceability is thereby ensured. Frequent audits are performed, and certified standards are chosen. Fixing these rules will create trust among consumers and may be their safety net in case of recall or failure of product due to lack of seal strength.

Best Practices for Ensuring Compliance

Before starting off with seal strength testing, manufacturers need to establish clear protocols for performing these procedures. These standards specify particular methods to be used in testing the seal integrity so that tests vary as little as possible from one to another and that they are reliable. Training must be provided to staff to perform tests correctly, evaluate them, and interpret results, as misinterpretation can bring about the wrong conclusions and generate potential noncompliance issues.

Next, routine checks and maintenance of testing machinery equipment should be instituted. Calibration must occur at defined intervals to have confidence in the instrument functioning accurately and reliably. A manufacturer must be able to document its calibration procedures or document any corrective action taken. This is to assure an accurate test and to pass the audit, having set the quality standard and compliance upon itself. Using a certified reference material during calibration will enhance traceability and reliability.

Final developments include keeping records of all tests conducted, including results, methods, calibration, and quality control information. Such records act as an important guarantee for traceability in the event of a recall or investigation into a manufacturing issue, thereby ensuring rapid attention to any manufacturing problems. If maintained and enforced fully, these practices would enhance product seal testing integrity with consumer confidence.

Future Trends in Seal Strength Testing

As an evolving field, the seal-strength testing field is adding newer technologies and data analysis methods into its traditions. Among the major trends is automated testing, which offers speedy and accurate measurements. These systems use sensors and software to minimize human error and maximize repeatability, thus ensuring consistent data collection across various testing iterations. Reduced costs and increased efficiency further augment the interest in automation among manufacturers seeking to maximize output.

Another big trend here is predictive analytics and machine learning. These analyses of past seal strength data show manufacturers patterns and the potential issues that arise before they even occur. By addressing issues beforehand, company image and product quality actually get better, with less chance of a recall or customer complaint. Predictive tools have become an essential part of quality control so that companies can fine-tune their processes and react faster to new challenges in sealing performance.

With the general trend of industry embracing more environment friendly methods, sustainable testing methods are gaining in popularity. There is a growing preference for nondestructive testing methods which permit the manufacturer to check for seal integrity without impairing the capability of the packaging for commercial sale. Materials testing is equally moving toward greener options so that the seal is tested for durability without violating sustainability criteria. These developments are indicators that the industry is still trying to balance innovation with environmental awareness and take steps toward the further development of robust and sustainable packaging.

Frequently Asked Questions (FAQ)

Q: What is seal strength, and why is it so important?

A: Seal strength is the whole range of forces that can act on a package seal, which is a means for the seal to resist breakage. That would serve to maintain the integrity of a package, especially when it comes to packaging for medical devices, where a proper seal would guarantee that the contents are not contaminated and are safe for use.

Q: Describe how seal strength testing is generally done.

A: Typically, seal strength testing methods pertaining to ASTM F88 are performed. This standard prescribes measuring the force required to separate a test strip of a material containing a seal. The specimen is held in opposing grips, and a test is performed so the maximum seal force can be determined.

Q: What are the common techniques used for seal strength testing?

A: Some of these common methods include Technique B and Technique C, which vary primarily in how the specimen is prepared and tested. These methodologies help packaging engineers determine seal strength for flexible barrier materials in different situations.

Q: Factors affecting seal strength of flexible barrier materials?

A: More factors affecting seal strength are: adhesive properties of the materials, width of the seal, and contaminants. Other factors include ambient conditions during sealing time.

Q: What is the seal strength minimum requirement for medical device packaging?

A: The minimum seal strength requirement is stipulated in regulatory standards like ISO 11607 to ensure the integrity of a medical device packaging during its defined shelf life or sterilization.

Q: What role do packaging engineers play in assessing seal strength?

A: Packaging engineers are responsible for testing, interpreting results, and optimizing packaging designs to ensure that the seals meet strength requirements and comply with the relevant standards.

Q: How is seal integrity measured by the peel test?

A: The peel test applies forces at 180° to the tail of the specimen to determine the seal integrity. This method measures the adhesion and gives insight into the seal’s performance when subjected to stress.

Q: What are the results of inadequate seal strength?

A: Inadequate seal strength results in a package failure; hence, it compromises the safety and efficacy of a medical device inside. These consequences could result in contamination, product recalls, and legal implications for the manufacturers.

Q: How does the specimen’s alignment in the grips affect the seal strength test?

A: The specimen’s alignment in opposing grips must be precise to maintain accuracy in the test result. Inaccuracies in positioning introduce forces that are not applied evenly, resulting in data that misrepresent attributes of seal strength and performance.

References

-

-

Intertek – Seal Strength ASTM F88

This source explains the tensile strength of seals and the maximum force required to separate seal layers. -

PKG Compliance – How Do You Determine Seal Strength?

A guide on measuring seal strength using ASTM F88 standards. -

Instron – ASTM F88 Seal Strength of Flexible Barrier Materials

Details on testing the peel strength of packaging under ASTM F88.

-