When you consider flexible packaging, seal integrity is one of the most eminent parameters for your product’s safety, quality, and performance. Whether food, medical, or consumer goods, the sealing power of your packaging can very well define the product’s acceptance and consumer satisfaction; ASTM F88 therefore tests seal strength: it is a standardized test method for testing the seal strength of flexible materials. This article delves into the nitty-gritty of ASTM F88, why it is the gold standard for seal strength testing, and how certain various industries can rely on it for sanction and accountability. We look into its intentions, procedures, and applications to get you familiarized with how this test method practically assures the recipients of packaging reliability and regulatory stand. Whether it be engineering packaging, quality assurance, or owning a business all through some way, this will give you something through which you can comprehend how to enhance packaging procedures toward performance enhancement. Stay tuned to find how ASTM F88 testing can help your seal validation from one way to another.

Introduction to Seal Strength Testing

1Definition and Importance of Seal Strength

Seal strength is the force measurement needed to pull apart or peel two layers of materials bonded together. This force measurement is considered very important in evaluating the packaging seal’s quality, mainly for products that need to be securely enclosed to ensure their quality and safety. The tighter the sealing, the more the packaging succeeds at safeguarding the contents from contamination, leakage, or outright destruction while in transit and storage.

Seal strength plays a vital role in guaranteeing product safety, particularly in industries like food, pharmaceutical, and medical device sectors. It basically ensures that the seal is resistant to moisture entry, bacterial contamination, or unintentional spillages while minimizing tampering. A manufacturer can bring its compliant quality standards to expectations by maintaining the seal strength.

Seal strength testing protects the products from damage, engenders consumer confidence, and leads to comparatively fewer returns and damaged goods. Considering the weak points in the packaging, this testing guides companies toward improving their processes and materials to install durability and actively reduce the hits in product failure.

2Overview of ASTM F88 Test Method

The ASTM F88 test method is a standardized process that measures the seal strength of flexible packaging materials. This physically means testing the packaging for its resistance to force by separating a sealed area, making sure that the packaging remains intact during shipping, storage, and handling. Seal strength is an essential consideration for keeping product quality intact, and thus preventing contamination or tampering.

The test is performed by cutting the sealed packaging material into uniform samples and placing them into a tensile testing machine. The machine then applies force at a constant rate to pull the seal until it breaks. The maximum force recorded is then used to calculate the seal strength. The results of this test would help to analyze the performance of packaging and to consider what weaknesses might be found.

Manufacturers have a concrete base to check the effectiveness of their seal processes and determine where changes need to be made to fortify the mechanical strength of the packaging by applying ASTM F88. By doing so, the packaging systems will be in compliance with industry standards, create good customer confidence, and allow hardly any occurrence of products getting damaged at the time of distribution. In cases where product safety and quality remain at stake, ASTM F88 is a perfect choice to maintain the package seal integrity.

3Applications in Flexible Packaging

Flexible packaging finds more and more applications, given its versatility and relative light weight and cost-effectiveness. ASTM F88 helps build on the concept of safeguarding packaging materials by testing how strong their seals are, which is an essential ingredient for product protection. The test method finds application in industries like food, pharmaceutical, and consumer goods, where product safety and quality have the utmost importance. For instance, food packaging must keep the contents dry from contamination and ensure air-tight conditions.

The manufacturers can use ASTM F88, for instance, to check seal strength of flexible packaging and evaluate that any weak spots that are likely to compromise the integrity during storage or transportation are identified in time so as to make sure the product stays secure and uncontaminated all along and garners much in terms of increased shelf-life. Especially, seal integrity is critical for products that get spoiled or become unsafe upon exposure to air, moisture, or contaminants.

In addition, ASTM F88 test results provide a basis for process improvements and quality control. Manufacturers may utilize these results to enhance sealing techniques, determine appropriate materials, and stay within regulatory guidelines, therefore promoting superior product performance and fostering consumer trust, to the extent of reducing product returns, waste, or recalls from packaging failures. In this way, through tests like ASTM F88, flexible packaging today keeps pace with fulfilling industry demands while assuring product integrity.

Understanding Flexible Barrier Materials

1Types of Flexible Barrier Materials

Flexible barrier materials are indispensable for modern packaging in creating a shield against environmental influences such as moisture, oxygen, and light. They are thus meant to impart shelf life, maintain quality of the product, and guarantee the safety of the users of the product. Generally, the most common types of flexible barrier materials are plastic films, metalized films, and multilayer laminates.

Plastic films such as PE and PP are widely used due to their light weight, durability, and versatility. These films give varying levels of barrier protection depending upon their thickness and composition. These plastic films are used generally for food packaging, for medical-grade supplies, and also for consumer goods because they are reliable yet inexpensive.

The metalized films and the multilayer laminates are for more-greater barrier properties, where different materials are combined to best satisfy a certain protective need. Metalized film, coated with an ultra-thin layer of aluminum, has very effective acoustic, particle-blocking moisture, and light blockage qualities. Multilayer laminates are constructed with different combinations of plastic, paper, and aluminum layers to make trade-offs between strength, flexibility, and barrier property. Such materials are preferred where application requires superior protection, such as pharmaceuticals and very high-performance food packaging.

2Characteristics Affecting Seal Strength

Numerous factors affect seal strength, including the properties of the material, sealing process parameters, and environmental conditions. The properties of the material themselves greatly influence sealing since thickness, surface treatment, or composition hinder or facilitate forming a proper seal. Multilayers can be more effectively sealed by virtue of the synergy of flexibility and barrier protection afforded by the layers.

However, sealing process parameters such as temperature, pressure, and dwell time come fourth as being critical to achieving good seal strength. As heat can help or mar the strength of the seals, the pressure must be sufficient for any air or voids to be removed. The dwell time will also have a marked impact on the strength and uniformity of the bond.

Environmental conditions during storage and use can also put a seal into performance. Temperature fluctuations, humidity, and forces exerted from outside may all weaken a seal. These should be duly accounted for during packaging design and tests to ensure that all seals remain reliable for the duration of the product’s lifecycle. In summary, the achievement of seal strength comes with considerations of material properties, process conditions, and environmental factors.

3Role of Seal Integrity in Packaging

The seal integrity in packaging has a vital role to play in guaranteeing that the quality, safety, and shelf life of the product are upheld. A properly sealed package would serve as a barrier to contamination by external agents such as moisture, oxygen, and microorganisms and thereby compromise the contents and cause spoiling and degradation. It is exactly in those scenarios where sealing would have direct consequences on consumer health and safety: in food products, pharmaceuticals, medical devices, etc.

In addition to protection, seal integrity ensures that the product can meet regulatory requirements and build up consumer confidence. Many products are under strict packaging criteria, and the noncompliance with such criteria may lead to the recall of the product, fines, or loss of reputation. Packaging refillability is proof of an assurance of quality that consumers are able to put trust in. On the contrary, without this, they would face leakage, contamination, and tampering risks that would surely lead to adverse implications for a particular organization both financially and from a reputation standpoint.

From the environmental perspective, seal integrity pays for sustainability by cutting down on waste. Packaging failures cause a huge loss of products throughout the supply chain, which is something hazardous environmentally and economically. By assuring that proper sealing is in place, the manufacturer would prevent the damage and thus work toward enhancing the efficiency of resourcefulness. Thus, the packaging seal integrity would mean the protection of products, consumers, and flora and fauna.

The ASTM F88 Seal Strength Test Method

1Procedure for Conducting the ASTM F88 Test

Seal Strength Test ASTM F88 measures seal strength of flexible barrier materials. Integrity tests packaging to ensure the packaging is capable of a secure seal under acceptable test conditions.

- Prepare the Test Sample: The packaging material is cut into a standard-sized strip of usually 1 inch wide, and the sample must fully cover the seal area. Proper preparation reduces variability, resulting in consistent test results.

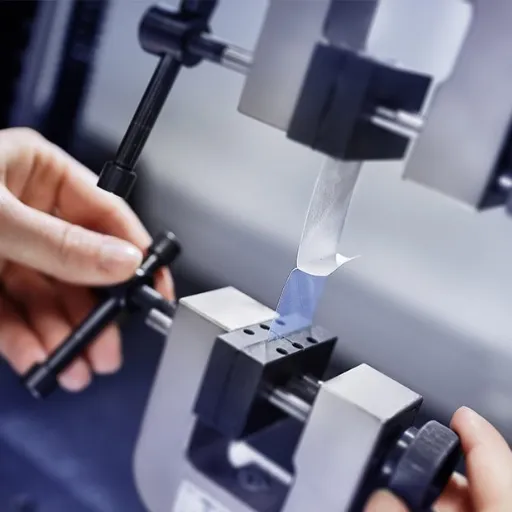

- Mount the Sample: Clamp the sample into the testing-machine grips, ensuring it is aligned properly for a fair test; otherwise, it will skew exact measurement. Choose the way of testing probably, a 90 or 180, depending on the seal and type of material.

- Conduct the Test: Operate the testing machine to apply force at a constant rate, essentially pulling the seal apart. The machine measures the force required to tear the seal apart-the seal strength.

Thus, by carrying out the steps of the ASTM F88 test, worthwhile data are gathered to inform on how strong the packaging seal is and how well it performs under use. The significance of this approach lies in pointing out flaws in packaging design, which ensures product safety and quality throughout the supply chain.

2Equipment Required for Seal Testing

Testing of the seal requires the use of a universal machine. It applies an unvarying, well-controlled force on the packaging seal to measure the force required to pull it apart. This ensures accurate and repeatable results, which are indispensable in seal integrity evaluation.

Specialized grips or fixtures are also required for holding the package material, preventing movement during testing. These grips are necessary so that there is no slippage and an even force is applied across the seal so the measurements can be accurate.

Test samples need to be made appropriately from the package material, cut to dimensions given in ASTM F88, to give consistent and reliable results. Used together, these provide a final effective seal test that gives very useful insight into how the seals hold up in packaging.

3Interpreting Test Results

Interpreting the results from seal strength tests becomes practical once the blend of functionalities and durability can be understood. In a way, maximum seal strength is the key metric, often translated into pounds per inch or newtons per millimeter. The seal must be strong enough to protect the contents of the package while an excessively strong seal could make the package extremely hard to open, thereby compromising user experience. Preferable results illustrate a seal strength that maintains integrity without excessive effort required for opening.

Of course, the test should also determine whether the failure mode is cohesive, adhesive, or peel. Cohesive failures where the material breaks within itself usually indicate a strong seal bond. Adhesive failures, where separation is between two surfaces of the seal, could indicate an insufficient sealing parameter such as not enough heat or pressure utilized in the sealing process. Peel failures, although somewhat desirable in the context of end-user convenience, show that materials are separating under their own design. These design modes reveal information about manufacturing decisions and the functionality of the seal.

Last but not least, minimal variation across test results is highly desired. If the seal strength of samples tested is in the same range, the sealing process can be considered stable and uniform. Otherwise, if variations are significant, the process may have inconsistencies that need addressing. With a thorough review and analysis of all these factors, the manufacturers can optimize the seal strength to meet both functional and quality requirements, ensuring reliable performance in packaging.

Peel Test and Its Significance

1Understanding the Peel Test Method

The peel test is a common method for evaluating bonding strength and integrity, especially in packaging. There is a force exerted to separate two materials joined by an adhesive, heat seal, or any kind of bonding method. It is essential to ensure that the bond is sufficiently strong to undergo the mechanical stress it is subjected to during transportation, storage, and usage.

In the test, the two bonded layers are held in place via clamps in a testing machine that pulls them apart at a standardized angle, speed, and force. The force exerted is recorded, providing a value of peel strength and quantifying the strength of the seal or adhesive. Generally, the results are given in terms of peel strength value reported in force per unit width, such as pounds per inch or newtons per meter.

The peel test analysis allows manufacturers to assess the sealing or bonding process quality and consistency. This aids in identifying weaknesses or defects in materials or processes, ensuring product performance, and meeting durability standards before hitting the market. This process is very important during quality control and development of products in several industries.

2Comparing Peel Test Results with Seal Strength

Peel test results and seal strength are deemed highly synonymous in that both ascertain the performance of materials with regard to their integrity. Yet one should realize that the two inspect different facets of said performance. Peel tests give more heed to forces that come into play during the removing or separation of layers, emphasizing adhesion properties of the materials involved. Seal strength, however, sees to the integrity of the seal structure vis-a-vis its ability to take on forces that would otherwise cause the seal to break or fail.

In comparison, peel test results give information about surface bonding, such as whether the adhesive or bonding agent is uniformly spread. Seal strength can be considered as the durability and reliability of a product subjected to different conditions such as pressure or stress. Combining the characteristics of both tests can give more insight into the quality of the product, providing a micro view (adhesion properties) and a macro-level assessment (seal robustness).

Through the analysis of both peel test results and seal strength, it is possible to pinpoint weaknesses and areas for improvement. This ensures that the products are fit for function and durable before they are put on the market. By assessing these two parameters, a product can undergo the most in-depth quality assessment, hence reducing the risk of product failure and elevating consumer satisfaction.

3Case Studies on Peel Test Outcomes

Packaging Durability

In a study, the peel resistance of food packaging was tested under various environmental conditions. High humidity conditions visibly reduced seal strength as compared to sealing at standardized conditions. The results underline environmental factors influencing packaging integrity. Accounting for these conditions in the sealing procedure, manufacturers were able to optimize this aspect and thereby improve packaging durability during transportation and storage.

Medical Product Packaging

Another case evaluated packaging for sterile instruments from a medical standpoint. Peel tests established that the seals met the regulatory standards for maintaining sterility. Specimens that passed the required seal strength requirements ensured that contamination of package contents could be prevented. This case shows that by assuring the integrity of critical packaging components, peel testing can, in effect, be a matter of patient safety.

Improving Consumer Experience

A consumer goods company analyzed peel test reporting in order to balance seal strength against ease of opening for a household product. If a product was too hard to open due to a strong seal, there were consumer complaints. On the other hand, weak seals might result in premature opening. The company responded to the peel test results by adjusting adhesive levels to provide product integrity as well as a positive user experience, thereby showing the value of peel testing in meeting consumer demands.

Troubleshooting Common Seal Strength Issues

1Identifying Common Problems in Seals

Seal strength problems arise from several sources that can affect product integrity. An inconsistent application of adhesives is a common problem: either the seals are too weak, or they are too strong-and hence not appropriate for the package. This variation may result from manufacturing errors such as the application of adhesive in an uneven manner or the incorrect quantity of sealant. It is of utmost importance to conduct quality checks at regular intervals to pinpoint such inconsistencies and even to further address them during production.

Another very common problem is choosing materials that are not suited for the sealing process or the conditions that the product will encounter. For example, certain plastics will not bond properly with certain adhesive types, or the seal might fail under conditions of humidity or temperature extremes. Ensuring the materials are compatible while also designing the seal in view of the environmental factors can prevent such typical problems from occurring.

The final problem that might affect seal strength is faults within the machines. Misalignments in sealing machines or changes in sealing temperature and pressure might affect how well the finished item works. Through regular maintenance and calibration, equipment can be made to perform consistently and within specifications, making it possible for the seal process to produce reliably performing products.

2Solutions to Improve Seal Strength

Enhancing seal strength needs a complete approach that takes into account material quality, machine performance, and process optimization. First, one has to make it into the top-class materials. Make sure that the materials that go through the sealing process are compatible with product requirements and possess sufficient durability and flexibility to form a strong bond. Testing out materials before use can show which is appropriate for specific applications in sealing.

Second, equipment maintenance is crucial to consistent results. Regular cleaning, lubrication, and part replacements make sure sealing machines are working as intended. Furthermore, periodic calibration of sealing equipment would help to keep parameters such as temperature and pressure within the necessary range so they do not produce weak or inconsistent seals.

Third, process audits and operator training can work wonders for improving seal strength. An audit helps to identify inefficiencies and solve them, whereas a trained operator will recognize the issues and address them promptly. Thus, in combination, good-quality materials, well-maintained equipment, and trained personnel can reliably achieve strong and durable seals in production.

3Best Practices for Quality Assurance

Quality assurance, in this respect, implies a proactive approach to generate high-quality products. It is imperative to stick to the appropriate inspection and measurement techniques at all phases of production. Periodic inspections help early detection of defects, barring the possibility of questionable items being sold to end consumers. Another method is to standardize quality parameters so that teams can monitor performances over time and easily spot trends or deviations from improvement.

Another important aspect is communication among team members. Communication lines make sure that all quality standards are understood in every department, hence reducing errors caused by misinterpretation or miscommunication. For instance, regular meetings or training sessions can reiterate these standards and further foster an accountability culture in which every team member takes responsibility for the quality of the finished product.

Finally, on occasions, technology can come to the aid of quality assurance processes. An automated testing tooland data analysis and monitoring software may serve an excellent purpose in both detecting real-time production inconstancies so that they get corrected right away. These tools, integrated with routine audits, can provide an organization with consistency in delivery of quality products.

Frequently Asked Questions (FAQ)

What is seal strength testing?

The seal strength testing is a crucial examination that specifies the minimum seal strength and bond strength that may be required of packaging materials used in the packing of medical devices. The average force to peel open a test strip of material containing a seal is measured to assess whether or not the packaging engineers can determine the seal integrity and performance under different conditions.

Why is seal strength important in medical packaging?

The seal strength for medical packaging is crucial for maintaining package integrity in order that the sterile barrier be not compromised. It aids the manufacturers in ensuring that there are processes in place for the packaging that should always be capable of placing consistent seals on behalf of their respective product, thereby conforming to regulations, safety standards, and against contamination, assuring the efficacy of the product.

What are some common test methods for seal strength?

Test methods are commonly ASTM F88, where a universal testing machine is employed for measurement of the peel strength of flexible barrier materials. It consists of applying a force to separate a test strip clamped in opposing grips and measuring the force to achieve separation.

How does the alignment plate affect seal strength testing?

The alignment plate helps in properly securing the test specimens during seal strength testing. Proper alignment will reduce variation in testing results and result in more accurate readings of average force to open the seal.

What is the significance of the average force required to separate a test?

The significance of the average force required to separate a test is an indication of the high performance and reliability of the seal. Usually, high average force means that the seal strength is much better; in life cycle testing, when the packaging of medical products has poor seal strength, this can be a matter of great concern.

How do packaging engineers ensure consistent seal strength?

In maintaining consistent seal strength, the packaging engineers work on monitoring the ability of the packaging processes to produce seals that meet the minimum seal strength requirements.

What are the implications of unsupported seals in packaging?

Unsupported seals may be liable to failure under a condition of stress. Evaluating the performance of unsupported seals during the test for seal strength would allow identifying weaknesses that could eventually lead to problems with package integrity.

What role does package integrity testing play in seal strength evaluation?

Package integrity testing is a complimentary approach to seal strength testing, evaluating the overall package performance, including how well the package maintenance of protecting qualities, such as prevention of leaks and maintenance of sterility, being key requirements for medical device applications.

What are the factors that affect the maximum seal force in packaging?

The factors can be said to be the materials involved, the configuration of the seal and the conditions under which the testing is carried out. If these factors are well understood by the manufacturers, it will give them the ability to select the best process and in which case the seal will be able to stand up to the forces it has to endure during actual use.

References

-

Prewell Labs: Seal Strength Testing: Importance, Standards, Protocols, and Advanced Considerations – This source provides an overview of seal strength testing, its importance, and advanced considerations.

-

FlexPak Inc.: ASTM F88 Seal Strength Testing – A detailed explanation of the ASTM F88 standard, which is widely used for measuring seal strength in flexible barrier materials.

-

Greener Corporation: Seven Seal Testing Methods for Flexible Packaging – Discusses objectives, methods, and limitations of seven common seal testing methods.

-

Smithers: Plastic Seal Strength Testing – Focuses on dynamic and static seal strength testing, including compliance with ASTM F88.

-

ASTM International: Standard Test Method for Seal Strength of Flexible Barrier Materials – Official documentation of the ASTM F88 test method, detailing procedures and failure modes.