When it comes to evaluating materials for both longevity and malleability, the ability to bend a material is critical. It is essential to test different materials with respect to their bending behavior to determine their capacity to perform in specific roles. Engineers, builders, and manufacturing personnel all need to ensure they are using the right materials for the job. Whether it is a metal, plastic, or composite, its bending characteristics are crucial. The purpose of this guide is to provide a more nuanced study of bend testing, which is used in disciplines such as civil engineering and aviation, so that such tests along with their techniques can be well understood. If you want to delve deeper into the discussion related to bend testing, you have come to the right place. Let’s venture into the discussion and understand the core principles that are involved with material bend testing.

Understanding Bend Tests

Purpose and Significance of Bend Testing

The primary uses of bend testing concern assessing the metals, plastics, and composites; with a focus on the materials’ ability to withstand rupture and the question of its strength and overall standard of the product of materials. Consequently, bend testing becomes a critical requirement in industries that prioritize the reliability and safety of products. For example, in order to confirm the ability of a particular product to withstand the stress burdens, the profile beams in buildings and those in airplanes have their separate critical bend-testing requirements. There is a need for a material to be ductile or plastically deformable.

Any weak spots, such as defects, such as cracks or other forms of materials failure, can be effectively determined through bend testing. These such details are necessary to determine whether the material is useful for a particular task. Engineers can estimate the material behavior under different stress conditions and risks by observing the components under a controlled load and bending.

Bend testing is further crucial in the framework of quality assurance, materials research and development (R&D), and manufacturing improvement processes. With bend test trials, industries can guarantee that the materials meet the industry requirements and comply with the set standards of the materials. For instance, the produced materials can meet the ensured consistency and safety level of the exposure of sourced products. These test materials help manufacturers understand the process of optimization in terms of the intended applications from materials.

Role in Assessing Material Flexibility and Durability

In the realm of materials, flexure testing is the gold standard for gauging material means, toughness, and overall performance. The sole objective of these tests is to identify the potential of a material to deform without physical rupture or structural damage — a property of key interest to applications across multiple operational spectrums. When a sample is put under standardized die swaging, the tests offer a peek into the swaging material’s mechanical stress handling, greatly simplifying the cost–benefit evaluation amid operating conditions.

The ability to fracture material and hence toughness is a principal concern in the testing for materials with die swaging. Slower curvature, engineering and vehicle parts, for example, you have crooked foundations in the automotive industry, and you require materials that can curve more than once. Die swaging also enhances the application because it assists with the redesign of the material components and they can be used in other systems because of the intelligent use of currents and standards.

On the other hand, in the context of materials, the attention is trained on the manner in which materials respond to the application of a load combined with stress—all the while keeping the material’s shape intact. Choosing the right construction materials, for instance, in the case of infrastructure or aviation industry, necessitates long-term reliable solutions under the most extreme conditions. Addressing the issues about flexibility and strength of materials allows the industries to comply with stringent guidelines and at the same time secure high operational effectiveness with affordable sustenance.

Overview of Mechanical Testing and Materials Testing

The assessments of materials using mechanical and material testing are crucial for acquiring information about their behaviors and performance under various conditions. The proper evaluation of the materials provides valuable data that helps industries in ensuring the materials for their applications have both a safe and suitable life. The materials can be evaluated with the help of their tensile strength, hardness, and even flexibility to make sure they meet the desired criteria. Industries that prosper in aerospace, construction and automotive industries usually pay more attention to their needs of corrosion resistance, wear ability and the tolerance materials that are to be used.

A proper examination of materials with the help of mechanical testing is used for testing the hands of materials to respond to the forces being applied such as tensile, impact. The impact of a test on materials is in the tensile manner, and the test of the tensile is an example that measures the ability of something like an object to be stretch under the sudden force to break. The tests also include the resistance of materials during impact of a force with the impact of a force with impact of force the test which does that will be the impact test.

For proper engineering, materials testing includes the structure, chemical, and composition along with proper engineering. These tests and evaluations determine the wear and the ability of materials to recover from the breakdowns and corrosive materials that are used in particular engineering designs. Annotations of materials are utilized to grant the necessary information and proper testing and operations are utilized to determine the engineering’s characteristic of their materials, the applications that utilize certain designs, and any other aspects of the products that are utilized in connection with engineering designs.

Industry Standards for Bend Tests

ASTM Guidelines and Their Importance

ASTM guidelines actively serve a critical, overarching purpose with regards to maintaining dependable products and materials: they supply precise standards for the performance of critical cutting-edge testing—like, bend tests that determine the materials’ mechanical properties, stretch, and termination—manufacturers and industrial. This reduces the risk of materials with problematic properties as well as areas of exceptions in documents, thus far easier to comply with engineering designs. Advanced technologies and solutions are made possible, lowering costs of implementation, thus accelerating time-to-market and reducing regulatory scrutiny.

Key Advantages of ASTM Guidelines:

- Repeatability and accuracy in testing procedures

- Uniform standards across various materials including carbon fiber, composites, stainless steel, and aluminum

- Reduced regulatory scrutiny and faster time-to-market

- Enhanced product reliability and safety

Furthermore, ASTM guidelines are made for the advancement of the technologies, and they definitely encourage new product development and testing. In addition, such research materials enable advances, product development, and production, while overcoming challenges of modern adhesive technology by complying with ASTM guidelines. Such advances are made possible with the new and constantly developed and improved adhesives, making the “adherent bonding” solution possible. It has and will always have the role to enable the streamlining of technologies and materials, the challenges and threats of the new technologies can be easily overcome.

ISO Standards and Compliance Requirements

The ISO holds significant importance in almost every industry because the standard ensures the products and services are safe, efficient, and of the highest quality. The standard have been set to make sure that products and processes are in uniformity and to make global market easier for industries. For every product and process, the ISO sets the bar, enabling the process of achieving the goals easier. Meeting the policy standards and behaving according to the laws makes the ISO-certified organization adhere to the policies and maintain good customer credibility.

For instance, if the organization uses adhesive technology for any purpose, there is a need of a guideline to be followed, and adhesive standards must be met. These refer to the rules and guidelines and how adhesive should adhere to the surfaces. Adhesive should be used given whipping performance as the standard sets. In doing so, it is beneficial in the vehicles construction, aircraft, motor-vehicle, and much more industry, increasing adhesion technology and the performance and quality of the vehicles.

Globally, meeting the ISO standard is vital. The effects are felt almost immediately. Greater innovation with using new standards adhesives has increased technology by a magnitude. An example of this is the VOCs I mentioned with ISO accompanying the standards. By doing this, I suggest following the environmental compliance. All the whilst, the products increase in terms of quality, and the industry enjoys globally recognised good practices.

Variations Across Different Industries

ISO standards serve as a common ground for major principles, but viewing the areas to which industries focus on ISO standards show vast differences. For example, manufacturing relies on quality management and implementation of ISO 9001 to streamline operations in line with desired standards and manage the quality of their products, which is their main product. Under ISO 9001, companies are able to control and sustain objectives throughout the entire value chain.

| Industry | ISO Standard | Focus Area |

|---|---|---|

| Manufacturing | ISO 9001 | Quality management and operations streamlining |

| Healthcare | ISO 13485 | Medical devices and safety procedures |

| Energy & Construction | ISO 14001 | Environmental management and pollution reduction |

| IT Sector | ISO/IEC 27001 | Information security and cyber threat management |

Data is the most important resource and, at the same time, the most important security vulnerability, so the IT sector is on the way to implementing ISO/IEC 27001 to implement managing methods for cyber threats as well as certification for providing evaluation to information risk based on the significant know-how in protecting data. In a world of changing needs, cyber, as well as normative threats, need to be addressed, but as the numerous sectoral threats come to the rise OF new, organizations need to protect against cyber threats as well, and different industry norms assist in pursuing improvements in risk management.

Common Bend Test Methods

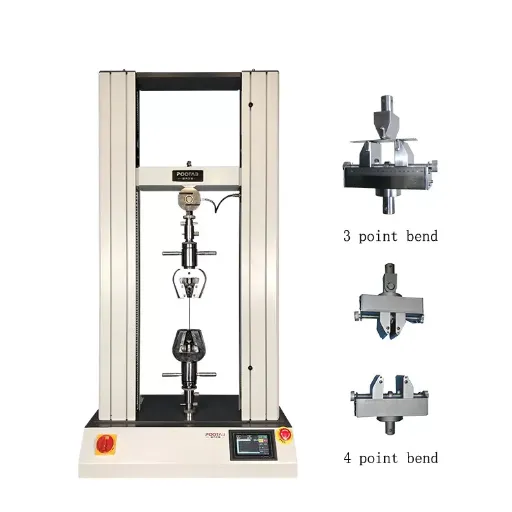

Three-Point Bend Test: Methodology and Applications

Flexure and its properties are tackled subject to three-point bend tests, and are put to the test by forcing and supporting loads on ends and applying a load in the center, failure and deformation are to be identified. The yield of the material directly depends on the load supported, and the yield on the specimen. The specimen that contains the applied load is then deformed until it fails, and the deformation is to be studied and recorded. The load as well as the deformation are determined in order to establish and study the flexural strength. The complex flexural modulus material is used due to its linear flexural measurement and life, depending on the elastic modulus constant. Notes like the load versus deflection curve, clearance between the loading noses, and the loading rate of the testing machine collects the test data and is stored and analyzed.

Three-Point Bend Test Applications:

- Plastic Materials: Assessment of flexibility and break resistance

- Metal Components: Evaluation of ductility and strength properties

- Composite Materials: Testing of layered material integrity

- Engineering Applications: Component design and stress analysis

The three-point bend test carries vital weight for materials that have a special need for bending and demand the knowledge of their bearing abilities. Besides, it is often needed for plastic, metal, and composite. For each material discussed, the flexural strength and the module of the elasticity are materials that need the three-bend test. Engineers who wish to work are advised to consider the different components of a categorical product and the loading-maximum stress value. Furthermore, the university specifically advises students to access and look specifically into the advantages of the reverse engineering of the specific and all related components urgently.

Four-Point Bend Test: Differences and Use Cases

Four-point bend testing is the method used to test the flexibility and rigidity materials through the placement of 2 pins on both ends of a beam resulting to a 4 point supported beam. Alternatively, three-point bend testing involves loading a beam by a single imposed load. The load is designed in such a way that it can distribute various magnitudes of loads for the first test, the load and the distance from the load are individually calculated. Subsequently, the remaining 3 points of the beam are each given the exact same load; the 4 point bend test has a distinct difference in the configuration of the set-up and the load it can accept when the load and its application points refracted. Treating the whole beam as a cantilever will lessen the stress produced by reasons of that beam.

Three-Point vs Four-Point Comparison

Three-Point: Single load application point, concentrated stress

Four-Point: Distributed loading, reduced stress concentration

Four-Point Advantages

Better for brittle materials, uniform stress distribution, improved reliability for structural testing

The 4 point bend test can provide a non-cantilever or a non-cantilever test configuration, which reduces material quality task tactics and increases its application to material study which if highly or semi-brittle materials. Highly brittle materials and composite materials tend to fail abruptly in under-loaded tests, which are facilitated by the four-point bend test which advocates tests under stress concentration, and the wide distribution of the four-point bend in the arrangement of the load required to the materials means structures that could be heavily stressed will not be.

Four point test, in construction, aerospace, and automotive sectors, is a non-talented and a non-symmetrical test which is used against materials which are usually highly brittle and industrial. The material quality checks in these sectors is four point bend test leaves room for materials other than mild steel and mild plastic. In terms of plate structures which deal with loads that are uniformly distributed, there is the beam. In modern days, there are seals which are also classified as plate structures. The testing of seals structurals must maintain the elastic or reversible strain over the plate.

Guided Bend Test: Procedures and Benefits

The examination of a welded test piece is the fundamental purpose of using guided bend testing to check the welds. It involves bending a welded test specimen to a particular bend angle or radii to check any existence of defects such as cracks or fractures. It allows enough inspection of the welding to ensure that it meets the required criteria instead of just checking the surface. This also ensures that the welding will not fail unexpectedly when used as intended.

Guided Bend Test Procedure:

- Specimen Extraction: Remove test piece from welded structure

- Preparation: Prepare specimen according to testing requirements

- Machine Setup: Place specimen in guided bend testing machine

- Controlled Bending: Apply controlled force around former to specified angle

- Inspection: Examine for visible defects, cracks, or separations

Of the most relevant characteristics of guided bend testing is the test’s ease and directness with regard to the evaluation of the welds. Welds can be thoroughly tested for inclusions or other issues without involving any complex operations. The results will shed light on the weld’s appropriateness for its mechanical application. This assists in ensuring the structure’s safety, eliminates the likelihood of failures, and aids in meeting the desired and applicable standards. The guided bend approach is useful for identifying defects, which in turn, streamlines the manufacturing process, thus, reducing the process cost of identifying defects.

Essential Testing Equipment

Testing Machines and Their Specifications

A bend test machine is a device that evaluates a material’s ductility and strength. The way it does this is fairly simple: A controlled force is applied to the material in order to bend it. This machine is indispensable in determining how a certain material can perform underneath pressure and deformation, and it aids in thoroughly understanding the material’s properties.

Thus, this type of machine is essential as it directs a systematic bending of the test specimen. It engages a loading mechanism that is quite effective and can therefore be easily utilised to detect various deficiencies like cracks, surfaces that are not even, or weaknesses present internally. This type of machine can be used to determine if the material is meeting the crucial requirements.

Key Machine Specifications:

- Force Control: Adjustable force application for different material requirements

- Clamping System: High clamping force to secure materials during testing

- Versatility: Capable of handling various material types and sizes

- Precision: Accurate measurement and control systems

Fixtures and Testing Setup

The bend test machine must have materials securely held in place during tests. These materials must be aligned with the standards and material dimensions set in place. The bend test machine must be adjusted to allow the use of a variety of materials such as metal, plastic, and composite.

During the bend test, the machine must be properly calibrated. The calibration includes configuring the force assistance and confirming the fixation is properly aligned with the material under testing. By doing this, the testing errors can be controlled and perfect results can be produced. The operators must ensure the protection of the users during the test like shielding and encasing of the testing product.

To proceed with the bend test the testing machine must be in a controlled environment to prevent us external factors like vibrations and temperature changes. Even more so, the testing machine must have its testing parameters like material dimensions and force to be applied and even the temperatures must be readily documented for subsequent data analysis. This helps protect the individuals in the product development and quality assurance processes as well as save time.

Measuring Tools and Sample Geometry Considerations

To obtain dependable results, there is a need for high precision machines that are used when measuring the features of a material to be carried out. The above work is done with the help of high-end devices like calipers, micrometers and laser measurement equipment which are used to measure the length, width of a test material, along with its thickness. A material testing lab does have the ability to maintain the calibration of the instruments above since it ensures that the data is reliable. In comparison, the presence of a measuring error is an indicator that the data might have some variations.

Essential Measuring Equipment:

- Calipers: Precise measurement of specimen dimensions

- Micrometers: High-accuracy thickness measurements

- Laser Equipment: Non-contact precision measurement

- Calibration Tools: Ensuring measurement accuracy and reliability

On the other hand, the test material geometry is also crucial. A simple material like a cube should be of a particular standard size to be recognized and defined academically. Being ASTM, ISO and many others known, such standards require preparation of the samples to meet the stated standards so as to be recognized and defined. Any deviation in the previously stated geometry has to be of a cube should be of a particular standard size to be recognized irregardless of the standards it meets and requires a new to be sampled cube along with a new document and its recognition and be defined. During these tests, the samples have to be manufactured and cut to meet the geometry requirements for ASTM, ISO, and such, which is given for each type of test.

Importance of Compliance with Testing Standards

Ensuring Consistent Product Quality

Maintaining and strategies which adhere to high testing benchmarks is vital to develop safe and dependable products. Not only does this produce reliable results, but it also allows manufacturers to fabricate materials and products that have been quality tested. While this does help with minimizing variants in the production, the end goal to validate each product against set standards increases the high to which the material can be functioned to. Such regulations help the overall build quality, and even end users are able to rely on the completed product to be safe and to have a baseline of performance they can trust to deliver consistently.

Benefits of Standards Compliance:

- Enhanced product transparency in markets

- Simplified product evaluation and benchmarking

- Reduced regulatory obstacles

- Increased consumer trust and confidence

- Consistent performance delivery

Furthermore, these standardizing regimes help in enhancing product transparencies in the markets. In this new age, the standard identifying terminology when used makes it much simpler to evaluate and benchmark different versions, be it from the same or from different manufacturers. As all products fall under the same checks and balances, as a result, this makes the world a better place to operate in, as the phrase “product dumping” is only reduced as people can now make their choices fully knowing which offer to take. This adds to the trust aspect and also helps eradicate some of the regulatory obstacles, if fully recognized.

Enhancing Safety and Meeting Regulatory Requirements

Every product made and sold is a risk to humans. To reduce the risk to the consumers and the population at large, safety measures have to be adhered to and products have to be required to not pose unreasonable risks. At the same time products have to be able to function effectively to avoid unnecessary risks. The measures to be taken to satisfy these requirements have to be put in place. Furthermore, industries have to align and follow the standards that are required for the safety, protection, and the industries.

To promote the safety of the industries, outlets must strictly follow the set of standards that have to be implemented worldwide. These standards are to be followed through strict adherence to quality control, extensive product and risk analysis to develop a product risk profile to ensure that a product is risk assessment is in print and is follow through the process. To aid further, labeling plays a critical role in promoting safety in addition to enhancing the customer safety all products have to be resourced with the labeling versions that serve the customer with the necessary information to avoid the misuse and any accidents.

In contrast, meeting the regulatory demands stresses equitability and responsibility marketed goods. Meeting and complying with these satisfaction standards builds the confidence of the customer more than that of the safety. Equitability, the safety regulations of markets, regulatory requirements corporate and identified protective focus, customer and previously regains the regulatory risk balance. Compliance with the regulations engenders compliance with the standards. Verified with the dedication of the regulatory team , customer and the request and compliance with the requirements, compliance with the careful distribution of the product and its development.

Avoiding Failures and Costly Recalls Through Proper Testing

Proper testing is of utmost importance to maintain the safety and quality of any product and thus work away from the negative impact of failures and costly recalls. Real and helpful implementation of quality control and reliability testing in the early stages of the development is quite beneficial in addressing potential problem areas. These also validate the assessment models that the product complies with all regulatory, customer and standard safety standards while preventing unwanted and non-conformed products from being marketed and preserving the product still in validation and risk assessments prior to the implementation and products and releasing the project of unsafe and unwanted products.

Consequences of Inadequate Testing:

- Financial Impact: Costly product recalls and liability issues

- Reputation Damage: Long-term brand image deterioration

- Safety Risks: Potential harm to end users

- Regulatory Issues: Non-compliance penalties and restrictions

- Market Position: Loss of competitive advantage

Also, it addresses the lack of validation failures of the product against various consumer use environment, and thus, with the use environment the product was designed and intended for purpose. Robust testing is also backed up by environment and stress testing as well as product performance evaluation, which in combination to real world product testing can prevent unwanted and unsafe products. These actions show the vie to safety and customer satisfaction and in the end, add to consumer and company trust and the reputation of the company.

Proper testing is a step to save the company’s money because it integrates control of the safeness of the product. Recalling a product is a financial and logistical nightmare, and more often than not, it is also a damage to the company’s image, which takes a very long time to be retrieved. With the company’s focus on testing in the production stage, limits can be reduced and safeness of the product can be ensured, and as a result, and in the meanwhile, the company meets its commitment of producing its products at a higher standard.

Frequently Asked Questions (FAQ)

Q: What is the guideline for bend test?

A: Bend test guideline refers to defined methods and criterion that provide sketch for conducting such tests for looking out the properties and strengths of the materials. This ensures the repeatability and reliability of the results, by making available relevant information concerning the preparation of specimens, techniques to be used during testing, and the equipment used to facilitate the test.

Q: What is the significance of bend force in bend test?

A: The materials’ bending strength and ductility evaluation require the use of bend test forces in order to determine load the specimen is subjected to during the test. This is so because the strength is material characteristic that, similarly to other characteristics, has to be determined with the use of prescribed/fixed/tested forces. The test results of a material’s existing and conditional cracks are depending on the applied forces, and material resistances are called.

Q: What does the application of different bend test methods allow?

A: The 3-point bends and specially semi-guided bends provide a complex set of materials bending characteristics. The type of a bend tests loads in a special way giving a optimal evaluation of a material’s bending ductility and strength. Each specific type is more instrument to the special material compositions and special conditions of material utilization.

Q: How are bend test testing machines instrumental in materials testing?

A: The machines used in the testing, universally known as UTM (Universal Testing Machines), are used to bend the test samples with special considerations to their bending and then to measure the maximum load and the specimen’s displacement. Machines fitted with extensometers and load cells provide the bending forces and make it certain that the test is performed correctly. The amount of the applied force is always measured optimally which is a key part in the test.

Q: Why is the sample preparation for a bend test so significant?

A: Proper preparation of the test sample assures that the specimen is a true representation of the material it is being tested. Specimen shaping and cutting are preparation measures that are used to reduce surface defects ensuring a more consistent, uniformly structured cross-section. The latter is indispensable in the accuracy of the test and in making the test repeatable.

Q: How does coating affect the results of a bend test?

A: The addition of a coating, as in most cases, can have an appreciable impact on the final properties of the identification of a specimen. As an example it can enhance or decrease the ductility and strength. Therefore an understanding of how coatings and materials can affect testing is more or less unusual, in the case of metals, the reduction in qualities might be modelled.

Q: What are the primary influences on the bending ductility of materials?

A: The bending of materials is classified as ductile. The process can be carried out when the materials are in a ductile state. The presence of materials in discontinuity caused impurities to form. This then added to the geometric specifications of the material, which in turn aided in form failure resistance to certain angle levels.

Q: How do bend test experts determine the right testing techniques?

A: Bend test experts consider bend techniques and select bend test methods and procedures based on the specific materials and requirements. Materials experts carry out the assignment by selecting optimal testing through EN standards which target the specific requirements needed. In the case of metallic testing techniques they aim to mimic the different requirements of EN standards.

References

- Bend Testing – AHSS Guidelines – Lists standards like ASTM E290, ISO 7438, and JIS Z2248 for bend testing of metals, including details on the Three-Point Bend Test.

- ISO 7438: Bend test on metals – Explains ISO 7438, a standardized method for determining the bending properties of metallic materials.

- Fundamentals of Bending Tests (BND) – Covers bending standards for sheet metals (ISO 7438, ASTM E290, VDA 238-100) and plastics (ISO 178, ASTM D790, ASTM D6272).

- Bend Testing 101 – Discusses the purpose of bend tests, including measuring flexural strength, strain, and stress.