Where ductile materials’ mechanical properties are the subject of study, one class of tests that stands out is bend and tensile. These tests are crucial for determining for a given set of criteria that measure strength, flexibility, and stress endurance, and also place the very foundation for construction and manufacturing quality checks. This blog will put emphasis on the importance of these tests and how the methods are carried out; the key results they give and their implications in real life. At the end of this article, you should have a clear understanding of how bend and tensile tests fit into designing safer and more durable materials for all industries.

Understanding the Bend Test

What is a Bend Test?

A bend test is a standardized testing procedure conducted under a set of conventional conditions to verify the flexibility, ductility, and strength of materials by observing their behavior subjected to bending stresses. This test gages a material’s ability to resist cracking or fracturing or distortion when it is placed under some particular bending force. By subjecting the material to bending angles of a set value, the test enables one to assess how the material will behave under normal circumstances such as pressure, impact, or load.

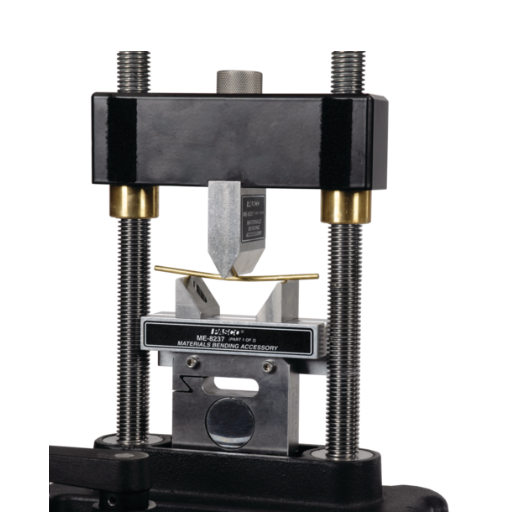

This test mainly happens on the metal and plastic made for crucial structural and industrial applications. It involves placing the test sample on the machine and applying force to bend it at a predetermined section. The factors considered during the bend test are the angle of bend, surface cracking, and whether the material ruptures under stress. These impressions are the outlooks with which one arrives at the toughness and durability of the material, all of which are very important for construction or aerospace or automotive industry.

Bend testing machines are designed to produce reliable and repeatable test results. These machines allow the forces to be applied under controlled conditions with precise measurements to assure testing according to ASTM or ISO standards. Using these machines, manufacturers ensure that materials meet safety and performance requirements that minimize failure risks, especially in critical applications. The benefits of bend testing extend into quality assurance as well as aiding in an engineering vision to create stronger and more dependable materials.

Importance of Bend Tests in Material Testing

With the character of their assessment, bend testing critically talks about flexibility, ductility, and resistance to deformation. With force applied to the specimen until it bends or fractures, the researchers and manufacturers analyze how the material will actually behave when subjected to stress in application. Thus, one can guarantee whether the material meets safety standards and is capable of performing its purpose sufficiently.

Key Benefits of Bend Testing:

- Identification of imperfections: cracks, weak points

- Quality improvement for materials

- Prevention of failures in critical applications

- Enhancement of product reliability and durability

A bend testing machine allows for controlled and precise measurements to be able to give consistent and repeatable test results. Using these tests, manufacturers must guarantee the performance of their materials in creating stronger and dependable products for customers.

Types of Bend Tests

Three-Point Bending Test

The three-point bending test is very common in most bend testing procedures that include strength and flexibility tests. In this kind of test, a specimen is placed on supports and pressure is applied at midpoint until the specimen bends or fractures, which is very useful for finding the elastic modulus of materials and their flexural strength and their ability to resist deformation under stress. This uniform load helps the manufacturers to test how well their materials stand up against structural wear and tear.

Four-Point Bend Test

The four-point bend test is similar to a three-point method but provides a more evenly distributed stress load. Instead, this test applies two forces equally spaced along the specimen. This allows for a greater length of pure bending, thus reducing stress concentration and giving more accurate data for materials with local weaknesses. This test is commonly used in industries to analyze materials demanding extreme uniformity-inter alia composites or aerospace components.

Guided-Bend Test

Guided-bend testing is a ductility test and a check for material weld soundness. It works sideways: a welded sample is bent on a definite radius to witness cracking, imperfection, and inconsistency along the weld joint. This procedure checks whether the weld meets rigorous standards for quality and safety and is, therefore, essential in the construction and pipeline industries. Guided-bend tests, through controlled bending, will definitely highlight blemishes in welds that could have a structural impact if left unchecked.

Tensile Tests and Their Relation to Bend Tests

Overview of Tensile Testing

Tensile testing is a basic method of testing to ascertain the strength and ductility of materials. The test forces a sample specimen uniaxially until it breaks, giving essential insight into the behavior of materials under stress. In essence, the test measures tensile strength, yield strength, and elongation-to-failure properties of materials-a-necessary treatment for materials to meet appropriate safety and performance parameters.

While tensile tests assess a material’s behavior up to its failure, they complement bend testing by focusing attention on the ability of a material to stretch or deform without cracking. The bend test, alternatively, will be one to measure the flexibility and soundness of a weld, also giving proof to surface imperfections or defects that tensile tests may not have been able to detect. The tensile test and the bend test together give a full picture of material behavior, acting almost like a civilization in construction, transportation, and pipelines.

The bend testing machine is a pivotal apparatus in both tensile and bend testing methods. These machines exert a measured force on a specimen under controlled conditions to maintain accuracy. For weld testing, the bend testing machines detect major imperfections, like porosity or incomplete fusion, in joints and meet given quality standards. They play a pivotal role in material testing for safer and reliable structures and systems.

Strength and Ductility Measurements

Strength and ductility measurements are two prime indicators of a material’s performance when subjected to stress. Bend testing machines play an important role in the evaluation because these instruments assess a material’s response to elements of bending force without causing the material to fracture. Furthermore, the machine measures the capacity of the test material to yield plastically whilst keeping a certain amount of structural integrity, which is needed for construction, fabrication, and transportation applications.

| Property | Measurement Focus | Application Relevance |

|---|---|---|

| Flexural Strength | Ability to resist bending | Structural components, beams |

| Ductility | Deformation without failure | Impact resistance, safety |

| Elastic Modulus | Stiffness measurement | Design calculations, deflection |

These tests are crucial for control of quality and compliance with industry norms. Companies usually depend on these measurements to verify if materials conform to certain performance levels under specified conditions so as to minimize risks and enhance safety in critical structures. For this purpose, a bend testing machine delivers reliable data necessary for scientific decision-making for material choice and structural design.

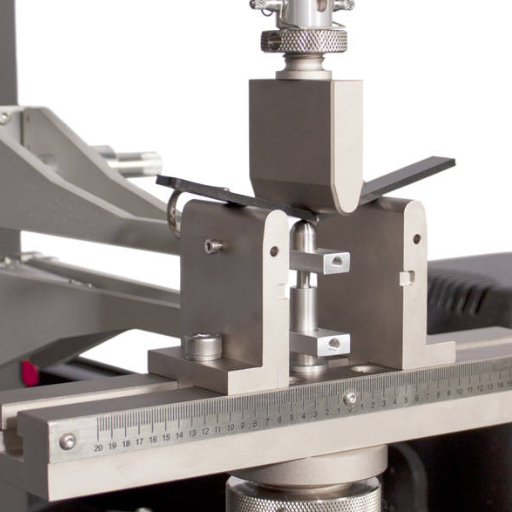

Using Universal Test Machines

Bending tests, being of utmost importance in Universal Testing Machines, acquire ultimate precision, are versatile, and can deal with a wide range of materials. It tests for flexibility, ductility, or strength of the material under some applied stress, just by introduction of bending forces. These tests are necessary for industries such as construction, aerospace, and manufacturing where material bending behavior must be understood to uphold safety and durability requirements.

The bending test is conducted on a universal testing machine by placing the specimen between two supports and applying a load at its centre with two or three points or in a four-point loading manner, depending on the particular standard nature considers. In turn, all the force applied together with the deformation undergone is recorded by the machine, giving data regarding the material’s elastic limit, its yield point, and the maximum load it can take under bending load. This data helps in choosing materials that cannot fail under loads or get deformed beyond prestige.

Universal test machines are used to ensure materials comply with quality assurance norms of different industrial organizations, such as ASTM or ISO, etc. It makes measurements to reproduce an effect and to be free from possible inconsistencies assuring reliable results. This efficiency and level of accuracy coming up with the product make it indispensable for quality control and research purposes to improve product safety, cost optimization, and fulfilment of engineering requirements by the manufacturers.

Equipment Used in Bend Testing

Types of Test Machines

Bending tests are carried out on various machines that measure materials for strength, elasticity, and resistance to stress. The most common types of these test machines are the universal testing machines and three- and four-point bending test machines. These machines fall under the category of test equipment wherein consistency and accuracy are of the highest priority in testing, thus guaranteeing reliable results to ascertain material performance.

Universal Testing Machines

Universal testing machines are flexing devices capable of performing virtually any mechanical test and include the bend test in their repertoire. Such equipment subjects a material sample to an applied force and observes its response to bending stresses. These UTMs have become a popular choice in various industries because of their versatility in handling different specimen materials under standardized test conditions.

Three-Point and Four-Point Flexure Testing Machines

Three-point bending test machines are custom-built applications for bending. The single loading point is applied at the centre of the sample; on each side, two supports hold the material. It is suitable for checking ductility and fracture resistance of materials. On the other hand, four-point bend test machines apply forces evenly across the two loading points, and hence they are able to produce uniform stress on a larger portion of the material. This is especially useful when the materials tend to get preferential stress application. Both types provide valuable information in assessing the properties of materials and their fulfillment of engineering requirements.

Specialized Tools for Metal Testing

The bending test machines are vital in testing metals concerning their mechanical attributes, especially regarding flexibility and force application until failure. Bending tests measure the elastic deformation and yield strength for metals and give primary insights into how a particular material performs under stress. Usually, the two-point bending framework employs three-point or four-point bending configurations, depending on the nature of the stress distribution and the properties of materials involved.

These three-point bending test machines put concentrated stresses onto the center of a metal specimen supported by two points. Under this setup, the stress at the central occurrence is tensile in nature, making the test especially well-suited for measuring tensile strength or the point at which a specimen fractures. It can be used best to investigate localized weaknesses or any flaws in the structure within the tested metal.

On the flip side, in a four-point bending, the regions under control stress are relatively large in area, whereas the local deformation occurs in a smaller area in the three-point bending test. This makes it suitable for metals susceptible to stress concentration or those that have to be checked for their entire length. These tools are necessary where metal properties need to be specified exactly for safety and performance. Hence, the industrial applications exist in aerospace, construction, and automotive manufacturing.

Setting Up a Bend Test

- Specimen Preparation: As an initial step of any bend test, prepare the test specimen with respect to dimensions and material standards. Each specimen must be cut and shaped without any defects that alter the test outcomes. The surface should be clean and free from debris or corrosion that might interfere during the process.

- Machine Setup: Next, set up the testing machine. Align the specimen on the supports of the bending apparatus. The length of the span between the supports must be fixed as per the established standards and types of properties being measured. For both three-point and four-point bending, the location of the loading nose is important and usually positioned at the midpoint, or as specified by the standards, in order to generate uniform bending stress.

- Test Execution: Finally, put the bend test into effect through a controlled force bending the specimen. The force should be increased steadily as the response of the material is observed. Data points required for analysis should be recorded, thus the force applied and the deflection of the specimen. Afterward, examine the specimen for failure, including cracking, fracturing, or permanent deformation.

Documenting the test setup, results, and any anomalies ensures that an acceptable standard of reliability and accuracy is maintained by the test.

Material Characteristics and Bending Behavior

Ductile vs. Brittle Materials

Different behaviors are exhibited by ductile and brittle materials when subjected to bending. For example, a ductile material such as steel and copper can undergo massive deformation before fracturing. Some of these materials impart large amounts of energy into bending or stretching before they fail. On bending, the specimen of ductile material shows permanent deformation, which can be measured or observed after the test has been conducted. These behaviors are common features of materials that respond through plastic deformation when subjected to long static loading.

| Material Type | Behavior Under Bending | Failure Characteristics | Applications |

|---|---|---|---|

| Ductile (Steel, Copper) | Massive deformation before fracture | Gradual failure with warning signs | Construction, automotive |

| Brittle (Ceramic, Glass) | Sudden failure with minimal deformation | Instant catastrophic failure | Electronic components, tiles |

Conversely, in bending, a ceramic or glass type material will just too suddenly with no prior appreciable deformation. With the inability to dissipate stress through deformation, they just suddenly break once stressed beyond their tensile strength. Fracture surfaces of brittle materials are mostly smooth and flat, indicating an instant and catastrophic failure. However, the difficulty of fracturing makes brittles less adaptable for ductile applications or where flexibility under load is required.

The necessity of understanding materials’ behavior in bending is essential in material selection and structural design. For instance, applications requiring resilience and energy absorption, such as in construction or automotive industries, will use ductile materials. On the other hand, granite is suitable for applications requiring rigidity and high compressive strength, such as ceramic tiles or electronic components. The outcome of bending tests will give a clue of these mechanical properties for engineers to make an educated decision for its specific application.

Factors Affecting Bending Strength

- Material Composition and Microstructure: Several factors directly influence the bending strength of a material. The most critical is the combination of material composition and microstructure. The types and structural arrangements of molecules or crystalline grains within the material define the resistance it has towards deformation under stress. For example, steel with fine grains usually presents greater bending strength than mildly coarse grade of the same due to more efficacious distribution of stress.

- Specimen Shape and Size: Another very important factor is the shape and size of the bending test specimen. The cross-section area and geometry of the specimen are vital in defining bending strength. A thicker or wider cross-section will resist bending forces better than thinner ones. Besides, cracks and surface notches act as flaws, cutting down on the strength of the specimen under bending force because the stress gets concentrated at those points.

- Environmental Conditions: The results of the bending test are also influenced by environmental conditions during its conduct. Changing variables such as temperature, humidity, or the presence of corrosive elements could be altering the properties of materials. Examples include metals that become brittle at fairly low temperatures while this reduces the bending strength. Another key point to factor in the interaction between these elements for a proper interpretation of the results returned during the bending test and to assure that the material is appropriate for a specific application.

Deflection and Its Importance

Deflection is an important aspect related to how the materials react under stress, mainly during a bending test. Appropriate deflection measurement is the bending of the structural element under load. Deflection measurement during bending tests goes a way to find out how flexible or elastic a material is. This measurement is therefore significant in knowing how a material will behave in terms of structure-and-will it be able to bear forces when practically applied.

Why Deflection Matters:

- Safety and performance assessment in industrial applications

- Prevention of misalignments or performance impairment

- Material selection for rigidity-critical applications

- Measurement of modulus of elasticity

During bending tests, the deflection of material measures the modulus of elasticity or the material performance under stress. Reliable data provide the grounds for engineers and designers to make material choices and design decisions to ensure that the ultimate structure or product is capable of withstanding various external forces. The ultimate structure or product should maintain its integrity, function, and safety. In all engineering projects, such evaluations shall ensure cost-effective and durable solutions.

Real-World Applications of Bend Tests

Construction Industry

Quality evaluation of reinforcing bars, welding joints, and structural elements to ensure building stability and safety compliance.

Manufacturing Sector

Quality assurance for metal parts, plastic components, and composites used in automotive, aerospace, and consumer goods.

Role in Construction

Bend tests serve the fundamental role of establishing structural reliability and safety for materials intended for construction. Bend testing provides a measure of the ductility, flexibility, and strength of materials like steel, concrete, and various other structural elements under stress. Analyzing material response under the stresses of bending will enable an engineer to determine whether materials are suitable for application in particular constructions. It thereby minimizes the risk of material failures that can occur either during an earthquake or under heavy load.

In construction, a fairly common application of bend tests is the quality evaluation of reinforcing bars. Since rebars are expected to resist heavy tension and flexion during concrete works, bend tests ascertain whether these bars will not crack or break when put to stress, thus ensuring the stability of buildings, bridges, and other civil engineering works. Similarly, the bend tests help check welding joints and connections when they must withstand pressure and remain strong and secure.

These tests also help fulfill industry standards and regulatory requirements. Construction projects are frequently under stringent codes to assure safety and quality. When conducting a bend test, manufacturers and engineers certify that the materials stand these specifications before usage at site. This approach mitigates undesirable failures, leading to cost-efficient and durable construction.

Applications in Manufacturing

Bend tests are vital in the manufacturing industry to assure the quality and suitability of materials. These tests measure the material’s flexibility, strength, and ductility and vary from metals to plastics and composites. Such a technology will allow manufacturers to confirm the appropriateness of materials used for structural components or machines, or as consumer goods.

One very important application of bend testing lies in manufacturing metal parts and weld joints. During manufacture, it is essential to ensure that welds and metal materials can withstand variable loads and bending forces without cracking. Bend tests thus help the manufacturer assess the toughness and durability of parts so that they may be assured that products will conform to safety and industry standards.

In addition, the generally considered materials for bend testing are many kinds of plastic and composites. These materials find many applications in automotive, aerospace, and construction fields. The bend tests check whether such materials retain performance under stress and do not fail prematurely. Bend tests are performed fairly early in the manufacturing process to optimize the production, minimize risk, and maximize customer satisfaction through quality outputs.

Future Trends in Bend Testing Techniques

Emerging Technologies

- Automated Testing Systems: In the domain of bend testing, a rapid evolution accompanies the technological graduates and an increasing straining for sweeter performance of materials. One of the corresponding updates happening is to meld in an automated testing scheme. Automation promises equal results in even time and free of human errors, thereby granting the perfectness of measuring and collecting real-time data on the properties of a material and its evaluation in manufacturing workflows through advanced-day machines interfaced with proper sensors and computer software.

- Non-Destructive Testing Integration: Another significant trend is the integration of NDT methods with bend testing. These processes allow for the evaluation of material properties without any damage. This is especially advantageous in aerospace and automotive industries, where component integrity during testing needs to be maintained. New imaging techniques such as 3D scanning and infrared thermography are being innovatively applied to observe stress distribution and detect defects early on.

- Digital Modeling and Simulation: Lastly, the contemporary developments of simulation and digital modeling are greatly helping in bend testing. By means of tools such as finite element analysis (FEA), manufacturers can now simulate bending under different scenarios, thereby minimizing the actual physical tests and accelerating the development time. This technology is much cheaper to use as it saves more time and other resources but also helps in designing and optimizing new materials for higher performance.

All of these trends are much more conducive to changing the bend testing methods thereby offering more accuracy, efficiency, and sustainability while testing materials.

Frequently Asked Questions (FAQ)

Q: What is the purpose of the bending test?

A: The bending test is carried out to establish the bending properties of the material being considered, that is, their behavior when subjected to bending loads. Resistance to bending is assessed by subjecting the specimen to bending moments till it is bent up to a procedure-defined degree or until it fractures.

Q: What are the types of bending tests?

A: Mostly applied bending tests are 3-point bending and 4-point bending. These tests are capable of pinpointing the reaction of materials to bending forces as well as the bending strength and other mechanical properties of materials under bending loads.

Q: What is the difference between a 3 and 4-point bending test?

A: In a 3-point bending test, a single load is applied right at the center of the specimen, which is supported at the two ends-the load projects a bending moment in the specimen that is maximum at the center. Contrarily, the 4-point bend test applies two loads equidistant from the specimen, splitting the bending moment over a larger section of the specimen, and thus, providing a region of uniform stress for the test.

Q: What is the significance of the stress-strain curve in bending tests?

A: The stress-strain curve obtained from a steel bending test gives valuable information concerning the material mechanical properties, such as yield strength, ultimate tensile strength, and ductility. This curve aids in understanding the mechanism the material undergoes under bending forces, thus assisting in engineering decisions.

Q: What are the factors affecting steel bending test results?

A: Bending results can be influenced significantly by factors such as the specimen dimensions, material type, set-up of the test fixture, and the rate at which the test is carried out. Of course, the bending results also greatly depend on the particular test needs and standards one is following.

Q: What is a guided bend test, and when is it used?

A: A guided bend test is an actual test setting for testing the bending properties of sheet metals and other ductile materials. The specimen is guided through a pre-set bending path to determine whether it can resist the bending without cracking or permanent deformation.

Q: How might fatigue testing have an application in steel bending tests?

A: Fatigue testing is closely related to steel bending tests in that it evaluates material behaviour under cyclic loading. Bending tests may, thus, induce bending forces to simulate the repeated stress that may be imposed upon materials in service, thus gaining insight into service life and durability.

Q: What else can the steel bending tests be put to use for?

A: They are used widely in construction, automotive, and aerospace industries to determine whether materials will withstand bending forces during service. Each material must meet certain standards and safety levels that have been set, and steel bending tests serve as a means for engineers and designers to select appropriate materials.

Q: What usually is the equipment configuration for the steel bending test?

A: Equipment such as testing machines with test fixtures to conduct bending tests are often involved. Such machines apply a preselected bending force to the specimen and simultaneously record deflection and other parameters to suit bending analyses for accuracy.

Q: How can results for a steel bending test be interpreted?

A: Interpretations can be made for steel bending test results by looking at the maximum load presented, the load of bending applied, and the stress-strain curve that results. The analysis of those results provides information about the material’s strength and ductility as well as its behavior under bending conditions, thus helping in material selection and design process.

References

-

TestResources – Bend Testing

A comprehensive overview of bend testing, including its purpose and applications in assessing material properties. -

Biopdi – Essential Guide to Bend Testing: Evaluating Material Strength

This guide explains the mechanical test used to evaluate a material’s resistance to plastic deformation caused by bending. -

ZwickRoell – ISO 7438: Bend Test on Metals

Details the standardized method for determining the bending properties of metallic materials. -

Transportation Research Board – Bend Testing of Steel

A study on the effects of bending and deformation in steel specimens. -

TWI – Bend Testing

An explanation of bend testing as a qualitative method to evaluate ductility and material soundness.