Wood, being highly versatile with natural materials, owes much of its high functionality to its tensile strength. Whether making furniture, erecting a building, or constructing an architectural structure, one must always understand the tensile strength of softwood and hardwood in order to select suitable materials. This article examines the cellular structure, density, and grain patterns of softwoods and hardwoods, which significantly distinguish the two and impact their tensile strength. Ultimately, we present a clear perspective on why tensile strength is crucial in wood selection and how to make an informed decision based on the specific requirements at hand.

Introduction to Tensile Strength

Tensile strength is the maximal tensile (pulling or stretching) force that a material can sustain before giving way. For the tensile strength of wood, cellular structure and density are significant contributing factors. The fiber composition in hardwood is denser, resulting in greater tensile strength than softwood, making it suitable for tasks that demand greater durability under tension. Softwood is lighter and more flexible, making it a good choice for projects where weight and ease of processing are key considerations. If kept in mind, these differences will prevent the inappropriate selection of materials for projects put forth by any task.

What is Tensile Strength?

Tensile strength is a property of materials that describes their resistance to stresses developed through forces and can be measured by the amount of tensile stress applied to a material before it yields or breaks. Along similar lines, the tensile strength helps in evaluating the performance of the material when subjected to pulling or stretching forces. It is measured as the force applied over the cross-sectional area; the typical units are pascals (Pa) or pounds per square inch (psi).

Based on the most recent data, tensile strength customarily falls into three main categories: yield strength, ultimate tensile strength, or breaking strength. Yield strength is defined as the stress at which permanent deformation begins in a material. After this point, the material will not return to its original dimensions. The UTS or ultimate tensile strength is considered to be the maximum tensile stress that a grade of material can sustain before it starts necking or undergoes significant plastic deformation. Breaking strength refers to the material’s ability to sustain stress until it actually breaks down.

Modern tensile strength testing has a wide range of industries like construction, aerospace, and manufacturing. For instance, steel, with its good tensile strength, finds immense use in structural engineering, whereas carbon fiber is used due to its lightweight and high-performance properties. Knowing the tensile strength is essential for an engineer or designer to choose a material that will be subjected to the ultimate mechanical loads it will encounter.

Importance of Tensile Strength in Construction and Design

Tensile strength is a property considered in the working of construction and design, which ensures the integrity and durability of a material subjected to various stress conditions. For construction purposes, materials such as steel and concrete are considered materials of higher tensile strength, capable of resisting tension, compression, and bending forces. This property of tensile strength is utilized in the development of bridges, skyscrapers, and other load-bearing structures, where safety and durability are essential qualities that cannot be compromised.

In design applications, particularly in the aerospace and automotive industries, tensile strength often dictates material selection for making lightweight yet sturdy components. Carbon fiber is an example-oriented name because of its tensile strength-to-weight ratio being the highest and thus suited for high-performance and fuel-efficient designs. Through the review and selection of materials with tensile properties relevant to the application, an engineer optimizes functionality while adhering to safety and regulatory guidelines, thereby mitigating the risk of mechanical failure or degradation over time.

Overview of Strength and Stiffness in Wood

The anisotropic nature of wood implies that its strength and stiffness vary according to the direction of the load applied concerning the grain. The significant parameters controlling the strength and stiffness behavior of wood are its species, density, moisture content, and growth characteristics, such as the arrangement of the growth rings. More recent data show that dense hardwood species, such as oak and maple, impart better compressive and bending strength than lighter softwoods, such as pine; thus, they are used in applications requiring high durability and stiffness.

Wood modulus of elasticity (MOE)–meaning its stiffness–ranges from 700,000 psi for softwoods to above 2,000,000 psi for some select hardwoods. Likewise, the tensile strength of wood varies, with hardwoods generally being more capable of resisting stretching forces than softwoods. Advanced engineering systems use inherent properties of woods, such as CLT, where the grains are oriented in a manner to supplement uniform strength and stiffness best, further facilitating the use of wood in modern construction, including tall buildings and infrastructure.

Factors Influencing the Tensile Strength of Wood

Tensile strength in wood is derived from the species itself, alongside grain orientation, moisture, density, and sometimes the presence of certain defects, such as knots and cracks. The species exhibits a range of mechanical properties, depending on the specific tensile strength in question, with hardwood generally having higher tensile strength than softwood. Grain orientation is a significant factor, as wood is stronger along the grain compared to being weaker against it. Moisture content influences strength in that it alters the elasticity of wood; the higher the moisture content, the lower its tensile strength. Density is also related to strength—the higher the density, the greater the wood’s resistance to tensile forces. Finally, defects lower the tensile capacity because of the breakage of structural continuity within the wood.

Wood Species: Softwood vs. Hardwood

Softwood species include pine, cedar, fir, spruce, and redwood, while hardwood species include oak, maple, walnut, cherry, and mahogany.

| Parameter | Softwood | Hardwood |

|---|---|---|

| Tree Type | Coniferous | Deciduous |

| Density | Low to Medium | High |

| Growth Rate | Fast | Slow |

| Durability | Moderate | High |

| Grain Pattern | Less distinct | Pronounced |

| Ease of Work | Easy | Harder |

| Common Uses | Framing, Panels | Flooring, Furniture |

| Cost | Lower | Higher |

| Moisture Res. | Moderate | High |

| Tensile Strength | Lower | Higher |

The Direction of the Grain and Its Impact

The direction of grain in wood largely determines its mechanical properties, workability, and aesthetic qualities. Wood grain refers to the arrangement of fibers in a material and can be characterized as either straight, spiral, wavy, or irregular. When cutting or working on wood, a direction of gliding with the grain is considered to provide a smoother finish, greater strength, and less wear on the tools. On the other hand, while cutting against the grain, it leads to splintering, tear-out, and less strength in the wood. Additionally, the grain direction affects fine structuring in moisture absorption and expansion. Thus, dimensions may be unstable when the grain’s direction is against environmental parameters. Therefore, a correct understanding of the grain direction provides insight into achieving strength, beauty, and optimal performance in wood construction or application works.

Effects of Moisture Content on Strength Properties

The moisture content in wood is detrimental to its strength properties, thereby affecting its mechanical behavior and structural integrity. Wood fibers become less rigid when the moisture content is high, thereby reducing strength and stiffness. Conversely, the strength of wood increases as it dries down to its fiber saturation point, especially in compression and bending. In contrast, if it dries too much, it will become brittle and may develop cracks. Thus, it is essential to keep the moisture at an optimum level, so the wood remains durable and dimensionally stable in its application.

Testing Methods for Measuring Tensile Strength

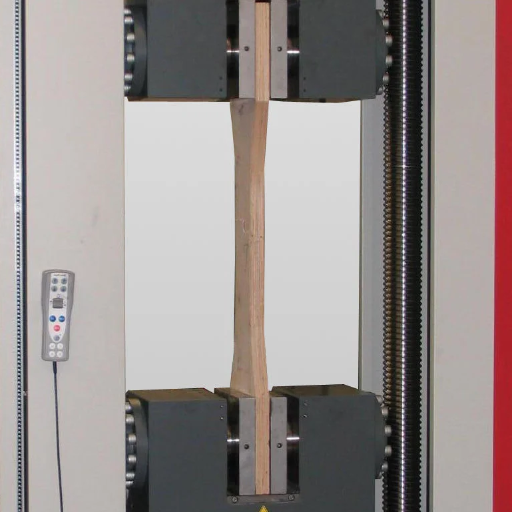

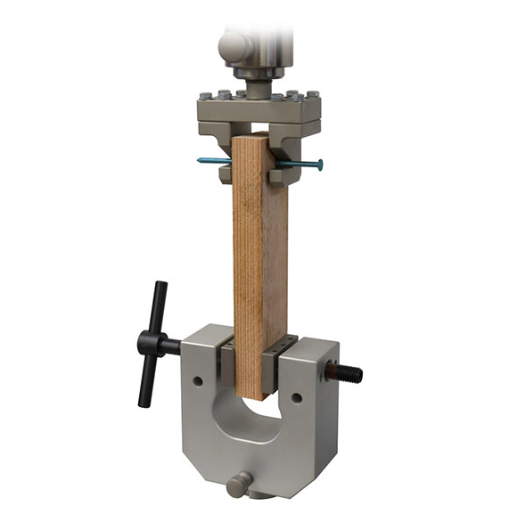

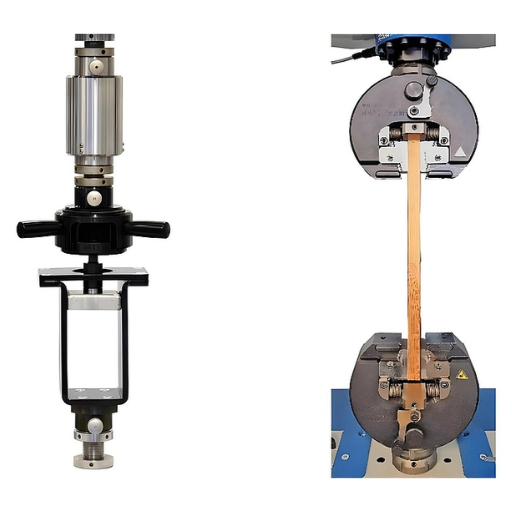

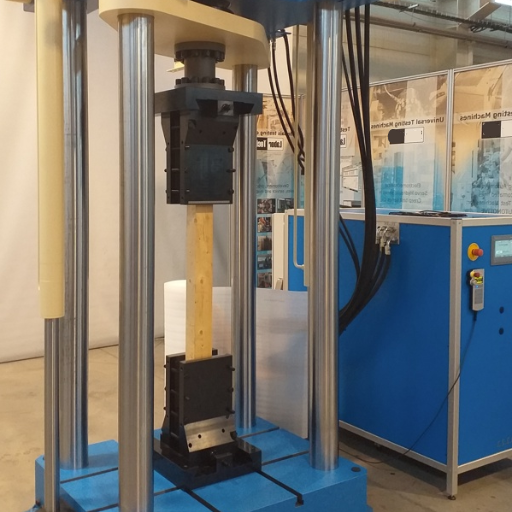

The accurate measurement of tensile strength in wood involves testing methods that, considered standard, measure the performance of wood subjected to tensile stress. The most commonly used machine type is a universal testing machine that applies an accurate tensile force on a tested wood specimen till its failure. The specimens are typically cut into standard shapes, allowing for reliable comparison of all test results.

Before testing, tensile strength is influenced by factors such as grain direction, moisture content, and temperature; therefore, during testing, all variables are kept constant. Tests performed axially parallel to the grain demonstrate a tensile strength value much higher than the tests perpendicular to the grain, since it is dependent on the structure of the wood fibers. The mechanical properties from this data are used to study wood material for the selection and prediction of performance under given conditions.

Laboratory Procedures for Strength Testing

Strength testing of materials involves a series of set procedures that guarantee accuracy and reproducibility in laboratory settings. Typically, the procedures begin with specimen preparation, where the specimens are cut, shaped, and conditioned to conform to a specific standard, such as ASTM or ISO, in terms of their actual physical dimensions. Grain direction, surface treatment, or moisture content are all factors to consider when working with materials like wood, as these factors can influence mechanical properties.

Testing involves using sophisticated setups, including universal testing machines, to apply controlled loads by tension, compression, or shear. During tensile testing, specimens are mounted in the grips of the tensile testing machine and subjected to an accelerated axial load beyond the specified limit until failure occurs. Observations recorded include ultimate tensile strength, elongation, and modulus of elasticity. For compressive tests, the samples are carefully positioned to avoid any bending stresses and are then compressed until they deform or fail.

Environmental factors, such as humidity and temperature, are closely monitored and controlled, as they significantly influence material behavior. More advanced setups will have climate chambers incorporated to simulate real working conditions. Finally, test results are analyzed statistically to understand the performance of these materials and their variability. This knowledge is of paramount importance in the design of dependable structures and in estimating failure under working loads.

Equipment Used in Tensile Strength Measurement

The equipment used in tensile testing is essentially a UTM that applies a controlled tension to the specimen. The typical UTM is equipped with a load cell to register the force being applied and an extensometer or strain gauge to measure elongation or deformation very precisely. Grips or fixed mechanisms hold the material during the test. Depending on the material and testing conditions, other components, such as environmental chambers, may be used to simulate operating conditions. In modern equipment, advanced software is used for the acquisition and analysis to obtain accurate stress-strain curves, thereby enabling the objective calculation of tensile properties.

Industry Standards and Best Practices

The strength measurement of wood must conform to specific standards and methods for the results to be trustworthy and reproducible. Among these documents, ASTM D143 describes the various test requirements for small transparent wood specimens. The tensile strength and other mechanical properties are determined by the forces specified in the standards, the preparation of the test samples, and the conditioning and execution of the tests. On the other hand, ISO 3349 outlines the conditions for determining tensile strength parallel to the grain, emphasizing the importance of grain orientation and its consistency for accurate measurements.

In tensile testing of wood, specimen preparation is crucial for avoiding imperfections, such as knots, that can affect structural integrity. Likewise, samples should undergo conditioning to a specified moisture content, usually 12% as per standards, because moisture plays a huge role in affecting tensile strength. Loading, during the testing process, must be uniform on the testing device to avoid any degree of shear force or bending resulting from it.

Comparative Analysis with Other Building Materials

Wood is often compared to steel, concrete, brick, and plastics in building materials due to differences in strength, weight, sustainability, insulation properties, cost, and durability.

| Parameter | Wood | Steel | Concrete | Brick | Plastics |

|---|---|---|---|---|---|

| Strength | Moderate | High | High | High | Low |

| Weight | Low | High | High | Moderate | Very Low |

| Sustainability | High | Low | Moderate | Moderate | Low |

| Insulation | Good | Poor | Moderate | Moderate | Good |

| Cost | Moderate | High | Moderate | Low | High |

| Durability | Moderate | High | Very High | High | Low |

Tensile Strength of Wood vs. Steel

In tensile strength, steel is orders of magnitude superior to wood. Thus, it serves as a better material where high tensile resistance and deformation are required. Mild steel is rated, on average, at some 400 MPa tensile strength, while a typical structural-grade wood, such as Douglas fir, falls somewhere in the 40 to 80 MPa region. Such a significant difference is due to the basic mechanical properties of steel, such as its uniform internal structure and the processes of alloying, whereas wood has natural weaknesses associated with its nomenclature, grain directions, knots, and moisture content.

Because steel behaves in a predictable manner and remains uniform under stress, it is used for major infrastructures that require load-bearing capacity, while wood finds limited applications, focusing more on aesthetics, sustainability, or cost-efficiency in low-stress environments. Appreciating these generalized differences becomes crucial in selecting materials for structural designs, ensuring they align with project requirements and safety standards.

Wood vs. Concrete: A Strength Perspective

From a strength perspective, various aspects are discussed. Concrete manifests superior compressive strength compared to other materials, let’s say, adequate for use in foundations, columns, or bearing loads. Its ability to withstand huge pressures with negligible deformation ensures the presence of structural integrity in large projects. Wood, on the other hand, offers tensile strength much better relative to its weight; hence, it can flex somewhat when stressed but stays much lighter than concrete. Generally speaking, in the long run, concrete does outperform wood, especially in the presence of moisture, fire, or decay. When deciding between them, one should consider the specific structural requirements, environmental exposure, and eventual use, as both possess specific merits that serve better under particular circumstances.

Advantages and Limitations of Wood in Structural Applications

✓ Advantages:

- Strength/Lightness – Wood has one of the highest strength-to-weight ratios among building materials, making it excellent for lightweight construction that requires strength.

- Sustainability – Wood is renewable, environmentally sound, and can be supplied sustainably when harvested under appropriate forestry practices.

- Ease of Use and Versatility – Wood is easy to cut, fasten, and assemble, which allows for great flexibility in design while minimizing construction time.

- Thermal Insulation – Wood has excellent thermal insulating properties due to its natural cellular structure, thereby providing energy-efficient buildings.

- Aesthetic Appeal – Wood offers natural beauty and warmth, making it a preferred choice in visually appealing architecture.

⚠ Limitations:

- Wetness and Decay – Long-term exposure to moisture, unprotected wood, can cause rot and decay, thus weakening the structure.

- Fire Risk – Wood is flammable and thus would need some form of treatment or barrier to impart it some fire resistance.

- Biological Deterioration – Without protection, wood can be attacked by insects, such as termites, and fungal agents.

- Dimensional Instability – Wood can shrink, swell, or warp when there are changes in humidity or temperature, which can affect its structural integrity.

- Reduced Durability in Severe Environments – Compared to steel and reinforced concrete, raw wood can offer only a shortened lifespan in severe environmental conditions.

Practical Applications of Tensile Strength in Wood

Wood’s tensile strength plays a crucial role in structural arrangements and design aspects, relying on the material to withstand tension without fracturing. During bridge construction, wooden floor structures and load-bearing walls require tensile strength under tension to maintain their stability; accordingly, design structures have been implemented. Tensile strength is required for furniture, veneers, and laminates, where mechanical forces come into play. Harnessing the tensile strength knowledge of wood ensures safe and economic design possibilities in a wide array of building and engineering projects.

Impacts on Structural Design Choices

When it comes to structural design, tensile strength has a significant bearing on design choices because it profiles how materials behave under stress and strain when subjected to load. Engineers consider various factors, such as wood species, moisture content, grain orientation, and defects like knots, to ensure safety and optimal performance. They want the materials having tensile stresses raised as high as they can be on a very few critical components like trusses, beams, and cross-laminated timber in modern structures subjected to load, so as to ensure that the components can bear well. Tensile strength is thus increased through various treatments and preservation methods, enabling the wood to bear in these circumstances reliably. The considerations involved go into proper architectural designs that are efficient and weld together with the timber work.

Woodworking Projects and Their Strength Considerations

When starting woodworking projects, it is essential to be aware of the material’s strength to ensure functionality and safety. Wood selection is critical, as different types of wood have distinct characteristics, including hardness, compressive strength, and elasticity, which vary among species. For example, hardwoods like oak and maple offer greater durability and load-bearing capacity, making them suitable for use in furniture or structural bases. Softwoods, on the other hand, are typically used for lighter applications.

Joinery techniques affect the overall integrity of a project. Strong joints, such as mortise-and-tenon or dovetail joints, enable better distribution of weight and stress than simpler joints like butt joints, thereby minimizing the chance of failure. Grain orientation considerations in cutting and assembling the wood are also a means of preserving strength; any misalignment could weaken the construction.

Consider the environmental impact as well. Treatments such as sealing or laminating can protect wood from moisture and insect attacks, extending its life. Combining appropriate material selection with a suitable construction technique and protective treatments will provide a woodworking project with core strength and longevity.

Development of Engineered Wood Products like CLT

Engineered wood, including CLT, truly heralds new age construction materials, providing a much-needed option toward sustainability and versatility. It is achieved by layering wood boards perpendicular to each other, thereby strengthening the material and making it dimensionally stable. This process also addresses the issues of shrinkage and warping typically associated with solid wood. Cross-laminated timber panels can be engineered using modern adhesives and state-of-the-art machinery to meet the structural requirements for both residential and commercial applications.

One of the primary advantages of CLT is its excellent performance in terms of strength-to-weight ratio, fire resistance, and thermal insulation, making it suitable for multi-story buildings. Furthermore, its production aligns with sustainable practices by utilizing fast-growing softwood species and minimizing waste during the processing stage. These panels also facilitate faster assembly due to their prefabricated nature, thereby reducing construction time and labor costs. Overall, CLT represents a significant innovation in the construction industry, combining environmental benefits with robust structural performance.

Reference Sources

-

Study on the Fracture Toughness of Softwood and Hardwood – Provides detailed tensile strength ranges for both softwood and hardwood, along with insights into their fracture toughness.

-

Softwood and Hardwood – Structural Strength Classes – Discusses strength classes, bending stress, and mean density for various types of softwood and hardwood.

-

Wood Strength: Grain Direction and Measurements – Explores how grain direction, specific gravity, and other factors influence the strength of common hardwoods and softwoods.

-

Tensile Strength Classes for Hardwoods – A research paper proposing a system for analyzing the tensile strength of medium-dense European hardwoods.

-

Let’s Talk About Softwoods and Hardwoods – Offers a general overview of the differences between softwoods and hardwoods, including variations in density and hardness.

Frequently Asked Questions (FAQs)

What is the tensile strength of wood?

How does moisture content affect the tensile strength of wood?

The mechanical properties of wood are highly dependent on its moisture content. Generally, with increased moisture content, tensile strength decreases. Water inside the cell will weaken the bonds between fibers, causing wood to deform and fail more rapidly under tensile loads. Wood should be dried with the desired moisture content before application to attain higher tensile strength.

What are the mechanical properties of different wood species?

Mechanical properties, such as tensile strength, shear strength, and compressive strength, vary from one wood species to another. Generally, hardwoods such as oak and maple tend to have a higher strength-to-weight ratio than softwoods like pine and fir. Hence, it is critical to understand the characteristics of a given type of wood when selecting lumber for construction or engineering purposes.

How does wood design affect tensile strength?

The wood design, such as fiber orientation and the arrangement of wood cells, largely determines its tensile strength. Wood is stronger in tension when loaded parallel to the fibers. In contrast, when forces are applied across the grain, tensile strength is significantly reduced. This shall be an essential factor in designing wooden structures and products such as laminated veneer lumber.

What is the relationship between wood density and tensile strength?

Wood density has been thought to agree with the idea that denser species of wood will have a higher tensile strength. The reason for this is that in wood of quiet and steady consistency, cells lie tight together, with greater cell wall thickness offered by denser wood species, and resist tensile force to a very great extent. While technical applications demand more tensile strength, the densities of such woods should always be kept in mind.

What is the tensile strength of laminated veneer lumber?

Laminated veneer lumber is an engineered wood product made of wood veneers. The veneers are glued together to promote tensile strength for the offered applications at construction. Highly tensile and stiff, LVL can span much longer distances than simple wood, thereby reducing material usage.