Instrument And Equipment Wholesale

High-Quality Tensile Testing Machine Manufacturer in China

These machines are phenominal in their accuracy and are regularly used in the aviation, building contruction, and manufacturing verticals for the quality control checks and other reasearch and investigation activities. In addition to their unparalleled accuracy and reliability, our tools also offer automated self-calibration checks in addition to their other formiddable multifunctional capabilities enabling testing versatility to answer to diverse needs.

What Is A Tensile Testing Machine

-

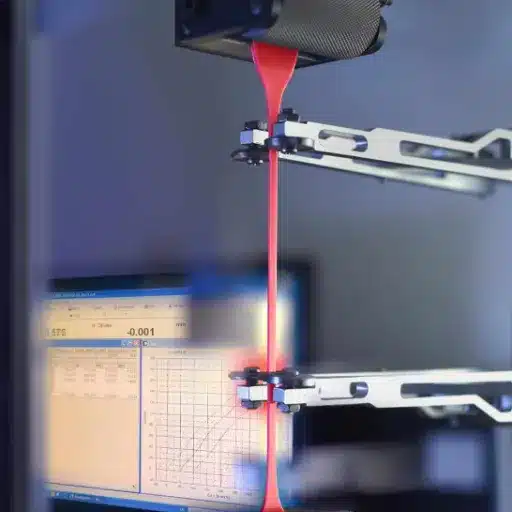

A Tensile Testing Machine measures material strength by applying tension until failure, assessing tensile strength, elongation, and modulus for quality assurance.

-

The universal tensile testing machine performs tension, compression, and bending tests, offering versatile solutions for various materials and industries.

-

Equipped with advanced software, our tensile strength testing machine provides precise data analysis for consistent and reliable test results.

-

Our machines include tensile testing machine calibration features to ensure accuracy, meeting international standards like ASTM and ISO.

-

The tensile test apparatus is engineered for durability, handling high-capacity tests for metals, plastics, and composites with ease.

Essential Tests You Can Perform with a Tensile Testing Machine

Tensile Testing Machine is not only utilized for performing tensile tests but also for testing the strength and durability of the materials precisely. It is manufactured from high quality raw materials and used in construction and manufacturing industries to ensure the quality and hallmark material benchmarks are performed.

Tensile Strength Test

This machine uses tensile strength testing to analyze the maximum weight a material can withstand. Materials such as plastic and metals are adhered to pulling forces and evaluated aligning with ASTM & ISO regulations. Its importance is felt in the automotive and aerospace industries, where agility needs to be matched with precision along with component redundancy ensuring trust.

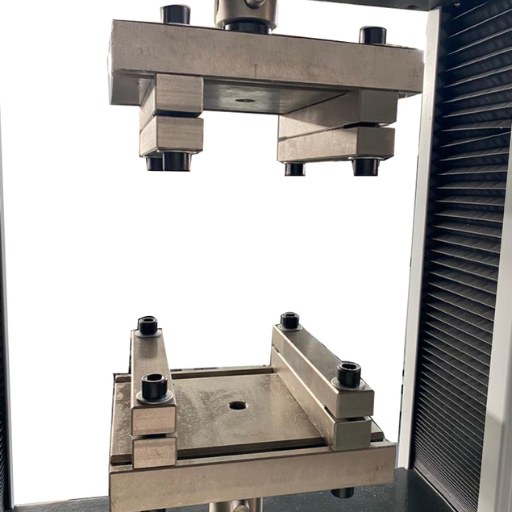

Compression Test

This test forecasts the behavior of a certain material upon being subjected to crushing forces. It is carried out on concrete, composites, and metals in universal tensile testing machines to evaluate their structural robustness. Thus, it certifies that such materials would not fail safety checks during construction and manufacturing stages thus making sure of their application reliability.

Flexural Test

Describes testing composites and plastics under tensile bending loads using flexural equipment. It is also performed on ceramics as they measure deformation under compressive stresses. This test supports construction and aerospace industries ensuring that materials withstand bending stresses are easily endured.

Elongation Test

The elongation test assesses the extent to which a material stretches and is specific to engineering materials “testing” breakage via tensile testing machines. This is important to textile, polymer and metal industries as it determines if the material is pliable enough for packaging, automotive, or medical devices manufacturing, compliance to industry standards.

How to Choose the Right Tensile Testing Machine?

- Load Capacity: Ensure the machine’s load capacity (e.g., 100 kN to 500 kN) matches your material testing requirements for accurate results.

- Test Versatility: Choose a universal tensile testing machine that supports tensile, compression, and flexural tests for diverse material applications.

- Calibration Accuracy: Opt for machines with automated tensile testing machine calibration to maintain precision and comply with ASTM/ISO standards.

- Software Integration: Select a machine with user-friendly software for real-time data analysis, simplifying operation and reporting per the universal testing machine manual.

- Material Compatibility: Verify the machine tests a range of materials, from metals to textiles, to meet your industry’s specific needs.

What are the Tensile Testing Machine Uses?

- Quality Control: Ensures material strength and reliability for manufacturing industries, validating metals and plastics meet production standards.

- Aerospace Testing: Tests aircraft components for tensile strength and durability, ensuring safety under extreme conditions.

- Automotive Applications: Evaluates car parts like steel frames and composites for structural integrity and crash resistance.

- Construction Validation: Assesses concrete and steel strength to ensure compliance with building safety regulations.

- Research and Development: Supports material science studies by testing new alloys, polymers, and composites for innovation.

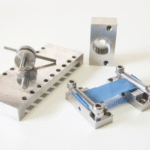

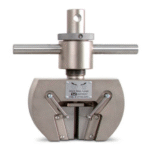

Components of Tensile Testing Machine

Our Tensile Testing Machine comprises precision-engineered components for reliable performance. From load cells to software, each part ensures accurate testing for industries like manufacturing, aerospace, and research.

View our Tensile Testing Machine Price

Advanced tensile testing machines with precision load cells, digital controls, and durable build, ensure quality now!

Horizontal Tensile Testing Machine

A Horizontal Tensile Testing Machine evaluates the tensile strength, elongation, and mechanical properties of materials like metals, plastics, and textiles. Designed for precision, it features advanced load cells and software for accurate data analysis, ideal for industries such as manufacturing, aerospace, and quality control.

Steel Strand Tensile Testing Machine

Steel Strand Tensile Testing Machines evaluate the tensile strength, elongation, and mechanical properties of steel strands. Featuring high-precision load cells, digital controls, and robust frames, they ensure accurate testing for construction, manufacturing, and quality control applications.

Tensile Testing Machine Data Overview

| Parameter | Details |

|---|---|

| Load Capacity Range | Ranges from 0.001 kN to 1000 kN for versatile testing. |

| Testing Versatility | Supports tensile, compression, and flexure tests. |

| Accuracy and Precision | Features ±0.5% accuracy with digital display. |

| Environmental Conditions | Operates from -50°C to 250°C with 20% to 90% RH. |

| Software and Automation | Includes intuitive software with data logging. |

| Speed Range | Adjustable from 0.5 mm/min to 500 mm/min. |

| Crosshead Travel | Offers up to ±2000 mm displacement. |

| Extensometer Integration | Supports external extensometers for strain. |

| Power Supply Options | Compatible with 110V/60Hz or 220V/50Hz. |

| Safety Features | Equipped with overload protection and emergency stop. |

Why Choose Our Tensile Testing Machine Manufacturers

Our Tensile Testing Machine stands out due to its accuracy, longevity, and adaptability, making it quintessential in aerospace, automotive, construction, and materials research. With hisgh precision load cells and automated calibration, aggravates compliance with ASTM and ISO standards. The universal tensile testing machines performs tensile, compressive, and shear tests on metals, plastics, textiles and composites.

Detailed manuals alongside intuitive software ensure effortless operation and long-lasting dependability. Tailored for QC and R&D’s rigorous demands, these machines combine outstanding versatility, low-cost, and thorough after-sales care with uncompromised precision for a wide range of testing applications.

What Our Client Says

Understand from our clients what they say about doing business with us and the unique value addition we provide.

Expert Insights on Tensile Testing Machine

What makes a tensile testing machine reliable?

Reliability comes from high-precision load cells and automated tensile testing machine calibration. These ensure accurate measurements, compliance with ASTM/ISO standards, and consistent results across metals, plastics, and textiles, vital for industries like aerospace and automotive.

How does software enhance testing?

Advanced software in a universal tensile testing machine provides real-time data analysis, customizable test parameters, and detailed reporting. Per the universal testing machine manual, this simplifies workflows and ensures precise results for complex material tests.

Why is calibration critical?

Regular tensile testing machine calibration ensures accuracy and compliance with international standards like ISO 7500-1. Automated systems reduce errors, making the machine reliable for quality control in manufacturing and construction industries.

Can it handle diverse materials?

Yes, our tensile test apparatus tests metals, polymers, textiles, and composites. Its versatility supports tensile, compression, and flexural tests, meeting the needs of industries from automotive to medical device manufacturing.

What are key features to look for?

Look for high load capacity, automated calibration, and versatile testing modes in a tensile strength testing machine. These ensure precision, durability, and adaptability for applications in research, aerospace, and construction.

How does it support R&D?

The tensile testing machine aids research by providing precise data on material properties like elongation and strength. Its flexibility supports innovation in developing new alloys, composites, and polymers for advanced applications.

Latest Blog Posts

Maintain Inventiveness by Following The Blog for the Latest Best Practices, Techniques, Innovations, and Insights in the Field.

Testing is one of the most important methods, among others, to ensure the quality and reliability of materials, goods, or […]

When it comes to analyzing how long materials last under diverse conditions, tensile versus break strength are often the two […]

Break tests have become crucial in testing material durability and worthiness across many industries. From manufacturing to architecture and even […]

In the most basic sense, tensile strength is the quality of a material that dictates how much it […]

In considering material performance and durability, ultimate tensile strength (UTS) governs the discussion. This mechanical property indicates how much stress […]

Adhesive bonding has become an essential technique in many areas of industry, offering cheaper alternatives that are strong yet light […]

Comprehensive Guide to Tensile Testing Machine Calibration

Proper tensile testing machine calibration is critical for ensuring accurate and repeatable results. Our machines include detailed calibration guides in the universal testing machine manual, ensuring users can maintain precision. This process enhances reliability in industries like aerospace and automotive, where material failure is not an option.

Frequently Ask Questions

Q: What is a Tensile Testing Machine?

A: A Tensile Testing Machine measures material strength by applying tension until failure, ensuring quality for industries like automotive and aerospace.

Q: What materials can Tensile Testing Machine test?

A: Our universal tensile testing machine tests metals, plastics, textiles, and composites, supporting diverse applications with reliable results.

Q: How does calibration ensure accuracy?

A: Automated tensile testing machine calibration aligns with ISO and ASTM standards, ensuring precise measurements and consistent performance.

Q: Can Tensile Testing Machine perform compressive tests?

A: Yes, our compressive test capabilities evaluate material strength under crushing forces, ideal for construction and manufacturing.

Q: Is Tensile Testing Machine user-friendly?

A: The universal testing machine manual and intuitive software simplify setup and data analysis for efficient testing.

Q: How accurate is Tensile Testing Machine?

A: High-precision load cells in our tensile strength testing machine ensure accurate results, meeting industry standards.

Q: Can Tensile Testing Machine handle high-capacity tests?

A: Yes, with up to 500 kN capacity, it tests high-strength materials like metals and composites effectively.

Q: How often should Tensile Testing Machine be calibrated?

A: Annual tensile testing machine calibration is recommended to maintain accuracy, with automated systems reducing manual effort.