Calibration is needed, where the accuracy and reliability of test results in materials are to be ascertained. Whether you want to consider tensile strength of metals, polymers, or composites, it must be guaranteed that the tests are accurate as per their respective standards to be able to make wise decisions. This article navigates you through the calibration of universal testing machines by clearing the haze around the process and focusing on important factors to consider. The basis of this knowledge makes the way clear toward enhancing your machine performance for uniform test results. So sit tight to discover some top tips, challenges, and best practices that will smooth your calibration process!

Importance of Calibration in Tensile Testing

Ensuring Accurate Testing Results

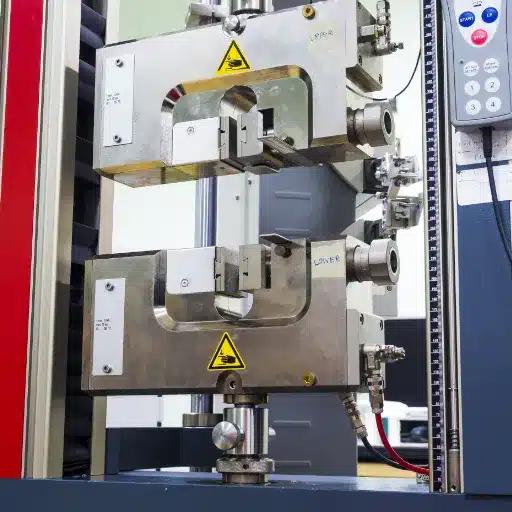

First and foremost, it is very important to ensure the correct handling of a tensile testing machine, with strict adherence to operational procedures. The very first thing operators need to do is to read and understand the manufacturer’s manual completely so that they are aware of how to set up the machine, operate it, and what safety precautions they should adhere to. Operators need to confirm that the machine is installed on a stable and level surface to prevent the possibility of vibrations or misalignment in the course of the test. Calibration is also an important procedure to ensure testing accuracy and reliable measurements-pressure.

Prior to testing, inspect all components allowing for grips, load cells, and any fixtures to be confirmed properly set and free from damage. Fasten the specimen securely without over tightening it so as not to apply any stress or deformation to the material that would interfere with the test. Always work within the load and speed specifications of the machine: exceeding these limits would damage the machine and invalidate the test results.

After each test operation, clean the machine and the fixtures to remove any debris or residue from the test. Place tools, grips, and accessories back in their respective storage places. With respect to maintenance, the manufacturer should indicate when mechanical parts should be oiled and updated on software. Good maintenance ensures constant throughput, reduces downtime, hence increasing the life expectancy of the tensile testing machine.

Impact on Compliance with Industry Standards

Tensile testing machines assist in determining the mechanical properties of materials to meet the desired standards. Tensile testing machines ascertain material properties such as tensile strength, yield strength, and elongation, which are vital parameters in determining whether materials have met their quality standards. Since industrial applications require the safe use of such materials, it is crucial for them to be measured by a standardized test.

Tensile testing maintained compliance with accepted international standards, such as those established by ASTM or ISO, which have exact definitions for test method standards. By following these standards, manufacturers and industries ensure that the materials conform to safety regulations, uphold product performance, and are recognized for international trade. Such standardization builds trust among stakeholders and increases product credibility in various markets.

In ensuring conformity to test standards, manufacturers should carry out regular calibration and maintenance of tensile testing machines. Functionality that deviates from the requirements causes non-compliance, affects the structural integrity of products, and leads to expensive recalls or safety risks. Therefore, investing in well-maintained and calibrated machines is needed for adherence to industry standards and the safety of operational excellence.

Benefits of Regular Calibration

It is necessary to calibrate testing machines to ensure the accuracy and reliability of measurement results. Calibration of machines ensures compliance with industry standards, which is of paramount consideration in whether a particular procedure is approved by quality assurance in manufacturing processes. Calibration interferes with accepting false data and ensures that material property testing is performed exactly, thus establishing safety and durability.

Other advantages of periodic calibration are the prevention of expensive errors. Uncalibrated testing machines can create faulty measurements, consequently leading to defects and a lack of compliance. This can, in turn, lead to product recalls or loss of reputation as well as to additional expenses due to cost of rework. Calibration of machines on a regular basis helps to keep them in the best working condition and thus minimize chances of such expensive problems arising, thus promoting efficiency in operations.

Last but not least, adhering to a calibration schedule consistently ensures trust and confidence in test results. Reliable test data validate the meeting of the specified performance criteria of tested products and the applicable industry standards. This dependable criterion enhances customer assurance toward manufacturing product quality and supports the company’s prestige in otherwise competitive markets. Regular calibration proactively sustains safety, precision, and accountability in any operations utilizing tensile testing machines.

Calibration Procedure for Tensile Testing Machines

Step-by-Step Calibration Process

- Preparations for Installation of the Machine: Check that the tensile testing machine is turned off while cleaning it. Next, inspect the entire machine for visible damages or wear and tear while securing every component. Use the manufacturer’s documentation to confirm that all configurations and set-ups in the machine are as required for the operation.

- Verification on Loading Accuracy: Attach a calibrated load cell or proving device. The machine is to be loaded with a series of known loads, in an incremental fashion, and for every load, the value displayed in the machine is compared to that obtained from the calibrated device. Any discrepancies are recorded for adjustment.

- Adjustment and Alignment: In case any inconsistencies are found, make adjustments to settings in the machine as suited by the operation manual. Ensuring that the application of load is even and correct alignment of grips and fixtures to measure force precisely and accurately.

- Calibration of Testing Speed: Check the crosshead speed from an external reliable device or a good stopwatch. It should be confirmed that under all testing modes the machine actually runs at the programmed speed within all acceptable tolerances.

- Verification of Data System: Verify the data acquisition system in terms of accurate recording and reporting of test results. Verify that software and sensors function correctly to produce consistent outputs matching the applied forces.

- Documentation and Certification: Ensure that all calibration results are recorded, including the adjustments carried out. An accreditation report has to be provided that certifies that the machine has passed according to industry standard and includes a date for the next calibration.

Ensuring frequent calibration of the tensile testing machines guarantees the provision of reliable and accurate results of a test. The measurement enhances the assurance of product quality while providing a platform to comply with regulatory standards, thus supporting operational efficiency and upgrading the established industry on a competitive level. Everyday calibration becomes a paramount issue for safety, correctness, and confidence on the part of customers.

Best Practices for Calibration

The calibration of tensile testing machines is required for the measurement of material properties with accuracy and reliability. To maintain consistent performance, it is best practice to establish a calibration schedule utilizing, based on the intensity of the usage of the machine, working environment, or on regulatory requirements. Routine checks can reveal in-precise measurements to a certain extent and thus, prevent the generation of costly errors from testing to production.

The calibration of the tensile testing machine should be done using certified reference materials and in the international standard way. These standards set forth the ISO or ASTM guidelines for maintaining precision and uniformity. Calibration activities must also be documented as evidence for traceability and regulatory and industry requirement compliance.

Calibration provided by well-trained technicians or certified service providers will further guarantee the proper calibration of measuring instruments. Such trained persons will fix issues of wear and other operational problems of the machine. By following the above-mentioned best practices, companies ensure that their tensile testing machines are functioning in an optimal state, thus ensuring product quality and meeting both consumer and regulatory requirements.

Essential Tools for Calibration

Certified Counterweights or Load Cells

Calibration of tensile testing machines must be done with very fine instruments to have reliable results. First and foremost, a set of certified counterweights or load cells is used to check the accuracy of force measurement by the machine. These weights must be forged upon industry standards; hence they provide correct readings during calibration.

Precision Extensometer

Other than that, another important tool is a device for measuring displacement, say, a highly precise extensometer. When measuring elongation or deformation of material under stress, this gives an operative means to allow proceedings in assessing the machine for capability in repeatable and precise strain measurements. The use of a trusty extensometer ensures the sanctity of the test results.

Environmental Monitoring Sensors

Also, temperature and humidity sensors are important to monitor environmental variables during calibration. They can affect the tensile testing machines’ performance, so proper conditions need to be maintained for consistent operations. Under these lines, by employing all these essential instruments during calibration, they may prove their equipment running at its very best, with so much validity and quality unto their testing procedures.

Industry Standards and Regulations

Overview of Calibration Standards (ISO, ASTM)

| Standard | Focus Area | Key Requirements |

|---|---|---|

| ISO 7500-1 | Force-measuring systems in uniaxial testing machines | Ensures accurate force measurements and international compliance |

| ASTM E4 | Force-measuring systems verification procedures | Periodic calibrations with traceable reference materials |

Calibration standards ensure that tensile test machines can maintain their accuracy, precision, and reliability. The ISO standards, mainly ISO 7500-1, deal with the calibration of force-measuring systems in uniaxial testing machines. This ensures that the value of the measured forces is accurate and suitable to meet international requirements, thereby supporting uniform testing procedures in various laboratories and industries.

ASTM standards, such as ASTM E4, set forth the test procedures used for verifying force-measuring systems in a testing machine. They stress the need for periodic calibrations and the use of traceable standard reference materials to ensure that tolerances are respected in the testing equipment. Moreover, they offer suggestions for maintenance and inspection to mitigate errors during testing.

For tensile test results to remain dependable, it is extremely important that they be carried out according to ISO and ASTM standards. Calibration in accordance with these standards will ensure proper measurement accuracy, decreases variability, and conformity with industrial and regulatory standards. Therefore, following these standards will provide companies with assurance that their materials are of good quality and safe, thereby further enhancing confidence in their testing process and outcomes.

How Standards Affect Testing Accuracy

Standards have a vital role in ensuring the proper working of a tensile testing machine. By following the prevailing ISO and ASTM standards, these machines are able to give consistent and accurate data related to material properties such as tensile strength, modulus of elasticity, etc. Standards establish what the calibration of the machine should be, how the test should be carried out, and the environmental conditions during testing, thereby minimizing discrepancies in testing and maximizing reproducibility of results.

If standards are properly adhered to, testing machines are calibrated for forces and elongations in the most accurate way possible. The highest degree of accuracy is of utmost importance while testing materials for the aerospace industry, building construction, or manufacturing, because wherein again minor inaccuracies may lead to severe consequences-to the extent of failing the material or non-adherence to safety regulations. Standards take into consideration the speed of testing, dimensional properties of test samples, and environmental conditions under which the test is being carried out, thereby making sure that factors come into play while measuring.

An outcome gained adheres to standards and means more accurate and respected by people; industry members can compare confidently the performance of their materials with industry standards, guaranteeing the support for quality control and regulatory purposes; this assurance minimizes the risks usually attached to defects in materials, thus creating confidence in the tested products as well as in the processes used for testing their soundness.

Importance of Calibration Certificates

Key Benefits of Calibration Certificates:

- Guarantee accuracy and reliability of tensile testing machines

- Ensure compliance with industry codes and quality management systems

- Build trust with clients, regulatory bodies, and stakeholders

- Help mitigate risks and avoid costly rework

- Enhance company reputation for delivering premium quality products

Calibration certificates are a must to measure and guarantee accuracy and reliability of tensile testing machines. These certificates assure that the equipment has been subjected to testing and calibration on recognized standards, thereby minimizing measurement errors. In tensile testing, accuracy is critical because strength and durability data from tensile testing serve as inputs to quality control and safety.

Having a certificate of calibration also guarantees that the organization abides by industry codes and quality management systems such as ISO standards. With regular calibration, manufacturers satisfy these rigorous standards, thereby mounting credibility to their test outcomes. The said consideration is very crucial for construction, aerospace, and automotive industries, since the performance of materials is critical to the integrity and safety of products.

The certificates of calibration serve stakeholders in building trust for the clients, regulatory bodies, and users with the assurance that the tensile testing machine is giving results that are correct and trustworthy. These certificates also help firms in mitigating the risks by maintaining current calibration, thereby avoiding rework, whilst simultaneously uplift the goodwill of delivering premium quality products.

Common Challenges in Calibration

Addressing Environmental Factors

Environmental Impact on Calibration: Environmental elements could affect calibration accuracy for tensile testing machines or permanence of calibration and test validity. Variations in temperature, humidity, or vibration in the testing environment may lead to measurement variations; materials can expand or contract in terms of changes in temperature, thus affecting test results. Therefore, it is advisable to keep the test environment controlled and monitored to maintain stable conditions.

Machine Placement and Insulation: Machine placement and insulation are supposed to help reduce the minimal environmental interference possible. The machines should be installed in places free from excessive vibration or sudden temperature change caused by other machines or air conditioners. Also, set humidity levels are critical since too much moisture or dryness could affect the behavior of sensitive components of the machine or materials under testing.

Regular Environmental Monitoring: Regular environmental checks ought to be incorporated within routine operating procedures for calibration and testing to overcome all these concerns. Calibrated sensors can aid environmental monitoring on temperature and humidity during the tensile testing process. When environmental factors are controlled, errors can be minimized, and hence reliable test results obtained, leading to compliance with industry standards and specifications.

Managing Equipment Wear and Tear

Equipment wear management plays a crucial role in guaranteeing tensile testing machines for long-term reliability and accuracy. Maintenance schedules should be drawn up for recognizing early signs of wear and rectifying them before excessive problems arise. Constant inspections should be conducted on crucial components such as load cells, grips, and actuator systems to ensure that they are not damaged or degraded to the extent that the results would be adversely affected. If the moving parts are lubricated regularly and the machines cleaned, dust, undesirable debris, or corrosion can be prevented from accumulating.

Proper environmental conditions for storage would include ensuring that the equipment is not subjected to excessive moisture or huge temperature fluctuations, which would otherwise contribute to a shorter operational life. Operators should be trained in order to operate the machine correctly so as to avoid using it outside of the specified load limits, thereby limiting undue stress on the system.

Furthermore, the prompt replacement of worn-out parts, along with timely services per the manufacturer’s guidelines, is considered an important factor that promotes the machine’s accuracy. Calibration should also be performed to maintain precise and standard-compliant readings on a periodic basis by certified technicians. These simple procedures will enable operators to extend the life of their tensile testing machines and develop their know-how in assuring quality and uniformity of the test results.

Minimizing Human Error in Calibration

Standardized Procedures

Human errors in tensile testing machine calibration can drastically be minimized by observing the standardized procedures and putting in place strong training programs. The standards should be clear and consistent and enforced in such a way that every step of the calibration process will be followed. Providing technicians with a procedure or a checklist can prevent oversight and promote accuracy.

Training and Certification

Furthermore, regular operator training and certification contribute to the reduction of errors. If all operators are familiar with the calibration procedure, common errors due to lack of knowledge or skill gaps will mostly be avoided. Current hands-on training as well as occasional qualification maintenance, support a high level of operational performance and keep operators current with the equipment.

Automation and Digital Tools

Automation coupled with digital tools further improve the accuracy and consistency of the calibration process. More sophisticated systems, such as automatic calibration software and error detection algorithms, minimize human error. Moreover, proper documentation of calibration results can assist operators in tracing trends and recurring issues, and to make adjustments for improvement.

Actionable Tips for Maintaining Accuracy

Regular Maintenance Schedules

Mechanical Component Inspection: For a testing tensile machine to function optimally, regular maintenance must be ensured. The first thing to do would be to inspect all mechanical components such as the grips, load cells, and crossheads. Look out for signs of wear, corrosion, or damage. If found, it must be lubricated regularly where applicable. Lubrication is needed to keep the moving parts from frictions that can hasten wear.

Calibration Maintenance: Calibration maintains the accuracy of the tensile testing apparatus. It involves the application of standard checks at regular intervals to ensure that the force and displacement applied are measured correctly. Thus, the testing working domain remains convincing and orderly with relevant industry standards; if, however, discrepancies are noted during the calibration, then immediate adjustments to conform with requisite specifications will be made.

Software and Electronics Review: The software and electronics also require periodic review. Machines need to be updated regularly to ensure against operational errors and enhancements to functionality. Log all maintenance activities performed, including inspections, repairs, and calibration. The record can aid in identifying trends, facilitating part replacement planning, and avoiding downtime, all of which augment equipment life.

Proper Machine Handling Techniques

First and foremost, it is very important to ensure the correct handling of a tensile testing machine, with strict adherence to operational procedures. The very first thing operators need to do is to read and understand the manufacturer’s manual completely so that they are aware of how to set up the machine, operate it, and what safety precautions they should adhere to. Operators need to confirm that the machine is installed on a stable and level surface to prevent the possibility of vibrations or misalignment in the course of the test. Calibration is also an important procedure to ensure testing accuracy and reliable measurements-pressure.

Prior to testing, inspect all components allowing for grips, load cells, and any fixtures to be confirmed properly set and free from damage. Fasten the specimen securely without over tightening it so as not to apply any stress or deformation to the material that would interfere with the test. Always work within the load and speed specifications of the machine: exceeding these limits would damage the machine and invalidate the test results.

After each test operation, clean the machine and the fixtures to remove any debris or residue from the test. Place tools, grips, and accessories back in their respective storage places. With respect to maintenance, the manufacturer should indicate when mechanical parts should be oiled and updated on software. Good maintenance ensures constant throughput, reduces downtime, hence increasing the life expectancy of the tensile testing machine.

Ensuring Qualified Professionals Perform Calibrations

It is necessary that calibrations be performed by qualified persons to ensure that the tensile testing machine gives competent results. If the machine is properly calibrated, it operates within specified standards and will give dependable results. A professional calibration expert knows how to identify errors, test the performance of the machine, and adjust it to comply with industry standards.

Calibrators follow a standard method to check things such as the force applied on the specimen, accuracy of the extensometer, and alignment of the machine. This is important for keeping tensile test data intact, especially in industries requiring precision, such as aerospace, construction, and materials manufacturing. Without periodic calibration of the tensile testing machine, there might be inaccurate test results that lead to an irrelevant decision on product quality and safety standards.

Calibration by certified persons ensures the machine meets the acceptance criteria for specifications and goes a long way in enhancing the life of the machine. They can identify wear or zones of misalignment early enough such that maintenance can be carried out before they develop major problems. With professional calibrations performed regularly, organizations can assure a consistent operational output while sustaining the machine as a worthy instrument for material testing.

Frequently Asked Questions (FAQ)

Q: What is tensile testing machine calibration?

A: Calibration of tensile testing machines is the process of checking and adjusting the tensile testing machine to guarantee that it gives proper measurements of the force applied and elongation of the specimen during testing. This makes the result of tests more reliable as a guarantee that the machine operates within the specified tolerance level, considering uncertainties in the measurements.

Q: Why does the tensile testing machines require an accurate calibration?

A: Accurate calibration is the basis for tensile testing machines to provide reliable and valid results from testing. This brings about the potential need for certain industries to comply with the standards. Proper calibration helps to align the machine’s readings to industry benchmarks, thus sustaining the quality and the safety system for materials.

Q: How often should tensile testing machines be calibrated?

A: The testing machines are to be calibrated while under routine calibration, say once every year, or maybe two times as the usage and calibration requirements of the laboratory demand. Checking regularly will help maintain the accuracy and traceability of measurements so that the machine can perform consistently over time.

Q: What are the usual calibration services available to a tensile testing machine?

A: Usually available services for tensile testing machine calibration include force calibration, verification of measurement accuracy, and adjustment to improve the performance of the machine. Several calibration laboratories offer ISO 17025 accredited services, meaning the calibration procedures meet internationally recognized standards.

Q: What affects the accuracy of tensile testing machines?

A: The accuracy of tensile testing machines is affected by several factors: mechanical wear of the system, environmental conditions under which the system operates, and the measuring apparatus accuracy of the forces applied. At regular intervals, calibration of these machines will enable one to track any deviation levels so that the results generated from the tensile tests are always carried out correctly even under diverse loading conditions.

Q: What is the role of service engineers in calibrating tensile testing machines?

A: The service engineers are very important in the calibration of tensile testing machines, as they carry out the calibration process, make the required adjustments, and verify that the machine complies with the required specifications. Therefore, the skills of a service engineer ensure that the calibration is correctly undertaken and that the machine operates smoothly.

Q: In what way is tensile testing related to tension and compression testing?

A: Tensile testing is a type of force testing that determines how a material reacts to being stretched or placed into tension. Compression testing, on the other hand, checks the behavior of materials when subjected to compression forces. These two are very important in materials science and are generally carried out using calibrated testing instruments for reliable results.

Q: What value does a calibration service accredited to ISO 17025 bring?

A: An ISO 17025 accreditation assures that a calibration laboratory has been evaluated and meets the international standards for testing and calibration. This accreditation assures that services of calibration, including those of tensile testing machine calibration, are done with very high standards of accuracy and traceability; hence, provide a guarantee for the validity of the resultant data.

Q: Do tensile testing machines also test for ductility and flexural properties?

A: Yes—using special fixtures and test methods, tensile testing machines are capable of performing tests for ductility and flexural properties. These tests capture changes in material behavior in relation to different loading conditions and are critical in evaluating the general mechanical properties of materials.

References

- CrossCo – Compression and Tensile Tester Calibration

A detailed overview of calibration services for tensile and compression testing machines. - Presto Group – How to Conduct Tensile Tests & Calibration

A step-by-step guide on calibrating tensile strength testers. - Instron – Calibration of Materials Testing Systems

Information on on-site and factory calibration services for materials testing systems. - The Tech Plast – Tensile Testing Machine Calibration Standards

Insights into calibration standards, intervals, and the benefits of regular calibration.