Accurate force testing is necessary to complement mechanical integrity and component performance evaluation. Yet, well-designed test fixtures often prove to be a sine qua non condition for conducting force tests accurately, repeatedly, and reliably. Test fixture design is the most fundamental consideration in rendering force testing processes as close to real-world conditions as practical, while at the same time being able to function with utmost precision and repeatability. This article discusses some key solutions and tips for in-house design and execution of force testing fixtures. Whether you would like to streamline your testing operations or go through troubleshooting of common issues, this guide will provide insightful tips to help you enhance your results. Let us examine some techniques and considerations that will take your force testing work to a higher standard.

Understanding Test Fixtures

What is a Test Fixture?

A test fixture, in layman’s terms, is a proper tool designed to firmly hold a particular component, material, or product while it undergoes testing. Ensuring that the object receives unwavering support and alignment is paramount as modes of measurement are subjected to each test with or without a repeat. For newly imposed force tests, the fixtures become necessary in maintaining the sanity of the entire testing set-up, limiting any freedom of movement or variance that impairs absolute test results.

Force-testing fixtures are explicitly designed to apply or measure the forces acting on a test subject: tension, compression, shear, or torsion. In simple terms, they apply and measure force on the test subject. They may direct the forces in a way that mimics unconditional real-world scenarios, imparting some sense of genuine conditions to the forces involved. They stop the sample from being wrongly oriented and positioned during testing, and hence, they provide a more reliable set of data for analysis. The exact design and make of the fixture go hand in hand with what is to be tested, the characteristics of the material, and precisely how the force is applied.

Key Benefit: By means of a particularly designed force testing fixture will test subjects with greater accuracy and reliability, creating less unnecessary stress on the test subjects and the equipment, thereby in turn extending the life of such test subjects and equipment and present safety issues. A test fixture is a fundamental factor in every control and assurance of the mechanical property testing arising from the aspects of quality control, development of a product, or research on a particular material.

Importance of Test Fixture Design

Test fixture design is critical in ensuring the accuracy, consistency, and reliability of force testing procedures. A properly designed fixture holds the test sample firmly and accurately in position for force application. This process reduces the errors of measurement, minimizes the variability of results, and thereby leads to data collected with high confidence. Test fixtures must be designed properly to support the conduct of integrity tests and to establish that the result is compatible with the set industry standards.

Generally, the test fixture brings about safety and efficiency in the testing process. It minimizes chances of damage to the test subject and the equipment by firmly holding materials or components. The fixture also serves to reduce setup time and organize the required resources properly. With well-aligned equipment and a steady sample, the testing process will be smooth with no interruptions due to an improper hypothesis.

Lying in the middle of the extended reliability of the test equipment and test samples is the design of the test fixture. It performs effectively in absorbing stresses by evenly distributing these forces and preventing excess stresses to the equipment. It also prevents sudden deformation or failure of the test sample, thereby guaranteeing its reliability for a repeat test. In the end, a well thought out and well-designed fixture enriches the value of results and the long-term efficiency of the testing.

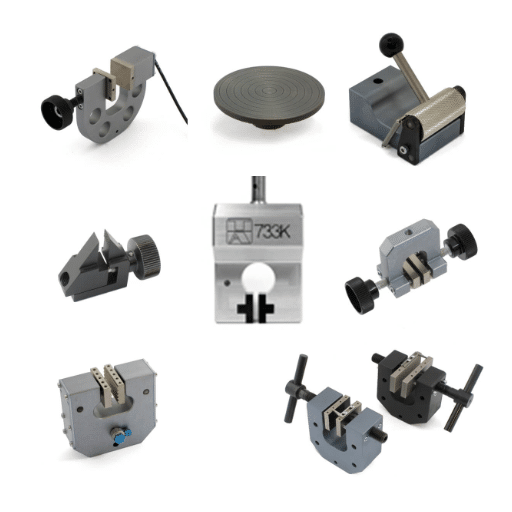

Types of Test Fixtures

These are special fixtures used during tests to apply and measure forces applied to the various specimens. In force testing, fixtures level the application of force onto the test specimens for correct readings, damage to equipment, and improper operation of the test method. They cater to diverse tests, including tensile, compressive, shear, and bending, and have become indispensable for the very sanctity of a testing process.

Tension Fixtures

Used for tensile testing of materials. Grips the test specimen firmly and ensures that the force is applied in only one direction so that the material response to the pulling force may be correctly measured.

Compression Fixtures

Used to evaluate a material’s ability to resist compressive forces by applying force in a specified manner until the material deforms.

Shear Testing Fixtures

Used to measure the resistance of the forces making two layers slide against each other.

Universal Fixtures

Fit virtually any force type and provide diversity to more testing needs, offering versatility for various applications.

Key Principles of Test Fixture Design

Essential Components of Custom Test Fixtures

A custom test fixture is essential for force testing and is the basis on which various materials or product designs are tested for reliability and precision. The major components of test fixtures are designed in strict accordance with the particular testing needs for accuracy and consistency.

Clamping System

The job of this system is to firmly hold the test specimen in place throughout the entire testing procedure. If the specimen moves or shifts during force application, the results may be rendered inaccurate. Hence, an efficient clamping system must be adjustably designed to accommodate specimens of different sizes and shapes.

Load Application System

Essentially, it should apply a force consistently on the test specimen. Depending on the nature of testing involved, it may impart tensile, compressive, or shear forces. The uniform distribution of the force is critical because force concentration at any point would always invalidate the test results. In fact, the accuracy of force application and its correct measurement is of paramount importance for the credibility of any fixture.

Alignment and Calibration Features

Alignment is the key to force application on the individual so that the data is not skewed. Usually, there are alignment aids incorporated in custom fixtures, and calibration is also done to ensure all the forces are applied evenly and exactly where intended. The regular calibration of the alignment mechanisms will ensure that the forces remain reliable and accurately applied for the entire period.

Result: By implementing the above-mentioned essential parts, custom test fixtures become versatile and precise to accomplish various testing needs. Careful design assists these fixtures in verifying product quality, identifying potential problems, and helping in design enhancement.

Designing for Accessibility and Efficiency

Force testing fixtures stand in a very difficult position between ergonomic constraints and the functional requirements for precision. Cumulatively, ease of installing the fixture should be promoted. A great deal of effort should be put into the use of clear labeling, intuitive design, and user manuals to alleviate the setup and operational complexity for users who have varied technical skills. Ergonomically speaking, perhaps components that provide for easy hand manipulation or adjustable height are good considerations that would greatly enhance accessibility for a wider range of operators.

Efficiency would mean less downtime and more throughput for a force testing fixture. Automated systems, wherever appropriate, can be used to take care of monotonous operations so that testing is uniform and exact without slowing down the movement. Time-saving since modular design allows an easy change of components or even adapting of the fixture to different application scenarios. Quick detection of problems through integrated monitoring systems will reduce unnecessary downtime, and wasting time through idleness.

Maintenance and updates, hence, form another pair of accessibility and efficiency. Making it easy to clean, inspect, and repair the fixture will therefore offer a longer lifetime and more consistent performance. Also, implementation of feedback loops, such as periodic user evaluations, would help engineers make further improvements to the areas of accessibility and efficiency in subsequent designs. Documentation itself should be clear in its interpretation, as should its support, so that users are enabled to troubleshoot on their own and, thereby, reduce any interruption of their work and able to enhance usability substantially.

Incorporating Automation in Test Fixture Design

While designing a force testing fixture, one can consider automation to increase precision, consistency, and efficiency. The automated systems provide for a more reliable testing procedure since the machines can exert a consistent level of force with meager deviations, minimizing human error. The automation of test procedures is critical for standardization, which allows for repeat testing and testing with high accuracy over a long period or in volume.

Automation Benefits:

- Programmable controllers and sensors for real-time measurement

- Immediate adjustment when parameters vary out of prescribed limits

- Enhanced reliability of gathered data

- Adherence to testing standards

- Smooth data collection and analysis system

- Clear reports for evaluation and decision-making

Lastly, the need for manual labor may thus be remarkably decreased, freeing the attention of operators for performing higher-level tasks and boosting safety by minimizing direct interaction with sometimes hazardous components. Therefore, automated force testing fixtures ensure the highest accuracy, efficiency, and safety for manufacturers and engineers, rendering it a vital point in contemporary test fixture design.

Practical Applications of Test Fixtures

Functional Test Fixtures for Electronic Devices

Force testing fixtures are good to have tools across many industries to ensure product reliability and durability. They are meant to apply a controlled amount of force to a given part or an assembly under test and assess its ability to withstand or resist stress. By simulating force conditions in real life, manufacturers are in a position to forecast the performance of their products in varying scenarios and to catch weaknesses in the design and production at an early stage.

Among the key processes for a force testing fixture are tests of the mechanical integrity of components. For example, measurements of force are taken in pressing, pulling, or operating some parts, such as switches, buttons, or connectors. The tests confirm that a device passes safety and performance standards and is consistent and pleasing from an end-user point of view. These fixtures are very versatile and can accommodate a wide range of forces depending on what the product requires.

One of their uses is still in metrology tests during high quantities of production. With this approach of force testing, very precise variations could be detected on batches or productions to reduce as much as possible delivery of faulty products to the customers. This will eventually cut down warranty claims, improve customer satisfaction, and strengthen brand equity. Hence, force testing fixtures are at the heart of modern manufacturing as they sculpt better-making-quality-safe consumer-oriented products.

Using Test Fixtures

Force testing fixtures are the tools used to ensure that the manufacturing processes meet the standards of quality and safety. They set a controlled environment wherein components or products are tested for forces-tension, compression, or shear against their strength, durability, and functionality. Under such realistic conditions, these fixtures allow the manufacturer to spot defects or weak points in the product before it goes to market.

Consistent results stand out as one of the major benefits of force testing fixtures. They allow for very precision measurements that can be repeated with minimal variability during production testing. Such levels of consistency ensure that each batch of product meets the same requirements for quality, and therefore, defects are almost absent. Moreover, fixtures can be adapted as needed to serve different industries-from automotive, aerospace, electronics, to health care, and thus are very versatile.

Economic Impact

Force testing fixtures also help ensure cost reduction and increase efficiency. Detecting the root causes of potential defects before the product reaches market will save the costly expenses of recalls or warranty claims from manufacturers. Also, the data obtained from these tests shall be used in making improvements on design and manufacturing processes. Therefore, by introducing force testing fixtures, manufacturers will not only be able to maintain safety and performance standards of products but also in delivering reliable and well-down products, which will build brand trust and ensure longevity.

Case Studies: Successful Applications

The Automotive Industry

Force testing fixtures have found wide utilization in the automotive industry to ensure that vital suspension components, seat mechanisms, and door latches withstand durability and reliability tests. These force tests are an excellent simulation of actual real-world forces acting on these parts, so that manufacturers might pinpoint weak points before the consumers have to suffer. Vehicle recalls are thereby cut down to a great extent, and vehicle safety also goes up, which in turn increases customer satisfaction.

Medical Devices

Precision is essential in medicine, and force testing fixtures are employed to ascertain the operation of medical devices. The force needed for surgical instruments or for operating prosthetics within the allowable range of displacement must be tested to see that these products conform to very stringent industry standards. This application guarantees the safety of patients while fostering confidence in life-saving technologies.

Consumer Electronics

Force testing fixtures have enjoyed success with consumer electronics, making sure that wearables, smartphones, and other portable devices are tested for durability. The pressure is simulated such that the items are expected to undergo daily usage-good shock to the screen or pressure on the buttons; no failure is the expected behavior. These tests, therefore, lead to quality products that win consumer trust and are reliable over long periods of use.

Cost Considerations for Test Fixtures

Factors Affecting Test Fixture Pricing

The pricing of force testing fixtures is affected by several major factors. One major factor is the complexity of design. Fixtures requiring very accurate customization or intricate configurations to meet some specialized testing requirements are usually priced higher. Price also varies with the accuracy requirements of the fixture because a greater degree of accuracy requires more advanced materials and technologies in the production process.

| Cost Factor | Impact Level | Description |

|---|---|---|

| Design Complexity | High | Intricate configurations and specialized testing requirements increase costs significantly |

| Materials Quality | Medium-High | Special metals or composites required for durability and large force handling |

| Accuracy Requirements | High | Higher accuracy demands advanced materials and technologies |

| Manufacturing Process | Medium | Complex machining, assembly, and checking procedures add to costs |

The second significant factor is the materials used for constructing the fixture. Materials that are durable and high-quality, such as special metals or composites, are usually required so the fixture can hold large forces during tests and remain reliable throughout the years. Such materials add to the costs but are necessary so that consistent results can be achieved in force testing.

Working charges and manufacturing processes are other factors that contribute to the price. The longer and more complicated the procedures for manufacturing, the higher the cost will be. Cost incidence may be contributed to by complex machining, assembling, and checking procedures. With regard to the pricing of a force testing fixture, all the related factors of design complexity, materials, and labor are involved in striking a balance between costs and performance parameters such as life and precision.

Budgeting for Custom Test Fixture Design

In budgeting for a custom force testing fixture, it is essential to consider the main factors influencing the price. These include the complexity of design, materials used, manufacturing requirements, and degree of customization. Forging an elementary design out of off-the-shelf raw materials is going to cost less than manufacturing an overly ornate fixture with exotic materials and special features.

Cost Management Tips:

- Clear Requirements: Elaborate on testing needs, specifications, and budget constraints

- Early Collaboration: Work with experts to identify cost-saving methods

- Off-the-Shelf Components: Use standard components wherever possible

- Simplified Design: Balance functionality with cost-effectiveness

- Modular Approach: Consider designs that allow for future adaptations

Customization is one of the major cost factors since the particular design of the fixture may differ in function from generic fixtures and require additional design and engineering work. This fine-tuning ensures the fixture meets the intended application for better accuracy and reliability in testing. From a design standpoint, additional design time and custom components could lead to an increase in costs. It is critical to assess the specific needs of the test process and concentrate on the ones that add the highest value.

Clear articulation of needs in writing to the design team is key to effective cost management. Elaborate on the need for testing, pertinent target specifications, and any budget constraints. Early collaboration with experts may lead to cost-saving methods involving the use of as much off-the-shelf components as possible, or otherwise simplifying the design of the fixture without compromising its intended function. This early roadmap would help maintain the balance between costs and performance.

Value Analysis: Cost vs. Benefits

In evaluating force testing fixture costs and benefits, one should consider the overall impact on potential testing goals and the long-term value. Designing and manufacturing a custom fixture can bring an initial cost that looks highly prohibitive. But these costs can usually be amortized over the lifetime of the fixture as it is able to perform the important function of preventing inconsistent or incorrect testing or test results, thus avoiding high costs and losses from defective materials and products that might end up being discarded due to faults or the cost of re-testing. This increased reliability is often enough to justify the fixture in high-stakes areas and applications.

Benefits

- Enhanced efficiency and precision

- Reduced manual intervention

- Consistent data collection

- Increased customer satisfaction

- Improved brand recognition

- Fewer operational disruptions

- Long-term maintenance savings

Cost Considerations

- Initial design and manufacturing

- Customization requirements

- High-quality materials

- Complex machining processes

- Testing and calibration

- Documentation and training

From a benefit standpoint, a force testing fixture further adds to efficiency and precision in testing processes. Other times, it cuts manual intervention of data collection, while at other times, it brings inconsistency due to variability in the data collection process, thereby impeding the decision-making process as well as product quality. These enhancements directly translate to increased customer satisfaction and brand recognition in a highly competitive market space. A good fixture tranlates also into fewer operational disruptions, thereby saving on maintenance in the long run.

Additionally, the balancing of the costs becomes paramount only in achieving an optimal output. When the budget constraints are considered non-negotiable, then modular design will provide cost-effective flexibility. Alternatively, simpler designs and use of standard components wherever possible will do the job with a few costs involved. However, the degree to which the force testing fixture ultimately contributes to your needs will depend upon how well its design and functionality fit your actual testing requirements and how well it can justify its expenses with measurable results from your test operations.

Challenges and Solutions in Test Fixture Implementation

Identifying Common Bottlenecks

Common Bottlenecks in Test Fixture Implementation

1. Design Misalignment

One of the common bottlenecks in the installation of force-testing fixtures pertains to the misalignment between the design of the fixture and the specific testing requirements. When the fixture-size, shape, or one or two properties not conceived for the test subject, it would result in a test scenario that is unreliable or even apt to destroy equipment. A thorough good analysis of the test subject and testing conditions is, therefore, paramount for ensuring that the fixture is optimized for best performance.

2. Accuracy and Repeatability Issues

Other such big hindrances come from lessening accuracy and repeatability subject to time. There is always the possibility that one or more of the parts degrade with the passage of time, might not be from good quality ones, or have never been treated well, and this is just one of the cases that would cause variation in the test results. Hence, to combat this, manufacturers need to establish an inspection, calibration, and maintenance schedule-a selection of good quality materials being one of the best measures. In the long run, repeatability in testing is what helps to maximize value.

3. Design Rigidity

Lastly, a rigid fixture design will simply hold an adverse position when testing a range of different components or should there be, ever so slight, an update of requirements. A flexible fixture shall be required in such cases: one that realizes variations or one with adjustable configurations that can allow for future needs. Modular design and detachable components maybe some of the best ways to keep down-time and modification costs at a minimum, thereby allowing fixtures to provide a more constant and trusted-rated result.

Improving Test Point Accessibility

A force testing fixture attempts to apply forces and measure the forces applied on or generated by a given component or system. A fine-tuned force testing fixture needs to be designed and used properly in order to yield credible results from the tests; improper use may lead to inaccuracies in testing output due to the impossibility of repeatability.

Along with ergonomics, adaptability goes a long way toward improving test point accessibility for force testing fixtures. Simple configurations that allow the tester to position and align test samples without any complicated manual adjustments are needed. Modular construction elements with quick release mechanisms will allow testers to hop in and out of test points with ease and efficiency. These designs cut down on the time used in setting up tests, which is increasing productivity where repetitive testing occurs.

Accessibility Enhancements

Movable clamps or interchangeable plates may be adjusted even further in order to optimize enhancements. In this way, the fixture would compromise for different sample sizes and configurations, thereby catering to a wider range of test requirements. Force testing fixtures with accuracy and are adjustable will keep delivering results that are trustworthy and consistent while reducing human errors and delays in operations.

Best Practices for Overcoming Design Challenges

Flexibility & Adaptability

When confronted with designing challenges for a force testing fixture, one should consider simplicity, adaptable to many types. Such a fixture ought to be capable of handling multiple sample sizes and shapes. A fixture having an adjustable mechanism, positioned clamps, or maybe interchangeable plates will help greatly. It facilitates easy adjustment and thus reduces the set-up time in-between tests. With such a design mindset aimed at adaptability, one achieves an operationally efficient fixture with a broader scope of applications.

Material Selection

The next big consideration is material selection. The various parts of the fixture must be sturdy enough for long use and undergo operations with disparate force conditions. Materials having greater tensile strength, or resisting corrosion, are highly recommended as they guarantee lasting sustainability and consistent performance. Notwithstanding, using materials that are light will make the fixture portable while reducing ergonomic burdens on the operator during setup and operation.

Precision & Accuracy

The next big thing to consider is exactitude, which is essential to guarantee that the results are accurate and repeatable. The design of the fixture should prevent extraneous variables from entering the picture, such as vibrations or misalignments, that would otherwise interfere with the measurement. Using fine-tuning adjustments and locking mechanisms will help ensure stability during testing. Regular calibration of the fixture and associated test equipment ensures that the measuring results remain accurate over time. Flexibility, durability, and precision are three sets of attributes needed to respond to the challenges while designing force testing fixtures adequately.

Frequently Asked Questions (FAQ)

How does Force Testing Fixture design impact product testing?

The Force Testing Fixture design ensures the DUT receives equal force and alignment throughout the test. It ensures precision during testing, especially for the in-circuit test (ICT) and the functional test, thereby having more standard for the overall testing framework.

What factors influence the price of a Force Testing Fixture?

The price of a Force Testing Fixture can increase basically because of complexity, materials used, number of test points, and level of automation of design. Specialized test fixtures for special purposes on a particular DUT may also attract higher charges because of specific requirements in their design.

What is the importance of test fixtures on high-volume production lines?

On a high-volume production line, test fixtures are indispensable for streamlining the setup of tests. They allow testing of multiple units efficiently, cut costs by reducing manual handling, and ensure quality control by instituting standard testing practices.

How can the building of a test fixture increase testability?

The building of a test fixture for particular DUTs increases testability by providing easier access to test points and ensuring that required interfaces exist. This provides more efficient debugging and less time in the assembly process.

What are the various types of test fixtures used in PCB testing?

The various test fixtures used in PCB testing are likely to include a bed-of-nails fixture, jigs, and custom test fixtures. Each of these possesses its benefits relative to the test requirements, such as in-circuit testing or functional testing.

How does the test software interact with the test fixture?

The test software works with the test fixture in automating the test process. It handles test system control, communicates with DUT, while collecting data during the run of a test for use in an effective analysis and debugging of PCB or assembly.

Could you explain the procedure of fixture development for a cover test fixture?

Fixture development for a custom test fixture involves various steps, including requirement gathering, CAD design, prototyping, and testing. The engineering team works co-operatively to make sure that the fixture satisfies the specific needs for both the DUT and the test method.

How do probes contribute to test fixture design?

Probes in a test fixture design are of prime importance when conveying electrical connections to and from the DUT. They need to be placed with great accuracy to ensure that they are making contact with the appropriate test points, which will assure the reliability of results being obtained during circuit tests.

How does the functional test fixture differ from a PCB test fixture?

A functional test fixture is to test the operation of a DUT under circumstances as close to reality as possible, for example, a real verification of its functionality, whereas a PCB test fixture would focus mainly on testing the electrical integrity of a circuit board; both are placed in a different role within the test infrastructure.

References

- Test Fixture Design, Custom Equipment, & Industrial Automation – Team Pipeline – Specializes in custom test fixture design, machine design, and industrial automation services.

- Test Fixture Design – Kinetic Vision – Offers expertise in test fixture design and development for product testing, metrology, tooling, and assembly.

- Force Testing: Purpose, Importance, Types of Testing – Xometry – Provides insights into force testing, including its purpose and applications.