Instrument And Equipment Wholesale

High Quality Test Fixtures Manufacturer in China

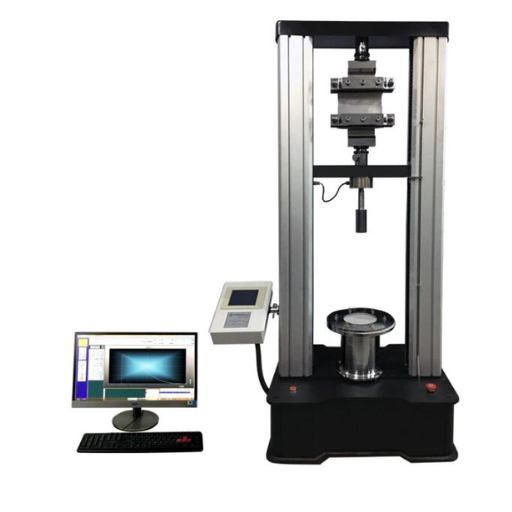

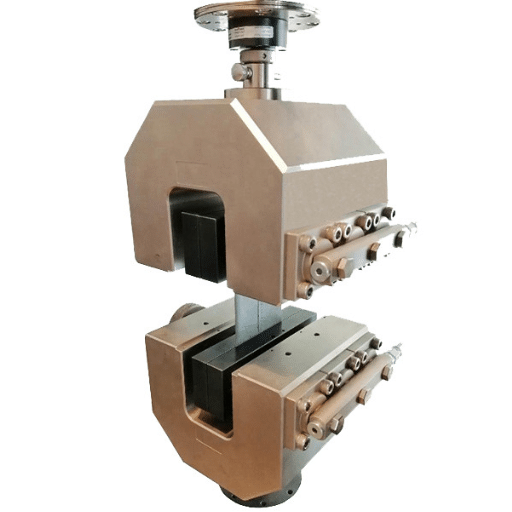

Introducing our Precision Test Fixtures, engineered by a top-tier factory in China known for excellence in material testing solutions. Designed for accuracy and durability, these fixtures ensure secure sample placement during tensile, compression, and impact tests. Built with sustainable materials and advanced engineering, they provide reliable performance for diverse applications. Ideal for quality control and research, our fixtures offer customizable options to meet specific testing needs.

What Is A Test Fixture?

-

Applies a controlled force to plastic samples to evaluate their strength and durability under simulated conditions.

-

Capable of performing tests that assess material resilience, tensile strength, and surface consistency.

-

Used across diverse industries including plastics manufacturing to ensure material performance and product reliability.

-

Often integrates with data acquisition systems and software for precise control, real-time monitoring, and detailed analysis of test results.

-

Available in various configurations and load capacities to accommodate different sample sizes and testing requirements.

Essential Tests You Can Perform With A Test Fixtures

Explore the advanced testing capabilities of our Test Fixtures. This precision equipment enables thorough analysis of plastic materials under controlled conditions, delivering essential data for research, development, and quality assurance.

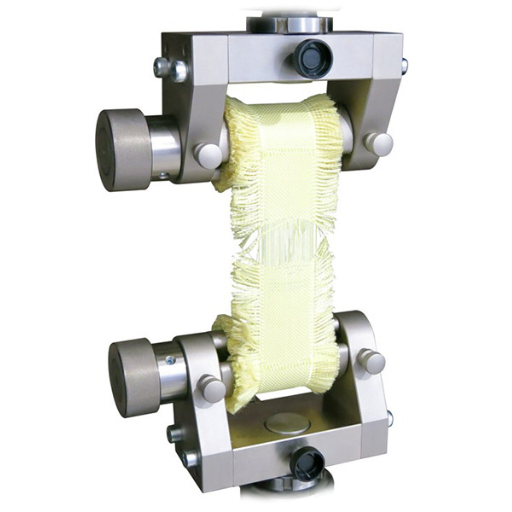

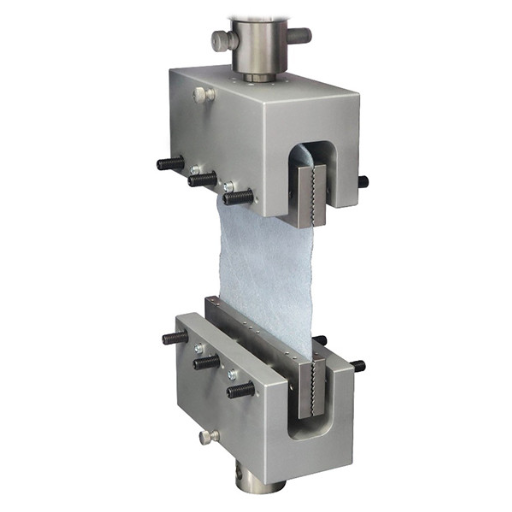

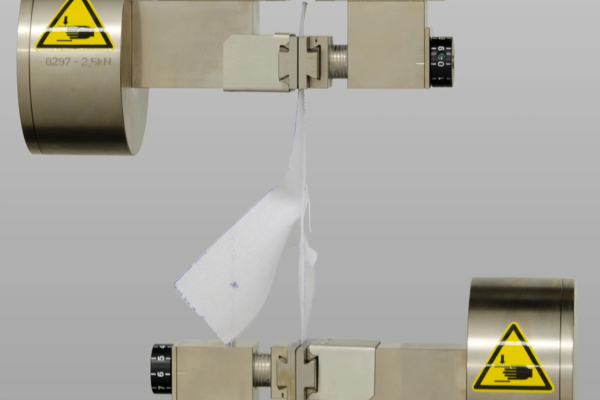

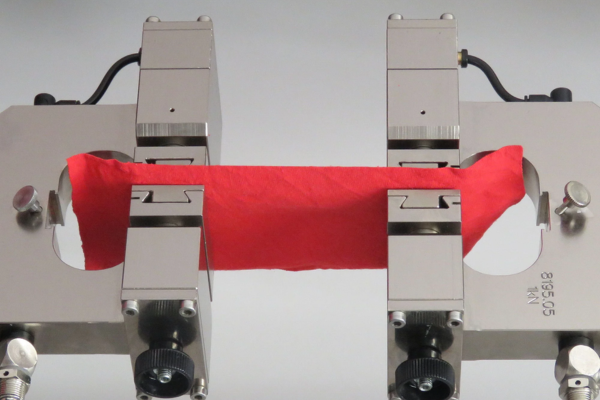

Tensile Strength Test

Measures the maximum force a plastic sample can withstand while being stretched, assessing its elongation and breaking point for performance evaluation.

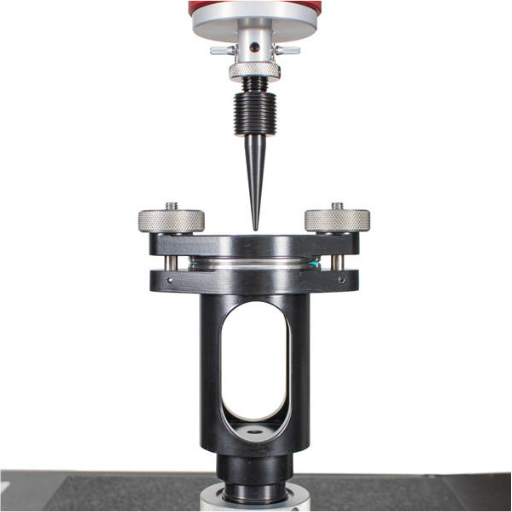

Impact Toughness Test

Tests the plastic’s resistance to sudden impacts, simulating real-world shocks to measure its toughness and energy absorption capacity.

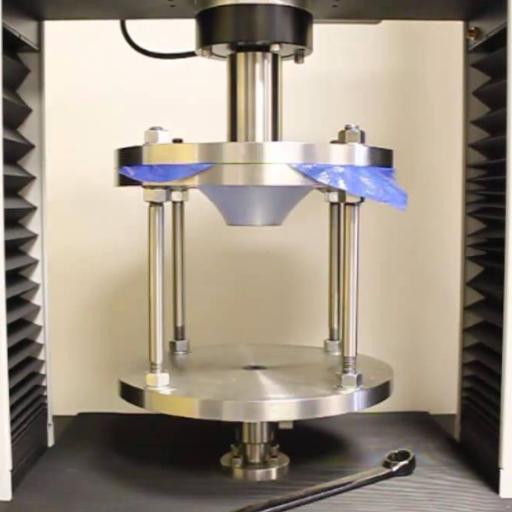

Compression Resistance Test

Evaluates the plastic’s ability to endure compressive forces, determining its deformation and strength under pressure for durability insights.

Flexural Bending Test

Assesses the plastic’s flexibility and bending strength, analyzing its behavior under bending stress to ensure structural integrity.

How to Choose the Right Test Fixtures?

- Select fixtures based on the maximum load capacity needed for your plastic testing requirements.

- Ensure the fixture’s design accommodates your sample dimensions and shapes accurately.

- Verify the fixture ensures precise and repeatable results for consistent data collection.

- Choose a model with adjustable settings for customizable tensile and impact testing methods.

- Confirm the fixture meets industry standards (ASTM, ISO) for reliable quality assurance.

What are the Uses of Test Fixtures?

- Plastic Manufacturing: Secures samples for tensile and compression tests to ensure material quality.

- Material Testing: Holds plastic samples during impact tests to assess durability under stress.

- Packaging Industry: Tests plastic films and containers for strength and deformation resistance.

- Quality Control: Ensures plastic components meet strength and flexibility standards during production.

- Research Applications: Supports studies on plastic behavior under various mechanical and thermal conditions.

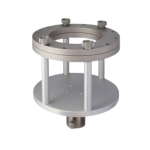

Components Of Test Fixtures

Select from a range of precision-engineered parts, fixtures, sensors, and more, all designed to perform thousands of industry-standard abrasion tests. When ready to customize your system, reach out, and an expert will help tailor it to your testing needs and budget.

View our Test Fixtures Price

Top Test Fixtures tailored for you, our advanced technology provides reliable quality efficiently and professionally.

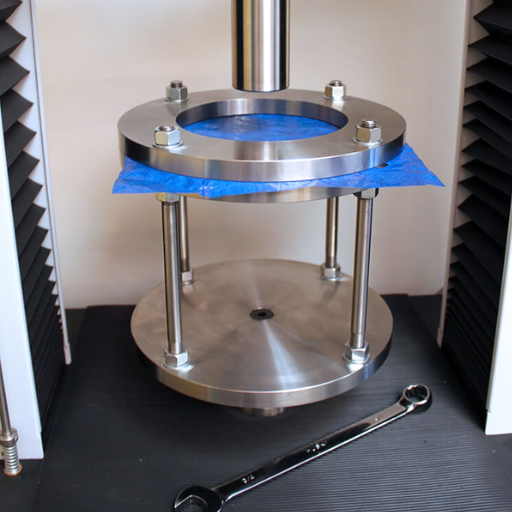

Geotextile Test Fixtures

Precision fixtures for geotextile testing, compliant with ASTM D6241 & ISO 12236. Securely clamps samples for accurate puncture and tensile tests.

Test Fixtures Data Overview

| Parameter | Details |

|---|---|

| Load Capacity | Ranges from 0.02 kN to 80 kN for light to heavy-duty plastic testing. |

| Testing Compatibility | Supports tensile, compression, and impact tests on various plastic types. |

| Accuracy and Precision | Features high-accuracy sensors with ±1% precision and digital calibration. |

| Environmental Conditions | Operates in -15°C to 55°C and 15% to 85% RH for realistic test simulations. |

| Software Integration | Includes user-friendly software for automated data collection and analysis. |

| Speed Control | Adjustable from 5 mm/min to 400 mm/min for precise testing adjustments. |

| Sample Displacement | Offers up to 350 mm travel distance for versatile sample testing. |

| Extensometer Support | Compatible with external extensometers for accurate strain measurements. |

| Power Compatibility | Supports 110V/60Hz or 230V/50Hz, adaptable to regional power standards. |

| Safety Mechanisms | Equipped with overload protection, safety interlocks, and emergency stop. |

Why Choose Our Test Fixtures Manufacturers

We are committed to delivering top-quality Test Fixtures with exceptional precision and reliability. Whether you need advanced testing equipment for industrial applications or research purposes, we offer solutions tailored to your specific needs.

We specialize as expert Test Fixture manufacturers, leveraging years of expertise to provide high-performance tools. Our designs ensure accurate tensile and impact results, while emphasizing durability with robust materials and innovative technology.

What Our Client Says

Understand from our clients what they say about doing business with us and the unique value addition we provide.

Expert Insights on Test Fixtures

How to use test fixtures?

To use test fixtures, secure the plastic sample in the fixture, attach it to the testing machine, set test parameters like load and speed, run the test, and analyze the data. Ensure proper calibration and alignment for accurate results in tensile, compression, or impact tests.

What types of test fixtures are there?

Types of test fixtures include tensile grips for pulling tests, compression platens for pressure tests, bending fixtures for flexural strength, and impact fixtures for toughness. They vary by sample size, material, and test type, ensuring versatility in plastic testing.

What testing machines can be used with test fixtures?

Test fixtures are compatible with universal testing machines, impact testers, hardness testers, and fatigue testing machines. They work with equipment like Instron, MTS, or ZwickRoell systems, supporting tensile, compression, and impact tests on plastics.

What are the application areas of test fixtures?

Test fixtures are used in plastic manufacturing, automotive, packaging, and aerospace industries. They ensure material quality, support product development, and verify compliance with standards like ASTM and ISO for diverse plastic applications.

Why are test fixtures so important?

Test fixtures are crucial for securing samples during testing, ensuring accurate and repeatable results. They enable precise measurement of plastic properties, supporting quality control, safety compliance, and material development in various industries.

What tests can be done with test fixtures?

Test fixtures enable tensile strength, compression, flexural, impact, and hardness tests on plastics. They also support shear and fatigue tests, providing comprehensive data on material durability, flexibility, and performance under stress.

Latest Blog Posts

Maintain Inventiveness by Following The Blog for the Latest Best Practices, Techniques, Innovations, and Insights in the Field.

A puncture test is a critical method applied in different industries for testing mechanical integrity, durability under stress, and performance […]

For professionals and researchers working with geotextiles, understanding their mechanical performance is critical to ensuring their effectiveness and reliability in […]

Selecting the right geotextile test equipment is a critical step for ensuring the quality and performance of geosynthetic materials in […]

Road construction is an intricate process that demands the precise integration of materials, engineering techniques, and quality controls to ensure […]

Geotextiles have become an indispensable component in modern engineering and construction, providing innovative solutions to challenges related to soil stabilization, […]

When evaluating the durability and strength of materials, particularly in geotechnical and engineering applications, selecting the appropriate testing method is […]

Elevate Your Testing with Our Test Fixtures

Enhance your plastic testing with our high-precision Test Fixtures. Designed for accuracy, they support tensile, compression, and impact tests, complying with ASTM D638 and ISO 527 standards. Crafted with durable materials and innovative technology, these fixtures offer customizable solutions for industrial and research needs. Partner with us, a trusted manufacturer, to optimize your quality control. Whether you need robust setups for manufacturing or tailored options, we deliver excellence.

Frequently Ask Questions

Q: What is test fixture design?

A: Test fixture design involves creating custom holders tailored to sample shapes and test types, using durable materials and precise engineering to ensure reliable tensile, compression, or impact test results.

Q: What is a custom test fixture?

A: A custom test fixture is a bespoke solution designed for specific plastic testing needs, offering adjustable features to accommodate unique sample sizes and test requirements like tensile or puncture tests.

Q: What are functional test fixtures?

A: Functional test fixtures are used to evaluate plastic performance under real-world conditions, supporting tests like tensile strength and flexibility to ensure product functionality and durability.

Q: What are electronic test fixtures?

A: Electronic test fixtures integrate sensors and data systems to measure plastic electrical properties and mechanical performance, ideal for automated tensile and impact testing in advanced labs.

Q: What is an impact test fixture?

A: An impact test fixture secures plastic samples for drop or pendulum tests, assessing toughness and resistance to sudden forces, ensuring compliance with standards like ASTM D256.

Q: What are mechanical test fixtures?

A: Mechanical test fixtures are designed for tensile, compression, and bending tests on plastics, providing stable sample holding to evaluate strength and deformation under mechanical stress.

Q: What are standard test fixtures?

A: Standard test fixtures are pre-designed tools compliant with ASTM and ISO standards, used for routine tensile, tear, and impact tests to ensure consistent and comparable plastic testing results.

Q: What is a puncture test fixture?

A: A puncture test fixture holds plastic samples to evaluate resistance to penetration, simulating real-world damage and ensuring durability for packaging and industrial applications.