Instrument And Equipment Wholesale

Top Geotextile Test Fixtures Manufacturer in China

Discover specialized testing solutions with our Geotextile Test Fixtures. Designed for accurately evaluating the mechanical and hydraulic properties of geotextiles and related materials, our fixtures are essential for grab tensile, strip tensile, CBR puncture, and other critical tests, ensuring material performance in civil engineering and construction applications.

What Is A Geotextile Test Fixtures?

-

Geotextile test fixtures are specialized attachments or grips used to hold and test geotextile and related geotechnical fabric samples accurately.

-

They are designed to perform various standard mechanical tests on geotextiles, geomembranes, geogrids.

-

Common tests performed using these fixtures include grab tensile strength, wide-width strip tensile strength, puncture resistance (like CBR puncture), seam strength, and tear strength tests.

-

These fixtures ensure that samples are gripped and loaded in a consistent manner according to specific ASTM, ISO, or other relevant geotechnical testing standards.

-

Using the correct fixtures is essential for accurately determining the material's mechanical properties under tension, puncture, or tear forces.

Main Features of Geotextile Test Fixtures

Geotextile Test Fixtures are specialized attachments designed to integrate with testing machines, providing reliable and accurate evaluation of geosynthetic materials under various stresses to ensure performance in civil engineering applications.

Standardized Gripping

Engineered to securely hold geotextile samples according to international standards (like ASTM D4632 for grab tensile or ASTM D4595 for wide-width strip tensile), ensuring consistent and repeatable test conditions crucial for accurate results.

Durability and Precision

Constructed from robust materials capable of withstanding the loads required for testing strong geotextiles, while manufactured with precision to ensure correct sample alignment and loading for accurate measurement of material properties.

Versatile Application

Designed to support a range of critical geotextile tests, including tensile strength, puncture resistance (such as CBR), and seam strength, allowing for comprehensive mechanical characterization of different material types and structures.

Compatibility with UTMs

Designed to be compatible with standard general-purpose testing machines, these units expand the capabilities of existing laboratory equipment to perform specific geotextile tests without requiring dedicated single-function machines.

Geotextile Test Fixtures For Sale

Geotextile Puncture Resistance Test Fixture

Measures geotextile's resistance to puncture by a probe. Essential for evaluating material integrity against stones or rough surfaces in civil applications.

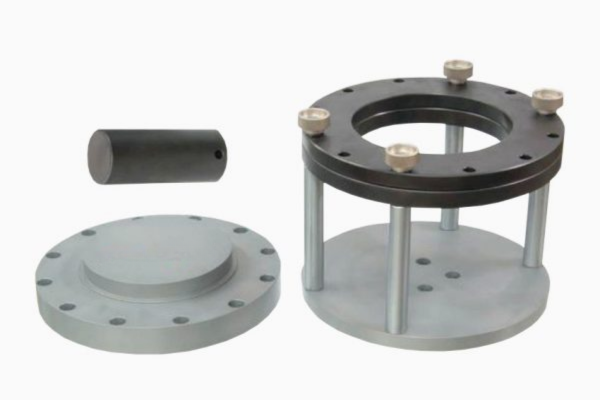

Geotextile CBR Static Puncture Test Fixture

Evaluates geotextile resistance to puncture by a CBR plunger under static load. Critical for assessing strength under concentrated stress in road/rail construction.

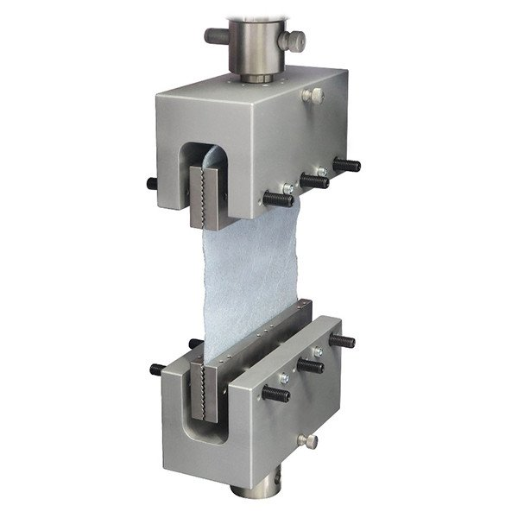

Geotextile Strip Tensile Test Fixture

Tests the tensile strength and elongation of geotextile strips using wide grips. Provides fundamental data on material strength under tension along specific directions.

Geotextile Trapezoidal Tear Test Fixture

Measures the force required to propagate a tear in a geotextile specimen. Assesses tear resistance, important for handling and installation damage potential.

Geotextile Test Fixtures Technical Specifications

| Parameter | Details |

|---|---|

| Supported Test Type | Specifies which mechanical tests the fixture is designed for (e.g., Grab Tensile, Strip Tensile, CBR Puncture, Trapezoidal Tear, Seam Strength). |

| Applicable Standards | Lists the specific geotextile testing standards (e.g., ASTM D4632, ISO 10319, ASTM D6241, ASTM D4533, ISO 13431) the fixture complies with. |

| Sample Dimensions | Indicates the range of sample widths, lengths, or required specimen sizes the fixture can accommodate for testing. |

| Load Capacity Rating | Specifies the maximum tensile or compressive load the fixture is designed to safely withstand during testing. |

| Gripping/Holding Method | Describes how the sample is secured (e.g., pneumatic grips, manual screw grips, wedge grips, specialized clamps) to prevent slippage. |

| Material Compatibility | Notes the types of geosynthetic materials (geotextiles, geogrids, geomembranes) the fixture is suitable for testing. |

| Interface/Mounting | Details how the fixture connects to the testing machine's crosshead or base (e.g., common adapter types, bolt patterns). |

| Jaw Face/Accessory Options | Mentions available interchangeable faces or accessories for different standards or material types (e.g., rubber coated jaws, serrated jaws, specific puncture heads). |

| Operating Temperature Range | Indicates the temperature range the fixture can function within if testing is conducted in a temperature-controlled environment or chamber. |

| Durability and Construction | Refers to the materials used in the fixture's construction, ensuring long-term performance and resistance to wear under repeated use. |

Application Industries of Geotextile Test Fixtures

Civil Engineering: Testing geotextiles used in roads, railways, embankments, and foundations for tensile strength, puncture resistance, and tear strength to ensure structural integrity and performance.

Construction: Evaluating geosynthetic materials for site development, drainage systems, and erosion control applications to verify mechanical properties and durability.

Geotechnical Consulting: Providing material testing services using standardized fixtures to assess geotextiles for various projects, ensuring compliance with specifications and design requirements.

Geosynthetic Manufacturing: Quality control and R&D for geotextiles, geogrids, geomembranes, and composites, utilizing fixtures for routine testing and characterization of new products.

Environmental Engineering: Testing geosynthetics used in landfill liners, containment systems, and filtration applications for puncture resistance and seam strength to prevent leakage and ensure long-term performance.

Request Information on Your Geotextile Test Fixtures!

Need reliable testing for geotextiles and geosynthetics? Explore our range of specialized Geotextile Test Fixtures. Designed for precision, these fixtures attach to your testing machine to perform critical tests like tensile, puncture, and tear according to industry standards. Get accurate data essential for civil engineering and construction projects. Contact us today for details and a custom consultation!

Frequently Ask Questions

Q: What is the main purpose of Geotextile Test Fixtures?

A: Their primary purpose is to securely hold and apply load to geotextile samples in a standardized manner during mechanical testing, ensuring accurate and repeatable measurement of properties like tensile strength, puncture resistance, or tear strength.

Q: Why can't standard universal testing machine grips be used for geotextiles?

A: Geotextiles are often flexible and have complex structures. Standard grips might cause jaw breaks, slippage, or stress concentrations outside the intended test area, leading to inaccurate results. Dedicated fixtures are designed for proper load distribution and gripping geometry per standards.

Q: What types of tests are commonly performed using these fixtures?

A: Geotextile test fixtures are used for tests such as Grab Tensile Strength (e.g., ASTM D4632), Wide-Width Strip Tensile Strength (e.g., ISO 10319), CBR Puncture Resistance (e.g., ASTM D6241), Trapezoidal Tear Strength (e.g., ASTM D4533), and Seam/Overlap Strength.

Q: What is the difference between a Grab Tensile fixture and a Strip Tensile fixture?

A: A Grab Tensile fixture grips only a central portion of the sample, leaving the edges unsupported, simulating localized stress. A Strip Tensile fixture grips the full width of a long strip sample, providing a more uniform stress distribution across the width.

Q: Do different Geotextile Test Standards require different fixtures?

A: Yes, specific test methods outlined in standards from organizations like ASTM, ISO, or national bodies often mandate particular fixture designs, dimensions, and gripping requirements to ensure comparability of results globally.

Q: What material properties do these fixtures help measure?

A: They facilitate the measurement of critical mechanical properties such as ultimate tensile strength, elongation at break, puncture resistance force, tear resistance force, and seam strength, which are vital for geotextile selection and design in civil engineering.

Q: How do Geotextile Test Fixtures connect to a testing machine?

A: Most fixtures are designed to attach to the crosshead and base of a standard Universal Testing Machine (UTM) via common adapters, clevis pins, or bolt patterns, allowing them to utilize the UTM’s load frame and data acquisition system.

Q: Is sample preparation critical when using these fixtures?

A: Yes, sample preparation is crucial. Samples must be cut or prepared to precise dimensions and often have specific markings or conditions (like pre-existing notches for tear tests) as defined by the standard applicable to the fixture and test method being used.