Understanding the strength and durability of geotextiles is essential to secure their proper performance in a vast range of construction and engineering applications. Since the material is assumed to be able to stand stress, pressure, or environmental-upset, heavy tests are carried out on the material. Among the most common tests are the tensile and puncture tests wherein these tests assess whether the material can endure force without developing cracks or losing in load. With this article, test methods by ASTM to assess the tensile strength and puncture resistance of geotextiles are covered. Well, by then, one would be familiar with how proper test procedures are followed, standards of the industry, and how crucial are the tests to safety and quality for edge-to-edge projects from roads to landfills. That said, stay tuned, for you will yet learn how these tests influence the design reliability and durability of geotextiles in real life.

Introduction to Geotextile Testing

Importance of Geotextiles in Engineering

Geotextiles have become important in modern-day engineering because of how they improve various issues such as performance, stability, and durability in construction projects. They are quite versatile in their applications and are capable of soil reinforcement, filtration, drainage, and separation with great flexibility. Hence, engineers have taken advantage of these properties to resolve issues related to erosion of soil, water management, and heavy load distribution.

Key Applications of Geotextiles:

- Road Construction: Prevent intermixing of soil layers and develop superior load-bearing capacity

- Slope Reinforcement: Stabilize soil and cease sediment runoff

- Landfill Construction: Act as filters and barriers to reduce contamination risks

- Coastal Protection: Protection against wave action or flooding

One of the key uses of geotextiles is in road construction, where they prevent the intermixing of soil layers and develop superior load-bearing capacity for the roads. The overall life of the road is thereby improved, reducing the road maintenance efforts and the risk of damage caused by traffic and environmental factors. In the same manner, the geotextiles are equally important for slope reinforcement and erosion control as they stabilize soil and cease sediment runoff into the neighboring environment.

Landfill construction and coastal protection represent environmental projects that depend on geotextiles. Acting as the filters and barriers, they reduce the risks of contamination from waste materials and protection against wave action or flooding. Hence, the provision of a sustainable and cost-effective approach by geotextiles has given them far great standing in engineering and infrastructure development in different environments.

Overview of ASTM Standards

For the purpose of facilitating discussions on quality assurance and maintenance, SUNDA and other international bodies have developed standards that serve as guarantees of the quality and reliability of materials used in construction. ASTM standards provide a common framework for testing and performance evaluation in different industries. ASTM standards help measure extinction among geotextiles in terms of durability, permeability, or strength so that engineers can determine if a particular geotextile is suitable for an engineering application.

Key ASTM Standards for Geotextiles:

- ASTM D4595: Tensile properties testing

- ASTM D4491: Water permeability testing

- ASTM D4833: Puncture resistance testing

- ASTM D4632: Grab breaking load testing

ASTM standards for geotextiles concentrate primarily on physical characteristics and mechanical properties, such as tensile strength, puncture resistance, and elongation, with tests conforming in a standard way. Standard methods for testing include ASTM D4595 for tensile properties and ASTM D4491 for water permeability. When deciding how to use geotextiles for filtration, separation, or erosion control, these standards are an invaluable guide to the engineers.

An ASTM standard thus ensures quality performance of a product, regulates it, and makes it global. This standard curtails chances of project failures by stating standards for material quality and the behavior of these materials under actual working conditions. ASTM standards, therefore, serve as an important catalyst for promoting the use of geotextiles in sustainable engineering and infrastructure development.

Purpose of Testing Geotextiles

The first objective of testing geotextiles is to establish their suitability for the anticipated engineering use of particular cases. They are installed at various levels in infrastructures such as roads, bridges, and drainage, where the performance of the geotextile maximizes the safety and working life of the particular project. Testing will ascertain the strength, permeability, and durability of the material under test and check if they match what they are required to have in the first place in order to function rightly.

Testing assists in determining how well the geotextile withstands environmental stresses and mechanical loads over a period of time. These include resistances to UV degradation, chemical corrosion, and biological attacks that could potentially degrade their performance. Testing simulates installation and service environments that allow the geotextiles to be tested for their performance under conditions created by different nature of environmental and operational challenges.

Testing promotes innovation and is a matter of compliance within the engineering realm. Abiding by established standards and protocols for testing facilitates manufacturers and engineers in their development of new geotextile solutions that can be counted on for uniformity and safety. Hence, it not only makes construction projects more dependable but also insures that infrastructure systems will be sustainable throughout time.

ASTM Standard Test Methods

ASTM D4595: Tensile Properties of Geotextiles

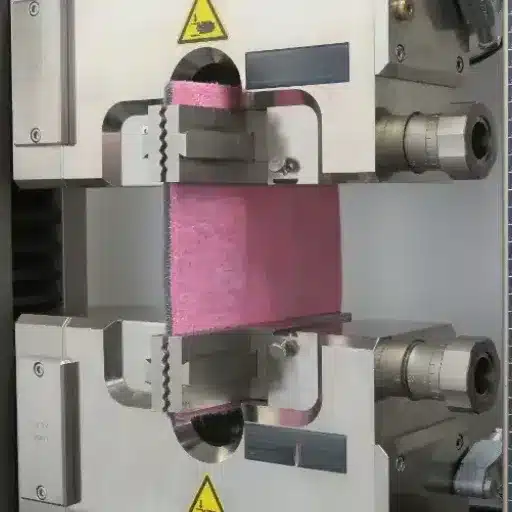

ASTM D4595 describes the standard method for tensile testing of geotextiles. The method determines the resistance and elongation of geotextiles subjected to a tensile force in standardized conditions. The test is carried out on wide-width strips of the material to provide for more reliable and reproducible results since these help to minimize variability due to edge effects and fiber orientation.

ASTM D4595 Test Procedure:

- Prepare wide-width strips of geotextile material

- Stretch specimen at constant rate until broken

- Record acting force and elongation data

- Control test specimen dimensions and environmental conditions

- Analyze results for tensile strength and elongation properties

The principal objective of ASTM D4595 is to attain data for tensile behavior that is reliable and reproducible for its use by other construction and engineering agencies. Among various other physical features, tensile strength and elongation are considered by engineers so that they can ascertain the amount of durability and performance expected from the geotextiles while undergoing stress, thereby ensuring that they are suited for certain applications such as soil reinforcement, drainage, and erosion control. The test results help make proper choices in material selection that finalizes the security and longevity of infrastructure projects.

The test method basically stretches a specimen of the geotextile at a constant rate until it is broken, while recording the acting force and the elongation data. The dimension of the test specimen as well as the environment of testing, that is, temperature and humidity, is controlled to allow for comparisons. It is a widely accepted test method to determine the performance and ensure that the geotextiles meet the structural and functional considerations posed by various civil engineering applications.

ASTM D4833: Puncture Testing of Geotextiles

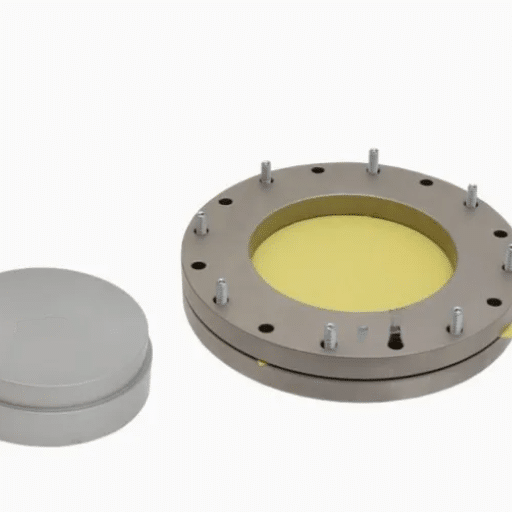

The ASTM D4833 Test Method is a puncture resistance test for geotextiles by measuring the force required to force a cylindrical rod through the material. Under controlled conditions, the geotextile is tested to determine its ability to withstand concentrated loads which could be placed on it during installation or in service. This method ensures the geotextiles have the strength required for their particular use in construction, e.g., separation, reinforcement, or filtration.

ASTM D4833 Test Procedure:

- Clamp geotextile specimen in circular opening with uniform tension

- Drive steel rod with rounded tip into fabric at constant velocity

- Record force required up to point of fabric failure

- Analyze puncture resistance data for material evaluation

The procedure involves clamping the geotextile test specimen in place in a circular opening, with uniform tension applied. A steel rod with a rounded tip is driven into the fabric at a constant velocity, with the force required being recorded up to the point of fabric failure. The test data provide invaluable information regarding the geotextile’s ability to resist puncture from sharp objects or uneven surfaces that could otherwise diminish its performance in situ.

This testing would come in handy when the geotextile goes through rough conditions like landfill liners, road construction, or drainage systems. Following the ASTM D4833 standards will ensure that engineers and manufacturers use the geotextile materials that are adequately durable and functional given that any damage to the site’s infrastructure would adversely limit their service life.

Comparison of ASTM and ISO Standards

| Aspect | ASTM Standards | ISO Standards |

|---|---|---|

| Origin | United States | International |

| Primary Usage | North America | Global markets |

| Development Process | US experts consensus | International collaboration |

| Focus | Technical consistency | Global interoperability |

When evaluating ASTM and ISO standards, one must appreciate their peculiar roles in regulating and assessing the quality of materials, products, and systems. ASTM standards find their origin mainly in the United States and, thus, are found most widely used in North America, focusing on setting and ensuring the technical consistency of testing methodologies for various industries. Thus, ISO standards are internationally accepted, aiming to align technical and procedural guidelines across the globe. Also, they guarantee quality and safety but consider their applications and conditions, which often differ due to local or international needs.

From the establishment perspective, these two entities are different. ASTM standards are developed in accordance with a consensus process making use of a tremendous network of subject-matter experts and scholars basically in the U.S., while ISO standards also follow a consensus process yet their instances are generated in international collaboration of member countries for a broader perspective. This distinction may serve ASTM standards leaning towards the interests of U.S. industrial and regulatory concerns, while ISO standards more often attempt to satisfy the concerns of broader international markets, thereby ensuring interoperability across nations.

Despite such differences, the standards issued by ASTM complement those under ISO on numerous fronts. For instance, there are many industries that employ the ASTM standards for exactness in testing procedures, whereas, for worldwide certification and trade purposes, they employ the ISO standards. This harmony, therefore, promotes matters such as quality assurance on the one hand, while also paving the road for business contending at both domestic and international levels. As is clear already, one must be in the know of how these standards operate vis-a-vis each other in choosing the appropriate set of standards for his/her particular engineering, manufacturing, or construction needs.

Tensile Test Method for Geotextiles

Overview of Tensile Testing Procedures

Tensile testing procedures for geotextiles are essential to measure the strength and elongation properties when the material is subjected to stress. These tests determine the tensile properties of the material, which are vital for confirming its applicability in construction, drainage, and reinforcement applications. The major focus is on testing the tension-stress-failure behavior of the tensile fabrics, ensuring their long-term performance in actual field conditions.

Key Parameters Measured in Tensile Testing:

- Maximum tensile strength

- Strain at break

- Elongation properties

- Load-deformation characteristics

The test, in essence, will have a universal testing machine pulling on the geotextile sheet with a precisely controlled tensile force until it breaks. During testing, parameters such as maximum tensile strength, strain at break, and elongation are recorded. Equivalent testing methods must be followed, such as ASTM D4632 or ISO 10319, to enable accuracy and repeatability of the test results according to the facility where the test is done or the project where it is required. These testing procedures can differ as per the type of geotextile, but technically, the principles remain the same.

For results to be reliable, proper sample preparation must be done. The dimension for the samples must be cut exactly as specified, and irregularities which could affect the outcome must be avoided. Conditioning of the geotextile at stated environmental conditions prior to testing must be observed to simulate the test with actual scenarios of application. Adhering to these standard procedures gives tensile testing data that are useful to engineers and manufacturers in decision-making with respect to choosing and designing a geotextile.

Wide-Width Strip Method Explained

A wide-width strip test is a standard test to evaluate tensile strength and elongation properties of geotextiles. The rectangular specimen of given dimensions is gripped in the tensile testing machine by holding both ends of the sample along its width. Equal tensile force is then applied along the width of the specimen until failure, thus measuring the ultimate strength and elongation at failure.

Advantages of Wide-Width Strip Method:

- Minimizes edge effects that could skew results

- Better reflects field performance under stress

- Provides accurate and reliable data for engineering applications

- Internationally recognized testing standard

The method is designed to simulate field performance of a geotextile under stress and thus provide for accurate and reliable data. By testing in wide-width strips, edge effects are minimized, and such behavior better reflects the true response of the geotextile under similar tensile forces in the application field. For this reason, the test is very practical for soil reinforcement, separation, and erosion control applications.

The wide-width strip method is internationally recognized and covered under various standards, such as ASTM D4595 or its ISO equivalents, for uniformity and reproducibility. The testing method is heavily relied upon by engineers for performance evaluation of geotextile, thus aiding in the selection of materials and design considerations in various construction, environmental, and developmental applications. The clearness and repeatability of the method make it essential in assessing and assuring geotextile applications’ long-term performance.

Elongation and Opening Size Considerations

The need to oppose elongation and the size of the opening stands as a crucial consideration in geotextiles. Elongation defines the extent to which a fabric may be stretched before it actually tears. This parameter is particularly important when fabrics may be subjected to large loads or movements of the ground. Generally speaking, higher elongation confers flexibility to the material that helps it accommodate the soil shifts and resist failure of the material. Conversely, a material with a low elongation may provide a higher stiffness in load distribution in more or less stable fields.

| Parameter | High Values | Low Values | Applications |

|---|---|---|---|

| Elongation | Greater flexibility, accommodates soil shifts | Higher stiffness, better load distribution | Variable based on ground conditions |

| Opening Size | Better drainage, separation applications | Superior filtration, fine particle retention | Drainage vs. filtration systems |

The opening size of geotextiles refers to the pore or gap dimension in the material and dictates its ability for filtering and separation of materials. Smaller opening sizes tend to restrict the movement of fine particles better as compared to water flow, and hence they find their primary applications in filtration. Large opening sizes find applications in drainage or separation where retention of fine particles does not become a major concern. Opening size is quantified by standardized tests, such as sieve analysis (ASTM D4751).

Both elongation and opening size require careful consideration to ensure that a desired performance is achieved in a given project. They must be considered against the environmental and structural demands posed by the particular application to ensure durability and efficiency of the selected geotextiles. Geotextiles with these characteristics in proper proportions stand our best chance at long-term project success, whether in road construction, erosion control, or drainage systems.

Puncture Test Method for Geotextiles

Understanding Puncture Testing Mechanisms

Puncture testing for geotextiles is utilized to assess their resistance to penetration by sharp or pointed objects. In other words, the test method is made to prove or disprove the durability of geotextiles horizontally under field conditions where some external forces or materials may impair their integrity. Having an idea of the puncture resistance of geotextiles helps design engineers in selecting materials that would withstand the various forces and demands of the application.

Critical Applications Requiring Puncture Testing:

- Road construction – Protection from aggregate penetration

- Landfill capping – Resistance to sharp debris

- Soil stabilization – Durability under concentrated loads

- Drainage systems – Protection from angular stones

The test involves subjecting the geotextile specimen to a set force under the test apparatus so as to simulate realistic force situations. The test measures the force exerted to puncture the specimen and thus provides information related to the mechanical performance of the test material. With these results, engineers assess whether a geotextile can be used to prevent abrasion, carry heavy loads, or stop sharp debris in various construction applications.

The result of puncture tests enables a decision-maker to be sure that a geotextile will maintain its performance through time even under unfavorable conditions. Such evaluation would be required in road construction, landfill capping, and soil stabilization projects where material failure may lead to further expensive repairs or environmental hazards. Puncture tests provide an ideal scientifically based tool to select geotextile that adequately meets the requirements of the project while ensuring serviceability and reliability for the long run.

Factors Affecting Puncture Resistance

Practically, several factors affect the ability of a geotextile material to resist puncture. The primary factor is the material constitution. Such geotextiles, made from high-strength fibers of polypropylene or polyester, usually offer more resistance to puncture. Fiber-specific parameters such as density and tensile strength essentially define the capacity of the geotextile to withstand hard treatment.

Key Factors Influencing Puncture Resistance:

- Material Constitution: High-strength fibers (polypropylene, polyester)

- Thickness and Weight: Heavier materials provide better force distribution

- Manufacturing Method: Needle-punched or woven structures

- Fiber Density: Higher density improves resistance

- Bonding Quality: Stronger fiber interlocking enhances performance

Other critical factors include the thickness and weight of the geotextile. The heavier and thicker the geotextile, the better its puncture-resistant capability since this would promote better distribution and absorption of the involved force. Thinness must, however, be considered to ensure that the geotextile satisfies applicable provisions concerning flexibility and fulfilling the requirements of the project.

The manufacturing method acts as another factor influencing the puncture resistance of geotextiles. Needle-punched or woven materials generally exhibit higher puncture resistance due to a fiber structure either tightly bonded or well interlocked. Choosing a suitable manufacturing method compatible with the intended application guarantees maximum performance and mitigates risks of material failure.

Interpreting Puncture Test Results

The key test results to be considered while evaluating the puncture tests are strength, elongation, and mode of failure. Puncture strength is generally given in newtons or pounds force and refers to the maximum force applied against the geotextile before the object penetrates. Thus, a higher puncture strength value means better performance when the geotextile has to resist sharp objects or pressure. Elongation gives us information on how much the material will stretch before rupture and helps us understand the amount of flexibility the material has to bear a load for a certain period without failing immediately.

Key Test Result Parameters:

- Puncture Strength: Maximum force before penetration (N or lbf)

- Elongation: Material stretch capacity before failure

- Mode of Failure: Tearing, clean puncture, or significant stretching

- Load Distribution: How force spreads across material

Interpretation of the modes of failures is another key factor in determining the suitability of the geotextile for a particular project. By observing whether the geotextile tears, punctures cleanly, or stretches significantly, one can garner an understanding of the sturdiness of the structure in question and its probable application. For example, clean punctures would typically imply lesser flexibility, whereas greater stretching prior to rupture may indicate an adaptable material. Illustrating these differences becomes crucial in helping decide on the best suited material for applications depending on pressure or exposure to sharp objects.

When choosing geotextiles, it is more accurate and reliable to compare the test results against several relevant standards. Standards from various organizations such as ASTM or ISO specify acceptable ranges for puncture resistance based on the application. By comparing actual test results to those standards, one can quickly establish if the material in question meets the performance requirements of the project so that the functionality can be guaranteed in the long run and obviously less chance of failure in the field.

Best Practices for Geotextile Testing

Ensuring Accurate and Reliable Results

Standardized testing procedures must be observed when the intent is to attain the results that are accurate and reliable from geotextile testing. Employing a protocol issued by an accepted organization such as ASTM or ISO assures consistency and replicability of the measurements. Testing machinery should strictly be calibrated before the execution of each particular test so that the difference in data may not arise from mechanical or technician-induced errors.

Essential Requirements for Accurate Testing:

- Follow standardized procedures (ASTM/ISO protocols)

- Calibrate equipment before each test session

- Proper sample preparation according to specifications

- Controlled environmental conditions (temperature, humidity)

- Regular quality control checks and documentation

Sample preparation is a must if one wishes to obtain reliable results. Specimens should be cut and handled in accordance with what is specified for the respective test to prevent the material from becoming damaged or dirty. Improper sampling can substantially affect test validity, while contamination introduced from an irregular cut is equally detrimental. In addition, tests must be undertaken under strictly controlled environmental conditions, because humidity and temperature may influence the material’s performance.

And quality control checks must be undertaken at regular intervals to meet a high standard of testing. This entails ensuring that laboratory technicians are properly trained and that cross-referenced tests are conducted to confirm the results. A proper record or documentation of each test carried out including test conditions, test results, and any abnormalities noticed contribute towards a good database for which utmost confidence is rested on the findings from geotextile testing.

Calibration and Maintenance of Test Fixtures

Calibration and maintenance of test fixtures are important to allow the accuracy and reliability of geotextile test results. Calibration is the process of setting up the testing machinery so that it meets some given standard. In other words, it is to see to it that the measuring mechanisms are exact and consistent with time. It should, therefore, be performed at intervals decided upon by any of the Regulators or by the Manufactures of such Testing apparatus.

Maintenance and Calibration Schedule:

- Daily: Visual inspection and cleaning

- Weekly: Basic functionality checks

- Monthly: Detailed equipment inspection

- Quarterly: Professional calibration verification

- Annually: Complete overhaul and certification

Maintenance of test fixtures includes visual inspection, cleaning, and minor and major repairs; all of these activities prevent adverse effects due to wear and tear from manifesting on the test results. Some checks will inevitably have to be carried out so as to be able to identify before their impact materializes misalignment or damage to the equipment that could otherwise affect its reliability. Preventive maintenance scheduling should be respected in order for performance to be from degrade or so as to cause surprises at times of testing.

Properly done and recorded calibration and maintenance ensure traceability for accountability. Records must include the dates of calibration, maintenance performed, and possibly what adjustments were made as proof of/from conformance with a testing standard. Hence, all these together give confidence to the validity of the geotextile testing data, which is further relied upon in many critical applications.

Documenting and Reporting Test Findings

Justifying and ensuring the reliability of geotextiles testing results call for adequate documentation of the test findings and their reporting. Testing begins with documenting all critical observations and measurements so as not to omit pertinent details. Each procedure should be furnished with an orderly report describing the objectives, material tested, methodology used, and significant results. This will help ensure the results are sufficiently clear so that they can be replicated by others.

Essential Documentation Elements:

- Test objectives and scope

- Material specifications and source

- Testing methodology and standards followed

- Environmental conditions during testing

- Equipment specifications and calibration status

- Complete test results and observations

- Data analysis and interpretations

- Recommendations and conclusions

The testing report shall appoint certain factors concerning all deviations or anomalies concerning the expected output, whilst suggesting its potential cause. In this manner, they promote transparency and render the parties capable of judging on candidate data. Also, including the conditions under which the tests were carried on, such as temperature, humidity, and specifications of the apparatus used, will be a great help in relating the results to anyone else’s work in the future.

Finally, each set of results must contain results’ interpretations or recommendations, for instance, for materials modifications or recommendations for design considerations. Presenting the results concisely and clearly will make understanding easier and aid decision-making processes in different facets entailing geotextiles. Do report thus ensure that data collected substantiated by standards, rendering it beneficial to the engineers, researchers, and decision-makers themselves.

Frequently Asked Questions (FAQ)

Q: What are the test standards for geotextile test fixtures?

A: Test standards refer to guidelines and protocols established to ensure the tests on geotextiles are conducted reliably and accurately. These standards consist of several test methods such as the grab test, puncture resistance tests, and tensile properties testing, which aid in determining the quality of geotextiles in civil engineering applications.

Q: How do you perform the grab test on geotextiles?

A: The grab test is a testing method for tensile strength determination of geotextiles. During this test, the prepared sample is loaded until it breaks. Research data provides insights into the strength and life of the material when subjected to load stressing.

Q: Why is acceptance testing of commercial geotextile shipments important?

A: Acceptance testing of commercial shipments of geotextiles serves to verify that the materials comply with their test standards prior to use in projects. Specimens of a team are tested to verify conformity with relevant ASTM publications and international standards.

Q: What is involved in the testing of tensile properties?

A: The testing of tensile properties is evaluating the strength and elongation of geotextiles under tension. It is used to predict tensile performance of the geotextiles with actual applications where the material is subjected to different loading conditions.

Q: How is puncture testing conducted?

A: The puncture test serves to establish the puncture resistance of a geotextile sample. This test measures the ability of the geotextile to resist piercing either during installation or in use for a civil engineering project.

Q: How do laboratories compare test results from the two laboratories?

A: When the two laboratories perform tests upon the same geotextile specimens, the results should be compared on the basis of the unpaired data with such acceptable probability as may be agreed upon. By doing this, variance between the two laboratories will be known, while users of the standard shall be able to interpret future test results correctly.

Q: What is the method for determining puncture resistance?

A: The method of measuring puncture resistance comprises placing a sample of the geotextile under controlled loading until puncture occurs. The force required to produce puncture is recorded to classify whether the material is suitable for the particular application with concern of puncturing.

Q: How does one prepare test specimens for geotextile testing?

A: Preparing test specimens for geotextile testing involves cutting samples with specified dimensions, typically in millimeters (mm), according to the applicable test standard. Proper preparation guarantees that the samples are representative of the material and that the results of the test can be accurately interpreted.

Q: What are the advantages of using nonwoven geotextiles for civil engineering?

A: Nonwoven geotextiles carry benefits such as high drainage, filtration, and puncture resistance characteristics. Such features make suitable applications for erosion control, soil stabilization, and road construction for testing standards for geotextile test fixture.

References

- D4595 Standard Test Method for Tensile Properties of Geotextiles – ASTM – Covers testing geotextiles for tensile properties using a constant rate of extension-type tension apparatus.

- ASTM D6241 Geotextile Puncture Testing – ADMET – Details the ASTM D6241 standard for determining the puncture resistance of geotextiles.

- ASTM D4632 – Standard Test Method for Grab Breaking Load – Instron – Explains the grab test method for measuring breaking load and elongation of geotextile fabrics.

- Geotextile Testing Standards – TestResources – Provides an overview of various geotextile testing standards, including ASTM D4632, ASTM D6241, and ASTM D4533.