In an ever-changing world of material testing, inaccuracy, and tardiness are not options. The Universal Testing Machines that, whether aerospace, automotive, construction, or any other industry requiring stringent quality control, remain the principal means of checking materials for the highest quality. Yet with so many manufacturers vying for attention, which ones truly stand out?

This blog goes into the top 10 Universal Testing Machine Manufacturers of 2025 and spotlights the innovators behind the next generation of material testing. From the most up-to-date technology to another level of customer assistance, these companies speak the language of industry standards. Should you be planning to bid for any devices for your lab or out of curiosity, then this guide will direct you with the very information you need to make your own choice.

So, let’s, without further ado, explore these leaders in the field and what distinguishes them in becoming the choices laid down by professionals across the world. Shall we check out the best?

1. Jinan Wangtebei Instrument and Equipment Co., Ltd.

- Founded: 2015

- Introduction: A high-tech corporation specializing in material testing machines for metals, non-metals, and composites. Known for innovation and customer-centric solutions.

- Main Products: Universal testing machines, tensile testing machines, compression testing machines, impact testing machines, and more.

- Advantages: Customizable solutions, global presence, and excellent after-sales service.

- Website: Jinan Wangtebei

2. Instron

- Founded: 1946

- Introduction: A global leader in material testing solutions, offering high-precision universal testing machines.

- Main Products: Universal testing systems, automated testing systems, torsion testers.

- Advantages: Advanced technology, precision, and reliability.

- Disadvantages: Higher cost compared to competitors.

- Website: Instron

3. Shimadzu Corporation

- Founded: 1875

- Introduction: A pioneer in precision instruments and testing machines, with a strong focus on innovation.

- Main Products: Universal testing machines, material testing software, medical systems.

- Advantages: High-precision load cells, user-friendly interfaces.

- Disadvantages: Limited customization options.

- Website: Shimadzu

4. ZwickRoell

- Founded: 1854

- Introduction: A German leader in material testing technology, offering a wide range of testing machines.

- Main Products: ZwickLine, ProLine, AllroundLine testing machines.

- Advantages: Modular design, precise measurements, and user-friendly software.

- Disadvantages: Complex systems may require extensive training.

- Website: ZwickRoell

5. MTS Systems Corporation

- Founded: 1966

- Introduction: Known for robust and precise testing systems tailored to specific industry needs.

- Main Products: Static and dynamic testing systems, fatigue testing machines.

- Advantages: Customizable solutions, high-performance load frames.

- Disadvantages: Limited availability in some regions.

- Website: MTS Systems

6. Tinius Olsen

- Founded: 1880

- Introduction: A trusted name in material testing, offering versatile and durable testing machines.

- Main Products: Universal testing machines, melt flow indexers, impact testers.

- Advantages: Ergonomic designs, advanced software.

- Disadvantages: Limited product range for niche applications.

- Website: Tinius Olsen

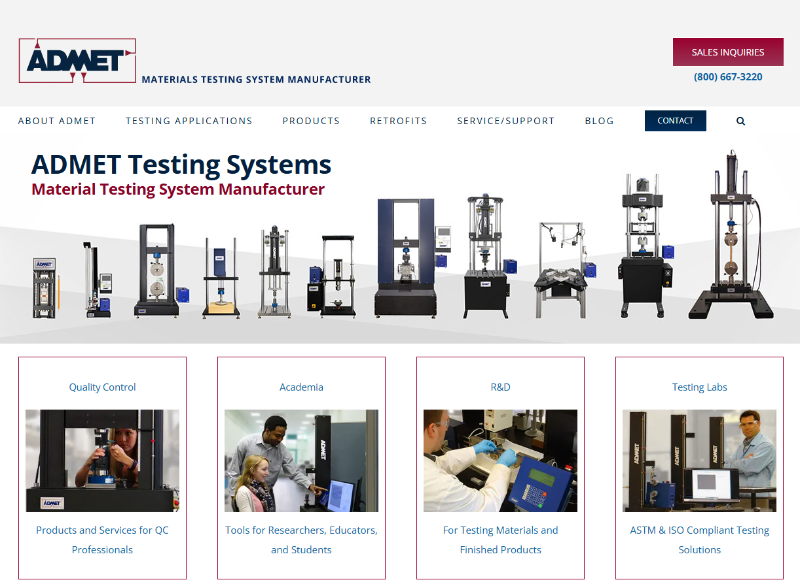

7. ADMET, Inc.

- Founded: 1989

- Introduction: Specializes in universal testing systems with a focus on precision and flexibility.

- Main Products: Universal testing machines, controllers, and software.

- Advantages: Modular design, innovative interfaces.

- Disadvantages: Smaller global footprint.

- Website: ADMET

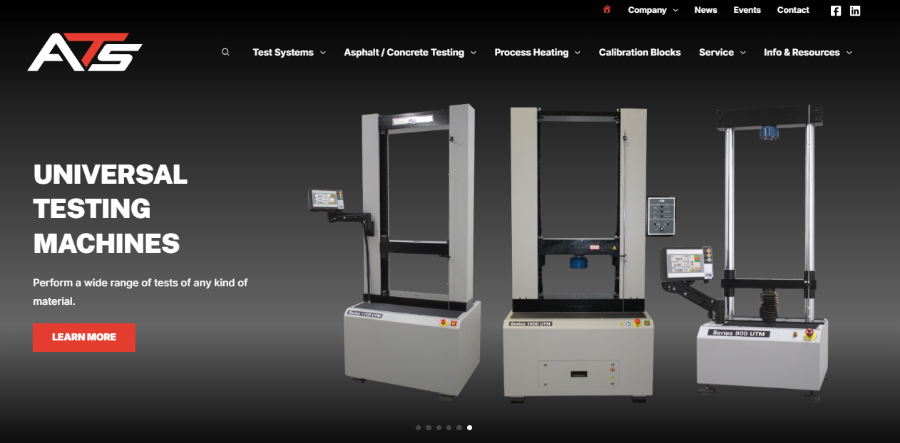

8. Applied Test Systems (ATS)

- Founded: 1965

- Introduction: A leading provider of materials testing equipment with a focus on quality and innovation.

- Main Products: Universal testing machines, calibration test blocks.

- Advantages: ISO-accredited calibration services, robust machines.

- Disadvantages: Limited product diversity.

- Website: ATS

9. Anton Paar GmbH

- Founded: 1933

- Introduction: Renowned for high-precision measuring instruments and innovative testing solutions.

- Main Products: Universal testing machines, rheometers, viscometers.

- Advantages: Advanced modular systems, integrated extensometers.

- Disadvantages: High initial investment.

- Website: Anton Paar

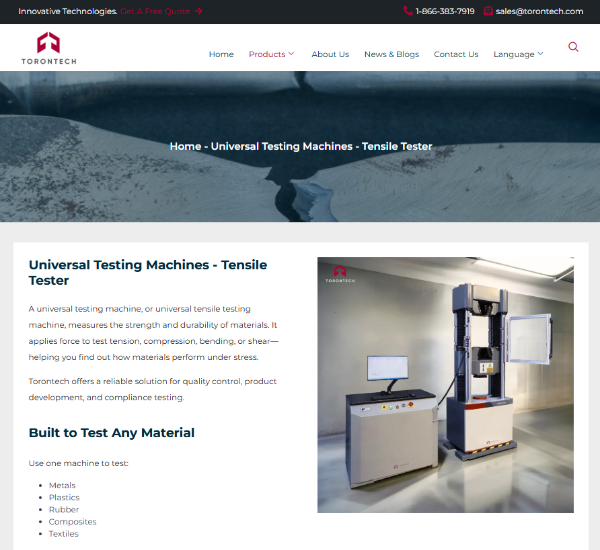

10. Torontech Inc.

- Founded: 2006

- Introduction: A Canadian manufacturer offering a wide range of universal testing machines.

- Main Products: Servo-hydraulic, electromechanical, and single-column universal testing machines.

- Advantages: Competitive pricing, reliable customer support.

- Disadvantages: Limited presence in some markets.

- Website: Torontech

What is a Universal Testing Machine?

The UTM serves as a general-purpose device to test the mechanical properties of many materials under tension, compression, bending, or shear conditions. The term “universal” comes from the fact that the UTM is capable of performing various kinds of tests from tensile strength, compressive strength, flexural testing, and fatigue testing. These machines play a crucial role in different industries such as construction, manufacturing, and materials science for quality assurance and to comply with engineering standards.

Modern UTMs usually consist of a load frame with strong crossheads, with either a single-column or double-column configuration, depending on the load requirements. They hold extremely accurate load cells and extensometers for obtaining test data in real-time of force, displacement, and elongation during the test. These systems are mostly computer-controlled, allowing for precise control and data analysis.

According to the latest Google trends in searching, the demand for universal testing machines has lately increased because of how much product safety and regulatory compliance now matter. UTMs are now adopted as an important R&D tool to simulate real-world stresses on materials or products. They are also used to test that the materials conform to specifications and predict their behavior under different conditions.

Factors Affecting the Price of Universal Testing Machines

1.load capacity: Involving the forces with which the machines are handling loads, load capacities are measured in Kilonewtons (kN). In messages related to prices, the greater capacities are, by beauty, associated with higher prices because of the very elements involved in its construction-selection of durable materials and fine quality of engineering design.

2.Type of Load Frame: Depending upon the type of load frame be it a single-column, double-column, or four-column type, there can be variations in price. Double- and four-column machines usually have higher capacities and are costlier than single-column models, which are more suitable for lower-force applications.

3.Software Capabilities: Higher level software for more sophisticated data acquisition and analysis will cost more than a more basic software. They are usually priced higher if they include options such as detailed report generation, automation, and ability to interact external systems.

4.Accessories and Fixtures: The need for special grips, clamps, or fixtures to meet testing requirements in varying industries can raise the price substantially. Prices are also raised by accessories like extensometers and heating or cooling chambers.

5.Level of Automation: Automatically controlled machines cost more as they offer better precision and efficiency compared to manual ones; examples of what types of automated testing features that contribute to such increased prices include robotic handling of samples, specimen alignment, and digital control.

Frequently Asked Questions (FAQ)

What would be some of the prominent universal testing machine manufacturers in 2025?

In the year 2025, there are expected to be certain prominent universal testing machine manufacturers, such as Jinan Wangtebei Instrument and Equipment Co., Ltd., Shimadzu, and MTS Systems, among others. These manufacturers are known for mass precision in material testing machines, along with a variety of innovations, catering to various industries ranging from automotive, aerospace, and construction materials.

How much would the universal testing machine market would grow by 2025?

The universal testing machine market is expected to witness heavy growth by 2025, primarily driven by the increase in demand for advanced testing solutions across many industries. The drivers behind this growth are the increasing need for quality control and assurance, coupled with international testing standards implementing that require precise and reliable testing instruments.

What are some of the most important aspects of a modern electronic universal testing machine?

Modern electronic universal testing machines have an advanced data acquisition system, ease of use, capabilities of tensile testing, compression testing, and cyclic testing, and are supposed to operate under extremely rigorous testing environments, thereby offering high-precision material testing for a wide variety of materials.

How important is the testing machine market report?

The testing machine market report is especially important as far as analyzing trends, opportunities for growth, and competitive analysis of various manufacturers are concerned. It helps the stakeholders understand the testing machine market’s size, opportunity in terms of emerging technologies, and demand for specific test instruments to support their strategic decision-making.

What materials could a universal tensile testing machine test?

A universal tensile testing machine tests various materials such as metals, plastics, composites, and construction materials. This is an example of a highly versatile testing machine to be used in various industries like automotive and aerospace, where knowing material properties is critical to safety and performance.

How does the testing machine market size vary within industries?

A testing machine market size varies widely within industries owing to varied testing requirements and applications. For example, motorsports and aerospace require a high degree of precision testing on safety components; the construction industry, however, concentrates on materials’ durability. This difference changes the requirements for testing equipment and manufacturers.

What kind of evolution will we see in the testing machine industry by 2025?

By 2025, the testing machine industry is set to evolve significantly with further development in automation; integration of the Internet of Things (IoT) technology for real-time data monitoring; and enhancement of software capabilities for better analysis of acquired data. These improvements will help to make testing work more efficient and accurate on grates, thus fulfilling the changing needs of industries such as automotive and aerospace.