With an essential role in determining the mechanical properties of materials, universal testing machines (UTMs) find applications from construction and aerospace through to textiles and electronics. With increasing demand globally for precision testing solutions, China has emerged to dominate the manufacturing and innovating world. Being home to some of the world’s finest UTM-producing companies, China blends technology with economy and assures acceptance of international quality standards.

This blogpost introduces and analyzes 2025’s top 8 Universal Testing Machine Manufacturers in China with having special emphasis on their distinctive strengths, path-breaking products, and handles with excellence. Reading on will familiarize you with the leading companies supplying cutting-edge solutions in material testing and why China still remains an excellent hotbed for this crucial technology. From innovation to reliability, this curated list will assist you in understanding manufacturers setting global benchmarks either for buying innovations or partnering with the best in the field.

List of Top 8 Universal Testing Machine Manufacturers in China

| Company Name | Founded | Location |

|---|---|---|

| Jinan Wangtebei Instrument and Equipment Co., Ltd. | 2015 | Jinan, Shandong, China |

| Amade Technology | 2002 | Dongguan, Guangdong, China |

| Dongguan Liyi Environmental Technology Co., Ltd. | 2008 | Dongguan, Guangdong, China |

| Jinan Wenteng Testing Instrument Co., Ltd. | 2010 | Jinan, Shandong, China |

| Shenzhen Wance Testing Machine Co., Ltd. | 2011 | Shenzhen, China |

| UTS International Co., Ltd. | 2000 | Dongguan, Guangdong, China |

| Chengyu Testing Equipment Co., Ltd. | 2001 | Qingdao, Shandong, China |

| Suzhou Qiantong Instrument Equipment Co., Ltd. | 2014 | Suzhou, Jiangsu, China |

1. Jinan Wangtebei Instrument and Equipment Co., Ltd.

- Founded: 2015

- Introduction: A high-tech corporation specializing in material testing machines for metals, non-metals, and composites. Known for its innovative solutions and global reach.

- Main Products: Universal testing machines, tensile testing machines, compression testing machines, bending testing machines, and manhole cover testing machines.

- Advantages: Strong R&D capabilities, customizable solutions, and a global presence.

- Website: Jinan Wangtebei

2. Amade Technology

- Founded: 2002

- Introduction: A leading supplier of universal testing machines, offering cost-effective solutions with compliance to international standards like ISO and ASTM.

- Main Products: Electromechanical universal testing machines, peel testers, and motorized pull testers.

- Advantages: High-quality machines at competitive prices, strong after-sales support.

- Disadvantages: Focused more on general-purpose machines, less on niche applications.

- Website: Amade Technology

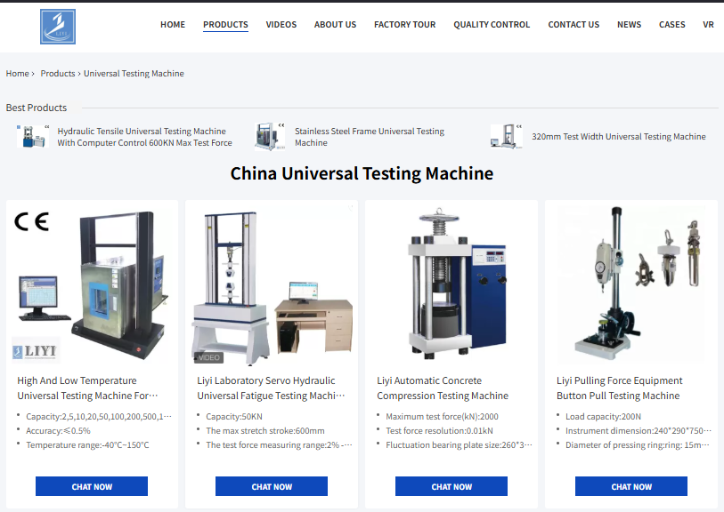

3. Dongguan Liyi Environmental Technology Co., Ltd.

- Founded: 2008

- Introduction: Specializes in environmental and material testing equipment, with a focus on innovation and quality.

- Main Products: Tensile testing machines, temperature humidity test chambers, and industrial ovens.

- Advantages: ISO-certified, strong focus on environmental testing.

- Disadvantages: Limited focus on heavy-duty industrial applications.

- Website: Liyi Technology

4. Jinan Wenteng Testing Instrument Co., Ltd.

- Founded: 2010

- Introduction: A diversified enterprise offering a wide range of material testing machines with a focus on customer satisfaction.

- Main Products: Electronic and hydraulic universal testing machines, fatigue testing machines.

- Advantages: Comprehensive product range, strong customer service.

- Disadvantages: Limited international presence.

- Website: Jinan Wenteng

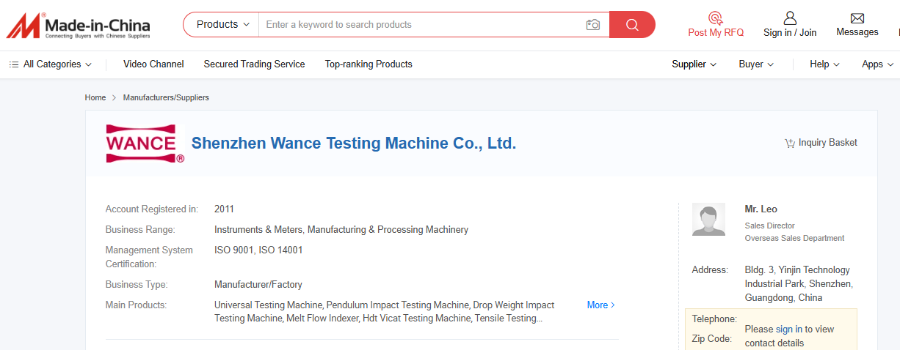

5. Shenzhen Wance Testing Machine Co., Ltd.

- Founded: 2011

- Introduction: A global provider of high-quality testing solutions, catering to diverse industries.

- Main Products: Composite testing machines, dynamic and fatigue testing machines.

- Advantages: Advanced technology and innovation-driven.

- Disadvantages: Higher price point compared to competitors.

- Website: Wance Testing

6. UTS International Co., Ltd.

- Founded: 2005

- Introduction: Specializes in testing machines for textiles, footwear, and toys, with a strong focus on international standards.

- Main Products: Textile testing machines, footwear testing machines.

- Advantages: Strong compliance with international standards, niche expertise.

- Disadvantages: Limited product range outside its niche.

- Website: UTS International

7. Chengyu Testing Equipment Co., Ltd.

- Founded: 2001

- Introduction: A professional designer and manufacturer of material testing equipment, serving various industries.

- Main Products: Static universal testing machines, impact testing machines.

- Advantages: Strong focus on quality and durability.

- Disadvantages: Limited customization options.

- Website: Chengyu Testing

8. Suzhou Qiantong Instrument Equipment Co., Ltd.

- Founded: 2014

- Introduction: Known for high-end testing machines and laboratory equipment, catering to diverse industries.

- Main Products: Material testing machines, solar PV testing machines.

- Advantages: Advanced technology and software integration.

- Disadvantages: Relatively new in the market, limited global reach.

- Website: Suzhou Qiantong

Why Choose Universal Testing Machine Manufacturers from China?

Owing to advanced technological capabilities, competitive prices, and a strong manufacturing infrastructure, China is a leader in manufacturing and supplying universal testing machines. Using the latest technology, Chinese manufacturers design universal testing machines that are of high quality and are extremely precise to meet the highest standards in the world, such as ISO, ASTM, and GB. The manufacturers have a strong production system and years of export experience to ensure timely delivery worldwide. Also, cost advantage is given to the manufacturing sector by China’s economies of scale. This combination of innovation, precision, and cost-effectiveness makes the Chinese manufacturers an ideal choice for the industry.

Key Factors to Consider When Choosing a Chinese Manufacturer

1.Compliance with International Standards: Check if the manufacturer follows internationally accepted criteria like ISO, ASTM, or GB for the purpose of producing reputable products.

2.Production Capacity and Scalability: The manufacturer is to be put on assessment so as to arrive at a conclusion as to whether they can cater for your current demand, down the road, maintaining promised deadlines and quality standards.

3.Quality Assurance Processes: Inspect on the quality control procedures, standards, inspection means, testing, or certifications to bring about the consistent performance of the product.

4.Communication and Responsiveness: Consider the manufacturer’s ability to communicate effectively and provide timely responses to queries while ensuring that they can professionally deal with any questions or concerns.

5.Experience in Export and Logistics: A manufacturer should be familiar with international shipping regulations, procedures for customs clearance, and provide for shortest, secure delivery to your location.

Frequently Asked Questions (FAQ)

What are the key features of an electronic universal testing machine?

Commonly, this device features advanced computer control for precision testing under tensile as well as shock compression on different materials. Servo motor is usually installed for smooth application in universal testing for quality control and accurate results in different applications, no matter what is being tested.

How do universal testing machines conform to international testing standards?

Universal testing machines are designed to conform to international testing standards like ASTM, and ISO, and computer-controlled machines manufactured from China to meet these standards of reliability in the test process of materials such as metals and non-metals and mechanical performance testing.

What materials are tested by universal testing machines?

Universal testing machines can be useful for testing any kind of material, including metals, plastics, rubber, and other composites. Certain machines, for example, rubber tensile testing or concrete compression, can give more information pertaining to the mechanical properties of a certain material.

What does a tensile testing machine measure?

Tensile testing machines measure the tensile strength of materials by applying a controlled force until the material fails. They report data such as yield strength, elongation, and other important mechanical properties of given materials, which are essential in quality assurance and manufacturing research and development.

What are the uses of the servo hydraulic universal testing machine?

Using hydraulic power and servo technology, the servo hydraulic universal testing machine can provide very precise force control during a testing procedure. This type of machine is used to carry out high-capacity tests and is commonly used for fatigue and impact testing.

Are there any environmental test chambers existing in China?

Yes, several environmental test chamber manufacturers in China can simulate climatic conditions of low temperature and humidity. These chambers are used for testing material performance under severe environmental conditions and are usually wearied with universal testing machines.

What is a drop test machine, and what is the difference between one and the other with a universal testing machine?

A drop test machine is used only to test the impact resistance of a product by dropping it from a predetermined height. A universal testing machine tests all sorts of things, including impact tests; however, the drop test machine is limited to only being able to do impact testing.

How can I find a universal testing machine supplier of good quality in China?

While searching for a reputable supplier of good quality universal testing machines in China, try any of these: directories, industry-related trade shows, or reading of customer reviews. It is advisable also to ask for samples or a demonstration so that you are sure that the particular machine suits your specific testing requirements.

What equipment is used for metal testing?

The usual equipment for metal testing is tensile testing machines, hardness testers, and impact testing instruments. Such machines record that metals fulfill mechanical performance criteria necessary and are in conformity with standards of the industry.