Introduction to Torsion Testing

Torsion testing serves as a means to examine and understand the mechanical behavior of materials under twisting forces. Properties under test include shear strength, modulus of rigidity, and the ability of a material to withstand torsional stresses, applying the stress up to deformation or failure. Effects of torsional stress commonly studied become relevant for materials and constituent parts that are often subjected to rotational forces; these examples may include shafts, tubes, and fasteners. In the application of torsion, torque is perhaps the most controlled quantity; it is from this measurement that inferences are drawn about the material and its overall performance and safety in real-world applications.

Definition of Torsion Testing

Torsion testing is a type of mechanical testing to determine the response of a material to an applied torque. A specimen is tested under a prescribed torque, and depending on the testing program, the machine records values corresponding to shear strength, torsional stiffness, ductility, or angle of failure, among others, so that the material’s behavior under shear stress can be fully understood. According to the latest data and guidelines from the Industry, torsion testing is essential for drive shafts, fasteners, springs, and medical devices since these components are subjected to multidirectional loading in their applications. However, torsion test equipment has undergone significant evolution in recent times, providing direct data acquisition and enabling engineers to perform high-fidelity analyses of the torque performance of materials under varying conditions.

Importance of Shear Stress in Torsion Tests

Since shear stress is the leading cause of failure by torsion, the magnitude or intensity of the shear stress determines whether damage occurs. Due to torsion, shear stresses are induced throughout the entire material cross-section, providing insight into its ability to withstand forces and distortion. Typically, the maximum shear stress occurs at the outermost fibers, which defines the limit of failure and is thus an essential input for design and analysis. Design-vs-safety analysis requires shear stress measurements as an input parameter; the engineer evaluates the material’s shear modulus, elasticity, or ductility to determine its suitability for use in torsional loading applications. This information is crucial for extending component life and ensuring compliance with safety and industrial codes.

Overview of Torsional Testing Machines

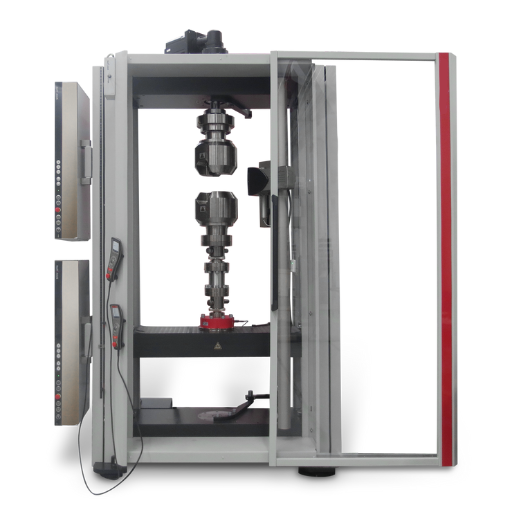

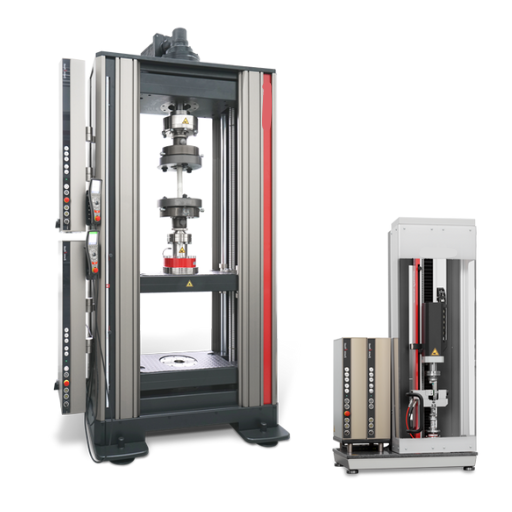

A torsional testing machine offers tests that reveal the behavior of a mature material or component under rotational forces (commonly referred to as torque). Torsional strength, shear modulus, yield stress, and fatigue resistance can be measured under controlled conditions. Most torsional testing systems feature a drive mechanism to apply force in rotation and a torque transducer to measure the resulting torque, allowing the specimen to be securely held in place using testing fixtures. The most sophisticated ones can be computer-controlled, allowing the load to be applied and data to be acquired automatically for the most accurate performance analysis possible.

These machines find applications in several industries, including automotive, aerospace, and manufacturing, where it is necessary to know the durability of materials. Torsion testing is ideally applied whenever components need to meet safety and performance specifications in various applications, such as shafts, fasteners, or structural elements. Depending on which standards organizations and agencies one chooses to follow, multiple standards could pertain to the operation of the machine to ensure repeatability and validity of test results, e.g., ASTM or ISO standards.

Types of Torsion Testing

1. Static Torsion Testing

During this test, a slow, continuous torque is applied to a specimen to ascertain its material properties under steady load conditions. The commonly measured properties include ultimate shear strength, yield strength, and modulus of rigidity.

2. Dynamic Torsion Testing

Dynamic testing measures the behavior of the material under cyclic or fluctuating torque. It is essential to determine the fatigue performance and durability of components affected by repeated stresses over an extended period.

3. Failure Torsion Testing

This test identifies the torque at which a material or component fails or fractures. It will then apply this knowledge to calculate safety factors and design limits for critical service.

4. Torsion Fatigue Testing

The Torsion Fatigue test subjects specimens to cyclic or oscillatory torques intended to study the effect of such stresses on fatigue life and crack growth.

Note: Each type of torsion testing serves specific engineering requirements to provide a reliable prediction of performance and safety in real-world applications.

Common Types of Torsion Tests

The common types of torsion tests include static torsion tests, torsional fatigue tests, fracture torsion tests, and torsion creep tests.

| Test Type | Purpose | Key Parameter | Material Tested | Load Type |

|---|---|---|---|---|

| Static Torsion | Yield strength | Torque | Metals, composites | Constant |

| Torsional Fatigue | Fatigue life | Cyclic stress | Alloys, polymers | Cyclic |

| Fracture Torsion | Crack behavior | Fracture limits | Brittle materials | Overload |

| Torsion Creep | Time-dependent | Creep rate | Thermoplastics | Sustained |

Types of Torsion Testing Equipment

Torsion testing equipment includes torsion testers, servo-hydraulic machines, electromechanical systems, rotary actuators, and digital controllers.

| Equipment | Function | Load Type | Material | Accuracy |

|---|---|---|---|---|

| Torsion Testers | Static torsion | Constant | Metals, composites | High |

| Servo-Hydraulic Machines | Dynamic loading | Cyclic | Alloys, polymers | Very High |

| Electromechanical Systems | Precise control | Sustained | Thermoplastics | High |

| Rotary Actuators | Angular motion | Cyclic | Various Materials | Moderate |

| Digital Controllers | Data monitoring | Various | Compatible Materials | High |

Comparison of Torsion Test Methods

The primary torsion test methods include static torsion, dynamic torsion, cyclic torsion, and precise control torsion testing.

| Method | Focus | Type | Materials | Accuracy |

|---|---|---|---|---|

| Static Torsion | Constant load | One-time | Metals, comps. | High |

| Dynamic Torsion | Repeated load | Cyclic | Polymers, alloys | Very High |

| Cyclic Torsion | Angular force | Sustained | Various | Moderate |

| Precision Control | Fine control | Static/Cyclic | Thermoplastics | High |

Purpose and Applications of Torsion Testing

Torsion testing is crucial in ensuring that materials behave as desired under twisting or rotational forces. It assesses the shear strength, elasticity, and fatigue life of the elements needed for the design of the components exposed to torsional stress. The aerospace, automotive, and construction industries utilize torsion testing to ensure the structural integrity and performance of elements such as drive shafts, fasteners, and springs. Torsion testing simulates real-world conditions, helping to refine materials and designs to meet safety and durability criteria.

Why Perform a Torsion Test?

Torsion testing is performed to analyze the material’s behavior when subjected to twisting forces, providing insight into critical properties such as shear stress, modulus of elasticity, and failure limits. This would enable engineers to simulate actual loading conditions under which materials must withstand a given torque while maintaining their functionality. Such testing is beneficial for highlighting weak points in a product, thereby enhancing its safety and improving its design and production processes in industries such as aerospace, automotive, and construction, where torsional loads must never compromise reliability.

Testing Applications Across Industries

- Aerospace Industry: In the aerospace industry, torsion tests are conducted to ensure the structural integrity of aircraft shafts, wings, and fuselage sections, thereby guaranteeing their performance under torsional stress during operations at altitude and speed.

- The automotive industry tests the durability of shafts, steering systems, and suspensions to ensure they can withstand the torsional forces experienced during acceleration, cornering, and braking.

- Construction: It is used to test building materials, such as steel beams and fasteners, to ensure they can withstand torsional loads during construction or heavy loads under structures.

- Medical Device Manufacturing: It tests surgical instruments, orthopedic implants, and other precision devices for torsional strength and reliability to ensure they are safe and functional in a medical environment.

- Energy: It tests the torsional strength of wind turbine shafts, oil drilling equipment, and other elements subjected to torsional stress during energy production and distribution.

Mechanical Properties Assessed by Torsion Testing

The following are some of the key mechanical properties of materials evaluated through torsion testing:

- Shear Strength: Establishes the maximum shear stress a material can withstand before fracturing, providing an indication of its load-bearing capabilities under twisting forces.

- Modulus of Rigidity or Shear Modulus: A measure of the stiffness of a material given in resistance to deformation under applied torque. This property becomes critical when material elasticity must be precise.

- Ductility: Refers to a material’s ability to withstand plastic deformation before breaking, thereby evaluating its suitability for applications involving significant twisting.

- Torsional Fatigue: Measures the ability of a material to withstand cyclic twisting loads without failure and is significant for those materials and components subjected to intermittent working.

- Fracture Behavior: Examines how and where failure occurs under torsional stress, thereby assisting in the design and selection of materials for applications subjected to high stress.

Important: These properties should be considered in terms of mechanical reliability and performance relevant to materials used in critical industries such as aerospace, automotive, medical devices, and energy systems.

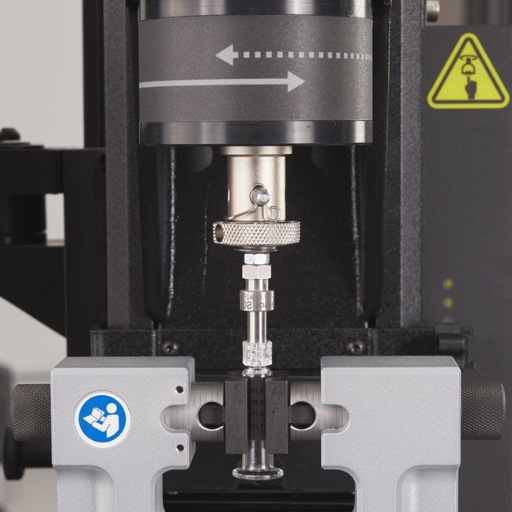

Equipment and Procedures for Torsion Testing

Torsion tests need particular equipment to achieve the accuracy and reliability of the results. The chief fixture is typically a torsion test machine, composed of mechanisms for mounting a specimen, generating torque, and precisely measuring the rotational angle. Typical specimens are cylindrical or tubular shapes fabricated according to standardized dimensions.

The specimen is set firmly in the torsion testing machine, and an increasing twist is applied, while the angular displacement is measured. The apparatus records continuous values of torque, shear strain, and shear stress. Standardized testing methods (like ASTM and ISO) provide a framework to promote consistency and reproducibility in the evaluation of material behavior under torsional loading.

Overview of Torsion Test Machines

Torsion testers are specialized pieces of equipment that test materials for their mechanical properties under torsional load. Generally, the testing machines comprise a driving motor, a torque sensor, a rotational fixture or grips for holding the test specimen, and measuring software for data analysis. Torsion testing machines today offer high precision with capabilities such as controlled rotation angles, varying torque ranges, and real-time data recording. The most expensive machines can also cover a broad range of sample sizes and material types, finding use in aerospace, automotive, and civil construction fields. Any software integration is capable of enabling extensive analysis of parameters such as angular displacement, maximum shear stress, and plastic deformation. Well-founded range and accuracy make these machines indispensable in material testing and quality assurance.

Step-by-Step Procedure to Perform a Torsion Test

1Prepare the Test Specimen

Select and prepare the specimen according to the prescribed dimensions and material requirements. The sample specimen should have no surface defects and conform strictly to testing standards that ensure precise alignment.

2Set Up the Testing Machine

Calibrate the torsional testing machine and verify the proper functioning of its components, including the grips and torque sensor. Ensure that you adjust the torsional machine within the limits specified in the test specifications.

3Mount the Specimen

Secure the test specimen in the machine using appropriate grips or fixtures, ensuring that the specimen is aligned correctly to prevent stress skewing along its length during testing.

4Define Test Parameters

Input all relevant test parameters into the software of the machine, such as angular velocity, maximum torque limit, or the deformation limit, as required by the testing protocol.

5Begin the Testing Process

Start running the test while paying close attention to any system malfunctions. The machine generates a controlled torque on the specimen, thereby creating a torsional state.

6Record Data Continuously

Data from the test must be recorded in real time, including torque and angle of twist, as well as the strain induced. Ensure uninterrupted recording of data with precision from the start to the end of the test.

7Observation of the Failure Point

The test should be continued until the specimen fails or some other stopping criterion is met, and the material’s changes in behavior and appearance are duly recorded.

8Analyze the Data

Upon completion of the test, collect and analyze the recorded data to aid the assessment of material properties, e.g., shear modulus, ultimate torsional strength, and failure characteristics.

9Inspect the Specimen

Inspect the specimen after testing for the physical conditions recorded for crack modes, necking mode, and shear fracture modes.

10Document Results

The findings will be presented in a descriptive report, which will include information on the parameters used for testing, observations, and analytical data, as well as a comparison of conformity with the applicable standards.

Torsion Testing Standards and Compliance

To yield accurate and reliable results in a torsion test, the test must be conducted in strict compliance with the set standards and regulations. For example, ASTM A938 describes methods for torsion testing of wire, and ISO 7800 specifies the test procedure for metallic materials. The standards set requirements for critical parameters, including twist rate, environmental considerations, and specimen preparation, to ensure uniformity in testing conditions.

Improvements in torsion test methods have increasingly adopted digital measurement systems and automation, aiming to enhance data accuracy and reliability. According to all standards, laboratories must ensure that equipment calibration is carried out by the requirements of certifying bodies, such as ISO/IEC 17025, which sets standards for testing and calibration laboratories. It is also essential that these tests be compared against good national or international benchmarks, so that if tests for a new material or manufacturing process are evaluated for industrial application, their results will stand as a basis for acceptance.

The advent of new technologies and testing methodologies, such as the integration of strain gauges or finite element analysis (FEA), will surely be considered in future revisions of these standards and, consequently, the evolution of testing methodologies.

Benefits of Torsion Testing

Torsion testing measures the behavior of materials subjected to twisting forces and determines a material’s shear strength, shear modulus of elasticity, and fracture behavior. This enables the engineer to determine the suitability of the material for applications subjected to twisting stresses, such as drive shafts, fasteners, and springs. Torsion testing is also employed to assess irregularities in composition or defects in manufacturing methods, ensuring the quality control of materials as specified in specific industry standards. Through the simulation of working conditions, torsion testing aids in design modification and enhances reliability in engineering applications.

Improving Product Reliability Through Torsion Testing

Torsion testing supports the reliability of a product by systematizing the observation of material behavior when subjected to twisting forces. Nearly all the main properties that work against an application can be determined through this method: the torsional strength, modulus of rigidity, or elastic limits of a material. It also reveals weak spots, inconsistencies, or flaws in materials or fabrication processes, allowing components to be tested and certified to meet performance and safety standards. Engineers can improve design for longevity, optimize material selection, and reduce failures induced by operational environments through analyzing torsional behavior under simulated operating conditions.

Ensuring Safety in Material Applications

From my perspective, torsion testing is crucial for ensuring the safe and reliable application of materials. It allows the specimen’s behavior to be studied under torsional loads, enabling precise determination of its strength, ductility, and failure limits. One can now simulate various operational conditions to detect weaknesses or inconsistencies early, thereby ensuring that materials or components meet safety and performance requirements. Optimizing designs and material selections for durability and mitigating failure in critical applications is another benefit that torsion testing offers.

Comparative Advantages Over Other Testing Types

Torsion testing offers unique benefits, including the ability to evaluate shear properties, simulate real-world loading conditions, detect material inconsistencies, assess ductility, and optimize designs effectively.

| Key Point | Details |

|---|---|

| Shear Eval | Measures the material’s shear strength. |

| Real-World Sim | Mimics operational stress scenarios. |

| Detect Flaws | Identifies inconsistencies early. |

| Assess Ductility | Evaluates deformation capacity. |

| Design Opt | Enhances durability through testing. |

Reference Sources

-

Torsion Testing: A Comprehensive Guide to Engineering – This source provides an overview of torsion testing and its applications in engineering.

-

What is Torsion Testing? – A detailed explanation of torsion testing, including its purpose and methodology.

-

Torsion Testing 101: A Beginner’s Guide – A beginner-friendly guide to understanding torsion testing and its significance.

-

Torsion Testers by Instron – Information about torsion testing systems and their capabilities.

-

Torsion Testing Machines by Tinius Olsen – Details about torsion testing machines, including their specifications and applications.

Frequently Asked Questions (FAQs)

What is the purpose of a torsion test?

Torsion testing is used to measure the mechanical properties of materials subjected to twisting forces. Among the parameters determined are the torsional strength, shear modulus, and assessment of how a material behaves under torsion, which is generally essential where such components experience torque during operation.

What are the types of torsion testing?

The torsion tests, generally speaking, include static torsion tests, dynamic torsion tests, and fatigue testing. These, ideally, are related to the material’s strength, its ability to withstand repeated loads, or its ability to withstand varying situations.

How is a torsion test actually performed in a testing machine?

A torsion tester performs torsion tests by applying a controlled torque to a test specimen until failure occurs. It measures the resulting angle of angular displacement and shear stress to evaluate the mechanical properties and torsional behavior of the test specimen.

What is a torsion test machine?

A torsion test machine is a special machine used for applying torsional loads to materials or components. These machines are equipped with sensors that measure torque and angular displacement, providing accurate data for analyzing the material’s behavior under twisting forces.

What are the typical applications of torsion testing?

Torsion testing is widely used in materials testing relevant to aerospace, automotive, and structural engineering. It helps test components, such as shafts, beams, or fasteners, for their behavior under torsional loading to ensure they comply with safety and performance standards.

What are the standards for torsion testing?

The torsion testing standards, such as ASTM E143 and ISO 6892, provide specifications for conducting tests, specimen preparation, actual testing, and delivery of test data or test results. Standardization of tests according to these guidelines helps assure that results are reproducible and trustworthy across different laboratories and industries.