Understanding Deformation in Material Testing

Deformation in material testing means change in shape, size, or structure of a material on the application of external forces. This forms an important parameter to quantify the response of the material to stress and thereby properties like strength, ductility, and elasticity are determined. During the various testing methods, such as tensile testing, compression testing, and shear testing, engineers determine a material’s deformation response in different load-conferred situations. All these assessments form the basis for establishing the safety criteria as well as the durability and relevance of a material to a specific job.

Definition and Importance of Deformation

The term deformation refers to a change in shape or size of a body resulting from external forces, thermal changes, or environmental stress. There are two basic types: elastic deformation, in which the material returns to its original shape after the removal of the force, and plastic deformation, which permanently alters the material’s structure. Studying deformation is thus very important in material science, structural engineers, or factories, as it helps familiarise a person with how materials behave under working conditions.

Recent data further underscore the growing importance of material deformation analysis in contemporary engineering applications. Industries are paying increasing attention to the use of advanced numerical tools, such as finite element analysis (FEA), to simulate deformation under complex stress states. The simulation enhances the experimental cost efficiency and enables the design of a structure with greater precision in response to dynamic stresses, thermal fluctuations, and safety requirements. Therefore, refining knowledge of deformation enhances engineering design innovations and increases the reliability of critical infrastructure.

Types of Deformation: Elastic vs Plastic

Elastic and plastic deformation are the two primary types, distinguished by their reversibility and behavior under stress.

| Key Point | Elastic | Plastic |

|---|---|---|

| Definition | Reversible strain | Permanent change |

| Stress-Strain | Linear relation | Nonlinear relation |

| Energy | Stored as potential | Dissipated as heat |

| Load Limit | Below yield strength | Above yield strength |

| Recovery | Full recovery | No recovery |

| Example | Rubber stretching | Metal bending |

Factors Influencing Deformation

1. Material Composition

Slight changes in the microstructure of a material affect the ability to undergo deformation. These also include atomic types or atoms bonded together and their various arrangements in space. Metals are ductile because of metallic bonding, while ceramics are the counterproduct of that with ionic or covalent bonding.

2. Temperature

High temperatures increase atomic mobility, allowing the material to deform plastically by reducing the strength of the applied stress, also known as yield strength. On the other side, the inability of atoms to move at low temperatures makes it quite brittle and able to deform comparatively less before failing.

3. Stress State

Changing the state of applied stresses, such as tensile, compressive, or shear stresses, would bring about corresponding changes in the mode of deformation. For example, shear stresses may produce dislocation slip while tensile stresses usually cause necking in ductile materials.

4. Strain Rate

Deformation characteristics change with the added strain-rate effects. An increased strain rate usually implies less time provided for the atomic movements, and hence, ductility is understood to decrease with a higher rate. Many materials exhibit a more brittle behavior at higher rates.

5. Environmental Condition

The environment is a factor that affects the integrity of materials, such as corrosive agents, humidity, or even radiation. These conditions will either cause cracking due to stress corrosion or accelerate creep deformation over time.

Different Types of Material Testing Methods

Material testing methods include tensile testing, compression testing, impact testing, hardness testing, fatigue testing, creep testing, non-destructive testing (NDT), and thermal analysis.

| Test Type | Purpose | Key Feature | Parameter | Material Behavior |

|---|---|---|---|---|

| Tensile | Test strength | Elongation | Load, Strain | Ductility |

| Compression | Test compressive | Deformation | Force, Strain | Bulk strength |

| Impact | Test toughness | Energy absorb | Impact energy | Resistance to shock |

| Hardness | Test surface hard | Indentation | Hardness value | Resistance to wear |

| Fatigue | Test durability | Repeated loads | Cycles to fail | Life expectancy |

| Creep | Test deformation | Time under load | Temp, Stress | Long-term strength |

| NDT | Test defects | No damage | Ultrasound | Internal flaws |

| Thermal | Test heat behavior | Temp response | Thermal rates | Expansion, change |

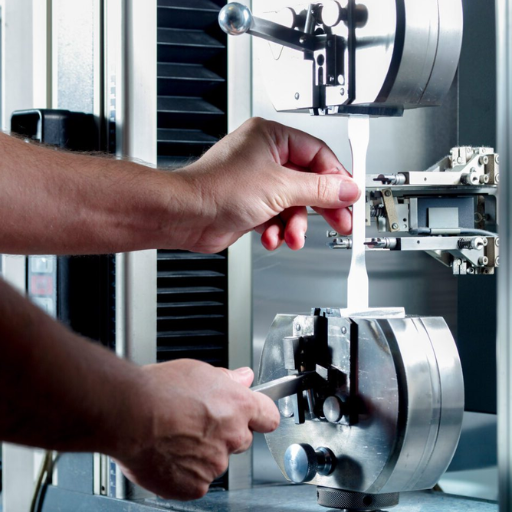

Tensile Testing: Evaluating Material Strength

Tensile testing is a fundamental method used to measure the resistance of materials against forces applied in tension. Tensile strength, elongation, and modulus of elasticity are classic examples of the properties measurable by this test. In tensile testing, a uniaxial tensile force is applied to a sample until failure, gathering data on the mechanical behavior of the material under stress-relevant factors, such as its ability to stretch, deform, and withstand fracture. This information becomes critical for projects where mechanical performance and safety are paramount, allowing the materials to be duly considered for design or in accordance with accepted industry standards.

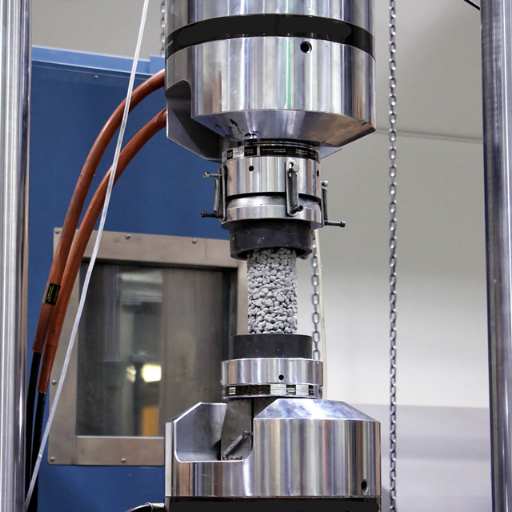

Compression Test: Assessing Material Durability

The compression test is a necessary testing process that determines a material’s ability to withstand compressive forces without failure or deformation beyond allowable limits. The axial compressive load is applied to the test specimen until it fails, in order to determine essential parameters such as compressive strength, modulus of elasticity, and strain behavior of the specimen under specified conditions. This test holds great importance in industries, particularly in construction, aerospace, and automotive, for validating structural components such as concrete, metals, and polymers.

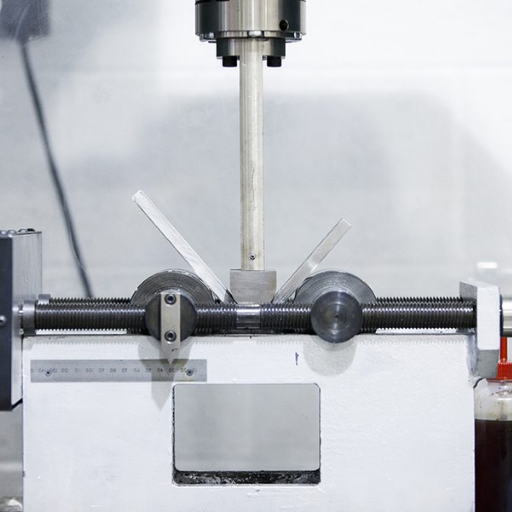

Bend Test: Understanding Flexibility in Materials

One of the mechanical tests to check a material’s ductility, resistance to breaking, and elastic deformation under bending forces is the bending test. Forces are applied to a specimen supported at its ends and loaded at the center in three-point bending configurations or along its length in four-point arrangements. Under such loadings, engineers can assess material behavior concerning stress without the possibility of complete fracture. Parameters such as maximum bending stress, deflection, and modulus of rupture are determined to indicate the material’s ability to tolerate bending without failure. This test is used for structural metals, plastics, or composites, especially for components that undergo cyclic or static loading during construction, transportation, or manufacturing.

Applications Across Industries

Material testing for deformation is of utmost importance in a wide range of industries, depending on design considerations such as safety, durability, and performance of various goods. Construction utilizes deformation testing of materials, such as steel, concrete, and composite materials, to certify whether they meet the eligibility criteria when subjected to loads and certain extreme environmental conditions. Deformation testing is used in the transportation industry to refine the design of vehicles, ensuring that components such as the chassis, suspension system, and aerospace materials are reliably tested under dynamic forces. Manufacturing utilizes deformation tests particularly to ensure that raw materials, works-in-progress, and finished goods perform up to legally defined standards. In such testing, innovation is guaranteed without compromising structural integrity or operational functionality in vital applications.

Material Testing in Construction

Material testing in construction assures the safety, durability, and performance of structures. It includes the testing and assessment of various materials like concrete, steel, aggregates, and asphalt for conforming to engineering and architectural specifications. Some standard tests include compression testing of concrete strength, tensile testing of steel strength, and gradation testing for aggregates. More advanced testing procedures such as Nondestructive testing (NDT) are also used to determine the material properties of materials. These rigorous testing procedures help identify any route for deficiency, reduce structural failures, and ensure regulatory compliance, which leads to the long-term sustainability of a construction project.

Aerospace Applications of Deformation Testing

Deformation testing plays a vital role in aerospace engineering, serving to determine the structural integrity, performance, and safety of components under stress conditions. Forces under control are applied to materials or structures to analyze their elastic, plastic, and fracture behavior. Techniques such as Digital Image Correlation (DIC), tensile testing, and fatigue testing are typically used to evaluate the deformation characteristics of critical components, including fuselage materials, wings, and engine parts.

The aerospace materials tested include titanium alloys, aluminum composites, and carbon fiber-reinforced polymers, ensuring they can withstand extreme conditions such as high pressure, variable temperatures, and mechanical stresses during flight. Alongside deformation testing, a numerical method called Finite Element Analysis (FEA) is frequently applied to realistically simulate the deformation pattern, allowing for design optimization before actual manufacture.

Such methodologies are primary for evaluating the load-bearing capacity, fatigue life, and failure thresholds of a material. Through deformation testing, aerospace engineers can optimize safety margins and achieve maximum fuel efficiency while conforming to strict industry standards, such as those set by the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA). Thus, they ensure aerospace applications in terms of component operational function and lifespan while considering the implications or risks associated with material performance.

Automotive Industry and Material Durability

As far as material durability is concerned, this is a critical factor in the automotive industry, and engineers carefully consider it about vehicle safety, performance, and product longevity. Testing methods are adopted by engineers to ensure durability when exposed to extreme environmental conditions, such as high temperatures and mechanical stress. Some of the tests and analyses conducted include tensile strength tests, fatigue analysis, and corrosion resistance testing. Lightweight and higher-strength materials, such as aluminum alloys, Advanced High Strength Steels (AHSS), and composites, are increasingly being used to save fuel and reduce weight. There are extensive validation methods that verify compliance with international standards like ISO 16750 so that automotive components pass the endurance requirements of automotive applications.

Advanced Techniques and Technologies in Material Testing

Material testing encompasses advancements that result from the integration of the latest techniques and technologies to ensure accuracy and reliability. Non-destructive testing methods include ultrasonic, radiographic, and magnetic particle inspections that can examine materials without affecting them. Higher-level microscopy methods, such as scanning electron microscopy (SEM), reveal microstructural features down to the nanoscale. Computational material testing is conducted using finite element analysis (FEA) modeling to gather information on the behavior of materials subjected to stress, simulating actual or simulated conditions. Testing automation under AI and machine learning will further increase the efficiency and quantity of testing, which consequently leads to the manufacture of improved and environmentally friendly materials for various industries.

Role of AI in Material Testing

Artificial Intelligence revolutionizes the approach to designing experiments and measurement methodologies for physical materials, thereby increasing the precision of measurements and/or reducing the time required for experimentation. Using complex algorithms, AI detects patterns or anomalous events in the voluminous datasets generated during material testing that may go unnoticed by conventional techniques. Neural networks, for example, can be used to predict behavior under varying stress states, thereby eliminating the need for repetitive physical testing. High-level image recognition algorithms, coupled with scanning electron microscopes or other imagery capabilities, also speed defect’ detection at micro and nano levels, thus enhancing quality control. Machine learning can fine-tune FEA simulations based on materials that have been previously tested, thereby speeding up the validation cycles for new materials under development.

Automation and Efficiency in Testing Processes

Testing automation utilizes technologies that include robots, AI, and software tools to automate repetitive tasks and time-consuming activities with minimal human intervention. Automation-oriented systems ensure consistent and impressive data records while minimizing human errors, thus elevating material appreciation accuracy. AI-based algorithms then optimize test parameters to quickly identify inconsistencies and anomalies, enabling predictive maintenance. Parallel processing of numerous samples in automation also increases the throughput speed of testing labs, lowering testing times.

Additionally, efficient testing frameworks establish a nexus of real-time monitoring and data analytics, providing immediate feedback and facilitating the swift adjustment of experimental setups. In the implementation of machine learning models, testing processes can evolve and learn from previous iterations, thereby refining protocols and enhancing predictions. When combined with cloud-based platforms, these developments will enable the seamless sharing of data between multidisciplinary teams, thereby minimizing the time required in the innovation cycle for new materials.

Future Trends in Material Testing Technology

Material testing technologies are expected to undergo future developments in the realms of automation expansion, the adoption of advanced computational procedures, and comprehensive mining of AI. Automation shall permit utmost time efficiency of testing by fast-tracking routine activities. In contrast, AI algorithms will evolve decision-making through predictive analyses and anomaly detection. Digital twins of materials have emerged to enable real-time simulation and analysis without physically damaging the material. Sustainable testing would delve further into emerging technologies by employing eco-friendly or recyclable materials, conducting thorough testing, and ensuring that performance is complemented by sustainability. In total, all these factors point towards the market evolution of smarter, faster, and eco-friendly material-testing methods.

Analyzing the Benefits and Limitations of Testing Methods

Material testing methods help determine the properties of materials, such as strength and durability, enabling engineers and researchers to ensure that these materials meet the required performance criteria. Among the significant advantages of current testing methods are their high accuracy and the ability of a testing method to extrapolate into real-world conditions, detecting even the smallest defects, thereby providing confidence for use in critical applications. There has also been a significant improvement in non-destructive testing that can be performed on materials and equipment without damaging them. From an economic point of view, these methods are cost-effective because the materials are not wasted during testing.

While many advances have indeed been made, some limitations remain. Conventional destructive testing methods provide the most comprehensive information but tend to damage the material and increase costs. On the other hand, NDT methods require very sophisticated equipment and specialized skills, which leads to high initial investments. Some techniques may not provide accurate simulations of real-life conditions, thereby introducing uncertainties in performance predictions.

Balancing the pros and cons involves weighing methods against their scenarios, considering the project’s needs, available resources, and the desired level of accuracy in the results.

Strengths of Different Testing Techniques

1. Simulation Testing

Simulation testing proves to be the best approach for promoting performance testing of specific situations in controlled, repeatable settings, without the associated risks of implementing real systems. This technique is often employed in identifying edge cases and conducting stress tests in systems. The ability to modify the environment makes this technique a crucial tool for predicting the behavior of a system.

2. Field Testing

Field testing is considered paramount for validating functionality and reliability under real-world conditions. By gauging performance in an actual environment, it captures nuances such as user interactions, environmental factors, and system integration challenges that are often missed in simulated contexts. Field testing is usually the most precise measure of overall system fit.

3. Automated Testing

Automated testing, hence the term, is a modern test process designed to achieve efficiency and scalability. Using pre-written scripts and frameworks, it performs repetitive test cases much faster and more accurately than a manual approach. The advantage is more pronounced in big projects or continuous integration environments where there are frequent test cycles.

4. Manual Testing

Manual testing is still necessary when human judgment is necessary; such a need may arise in usability testing or exploratory testing. Testers will be able to look at things like user experience, visual glitches, and convoluted workflows that scripts do not do a good job in capturing.

5. Regression Testing

Regression testing assures that modifications, change in code, or integration into the software do not hamper functionalities that already exist in the system. Through systematic re-testing, it guarantees that software stands the test of stability and reliability in dynamic or ever-evolving projects.

There are peculiar strengths associated with each of these techniques in the development lifecycle. Since selection criteria should be based on project objectives, resource availability, or the required precision in results, the best way to assess the material is to employ different methods for their complementary nature.

Limitations and Challenges in Material Testing

While materials testing is necessary for establishing properties and performance, it faces some hindrances. One major limitation is the potential for variability in test results, as differences in sampling, preparation, and environmental factors can all contribute to variations in results during testing. Efficiency-wise, traditional techniques are often quite time-consuming and, more importantly, require high-budget equipment, which may sometimes be an unreasonable demand for industries in their nascent stage or for smaller applications. Another major challenge which needs to be addressed regards scaling-an unknown quantity: results from laboratory-scale specimens do not always represent well the behavior of materials under real-world conditions. Last but not least, the ever-increasing use of advanced materials and composites has outgrown the current testing standards, which necessitate the formulation of new methodologies and equipment to adequately address the ever-evolving material properties.

Choosing the Right Test Method for Different Materials

With a focus on the specific properties to be measured, the method is selected according to the material under investigation, for instance, tensile strength, hardness, and fatigue resistance. The testing method must match the material composition and the intended application precisely; thus, thermoplastics will require different protocols than metals or ceramics. I will also consider the test scale so that it mirrors actual circumstances as closely as possible. Alongside this, I conduct periodic reviews of current industry standards and updates to ensure the methodology remains in line with those requirements; when necessary, I will utilize specialized equipment.

Reference Sources

Frequently Asked Questions (FAQs)

What kinds of deformation occur in material testing?

Some types of deformation in material testing are tensile testing, compression testing, bending testing, and shear testing. All these methods help to understand how materials react to applied stress and measure their mechanical properties, such as strength, ductility, and resistance to deformation. Hence, knowing these types helps in choosing the right material for a given application.

How does a compression test check deformation in a material?

The compression test is used to measure the mechanical deformation of a specimen by applying compression forces up to the failure or yield load. It determines a material’s ability to support a load without being plastically deformed. The method is generally applicable for brittle materials, which tend to fracture when subjected to compression, giving engineers an indication of its ultimate tensile strength and other mechanical properties.

What are the applications of elastic deformation in materials science?

Elastic deformation has far-reaching applications in materials science because it refers to the reversible deformation in a material when it experiences stress. Once the load ceases, it deforms in reverse to its original shape, allowing it to resist the force without becoming permanently deformed. Therefore, understanding elastic deformation is particularly useful for material selection in situations where an inert variable is maintained under operational conditions.

What test methods are used to determine the mechanical properties of different materials?

Test methods used to determine the mechanical properties of different materials include tensile testing, compression testing, bend testing, and impact testing. Each method assesses specific properties, such as tensile strength, ductility, and resistance to fatigue, which are crucial in the selection of materials and engineering applications.

How do materials respond to stress when under testing?

During testing, materials reveal a vast range of stress responses depending on their composition and structure. Elastic materials will undergo reversible deformation, while ductile materials may undergo massive plastic deformation before failing. Brittle materials, to mention a few, snap with minimal deformation. Predicting the performance of materials in real-life applications requires an understanding of these behaviors.

What is permanent deformation, and how can one measure it?

Permanent deformation refers to an irreversible change in the shape of a material when subjected to a load exceeding the elastic limit; it is measured in terms of the extent of strain retained by the material after the load is removed. The judgment of this measurement holds paramount importance in deciding the long-term performance and life of the material in the application.