In countless fields, it is vital to have a standard of uniformity set out universally in so far as the quality and safety of the end product is concerned, be it in the lines of textiles, medical equipment, infrastructure or electronics. In the field of these standards and norms some machines are utilized and without them, the evaluation of materials is impossible. This article will introduce you to them and the immense significance they carry in the field of material testing, as well as the wide array of applications they have. This guide isn’t just for those excited to understand how machines are ensuring the safety of buildings that are erected or the contribution they make to the latest scientific breakthroughs. This guide also highlights the technology and science utilized for the purpose of material testing.

Introduction to Material Testing Machines

What is a Material Testing Machine?

As companies have grown more reliant on technology, there has been a great increase in the need for a comprehensive cleansing of data, distribution, and storage of that data. In fact, there are more new terms constantly coming up, such as big data, deep learning, artificial intelligence, predictive analytics, and data engineering. This technology has the potential to bring great benefits to companies dealing with large quantities of data. And with the increased use of technology, the demand seems to be on the rise.

Data governance has become more important to companies especially in how they keep, distribute and store data. As well, data cleaning could be expensive, yet it is more crucial to the health of data companies have, process, or distribute. To get rid of this gap, new innovative technologies such as cloud computing, database management, and advanced data analytics frameworks are required. These technologies could reflect and at the same time offer mega data support.

Importance of Material Testing

The word ‘essential’ may seem overly used, but in this context it super serves its purpose. By testing materials, engineers and manufacturers can determine the properties, such as strength and durability. They can also check for the appropriate resistance to the environment. It further helps in the identification of the applications the materials can be put to use in, which prevents the occurrence of the risk.

Material testing comes in handy with the task of meeting set rules and regulations. For instance, the standard of the materials in construction and other three industries, where the use of asbestos is prohibited, must be tested. Each of these industries is useful in testing the material, which assists in increasing the safety of projects by ensuring customers and stakeholders, along with others, help to reduce charges that could lead to banning.

Filtrations and feedback loops, testing materials in the right use and grace. These new findings help in other studies and evaluations that do not use new advanced materials in certain models that may be in practice today. New studies and experiments with advanced new materials and designs, along with other advanced materials, ensure that silver appliances are performed. Materials under advanced designs and materials offer new product benefits along with industry benefits, which ensures that implemented models under advanced materials have new products benefits.

Overview of Types of Material Testing Machines

The work of material testing machines extends to verifying the competence and mechanical and physical properties of different materials in sectors, such as manufacturing, aerospace and construction. These examinations aim at ensuring the meeting of various standards and conditions, particularly on technical qualities, for instance: stability, reliability and durability of different materials. Every type of material testing machine performs a specific function. Tensile testing machines serve to point data on tensile properties, such as the elongation of material. As for metals and alloys, hardness testers evaluate the material’s resistance to deformation under a specific load, rather than its capacity to deform or penetrate. As for compression machinery, it’s used to test the capacity to deform under compressive force particularly to not the manufacturing materials like steel tablets and pen strength of the steel tablets school.

Tertiary machines not impacted by the manufacturing materials give an immediate assessment to the toughness and strength of materials. Fatigue machines give cyclic loading, and so industries give their immediate assessment for materials requiring sharply applied loads. These types of machines permit industries to restrict their testing to a very narrow the objectives of determining the safety, efficiency, and performance and reliability.

Tensile Testing Machines

Definition and Purpose of Tensile Testing

When a material is pulled from two sides, one is able to gather its mechanical information using the tensile test method. The main goal of this testing is to understand and provide support in the performance of stretching, whether it is the material’s strength, ductility, elasticity, or overall behaviour. A test is performed by pulling a sample of the material and slowly pulling it apart until the material fails. This provides comparative data of tensile strength, yield strength, and change in length at the time of failure.

The outcome of the tensile test isn’t just helpful for a single industry but even to a single material seller. It helps determine what material will pass their safety and comfort-testing standards. Understanding the tensile behaviour tells manufacturers if a material can meet stiffness requirements or withstand certain forces without reliability or life span concerns. Moreover, tensile testing recognises material irregularities that are of help to a production stage dedicated to quality assurance.

Looking to the future and as a part of the practical business, tensile testing is an extensive help along with the progress of new materials through controlled research. Dedicating resources to the business, it is uncovered how certain new families of metal, composites, or even plastics can find competitive usage, with completely new alloys and/or polymers revolutionised to have competitive strength. It is of immense use to secure the capabilities of materials invested across the globe in various sectors, engineering and safety needs.

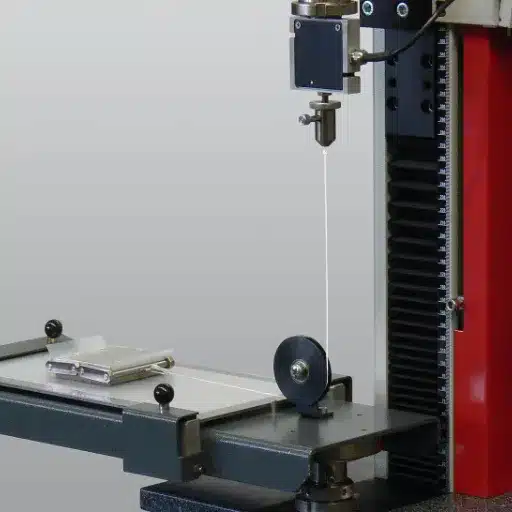

How a Tensile Testing Machine Works

Mainly, a tensile testing machine is used to grab a piece of material and pull on it to the point at which it changes its shape or breaks. The device is used to measure how the material reacts to an outside force, granting valuable insights into its brittleness, strength, and elasticity. The sample in use had a pulling force applied to it consistently while it was monitored for the force being exerted and the elongation. This is how the machine operates on the sample.

For a tensile testing facility, the apparatus’s main components are the load cell, grips for holding the sample, and the device’s pulling attachment, known as the crosshead. This entirety is certified under strict regulations and the applied machinery is uniformly modified to prevent unexpected behavior. To further professionalize and increase the credibility of the results produced by the equipment, the system is further digitalized. Special stages and clamps further digitize the clamping, securely ensuring that it remains still during the experiment, further automating the experimental part of the process, hence providing the utmost purity of outcomes. Adobe Acrobat is incorporated to extract and save the resulting documents.

From its inception, this methodology has been the best way to appraise the performance of materials in a wide range of products, starting from construction to the aerospace industry. The field of materials science combines materials used in construction, to the kinds of materials used in airplanes, to the materials that you have in your cars. Thanks to this information, we can appreciate the construction in buildings for example.

Components of a Tensile Testing Machine

A device for tensile examination has several key parts to properly evaluate the axial strength and deformation characteristics of the material. The following are the main parts of a typical tensile test machine:

- Load Frame: The load frame is the main body providing support to the entire unit. It consists of two crossheads, with one fixed and one movable, which are interconnected to a steady frame. This construction of the frame guarantees the highest degree of stability and perfect alignment of the load frame parts during the examination process.

- Load Cell: This is the part utilized to measure the force and load that is applied to the test specimen. Load Cell works by transforming mechanical force into electrical signals, giving way to more precise data collection.

- Fixtures Operating: There is always a need to keep a specimen in place, a need that can be serviced via fixtures called grips. Different designs like that of pneumatic clamps and of wedge grips are utilized to serve these basic purposes.

- Extensometer: This unit is of great significance in determining the compressive load of a sample. Strain is indicative of the material compressive strength this it is a material determinant that comes as a result of the tensile elastic modulus.

- Operating System: The function of the drive system is to provide a smoothly accelerating tensile force to the crosshead. A mechanical drive system is composed of electric motors to sequentially power the operation, and it acts under a continuously varying load.

- Data Acquisition System: This is the guard software, and the system includes a data acquisition device is responsible for feeding the test parameters. It is also used to monitor the test and all results.

Types of Tensile Testing

Standard Tensile Tests

Mechanical properties of materials are evaluated comprehensively through standard tensile tests. Tensile strength parameters help to examine Young’s Modulus, yield strength, and elongation strain. These standard tests help determine a given material’s performance based on the loads it carries.

In a typical standard tensile test, a built specimen is stretched using a uniaxial force. It is necessary to use a universal testing machine, which applies a continuously increasing tensile force. As the resistance, like the applied force and the amount of elongated material, is noted, the material resistance is captured by the stress-strain curve.

Material selection, quality control, and product design greatly benefit from the data these tests collect. For instance, tensile strength data helps engineers assess whether the material supports the loads it is subjected to. Similarly, the material’s deformation performance is revealed by the yield strength data, making it indispensable in creating safety standards and operational guidelines in mechanical and industrial processes.

Types of Grips and Fixtures

Different kinds of grips and fixtures play the role of securing the specimen during a tensile test. Along with the specimen, they make sure that the specimen is properly aligned. The kind of grips you use will depend on the type of specimen you have and other factors including geometry and the testing itself. The correct use of grips and fixtures not only avoids slippage but also help in achieving unbiased and repeatable data.

Wedge grips, among other kinds of grips, are commonly used for testing the strength of different materials. The gripping force of the specimen increases with the increase in the test load. Among others, plastics and metals with high clamping tolerances tend to have a high degree of self-tightening and therefore, are easy to test using wedges. Wedge grips also reduce high clamping pressures, posing a risk to the alignment, which helps to curb an unequal stress distribution.

Pneumatic and Hydraulic Grips are greatly suited to the materials that need to be clamped slowly, and this includes fabrics, thin films, and other materials that are quite delicate. With the timely pressurized fluid or air, these grips evenly expose the specimen to the pressure and risk of crushing, which is one of the many remarkable benefits. Special grips like button grips, V grips, and specially engineered components are used more often these days to support some unconventional tests. They are greatly useful and very convenient for protecting specimen with asymmetric shapes or designs, making them easy to adapt. Ensuring the grips and fixtures are correctly chosen and are properly checked will warrant the achievement of accurate and dependable test data.

Test Specimens and Their Preparation

Proper preparation of test specimens is vital to obtaining accurate and reliable test results.

- The first step in preparing specimens is to ensure that they are consistent in size, shape, and material properties. Variations can lead to discrepancies in test data, making it challenging to draw meaningful conclusions from the results. The specimens should conform to the applicable standards specified for the test method being performed.

- Next, it is important to handle test specimens carefully to prevent damage or alteration prior to testing. Any imperfections introduced during handling, such as scratches, dents, or uneven surfaces, may significantly impact the test outcomes. Specimens should be stored in conditions that minimize exposure to environmental factors like moisture or extreme temperatures, which could compromise their integrity.

- Finally, specimens should be inspected thoroughly before testing. This includes verifying their dimensions, integrity, and overall condition to ensure they meet the necessary criteria. Any deviations should be documented, or the specimen should be replaced to maintain the validity of the testing process. Proper preparation and inspection are fundamental to achieving precise and trustworthy data in testing environments.

Universal Testing Machines (UTM)

Functionality of Universal Testing Machines

These machines identify the unique and distinctive properties of various types of materials from various disciplines. These include tensile strength, compressive strength, and bending resistance of the material. By controlled force application and recording the responses, Universal Testing Machines provide a distinct testing ability that a guarantees that the materials meet the required tensile forces for its purpose.

Testing and measurements of force and a subject’s discontinuities can be an effortless task to do with Universal Testing Machines with the use of a load frame. Universal Testing Machines are a package of a linear load cell with grips, and test machines with cams are also a package of custom load cells with the combination of various load grips. Entirely, the entire machine is in a position to address all the applications of testing such as tensile, compression and flexure force. When the extensometers are tested by only the load cells, and the strain is tested by the extensometers, the tensile strength, elongation, and the yield strength is measurable. Universal Testing Machines are essential to the expansion of scientific and engineering research, as well as quality control and product development, and are critical in various industries such as aerospace and construction. Compliance with the strictest quality requirements, safe material applications, and effective reliability come as a consequence of their giving of detailed data of what benefits of material utilization.

Applications of UTM in Material Testing

The functionality of Universal Testing Machines (UTMs) is beyond the stretch. UTMs conduct public testing in various materials by creating many operational conditions, such as stretching strength, compression resistance, and twistability. But this data would not be generated in the absence of UTMs.

There is one more function of quality assurance in the industry. Materials that meet industry standards and performance can be independently tested with UTM. In the aeronautics, automobile, and building sectors, UTM, in which material rigidity and longevity are particularly important, these materials are tested. The data obtained in this case enables manufacturers to produce products that comply with rigorous instructions.

Furthermore, materials can be improved and developed with the help of Universal Testing Machines (UTMs). Engineers and scientists can examine new alloys, composites, or polymers with the help of UTMs to offer a broader material range to work with. This invariably leads to the creation of lighter, stronger, or reusable materials which advance technology and construction. The adaptability and UTMs’ dependability guarantee their prominent designation in the enhancement of material and engineering sciences.

Comparison of UTM with Dedicated Tensile Testing Machines

| Aspect | Universal Testing Machines (UTM) | Dedicated Tensile Testing Machines |

|---|---|---|

| Versatility | Can perform tension, compression, bending, and shear tests | Specialized for tensile tests only |

| Precision | Good precision across multiple test types | Superior precision for tensile-specific applications |

| Application | Ideal for labs with varying requirements | Best for high-volume tensile testing |

| Flexibility | Quick setup changes for different materials | Optimized setup for consistent tensile testing |

Universal testing machines (UTMs) and dedicated tensile testing machines are 2 kinds of machines that are used in material testing. UTMs are very flexible; they can perform very wide range of mechanical tests, which include tension, compression, bending, and shear tests. They can also switch to a variety of materials immediately (literally, they just have to change the fixture and/or the setup). On the other hand, dedicated tensile machines that specialize in tensile tests can be very focused on the tests they run, and with this training focus, they can achieve far better precision and reliability, especially for tensile-specific applications.

UTMs are very useful for materials testing labs that have varying requirements, but for labs that do a large amount of work with a specific material, using a versatile UTM might not be the best tool for the job. The choice between the two depends on the specific program’s requirements, such as daily test volumes, the materials being tested, and the required accuracy.

Other Types of Material Testing Machines

Compression Testing Machines

Compression testing machines are used to test the response of materials to forces that are applied to compress them. These machines give a quantitative value of the strengths of materials and deformation or performance materials exhibit when axis-materials are categorized is to test how much force is necessary to crush them and bear loads. Materials are tested under different categories; applied on them. Industries such as construction, packaging, and metals use these machines to satisfy the standards of performance and safety are a few of many.

It is an important feature to make a specimen to apply a controlled compressive force; the outcome will be measured. The compressive strength, elasticity, and durability is extracted from this test. The compression testing machines have a spectrum of applications, including testing the crushing strength of packaged and reinforced concrete, the compressive behavior of plastics and packaging materials, and the load-bearing capacity that can be achieved. The machines can have a wide range of sizes of specimens so that it can bear different material types, achieving desired precision and reliability in testing.

Quality Assurance of materials in research and experimentation materials is facilitated by the availability of compression testing machines. Boundaries of the intended to load are certain that materials do not fail. This essentially means that preparation of the highest standards for safety and reliability of products and structures is around a tested, appropriate for use. Furthermore, the machines provide valuable data on materials’ performance under stress, both in use and in development. It is important to remember that meticulous calibration and application of the machines is essential to compliance, in addition to the quality of output.

Flexural Testing Machines

Flexural testing is a type of testing used to assess the properties of materials under bending stress. The test makes use of the load-stretch curve to measure the properties of the material, such as strength, flexibility, or deformation resistance. By using the test, engineers can learn whether a material is suited to a specific application.

Flexural testing is usually carried out by testing of a rod or a beam by placing it between two supports, applying force on one or several points. This is done to create real-life scenarios to test the material under conditions of stress. Testing enables engineers to gain information about very basic properties such as modulus of elasticity, flexural strength, and even the mode of failure. All of these are immensely utilized in product design and in the safety of the designs as they help to set boundaries.

In industries such as construction, aerospace, and many others, material compliance is very crucial. Material compliance helps ensure that the material meets the relevant regulatory standards, and material reliability is improved. Flexural testing machines are used to conduct material testing, and they are very critical in the compliance of materials and help significantly in the enhancement of products. Flexural testing machines are particularly essential for the construction industry, where the safety of structures and airplanes can be compromised if not properly constructed or produced.

Fatigue Testing Machines

These machines are designed to evaluate the performance of materials reacting to cycles of stress in a repetitive manner. In industries such as oil and gas, automotive, shipbuilding and aircraft manufacturing the use of materials is vast, and such fatigue testing systems are crucial in determining the stress and improve the reliability to ensure the security of the aeroplanes, automobiles etc. Therefore, understanding the building material’s fatigue cycles has a significant impact on the testing fatigue machines located in The fatigue cycle provides an algorithm for designers to ascertain when a material will fail and what maintenance needs to be in place in order to avoid catastrophic repair costs. Keeping in mind the advances made in space exploration with assistance from fatigue testing, one significant achievement is the failure-free flight of the Space Shuttle and the ongoing reliable flights of the Concord.

The overall goal of fatigue testing is to identify the crack growth properties of a given material. This is because of the statement that “a given stage storage and release material defines itself as failure at some later stage.” Hence, the failure cycle is the ability to recognize the fatigue cycles and the testing. “Fatigue testing”, in engineering word salad, describes the previously mentioned paragraphs.

Frequently Asked Questions (FAQ)

Q: What are the different types of material testing machines, in general?

A: Material testing machines are universal testing machines, tensile testing machines, and compression testing machines. They are all designed to carry out different tensile tests and provide the analysis of materials in those tests. Materials can be evaluated for tensile strength, compressive strength, and hardness. Their usefulness is seen in experimental testing and rheological materials.

Q: How do the universal testing machines go about their work?

A: The universal testing machines are to be tasked with controlled load applications for the testing of test specimens until they either deform or fracture. These universal testing machines are capable of carrying out tensile tests alongside compression and flexural tests. This in turn, enables concerned personnel to perform a thorough assessment of the materials’ mechanical properties.

Q: Let’s discuss the importance of tensile testing machines.

A: It lets you measure the strength of materials, as well as other aspects of their mechanical functioning, an advantage that almost renders it mosaic. With the help of such an apparatus, you can put enough strain on a material component that it sustains fractures. The Eminent benefit lies in the fact that you can seek out the domain-specific applications in which the nature of a certain material will serve the best purposes.

Q: What kinds of materials can be tested using material testing machines?

A: Material testing machines beings up materials of varied categories where they can relay upon metals, plastics and composites. Almost all test type performance is related to the materials and their expressions.

Q: What impact do load cells have on materials testing machines?

A: The masking of the system which leads to materials testing systems reveals the answer to the question, as it is defined from the sense of measurements dealing with the object to analyse, providing the tensile and compression strength applied and the important materials properties which are embedded with the whole object.

Q: Can you perform fatigue testing on material testing machines?

A: Certainly, fatigue testing is among the forms that some material testing machines are equipped with. Fatigue testing works on the premise of repeated cycles of loading and unloading. Essentially, the longevity and the material’s performance in the real world will be determined.

Q: Elaborate on the testing requirements of various materials.

A: The demands of the materials to be rigorously tested out comply with different regulations, with some slightly varying. For example, tests of metals are better suited for ultimate tensile strength while tests of plastics for the evaluation of stiffness through compression tests.

Q: Identify the differences the use of grips and fixtures to the examination process.

A: In the course of testing, the use of grips and fixtures is indispensable since they are purposely employed to hold materials under investigation in place during testing. The kind of grips used in turn influences the accuracy of the results obtained, which is why utmost attention needs to be put while selecting the proper fixture that corresponds with the material being tested and the kind of test being conducted.

Q: Can you explain the significance of the international standards of ASTM and ISO in connection with the testing of materials?

A: ISO and ASTM standards are universally accepted rules applied in checking data for materials. It is very important when needing the data to be exact for product validation. Compliance is important for ASTM and ISO standards and is a must in the documentation of the procedures for the step-by-step.

References

- The Different Types of Material Testing Machines – AZoM – Discusses various types of testing machines, including tensile strength, compression, flexure/bend strength, and more.

- Most Popular Types of Material Testing Equipment – NextGen Test – Covers universal testing machines, hardness testers, impact testers, fatigue testing machines, and non-destructive testing equipment.

- 4 Types of Construction Material Testing Machines [GUIDE] – Forney Online – Highlights compression testing machines, flexural testing machines, universal testing machines, and more.

- Materials Testing Machines – Instron – Explains the variety of material testing machines and their specific applications.