A universal testing machine (UTM) is an essential part of materials technology and engineering which forms the ground when it comes to the testing of materials against various mechanical conditions. Its functionality is many, and the compression test stands out especially which is used to assess or understand the behavior of the material being tested against compressive loads. The objective of this paper is to provide working principles, applications as well as importance of the compression test in order to illustrate how it helps to evaluate such essential characteristics as strength, toughness, and ductility. In this article, I will discuss the compression test, its procedure, and its importance in the development of materials and applications which use materials. The exploration of the process leading to this test is awaited.

What Is a Compression Test and Why Is It Important?

An assessment referred to as compression test is carried out to determine the behaviour of a material when it is in compression. The test entails putting a material under a universal testing machine compression test to analyze its ability to withstand compressive forces. This test is important when evaluating factors like compressive strength, elasticity and failure, which determine some of the applications for the material. This means that a number of industries from the construction industry to the manufacturing industry, and from manufacturing to aerospace engineering all include compression testing to ascertain the safety and performance of materials in actual working conditions.

Defining Compression Test in Material Testing

In the domain of material science and engineering, compression testing plays a significant role as it provides important data for the construction of the most suitable pattern of ‘items’ to be made, i.e., to affect the design, production, and so on of many products. The aim of this test is to measure the changes in materials subjected to compression, such as stress-strain response, maximum compressive strength, and modulus of elasticity. This involves applying an incremental compressive force to a test specimen until the specimen shows deformation or becomes permanently deformed. Engineers make use of the results derived from these tests to enhance materials for structural purposes, whereby the materials can be used efficiently without failure in any particular condition. In the line with the improving standards of equipment and the increased capacity for testing, compression also gives more detailed and precise information that is related even to the development of thin structures such as wings of an airplane or construction walls. Moreover, in the Google search information enhancement of more automated compression testing apparatus has been constantly observed, allowing faster and more precise carrying out of the universal testing machine compression test without involving any expert work, which is a new trend applied to deal with material inspection.

Applications of Compression Testing Machine in Various Industries

1.Building Industry: To verify and confirm that concrete, bricks and other construction materials meet and maintain structural and safety standards, Compression Machines are heavily employed in the determination of the strength parameter of these materials.

2.Aviation Industry: Devices capable of performing compressive tests play an important role in the aircraft development process as regards compressive stress on structural composite materials and light-weight installations.

3.Car Industry : Compression testing is a requisite practice which is employed by most of the car manufacturing companies to ensure the structural durability of the different components such as rubber, metals and polymers which are subjected to heavy mechanical stresses when the vehicle is in motion.

4.Production Field: Compression testing is used to determine the extent of loading strength that a packaging material such as corrugated boxes or plastic can withstand during transportation and storage.

5.Health Field: When it comes to primary field of concern i-e, unloading behavior of materials, it is important to mention that universal testing machine and sepcificaly so compression test can be performed on various components such as bone implants, prosthetics etc for estimating their mechanical behavior.

Importance of Compressive Strength Measurement

The value of compression strength is measurable but important in many industries for several reasons. This trait determines a material’s resistance to any form of compression forces. It is in construction; readings derived from compressive testing keep buildings from falling apart as it provides information that maintains the integrity of concrete, brickwork, and other building elements. Equally important are these measurements in the industrial field where they aid in the control of fit and function of packages designed to hold items during shipment. In the area of medicine, the compressive strength test ensures the mechanical robustness of implants and artificial limbs. In quantitative assessment, the behavior of the material under the force of compression is studied, aiding in quality control purposes, the choice of materials, and the safety of products in various fields.

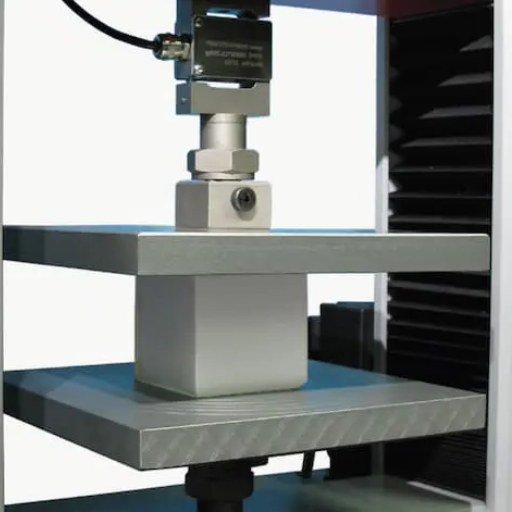

How Does a Universal Test Machine Work?

The universal testing machine applies an external force to the test specimen to characterize the material properties of the test sample. The main elements of the machine include the load frame, crosshead, load cell, and actuator that all apply a tension, compression, or shear force towards the load. During the process, the Complex assay consists of a sample that is attached to so called ‘jaws’ and certain forces applied during which load, displacement and deformation are measured by the machine itself. Results of this work is captured in the course of testing and analysis every engineering enterprise function with regard to material, in virtue of existing conditions and performance of the material. This advanced architecture, in a case of The universal testing machine compression test, enables quality control and research in various fields of activity.

Main Components of a Universal Test Machine

Every universal testing machine has several parts each playing different roles in testing. It is important to have a good understanding of these parts and their technical abilities so as to assess the performance of the system and how it can be used. The fundamental parts are as follows:

1.Load Frame

The load frame is the main scoring member of the Universal Test Machine, which is the most frequently used name for this component. It is usually comprised of a robust steel or even aluminum alloy that serves as the mechanical support for all the loads put on it when the tests are carried out. The frame may be designed for both stationery tests as well as active tests, such as those dubbed dynamic tests, while deeming the least bowing under the force. Frames are available in various sizes and thickest consisting supports of loads of ranges between 1 kN and over 1000 kN depending on the required application.

2.The Controller

System controlled by the controller contains components for control and execution of the examination. The controller internally maintains the correct operation of external devices with respect to load, speed of testing, then the recording of data. The control panel or the conjoined display screen provides the changing of operational parameters in accordance with the required type of testing (e.g., ASTM, ISO). Electronic components of high-resolution give precise readings of the quantities such as force and position with limits of deviation being 0.5% or less.

3.Load Cell

The load cell is the heart of the universal testing machine for it quantifies the force imposed on the specimen. A mechanic-electronic transformation is achieved by the load cell that works on the principle of the strain gauge. Load cells are manufactured in different capacities such as 0.1 kN, 10 kN, 50 kN and more, with sensitivity ranging around 0.01% of full scale force. Therefore, the stability and calibration are very important in the given range of measurement.

4.Crosshead and Actuators

The crosshead is a part that moves, and is fixed with the grips to hold the specimen. The actuators – hydraulic or electromechanical – provide the needed force during a test. Electromechanical actuators are suitable to conduct precision outward testing with delay technology (e.g, 1 mm/min to 500 mm/min). It is generally used for hydraulic actuators, which has high force ratios restart force behavior. It can be used for most sample types and this also applies in the compression test.

5.Grips/Fixtures

Grips, better called fixtures, hold the test samples. These are made based on the shape of the sample and the type of test, like tension, compression, or flexural tests. The most common grips used include wedge grips, pneumatic grips and threaded grips. Special self-tightening grips have been developed in order to avoid undue slippage during tensioning of the material.

6.Strain Gauge

Extensometers are designed for measurement of the elongation of a sample in a cutting outline of the universal testing machine. They may use clip-on strain gages or video extensometers, capable of measuring strains accurately to within +/-0.5%. These are advanced proprietary devices which are used for resolution of statics and dynamics, and in some cases involve large deformation or multi-axial strain.

7.Data Collection and Programs

UTMs available today are advanced and record various data as the test proceeds. It includes force, strain, displacement, and other parameters. A package of analytical software provides the ability to measure Young’s modulus, yield, fracture, etc. Software appropriate for such sectors is also compatible with ASTM E8 or ISO 6892.

All these elements complement each other to achieve high levels of precision, repeatability, and dependability in a variety of material testing processes, without the use of Universal Test Machines-assisted engineering or materials science becomes impractical.

Role of Compression Platen in Testing

The universal testing machine is robust and enables efficient compression test on various materials. It is a non-deformable and non-altering flat component that enables even application of forces on the sample being tested, so the load remains uniform throughout the test. These compression platens come in handy to aid testing of materials when compressive force is applied to determine the original height and stiffness and the maximum strength that can cause total collapse of the material.

Superior compression platens still need to be produced within certain limits to offer the degree of parallelisms as well as the surface finish required on ASTM and ISO. This is a necessity to reduce measuring errors and also avoid any undesirable deviations. It should be noted that such platens are applicable in the testing of metals, and elastic, hard or semi-hard plastic materials, plus ceramics, and other compounds or polymers as an addition to the QC, design, and material engineering processes.

Understanding Testing Equipment and Accessories

When it comes to choosing testing devices and accessories, absolute precision, international compliance, and flexibility across material types are the key parameters that I use. For example, I go for accessories such as compression platens, which are standard to ASTM and ISO laboratories, for accurate results and consistent practice. These additional devices are critical where metal, polymer, ceramic and composite materials are tested very strictly. Furthermore, equipment’s modularity features which support different uses such as research and development or production are also very important.

What are the Key Test Parameters in a Compression Test?

It is understood that from a compression test point of view, compressive strength is the maximum stress the material can take before breaking. The yield strength is the limit of this understanding beyond which the material does not regain the original shape after deformation. Another primary parameter of materials deformation is strain which is a ratio of proportional change to the original dimension and thus is related to the ductile behavior of a material. Displacement and modulus of elasticity, or elastic modulus upon provision of stress are very pertinent as well. Proper speed and load combinations have to be observed especially in reseals where testing has to be done to specific ASTM or ISO topologies. The ASTM and ISO standards combined with strict adherence to universality in this field require set speeds for such tests and the manner in which loads are applied and to what extent.

Setting the Test Parameters for Accurate Results

In materials testing, it is crucial that certain aspects, or parameters, be adjusted and monitored for relevance so as to get right results. This involves a certain temperature level at which the tests should be conducted as it will affect the behavior of the material and the rate of loading, which should be how the material will be used so that any corrections are not warranted. The specimen must be rightly fixed, if any irregularities play into the shape of surfaces, or if two dimensions are not compatible as members of conjugate surfaces then faulty measurements will arise. All load cells and extensometers that are used top calibrat the universal testing machine should meet ASTME4 or ISO 7500.1 calibration standard only. Resolved all the presented points, failure of the test and accurate analysis of material can be avoided.

Impact of Specimen Properties on Testing

Manufacturers and material scientists all understand design imperfections such as shape and size of a test body will have a determining influence on the precision of material properties assessed. Elements such as processing lines, thickness, and shape of the test specimens exert external constraints which bear a risk of distorting the test outcome. To illustrate this, let’s use the example of test samples with surface and manufacturing defects, for instance scratches or roughness, causing a premature collapse during the test. Likewise, the presence of surface distribution dimensional errors excluding standardized tolerances of stress or strain causes a distortion of the mechanical properties engraved by the measuring device.

The even distribution of fibers in composites exhibits a uniform internal structure which affects the performance and behavior of the test. Moreover, surroundings like temperature, and moisture exposition can build up an influence at last on the mechanical performance of the juridical sample. Examining Preparation puts strictitude for the dimensions as well including material preparation as within these bounds of these processes credibility or performance data would be the target of the process. Now Lets take the example of universal testing machine compression test.

Analyzing Test Data from Compression Tests

When reviewing results gathered from laboratory experiments specifically compression test, different indices are considered, which include compressive stress-strain, ultimate strength, and modulus of elasticity. To begin with, I verify whether the data collected is accurate or not by checking if the initial curve laws do not change and by looking for statistically inaccurate measurements in-composite force measurements. Next, I get ultimate compressive strength by extracting scalar ratio between peak force and cross-section of the sample. Tudor (2006) states that “It is also helpful to observe any failure mechanisms or plastic zones under constant or prolonged loading of the material in terms of the mechanisms to accommodate strains.” Lastly, making use of the developed and properly tested techniques and software, experienced persons were able to obtain accurate and reproducible outcomes that could be used in industrial or educational activities etc.

How to Conduct a Compression Test Using a Universal Test Machine?

To perform compression test using universal testing machine, the procedure commenced by area preparation,cleaning of specimen. The measure to prepare is that the polished surfaces are brought to the specified dimensions to ensure it does not contain any defects. The updated test specimen is carefully fitted into the compression plates of the machine coupled with an even arrangement to avoid skew and uneven load. With the help ofthe machine’s settings, set the test parameters such as the load time and the displacement period. Placeaggregate crush rate load evenly, as data on load p and displacement is being taken. The test is stopped at failure of the specimen or up to a certain limit. Afterthat, the recorded data is analyzed and converted into the concerned material properties which includes compressive strength, modulus of elasticity and distortion behavior of the material. However, obeying the appropriate standards (for instance ASTM, ISO review) in carrying out these operations is always recommended for accuracy and recall.

Step-by-Step Testing Procedure

1.Sample Preparation

The test sample must be ready for testing in accordance with the relevant standards (such as ASTM or ISO) and must not contain any defects that may affect the test.

2.Testing Machine Calibration

Make sure that the testing machine is well-calibrated and is able to produce precise and accurate readings.

3.Fabricate the Sample

Secure the sample into the test machine and position it correctly so as to prevent loading through any eccentric distance or unbalanced force.

4.Enter the Parameters

Adjust the machine to the designated settings, which include either the rate of loading, strain rate or displacement rate as a function of a given testing procedure.

5.Test the Specimen

Progressively apply load or displacement to the specimen as the control software dictates while recording data in real time.

6.Watch the Process

Check the test undergoing to make sure the system works well and look out for abnormal situations that could also cause the test to be rejected.

7.End at Failure or as Expected

Leave the test to run the sample until a failure is registered or the assessment reaches an endpoint level desirable for the purpose of the analysis.

8.Conduct on Post Mortem of Tested Samples

Examine the failed sample or the tested sample for any evidence of failure, distortion, or cracks in the specimen.

9.Compile Results Supporting Data

The loaded displacement data collected should be analyzed to determine compressive strength, yield strength, elasticity and elongation (or deformation).

10.Convey Results

Compose an extensive report as to all the results obtained during the tests, all conclusions reached, and any other pertinent observations.

11.Carry Out Machine Maintenance

At the end of the tests, the testing machine should be cleaned and inspected for any wear and tear, so as to keep it in good working condition for subsequent tests.

Common Challenges in Compression Testing and How to Overcome Them

1.Misalignment of Samples

Perhaps the biggest hurdle in conducting compression tests arises out of the crooked fitting of samples leading to – uneven stress distribution and erroneous results. To eliminate this, it is mandatory for the samples to be placed at the exact center of the platen along with proper alignment. Misalignment errors can also be reduced to a great extent by use of rational clamping devices or deformable hard plates.

2.Homogeneous structure or Thermal damage

This problem is mainly related to the fact that the materials turn out to be absolutely unsatisfactory. If the materials do not have any defects and the desired load rates along with platen velocities are ensured within the limitations by adjusting the test variables then the problem can be avoided. Pre-experimental evaluation is a practice that is carried out to prevent unexpected failures.

3.Personnel

In many instances, lack of accuracy of machines either due to calibration deficiencies or in other cases caused serious suspected compromise on the results. Such a problem is avoided by ensuring that the universal testing machine is always calibrated as required by its manufacturer and details on this information including maintenance procedures are appended. This is so that at any one point in time, one can be confident that the universal testing machine can be provisioned for and have the same results.

4.Data Analysis Barriers

Some difficulties may be present when it comes to deciphering certain stress-strain curves as well as deformation related figures. To avoid such mistakes, there are better software programs that help in the evaluation of test results, and even extra readings may be taken to aid in interpretation. Finally, modern developments and practices in the field help in interpreting data accurately.

By systematically addressing the above issues or constraints, attesting that compression testing provides replicable and reliable results that comply with strict standards of scientific research and engineering is solid.

How Does the Compression Testing Machine Differ from a Tensile Test Machine?

Compression testing machines and tensile test machines differ in operation, purpose, and the type of force they apply to materials, among other parameters.

|

Key Point |

Tensile Test Machine |

|

|---|---|---|

|

Force Direction |

Compressive |

Tensile |

|

Purpose |

Test material under load |

Test material under pull |

|

Deformation Type |

Shrinking |

Stretching |

|

Sample Shape |

Often cubes/cylinders |

Often rods/sheets |

|

Load Capacity |

High for compressive force |

High for tensile force |

|

Failure Mode |

Crushing/fracture |

Necking/fracture |

|

Applications |

Construction materials |

Wires, metals, plastics |

|

Strain Type |

Compressive strain |

Tensile strain |

|

Fixture Design |

Flat compression plates |

Grips for pulling |

Comparing Tensile and Compressive Strength

Both tensile and compressive strengths differ based on load type, material shape, strain type, failure mode, applications, and fixture design.

|

Key Point |

Tensile Strength |

Compressive Strength |

|---|---|---|

|

Load Type |

Pulling forces |

Pressing forces |

|

Material Shape |

Rods, sheets |

Cubes, cylinders |

|

Strain Type |

Tensile strain |

Compressive strain |

|

Failure Mode |

Necking, fracture |

Crushing, fracture |

|

Applications |

Wires, plastics |

Construction materials |

|

Fixture Design |

Pull grips |

Compression plates |

|

Stress Type |

Axial tension |

Axial compression |

Technical Differences Between Tensile and Compression Test Equipment

The technical differences between tensile and compression test equipment primarily lie in the direction and type of load applied, the fixtures used, material behavior under testing, and failure modes observed.

|

Key Point |

Tensile Test |

Compression Test |

|---|---|---|

|

Load Direction |

Pulling force |

Pressing force |

|

Fixture Type |

Pull grips |

Compression plates |

|

Strain Behavior |

Tensile strain |

Compressive strain |

|

Typical Failure |

Necking, fracture |

Crushing, fracture |

|

Material Tested |

Wires, sheets |

Cubes, cylinders |

|

Stress Type |

Axial tension |

Axial compression |

|

Equipment Use |

Elongation tests |

Load-bearing tests |

|

Result Focus |

Ductility, UTS |

Compressive strength |

|

Load Uniformity |

Uniform tension |

Uniform compression |

When to Choose Compression over Tensile Testing

I look for universal testing machine compression test when I am examining a material or structure which is predominantly engineered to be durable against compressive loads in its use. This comprises assessing parts such as concrete, ceramics or foam, whose compressive strength, stability or deformation pattern under axial loads, needs to be understood. The advantage of compression testing is that it aids in understanding of materials that are prone to buckling or getting crushed as it helps to determine their ability to handle load and their responsiveness to the same in practice.

Reference Sources

-

Instron: What is Compression Testing? – A detailed resource on compression tests performed using universal testing machines.

-

ZwickRoell: Compression Testing – Information on compression testing machines and their role in determining material strength and deformation behavior.

-

Wikipedia: Universal Testing Machine – A comprehensive overview of universal testing machines and their applications.

-

Xometry: Compression Test Overview – Insights into the accuracy, purpose, and applications of compression tests.

-

TestResources: Compression Test – A resource explaining the characteristics measured during compression testing, such as yield strength and stress-strain.

Frequently Asked Questions (FAQs)

Q: Can you explain in detail the workings of the universal testing machine and its purpose while examining the materials?

A: A universal testing machine is a piece of equipment that allows one to perform different physical tests on materials, to analyze their quality. Its primary function is to test the behavior of components or materials such as stress, strain, and ductility, as well as their mechanical properties such as tensile, bending or compression. The strength and strain properties of material are characterized under these testing conditions.

Q: Why is it important to conduct a compression test and what does it involve?

A: A standard compression test technique is a normal testing method carried out for testing the compressive strength as well as compressive deformation of any given material. The procedure consists in applying pressure to a given sample until the latter yields or breaks with compression as an important property of that material as well as all other residual strength properties of damaged specimens. This is because there are standard test limits of the material, which must be within the performance of the equipment.

Q: What are the common types of the compression test tools used in UTM?

A: Compression test instruments include, for example, fixtures, jigs, and the various components of the compression tester, all of which are intended to help hold the sample under force. These tools provide the basis for measurements on the sample carried out during a compression test for determination of yield strength, compression strength and so on.

Q: What is the purpose of ASTM D3574 in compression test?

A: ASTM D3574 is a compression test standard method used normally to assess indentation force deflection (IFD) properties of flexible cellular substances such as foams. It is its aspiration undertaking compression tests in order to check the characteristics of compressive residual strength as well as deflection of these materials with reference to industry standards.

Q: Is it possible for a UTM to do compression and tension tests?

A: Yes, a UTM is in fact capable to perform different kinds of tests, and these include tension and compression tests among others. The machine intex james chapel learns computer on ICERO dissolves using the appropriate test fixture can measure the tensile and compressive deformation whether polymer composite or otherwise.

Q: How useful or essential is the testing software during the usage of a UTM?

A: The testing software in a UTM helps to coordinate testing, gather acquisition data and interpret findings. It Made-for-UTM facilitates users to configure testing protocols, keep track of the test forces applied and takeaway qualitative reports regarding the stress and strain of materials.

Q: What apparatus is used for finding out the compressive strength of a polymer matrix composite?

A: The polymer matrix composite’s compression can be gauged by the equipped UTM using the right standard compression test apparatus. The material will be compressed till it the yield point or structure breaks allowing data regarding the residual compressive strength of the material as well as its performance in general to be gathered.

Q: How meaningful as well as relevant is a combined loading compression test?

A: Suitability of using combined loading compression test will be that it helps in determining compressive characteristics of different materials under conditions where more and multiple stresses are encountered. Such test technique appears to be very useful especially in the context of materials and components that come across different types of loading conditions in practice. It helps in providing a detailed picture of the strength and deformation behavior of materials and items under evaluation.