Compression testing forms an integral factor of material science, engineering, and manufacturing, as it provides an idea of behavior under compressive forces. At the center of this vital testing activity lies the Universal Testing Machine (UTM), which is a versatile and robust general-purpose machine for testing different types of mechanical properties of materials. This article is intended to be an all-around description of how the UTM works during compression tests, its essential parts, and the significance of accurate measurement. This exhaustive discussion will arm you with enough knowledge to understand the details of compression testing using UTM, whether you are in the industry trying to set up testing processes or a curious mind trying to learn more about mechanical testing.

What Is a Universal Testing Machine for Compression?

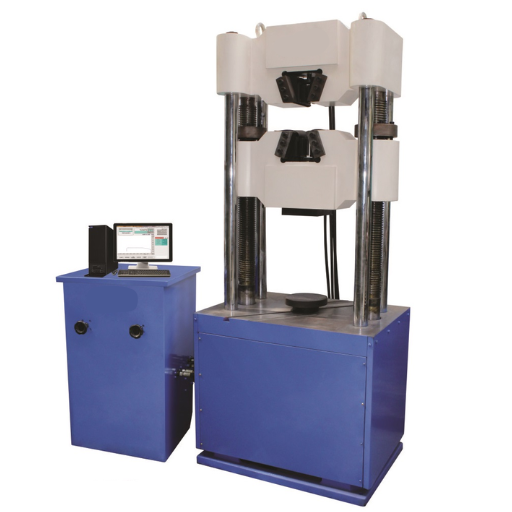

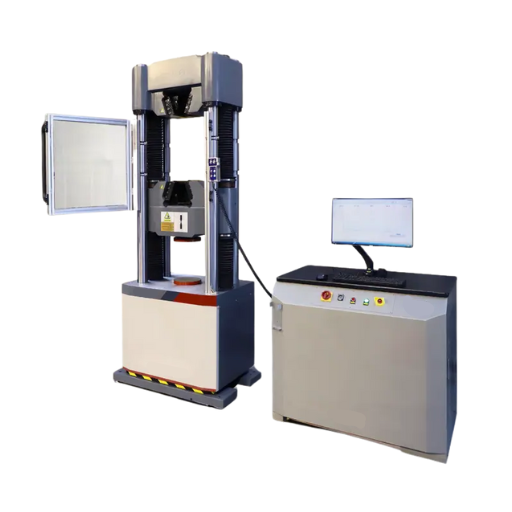

A compression universal testing machine is one designed to test the compressive strength and behavior of materials under applied force. Controlled pressure gets applied to a specimen until deformation or failure occurs, allowing measurement of parameters like compressive strength, elasticity, and deformation properties. Load cells and fixtures assure proper measurement in a UTM that is necessary for material testing in construction, manufacturing, and research industries. Its versatility allows one to test a double gamut of materials-from metals and plastics to composites-for consistent results.

How Does a Universal Testing Machine Work?

A Universal Testing Machine (UTM), by stressing the material under controlled conditions, is used in finding the mechanical properties of materials. For testing, the test specimen is clamped between tensile grips or compression plates, depending on the kind of test to be performed. The servo motor or hydraulic system forces the specimen to deform, maintaining a specific rate of deformation. A load cell measures the force applied to the specimen almost instantaneously. An extensometer or displacement sensor measures the deformation of the material simultaneously. Then, using sophisticated software, the data is processed to determine things like tensile strength, yield point, and elongation. The UTM further ensures highly reliable results are reproducible by automating data analysis and repeat calibration standards for accuracy across myriad industries and applications.

What Components Make up a Universal Testing Machine?

A Testing Machine is made up of some components that work together to perform many material tests. These components are:

1.Load Frame – The resilient and rigid structure houses the various machine components and provides adequate support for execution of the test.

2.Crosshead – The crosshead moves and applies a force to the test specimen, usually by means of motors or hydraulics.

3.Load Cell – An accurate sensor that measures the magnitude of force being applied on the specimen.

4.Actuator or Drive System – These move the crosshead either by hydraulic or mechanical means to apply the test load.

5.Fixture or Grip – Used to grip and hold the test specimen in place during testing.

6.Extensometer or Displacement Sensor – Measures elongation or deformation of the specimen during a test.

7.Controller and Software – The control system would manage the UTM operation, while the software would be used in data acquisition, analysis, and reports.

Together, these components provide control, accuracy, and versatility in a very wide variety of tests.

Why Is Compression Testing Important?

Testing compression is essential for material evaluation under compressive loads and analyses their mechanical properties. It is of great importance because it allows one to consider parameters such as compressive strength, modulus of elasticity, and yield strength so that the materials can be used in suitable applications. With industries like construction, manufacturing, and aerospace, materials need to take high compressive forces. Also, it helps to do quality control, choose materials, and analyze failures to get complementary information about how a material behaves when loaded, how durable it is, and how it deforms, information necessary to refine design and enforce safety norms.

How to Configure a Compression Testing Machine

1.Prepare The Machine

Make sure that the machine is clean and well-calibrated, and that all control switches are on. Ensure all safety systems, such as limit switches and emergency stops, are working properly.

2.Select the Fixtures

Fit the compression platens or other types of fixtures that correspond with the material or sample being tested, fastening them securely so as not to shift during testing.

3.Set Test Parameters

Input the desired test parameters, such as load rate, maximum load, or deformation limits, into the control system per the standard being followed.

4.Position Test Sample

Center the test sample between the compression platens for even load application. Double check its alignment to steer away from the inaccuracy during results.

5.Perform Pre-Test Calibration

Perform a short pre-test or zero-load test to verify the system is working correctly and sensors are responsive.

6.Initiate Test

Start the test and monitor it to check if it complies with the set parameters. Stop the test automatically once the desired limit is reached.

7.Analyze Results

Once the test is finished, check the recorded data for accuracy. Save or export to prepare for analysis and documentation.

Following this configuration process will guarantee reliable testing and accurate measurement of compressive properties.

Choosing the Right Compression Platens

In regards to choosing compression platens, I consider the material properties and dimensions of the samples, as this impacts compatibility with the testing devices. I check the plating material, as I usually prefer steel or tungsten carbide since they are sufficiently rigid to avoid deformation while the load is applied. Other considerations concern the surface finish; smooth ensures less variability in the measurements, while textured may bring specific advantages for some tests.Yet, I make sure the platen dimension and shape match the geometry of the test piece to ensure uniform pressure distribution and allow accurate results. By having these factors analyzed in accordance with what is relevant from the testing perspective, the reliability of proven measurements for compressive properties can be maximized.

Importance of Proper Test Fixture Selection

In the testing of materials, proper test fixture selection becomes the foremost factor for accommodating accurate results, reproduction of results, and highest reliability. A fixture grasps the specimen in a way that controls the application of load, establishing minimum variability. As per top-notch sources from materials testing and equipment manufacturing firms, the selection should first be compatible with the testing standard and material type. If a fixtureution does not conform to the specimen geometry and dimensions, they may cause an uneven stress distribution, thereby yielding inaccurate readings or causing premature failure.

Another consideration is that the fixture should be capable of handling the maximum load expected during the tests and yet, avoid any slipping or misalignment of the specimen. Indeed, using adjustable fixtures provides more flexibility; however, rigidity should be maintained during the testing procedure. Manufacturer specifications and preliminary alignment tests are worthy of consideration as it may assist in narrowing down the fixture selection further. Ultimately, proper design and proper maintenance of test fixtures ensure better reproducibility and test protocol compliance for generating accurate test data used either for research or for industrial applications.

Exploring Different Test Types in Compression Testing

Compression testing involves various test types, including uniaxial compression, confined compression, cyclic compression, creep testing, and fatigue testing.

|

Test Type |

Purpose |

Material |

Key Metric |

Load Type |

Environment |

|---|---|---|---|---|---|

|

Uniaxial |

Strength analysis |

Solids |

Max stress |

Static |

Controlled |

|

Confined |

Volumetric test |

Soil/Granular |

Bulk modulus |

Static |

Controlled |

|

Cyclic |

Fatigue behavior |

Solids |

Fatigue limit |

Dynamic |

Variable |

|

Creep |

Deformation rate |

Polymers |

Time-strain |

Static |

Constant |

|

Fatigue |

Durability |

Metals |

Endurance |

Dynamic |

Variable |

Static Vs. Dynamic Compression Tests

Static and dynamic compression tests differ by the loading rate, test duration, and material deformation behavior.

|

Parameter |

Static Test |

Dynamic Test |

|---|---|---|

|

Load Rate |

Slow |

Rapid |

|

Test Duration |

Longer |

Shorter |

|

Material |

Elastic/Plastic |

High-rate Response |

|

Deformation |

Gradual |

Instantaneous |

|

Energy Absorb. |

Low |

High |

|

Stress Strain |

Linear/Nonlinear |

Nonlinear |

Understanding Hydraulic and Electromechanical Systems

There are many differences between hydraulic and electromechanical systems in terms of working, efficiency, and areas of application. Hydraulic systems use usually incompressible fluids to exert forces through pumps, valves, and actuators and provide high power density with smooth motion control. They are ideally employed for heavy-load applications such as construction equipment and industrial presses because of their capacity to apply high forces.

The electromechanical systems are generally using electrical power for driving motors that convert electrical energy inputs to mechanical output, with their reputation for precise control, energy efficiency, and low maintenance being characteristic of those used in robotics, automated manufacturing, and precision tools. Both types of systems are integral to modern industry, with the buyer’s choice depending on several factors, including force, speed, control, and working environment.

What Are the Testing Standards for Compression Tests?

The compression tests are performed according to the standards to guarantee consistency, which makes them reliable and accurate under compressive load evaluation of material properties. Usually, ASTM E9 is followed for metal compression testing since it specifies the methods; or ISO 604 is followed for plastics compression techniques. These standards set all the critical parameters such as a specimen’s size, the rate of loading, and the testing environment so that every experiment is repeated in the same way. By conforming to these standards, one can get data that are weighty enough to stand comparison whether considered in different studies or among other applications.

Understanding ASTM and ISO Testing Standards

ASTM and ISO standards are internationally accepted descriptions and/or procedures for testing materials pursuant to the philosophy of ensuring uniformity, reliability, and comparison. ASTM is geared toward testing lab materials with procedures for testing and specifying practically all manner of materials and products, typically for industries such as construction, petroleum, and environmental science. The International Organization for Standardization, on the other hand, stresses international applicability and deals with testing standards in some sectors so that they may work together globally. Both organizations bridge the gap of testing practices, so tests can be harmonized, through which materials can be effectively evaluated in various geographic and industry-specific contexts.

Compliance with Standard Test Protocols

To ensure that the test results adhere to the accepted protocol, it is imperative that one has a thorough understanding of the specific guidelines formulated by ASTM, ISO, or any other related bodies. This is what I do: I follow the standardized procedure for material testing, ensure that all equipment is calibrated and maintained as per the specifications, and document the results to meet regulatory and quality assurance standards. The benefits of such an approach are that it promises genuine data, thereby easing the certification procedure and complying with national or international standards.

Understanding Compression Platens and Their Role

Platens for compression are the main parts of a material testing machine, intended to impose and distribute a uniform force on the test specimen during the compression test. These very-well-crafted surfaces help ensure that accurate values of compressive strength, elasticity, and deformation of the specimen are determined. The proper alignment of the compression platens and the finishing of the surface must be guaranteed so as to reduce any possible errors brought about by misalignment and to conform to a specified testing procedure.

Types of Compression Platens Used

The primary types of compression platens include fixed platens, self-aligning platens, hardened steel platens, textured platens, and specialized platens for specific material properties.

|

Type |

Key Feature |

Material |

Use Case |

Advantage |

|---|---|---|---|---|

|

Fixed Platens |

Rigid surface |

Hardened steel |

General testing |

High stability |

|

Self-Aligning |

Adjustable tilt |

Hardened steel |

Irregular samples |

Alignment aid |

|

Hardened Steel |

Durable surface |

High-carbon steel |

High-pressure use |

Long lifespan |

|

Textured Platens |

Grooved design |

Varies by type |

Slippery materials |

Grip control |

|

Specialized Platens |

Custom shapes |

Depends on use |

Specific materials |

Precision fit |

How to Choose the Right Compression Fixture

In choosing the right compression fixture, I have a few key considerations. One of those factors pertains to the material properties of the specimen to be tested. For instance, in working with irregularly shaped samples, self-aligning platens are a good choice due to the adjustable tilt, which improves alignment. Alternatively, if the pressure relations are high, then hardened steel platens are preferred due to the high resistance they offer over time to massive forces.

Secondly, I shall go ahead and work through the requirements put forth by the test. For generic applications involving standard materials, fixed plate furnishes provide good stability. Where slipping can be an issue, textured plate with grooved designs can provide much better grip and eliminate testing errors.

Finally, any specific requirements for the test are taken into consideration. For odd-shaped materials or special conditions, specially designed specialized platens provide precision and compatibility. By relating the fixture type to the technical requirements of the test and character of the material, I guarantee that the results will be accurate and reliable.

Maintaining and Calibrating Compression Platens

Regular maintenance and precise calibration of compression platens are the very heart of accurate test results and extending the life of the equipment. I examine these for surface wear, such as dents or scratches, which can threaten the accuracy of testing. The platens must be regularly cleaned, preferably with a non-abrasive material, to prevent contamination that may compromise the results. Calibration is done using calibration equipment with certified accuracy, considering industry standards for level and adequate alignment of the platens. A professional calibration will be periodically arranged to reconfirm, and re-align when needed, the equipment, thus ensuring compliance with testing methods and criteria.

Reference Sources

-

Instron – Universal Testing Systems: A comprehensive resource on electromechanical and hydraulic universal testing machines.

-

PCE Instruments – Universal Testing Machine: Details on universal testing machines for compression and tensile force applications.

-

Wikipedia – Universal Testing Machine: An overview of universal testing machines, their applications, and functionalities.

-

ADMET – Universal Testing Machines: Information on various universal testing machines and their capabilities.

-

Forney – Compression Testing Machines: Insights into compression machines designed for lab and field use.

Frequently Asked Questions (FAQs)

Q: What is a Universal Testing Machine for Compression Tests?

A: A Universal Testing Machine for Compression Tests is a mechanical testing system that performs various compression tests on materials and components to ascertain the compression strength and other properties of the specimen by placing it between two compression platens.

Q: How does the Universal Testing Machine differ from other testing systems?

A: Unlike other testing systems, a Universal Testing Machine is capable of performing tensile as well as compression tests and may thus be used for a wide range of other applications, including tensile testing and flexural testing.

Q: What types of materials can be subjected to testing using a Universal Testing Machine?

A: With a combined loading compression method, a particular Universal Testing Machine may be utilized for various materials (including high-strength ones) according to the customer’s requirement and testing capacity.

Q: What is the significance of the elastic limit in compression tests?

A: The elastic limit represents the maximum stress that a material can withstand without permanent deformation, as it is recovered to its original shape. This knowledge is trivial in compression tests while considering the behavior of a particular material.

Q: How is the compression strength of a material measured?

A: The compression strength of a material is measured by placing it between two compression platens and applying force until deformation or fracture occurs. The strength applied is usually expressed in kilonewtons.

Q: Can it be automated for the Universal Testing Machine?

A: Yes, the Universal Testing Machine can be automated, usually through the installation of advanced testing software that controls the tester and records data.

Q: What is the role of hydraulic testing in compression tests?

A: A series of universal testing systems use hydraulic testing to apply pressure and force in a controlled manner during compression tests, thereby enabling the exact quantification of material properties.

Q: How does a Universal Testing Machine ensure accuracy of all tests and their respective compression results?

A: A Universal Testing Machine makes use of appropriately calibrated equipment and testing software to assure the accuracy of all tests and compression results that it performs.

Q: What is the significance of conducting compression tests on the tensile testing machine?

A: Conducting compression tests on the tensile testing machine can provide necessary comprehensive testing of both the tensile and compression properties of materials and said tensile testing machine necessarily includes tensile and flexure capabilities.