A mechanical understanding of materials forms a basis in engineering, manufacturing, and quality control. Being one of the basic methods, tensile testing allows us to uncover a material’s strength, ductility, and elasticity. Funded by the Universal Testing Machine, this process can be varied across many testpieces and, with an advanced tensile test software, can translate raw data into valid inference. The blog examines how UTM and software help reduce the time and labor requirements during testing by ensuring accurate measurements and ease of data evaluation. If you are a material scientist, engineer, or quality assurance specialist, consider this article to be your guide on the key characteristics and benefits of tensile test software as it dissolves the layer of mystery on how it plays a pivotal role in innovation and accurate testing of materials.

Introduction to Universal Testing Machines

What is a Universal Testing Machine?

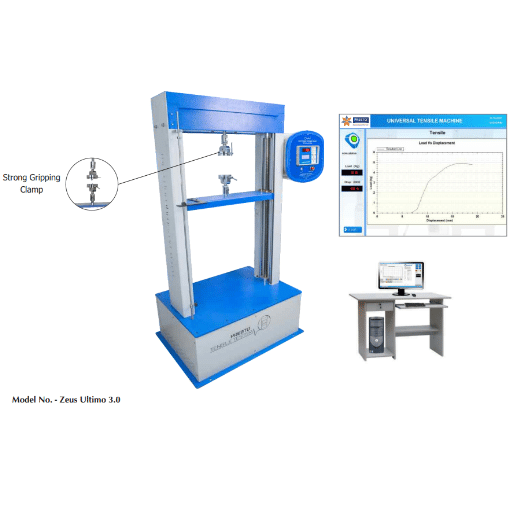

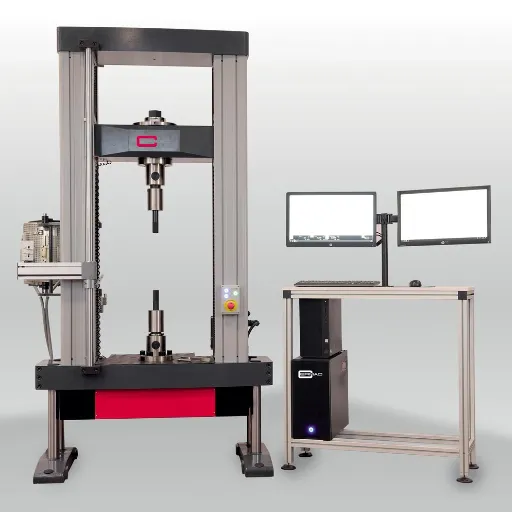

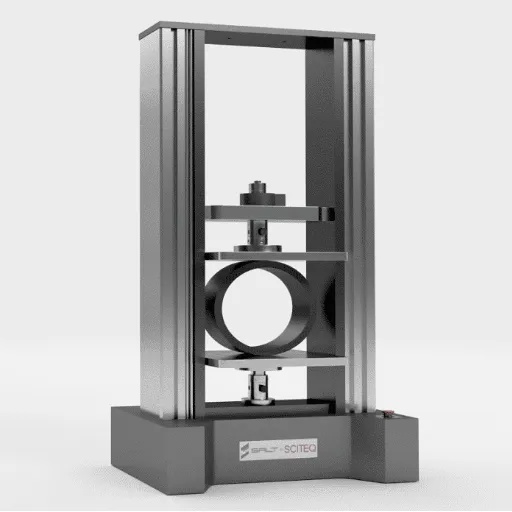

The Universal Testing Machine is used to test the mechanical properties of materials under different loading conditions. Its basic functioning consists of applying forces in a controlled way over a specimen and measuring its response to such a loading to characterize properties like tensile strength, compressive strength, and elasticity. The UTM can be used for performing tension, compression, bending, and shear tests.

A UTM basically consists of the load frame on which the specimen is mounted, a load cell for precisely measuring the forces applied on the specimen during a test, and finally, a device for controlling the applied force or displacement, measuring the strain during deformation, so that parameters influencing size or dimensions are set by the user. The force applied and corresponding deformation of the specimen usually is presented on a computer in graphical form so that further analysis of important material properties can be carried out.

Universal Testing Machines are widely used in areas like manufacturing, the building industries, aerospace, and research. These are materials testing tools in which a material is subjected to stress and the nature of its performance under such stress is observed for the very purpose of assuring materials of quality and material reliability. This is very important particularly in instances where one wants to predict a material’s behavior in actual working conditions, a key consideration while working toward material improvement.

Importance of Tensile Testing

Key Benefits of Tensile Testing:

- Understanding material strength, ductility, and overall mechanical performance

- Revealing maximum load capacity and elongation before failure

- Ensuring materials meet specific design and safety requirements

- Supporting quality control and improving reliability in end products

Tensile testing is critical for understanding the strength, ductility, and overall mechanical performance of materials. By applying a controlled pulling force to a material specimen, tensile tests reveal how a material will perform under tension, providing key data about its maximum load capacity, elongation before failure, and ultimate tensile strength. These insights are essential for ensuring that materials meet specific design and safety requirements.

The importance of tensile testing lies in its ability to identify whether a material is suitable for its intended application. For industries such as automotive, aerospace, and construction, it helps ensure that critical components can withstand operational stresses without deforming or failing. Additionally, tensile testing can benchmark material consistency, aiding in quality control and improving reliability in end products.

This testing method also supports the development of new materials by providing engineers with essential feedback regarding their mechanical properties. It helps predict how a material will behave in real-world conditions, enabling informed decisions in material selection and design processes. Overall, tensile testing is a foundational tool for maintaining safety, quality, and innovation across numerous industries.

Overview of UTM Software

The software for UTM forms an integral part of modern tensile testing systems, precisely handling the control and execution of the tests. The UTM software allows smooth interaction with the tensile machine and thus permits measurement of material properties, accurately and repetitively. It makes the entire system more user-friendly, allowing the operator to initiate tests within the system in the shortest time, observe the progress of testing, and finally analyze the results.

Key Software Features:

- Automated data collection and processing

- Visual data display through graphs and reports

- Customization for various industry needs

- Test parameter settings and data management

One of the prime features of the UTM software is its automated collection and processing of data throughout the testing procedure, leading to the reduction of human errors and maximum attention to analyzing stress, strain, elongation, and other key factors. With the method of displaying data visually through various graphs and reports, users can conveniently assess the performance of materials under various conditions.

Moreover, UTM software, in its general sense, supports customization to best serve the industries’ and testing standards’ varied needs. The user is empowered to set test parameters, save test settings for reuse, and manage datasets for general comparison, thus ensuring the utmost flexibility and efficiency. The adaptability truly breeds relevance of the software over wide application areas, be it for quality control or research and development. Ultimately, the decision-making processes in materials science and engineering are more effective as a result.

Key Features of Testing Machine Software

User Interface and Experience

Accessibility Features

- Clear and defined menus

- Simple navigation schemes

- Uniform presentation

- Reduced learning time

Customization Options

- Customizable displays

- User shortcuts

- Modular design

- Personalized experience

Testing machine software user interfaces are designed for accessibility, so operators across the spectrum of knowledge can access them. With clearly defined menus, simple navigation schemes, and uniform presentation, operators can readily locate whichever essential function they require. With the rationale of providing intuitiveness, ample thought is put into reducing the learning time and possible user errors, thus raising productivity.

Adaptability is yet another prime merit toward the interface design. This allows a user to shape the interface to suit his needs, carrying an experience that is more personalized. Functionalities such as customizable displays, shortcuts, and modular design ensure that an operator has at his fingertips only those tools and settings that are of most frequent concern. Increased adaptability boosts efficiency and satisfaction.

Moreover, the software depends on visual aids and real-time feedback to smooth out operations. Graphical explanations, progress notifications, and error alerts can tell the user what is happening in the test processes and what the outcomes are at a glance. In a way, the UI focuses on clarity and speed, so that it demystifies complicated testing procedures and in doing so frees the user to devote attention toward actually obtaining accurate and useful results.

Machine Control Capabilities

Advanced Control Features:

- Precision Regulation: Set parameters according to testing needs with consistent machine performance

- Automated Controls: Predefined sequences reduce manual intervention and human errors

- Real-time Adjustments: Dynamic parameter modification during testing

- User-friendly Operation: Accessible for all expertise levels

The software offers machine control possibilities such that testing apparatus is regulated with great precision and efficiency. Users are thus able to set parameters dictated by their testing needs to ensure that the machine continues to function consistently within those specifications. With a higher level of control, deviation is minimized and testing results are rendered much more reliable.

Another prime feature is to provide automated controls for repetitive tasks. By means of setting predefined sequences, the software acts by preventing the manual intervention by the user, which would eventually rank up to saving time and minimization of errors caused by human interference. Automated controls also ease the working of the system for users of all expertise levels by providing consistent execution, thereby not requiring them to have a lot of technical knowledge.

Finally, the software has the provision for real-time changes. Midway during testing, its parameters or the behavior of the machine can be somehow adjusted to suit some unexpected scenarios that may arise. This is another dynamic feature, which offers flexibility and responsiveness during testing in case the very acceptance criteria vary or the whole process itself has to be fine-tuned. These features, by and large, establish a very solid and user-friendly control system for a diverse set of testing applications.

Data Analysis and Reporting

Analysis of data forms a crucial function of universal testing machine software, as it can process and interpret the data that is obtained in testing. The software gathers and organizes the raw data of testing and presents this information in the form of meaningful insight. A few examples of insights it can generate include force-displacement curves, stress-strain curves, and other metrics that assist users in comprehending material or product behavior while being tested.

Reporting Capabilities

- Customized Reports: Tables, graphs, and summary statistics tailored to specifications

- Multiple Export Formats: PDF, Excel, CSV for external compatibility

- Real-time Monitoring: Instant observation and analysis of test results

- Automatic Calculations: Reduced time and human error in parameter computation

The reporting feature is intended to provide a clear and professional presentation of the results. Users can prepare customized reports containing tables, graphs, and summary statistics that address exact specifications. In case there is a need, these reports can then be exported to widely used formats such as PDF, Excel, or CSV for easy compatibility with external software and for wider dissemination among stakeholders.

Accuracy, reliability, and adaptability all characterize excellent data analysis and reporting tools in universal testing machines. Mostly, such software has provisions for real-time monitoring and automatic calculation of parameters, thus saving time and avoiding human error. It is worth noting that these capabilities ensure that the users have accurate information and can make an informed choice in any research, quality control, or production setup.

Tensile Testing Process with UTM Software

Setup and Calibration of the Testing Machine

Critical Setup Steps:

- Physical Assembly: Position on solid, level surface with proper grips and fixtures

- Load Cell Calibration: Verify against known weights or traceable devices

- Displacement Sensor Check: Ensure accurate response and proper zeroing

- Software Configuration: Set test parameters and run verification tests

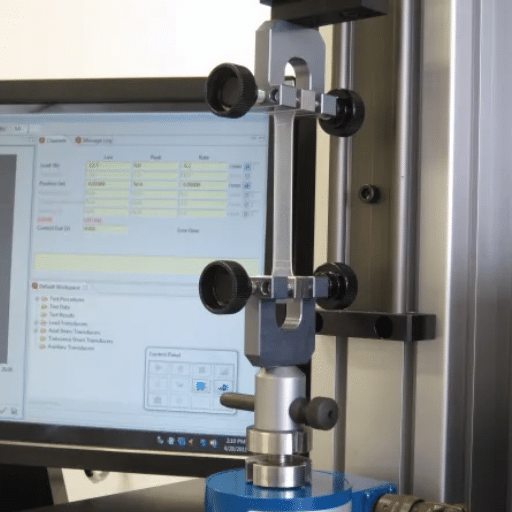

The testing machine must be set up and calibrated for tensile testing. First, the test equipment has to be assembled to ensure the instrument is completely put together. The testing machine should be positioned on a solid, level floor or surface, and should have attached to it grips or fixtures designed for tensile testing. All components must be joined with sufficient strength and aligned correctly; otherwise, it could seriously interfere with meaningful results during testing. Check the manufacturer’s assembly instructions to confirm the physical configuration.

Calibration next is vital to guarantee the accuracy and reliability of the testing results. The load cell is checked first, the device that measures the force involved in any given test procedure. Included in the calibration of the load cell shall be the weighing against the known weights or a device traceably calibrated. The displacement sensors are checked next to ensure that they respond accurately and are correctly zeroed. Consequently, the machine gives verified accurate readings of the specimen elongation or compression during the test.

Another thing to calibrate is software calibration, which is a must. Open the software interface of the UTM and set the test parameters like the crosshead speed, data collection rate, and load limits. Run a short verification test on a standard sample or known material, comparing machine outputs with predefined values. Any discrepancies found should be adjusted through a recalibration or a recheck of the machine setup. Maintaining periodic calibration and maintenance ensures that a good end result is obtained and that the test equipment lasts longer.

Executing the Tensile Test

1 Preparation of the Sample

Ensure the test sample is prepared according to the required specifications. The sample should be without any defects and should be properly measured, clamped into the grips securely, and checked for alignment on the Universal Testing Machine (UTM) since anything off-center may cause an uneven application of force during the test.

2 During the Test

With the sample mounted and the machine set up, commence with testing. A tensile force should be gradually applied by the UTM, which will prompt the material to elongate. The UTM should log all pertinent information like load, elongation, and stress-strain data up to the point of fracture or ultimate tensile strength of the specimen being tested. Observe to check that the equipment is operating according to its design.

3 Recording and Analyzing Results

Upon finishing, check the recorded data for values such as yield strength, tensile strength, and elongation at break. Compare these values with a benchmark or material standard to evaluate how the sample behaves. Document the results clearly for reporting and further analysis. Ensure to keep the data for reference and traceability in the future.

Interpreting Results and Data

| Analysis Step | Key Considerations | Expected Outcomes |

|---|---|---|

| Performance Evaluation | Compare recorded results with material specifications and standards | Determine material suitability for intended application |

| Failure Mode Analysis | Observe material behavior: brittle fracture, ductile deformation, or both | Understanding of structural strength and real-world performance |

| Report Generation | Present data transparently through graphs and tables | Comprehensive documentation for quality assurance and future reference |

The prime motive behind interpreting the test results of material is to determine if the sample meets the intended performance criteria. Following this, the recorded results for parameters, for instance, yield strength, tensile strength, and elongation at break, are considered. Then these values are contrasted with values of specification or standard of the material in order to check for deviations. When a certain material fulfills or exceeds a certain standard requirement, it can be said that the material is apt to be used for the purpose for which it has been specified. In the event that it falls short, there may be need for the review or alteration of the specification.

Next, the failure mode of the material shall be observed during testing. By observing how the sample behaves under stress-brittle fracture, ductile deformation, or both-we obtain an understanding of its structural strength and behavior under actual service conditions. A thorough understanding of the mechanism of failure can lead to additional decisions-deemed appropriate or not with the material under the intended load and the environmental considerations.

Lastly, all these observations should be collated into a comprehensive report. Present the data transparently through graphs or tables at times to allow for easy visualization of the results. Deliberate on the implications for the material’s performance and suggest any remedial actions. Clear documentation of the results will benefit not only in quality assurance, but will also be useful in future trials of the same or related materials or applications.

Common Challenges in UTM Software

Identifying Pain Points for Users

⚠️ Interface Complexity

- Steep learning curves for new users

- Lack of intuitive design

- Limited tutorial resources

- Navigation difficulties

🔧 Technical Issues

- Hardware compatibility problems

- Data format incompatibilities

- Export and analysis difficulties

- Synchronization challenges

💬 Support Limitations

- Limited technical assistance accessibility

- Unclear error messages

- Insufficient documentation

- Delayed problem resolution

Users usually face numerous common troubles when using UTM programs. Among such troubles is that the software interface tends to be tricky, and this develops steep learning curves for the new users. Lack of intuitive design and readily available tutorials can further hamper navigation, thereby leading to delays and errors in setting up or executing tests by the users.

Other pain points include hardware compatibility and data formats. The users, at times, find it hard to synchronize their software with various machines; at other times, they do face difficulties while trying to export and analyze results in compatible formats. Such incidents drag down productivity and may yield inconsistent reporting or outright inaccurate results.

Getting troubleshooting and support may be another area with problems, should they arise. Limited accessibility to technical assistance, unclear error messages, and lack of documentation all hinder users to fix problems quickly. If these concerns can be addressed, the focus can be on building a more user-friendly design, well-designed compatibility, and great customer support, leading to better general user experience and productivity.

Solutions Offered by Advanced UTM Software

Advanced UTM Software Solutions

Comprehensive Security

Consolidated security features including firewalls, anti-virus, and intrusion-prevention systems

Enhanced Support

Clear documentation, intuitive interfaces, and prompt customer support

Superior Compatibility

Perfect integration across devices, operating systems, and network environments

Generally speaking, Advanced UTM software attempts to present holistic solutions to increase product usability, tackle any technical issues, and increase efficiency. In shortening, a UTM system consolidates several security features into one platform so that the burden of network security may be eased. Different features including firewalls, anti-virus, and also intrusion-prevention systems work in cohesion to reduce the administration of network security and provide a strong area of defense against cyber threats.

An added advantage is the improved user support experience. Clear documentation is typically provided with Advanced UTM systems. Moreover, easy-to-navigate interfaces and prompt customer support enable quick and easy troubleshooting. As for automated alerts and detailed error logs, such features go a long way in helping users diagnose and troubleshoot issues thereby reducing frustration emanating from vague messages or lack of assistance.

Further, compatibility and integration stand as two major strengths of high-end UTM software. These kinds of systems are specified to ensure perfect working across different devices, operating systems, and network environments so that consistency and reliability exist. Updates are, therefore, done on a regular basis in order to further ensure adaptability with new threats and changes in technology, thereby allowing companies not only to operate at high productivity levels but also to secure their infrastructure from threats in an easy manner.

Case Studies of Successful Implementations

🏭 Streamlining Manufacturing Processes

A precision engineering company applied universal testing machine software to speed up its quality control processes. The software automates testing for material properties such as tensile strength and stiffness, reducing the time spent for analysis by 40%. This streamlined approach realized speed enhancements in production, as well as enhancing result accuracy to ensure consistent product reliability and greatly reduce waste.

✈️ Improving Compliance in Aerospace

With the advent of Universal Testing Machine software being put in place, fighting for aerospace standards for materials certification could be easier. The software permitted the tracking and documenting of tests in an orderly manner to keep up with regulations. By merging this novel technical solution into their manufacturing process, the company reduced the chances of error during audits and assured the meeting of stringent safety and performance standards for their components, thereby strengthening customer confidence and operational efficiencies.

🎓 Enhancing Research in Academia

The University Research Lab employed Universal Testing Machine software to enable advanced material science studies. With the software’s ability to run complex test configurations with detailed data visualization, it allowed researchers to delve deeper into the properties of novel materials. This led to great advancements into producing new environment-friendly materials, thus underlining the importance of the software for innovation and scientific realizations.

Future Trends in Testing Machine Software

Integration with Industry 4.0

Industry 4.0 Integration Benefits

IoT Connectivity

Seamless device integration

AI Analytics

Predictive behavior analysis

Cloud Storage

Enhanced traceability

Integration with Industry 4.0 into the universal testing machine software thereby revolutionizes material testing with the connectivity, automation, and analysis thereof. With the emergence of smart technologies such as the IoT (Internet of Things), such software solutions are enabled to connect seamlessly with other devices and systems across manufacturing ecosystems. Real-time communication and workflows are ensured so that businesses can remotely monitor and analyse material testing processes in utmost efficiency.

Furthermore, Industry 4.0 brings forth the possibility of advanced analytics by way of AI (artificial intelligence) and machine learning. These instruments allow for software to predict material behavior, signal alerts regarding possible problems in certain materials, and configure test setup adjustments from huge data sets. Such automation and insight advance research and production processes while lowering expenses and enhancing the overall quality of materials and products.

At the same time, the improved integration of data supports traceability and documentation of the highest level, which is important for industries that follow key strict standards-as in aerospace manufacture, automotive, or medical. With advanced visualization tools and cloud-based storage, testing results can be viewed and shared freely among teams to support partnership effort and regulatory compliance. Industry 4.0 integration thus ushers in a new age of accuracy, efficiency, and innovation for universal testing machine software.

Innovations in Machine Control and Automation

Adaptive Feedback Control

Dynamic parameter adjustment based on material response, reducing human interference and improving precision and reliability.

AI & Machine Learning

Predictive analysis of machine behavior and test data patterns, optimizing performance and detecting system anomalies.

IIoT Integration

Industrial Internet of Things technologies enabling seamless machine communication and centralized data collection.

The recent past has witnessed rapid advances in machine control and automation, amending the performance and functioning of universal testing machines. One big recent development has been an adaptive feedback control system. The user test varies testing parameters dynamically; therefore, it reacts to the material response with precision and high reliability. This reduces human interference, thereby, reducing the margin for errors and allowing the operator more time to analyze test results rather than having to control the process.

AI and machine learning algorithms can now be integrated into testing systems-the big change nowadays. These systems maintain the machines through prediction analyses of the behavior of the machines and test data patterns and optimizing their behavior. After some time, these systems may be able to detect some signs of inefficiency in a system or some anomalies arising in the raw materials, accordingly giving some recommendations for adjusting the systems in order to enhance testing. In addition, AI automation enhances productivity as it reduces the time needed to accomplish repetitive and labor-intensive tasks.

Under modern universal testing machine software, connectivity and data integration advances play a crucial role. As Industrial Internet of Things (IIoT) technologies are implemented, machines will be able to communicate seamlessly with other devices and systems. This connectivity supports real-time monitoring, remote operation, and data collection in a centralized fashion, which has proved to be convenient for the teams in question and increases traceability and compliance. Accordingly, innovations in machine control and automation together will form the basis of the next-generation universal testing facility that will boast of further efficiency and precision.

Ensuring Future Proof Solutions

Key Principles for Future-Proof UTM Software

🔧 Scalability & Adaptability

- Modular design for upgrades

- Response to new testing methods

- Standards adaptation

🔗 Compatibility & Integration

- Open architecture design

- Standardized communication

- Seamless system integration

📊 Analytics & Usability

- Predictive maintenance

- Performance optimization

- User-friendly interfaces

Developing a future-proof solution for universal testing machine softwares needs scalable, adaptable, and future-looking systems. When the software is designed in such a way that it can be upgraded modularly, testing facilities can respond to new testing methods, changed standards, and new technologies as the situation demands. An adaptive equipment becomes outdated and useless, which one cannot afford to buy over and over. This of course means huge savings in cost and resources.

Another aspect is that it should somehow be compatible with a fair number of devices and protocols via open architecture and a standardized communication interface. Such designs allow it to seamlessly integrate with other testing equipment, data management systems, and analytic tools. Such interoperability promulgates better operational efficiency during the upgrading of the system procedures, thereby promoting innovation without interruptions.

Future-proof software must also look at good usability and analytics for prediction. Well-thought-out user-interface designs and automation minimize errors and maximize efficiency, while data-driven insights could help in anticipating maintenance or optimizing performance. By emphasizing high reliability and flexibility, we can continue to regard universal testing machine software as a blessing to various facilities for years to come.

Frequently Asked Questions (FAQ)

❓ What is universal testing machine software?

Universal testing machine software is a specialized software designed to control and analyze the data obtained from universal testing machines (UTMs) used for tensile, compression, and flexure testing of materials. This software helps in automating the testing processes, data collection, and analysis, thereby ensuring compliance with standards like ASTM and ISO.

📱 How does the touch screen interface enhance the user experience with universal testing machine software?

The touch interface for universal testing machine software greatly enhanced the user experience by giving operators an intuitive and interactive platform. They could simply scroll through test programs, look at data in real-time, and make changes on the fly, quickly conducting tests in more pleasant ways.

🔵 What are the advantages of Bluehill Universal Materials Testing Software?

The Bluehill Universal Materials Testing Software has advantages which include sophisticated methods in data analysis, integration with the testing machines, and reporting tools. It supports testing methods in a variety of fields, acquires data in real-time, and secures the integrity of collected records with the help of audit trails.

🚀 How could I start with testing on a tensile testing machine using the software?

To perform testing with a tensile testing machine, first, ensure that the universal testing machine software is well installed and configured. Select the proper test program, input specimen dimensions, and continue by following the on-screen instructions. Throughout the testing procedure, the software will support real-time monitoring and analysis of the process.

🛡️ What do safety features in universal testing machine software stand for?

Safety features in universal testing machine software stand for operator safety and equipment protection. These features can be an emergency stop; conditional test parameters such that the machine will not perform unsafe operations; and live diagnostics analyzing the machine’s performance during testing.

🔒 How does the universal testing machine software guarantee data integrity?

The Universal Testing machine software ensures data integrity through mechanisms such as scenarios, which transparently access and track all actions taken during tests, and secure data storage protocols that make this information traceable and reliable. This is paramount for meeting industry specifications and regulatory obligations.

🔄 Is it possible to perform cyclic testing in this software, and what benefits does it have?

Yes, this software does support cyclic testing. Cyclic testing would be useful in assessing the survival and fatigue resistance of materials subjected to repeated loading conditions, thereby offering necessary insights into the material behavior with respect to time.

⏱️ What is the importance of data acquisition in real time for materials testing software?

Real-time data acquisition in materials testing software allows an instant observation and analysis of the test results as they are being recorded. This enables an operator to make immediate adjustments, where necessary, and guarantees correct data collection, which is critical in producing a legitimate test report.

👥 How is user material on a universal testing machine?

User management in universal testing machine software allows administrators to create and manage user profiles, set access levels, and monitor user activities. This user management feature increases the level of security by restricting application operation and access to sensitive data to only those persons that are authorized.

🛠️ What kind of technical support is offered out to users of universal testing machine software?

Technical support usually caters to users with issues related to installation, troubleshooting, and an explanation of the software’s utilization. Some providers offer dedicated support teams available through multiple channels such as phones, e-mails, and live chat, thus giving users easy access to quick solutions.

References

-

UTM Software – Larson Systems – Details on UTM software features, including test management, communication with testers, and offline programming.

-

testXpert Testing Software – ZwickRoell – Information on testXpert software, designed for fatigue tests and cyclic materials testing, compatible with ZwickRoell systems.

-

Software for Universal Tensile Testing Machine – Reddit – A community discussion on software options for universal tensile testing machines.

-

UTM Software – Larson Systems – Another reference to Larson Systems’ UTM software, highlighting its capabilities and standards compliance.

-

System Software – Materials Testing Machine – Information on MTI Universal Testing Systems software, which meets ASTM, ISO, and other standards for data acquisition.