Instrument And Equipment Wholesale

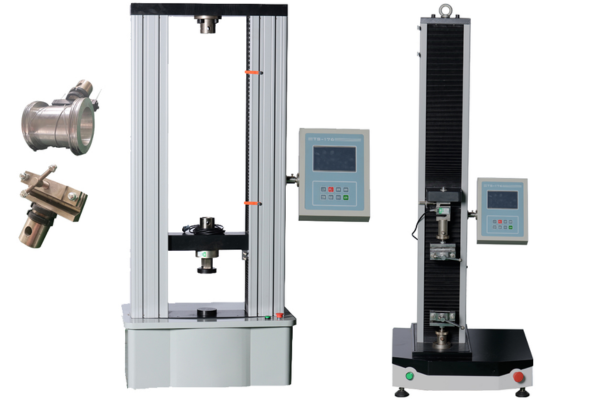

Premium Electronic Universal Testing Machine Manufacturer in China

Introducing the Electronic Universal Testing Machine, a sophisticated instrument engineered for precise and versatile material testing. This advanced system accurately measures mechanical properties such as tensile, compression, and bending strength, making it ideal for a wide array of industrial applications.

What Is A Electronic Universal Testing Machine

-

An Electronic Universal Testing Machine utilizes advanced electronic controls and digital components to precisely apply forces (tension, compression, etc.) and measure material responses.

-

It is capable of determining crucial mechanical properties like tensile strength, yield point, elongation, compressive strength, and flexural modulus from test specimens.

-

These machines are widely used in diverse industries for research, development, and quality control of materials and finished products across sectors like automotive, aerospace, plastics, and metals.

-

Equipped with sophisticated data acquisition systems and software, it provides accurate, real-time data, automated test control, comprehensive analysis, and detailed reporting of test results.

-

Available in various models and load capacities, Electronic UTMs can be configured with a wide range of grips, fixtures, and accessories to test different sample types and meet specific testing standards.

Main Features of Electronic Universal Testing Machine

Electronic Universal Testing Machine allows for detailed analysis of various materials and components under controlled conditions, providing critical data for research, development, and quality assurance.

Precise Electronic Control

Utilizes advanced electronic control systems and servo motors for highly accurate application and control of force or displacement during tests.

Versatile Testing Capabilities

Capable of performing a wide range of mechanical tests, including tensile, compression, flexure, peel, and shear, on various materials and components.

Digital Data Acquisition

Features sophisticated digital systems that collect, process, and display real-time data from load cells, extensometers, and other sensors with high resolution.

Comprehensive Software Functionality

Integrates with powerful software for easy test setup, automated execution, real-time monitoring, in-depth data analysis, and professional report generation.

Electronic Universal Testing Machine For Sale

Digital Drum Peel Tensile Testing Machine

Test adhesion and peel strength with our Digital Drum Peel Tensile Machine. Ideal for films and laminates, it offers precise digital control, meeting ISO and ASTM standards with capacities up to 50kN.

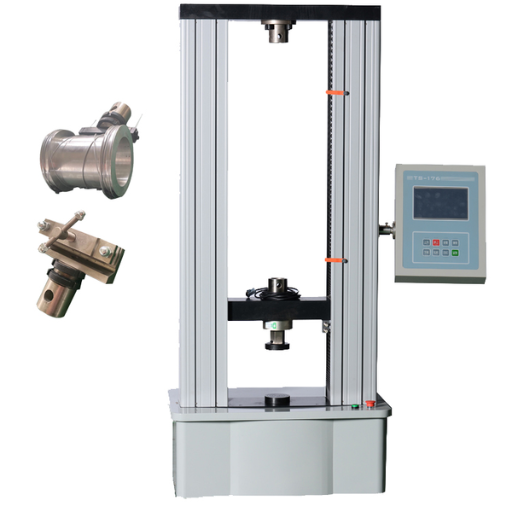

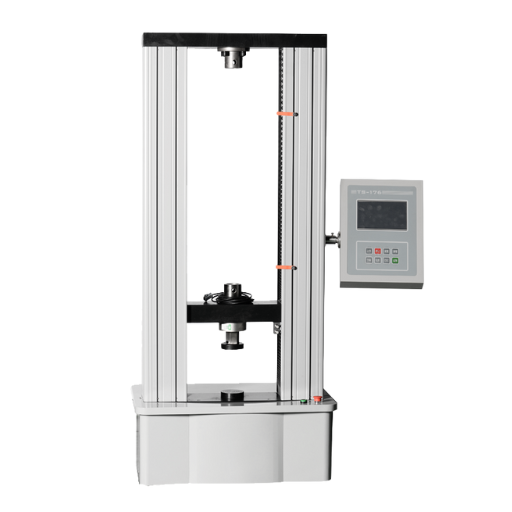

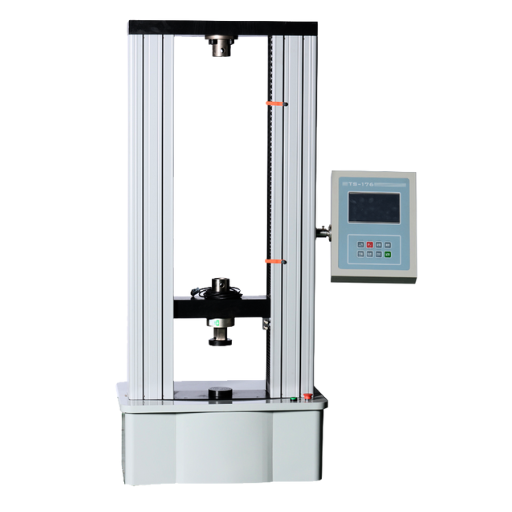

WDS-10KN Digital Electronic Universal Tensile Testing Machine

Our WDS-10KN Digital Machine provides accurate tensile testing up to 10kN. Equipped with servo motors and software, it’s perfect for films, adhesives, and small components with ±1% accuracy.

WDS-20KN Digital Door Frame Electronic Universal Tensile Testing Machine

The WDS-20KN Door Frame Machine offers precise tensile testing up to 20kN. With digital control and extensometer options, it’s ideal for rubber and metal, meeting ISO 6892 standards.

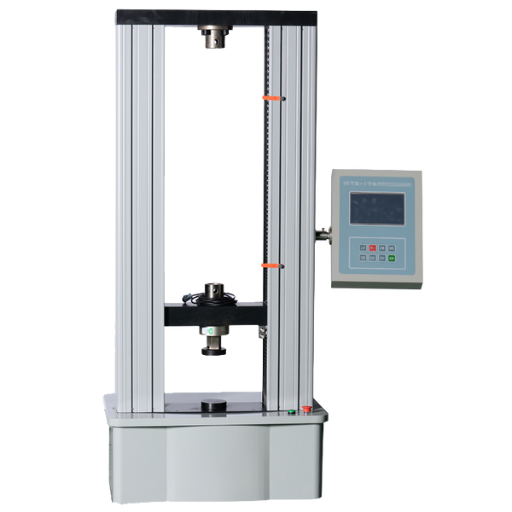

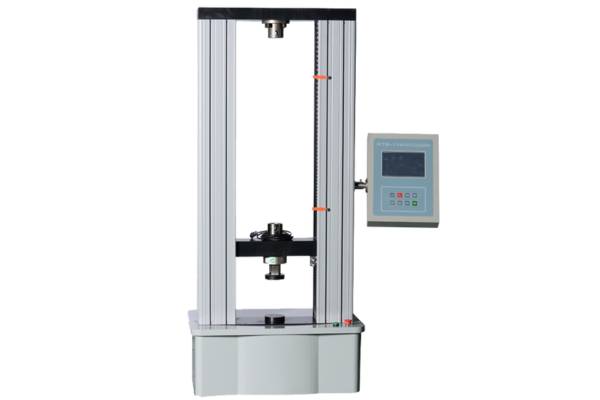

WDS-50KN Digital Two Columns Electronic Universal Testing Machine

Our WDS-50KN Two Columns Machine ensures reliable tensile and compression tests up to 50kN. Features digital display, servo system, and versatile fixtures for plastics, rubber, and geotextiles.

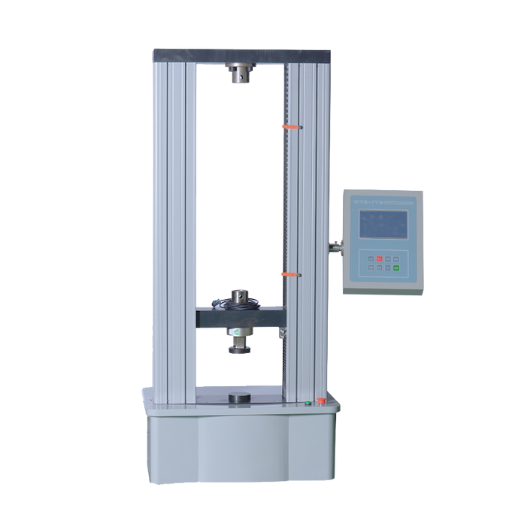

WDS-100KN Digital Electronic Universal Testing Machine

The WDS-100KN Digital Electronic Machine delivers accurate tensile, compression, and bending tests. With 100kN capacity, servo motor control, and AI-driven software, it’s perfect for metals and composites testing.

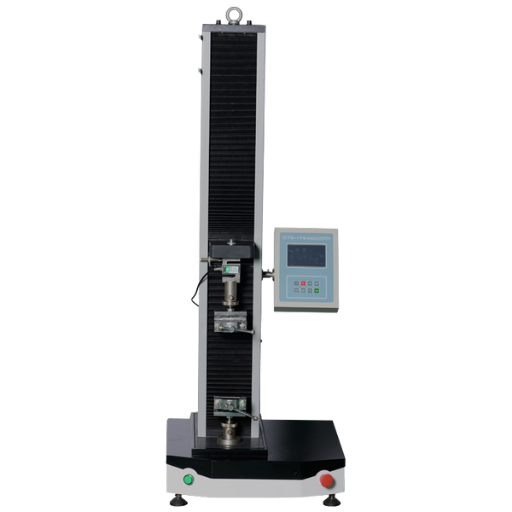

WDS Series Digital Single Column Tensile Universal Testing Machine

The WDS Single Column Machine offers tensile testing up to 20kN with digital display and adjustable speed. Ideal for plastics and textiles, it includes fixtures for versatile material analysis.

Wood Panel Bending Modulus Testing Machine

Test wood panels’ bending modulus with precision using our advanced machine. Ideal for construction, it measures stiffness and strength per industry standards, with digital controls and customizable fixtures.

Geocells Tensile Testing Machine – ISO 13426 Compliant

Our ISO 13426-compliant Geocells Tensile Machine tests HDPE geocell strength accurately. Features high-speed data acquisition and touchscreen interface, perfect for junction and strip testing.

Computerized Drum Peel Tensile Testing Machine

Evaluate peel strength with our Computerized Drum Peel Machine. Ideal for films and laminates, it offers precise digital control, auto-stop, and compliance with ISO standards up to 50kN capacity.

100KN Tensile Tester Factory

Our 100KN Tensile Tester Factory delivers robust machines for metal and composite testing. With servo motors and digital displays, it ensures accurate tensile results per ASTM and ISO standards.

WDW-5KN Computerized Single Column Tensile Universal Testing Machine

The WDW-5KN Single Column Machine offers tensile testing up to 5kN. Features compact design, digital controls, and extensometers for textiles and small samples.

WDW-10KN Computerized Electronic Universal Tensile Testing Machine

Our WDW-10KN Machine ensures accurate tensile tests up to 10kN. With computerized controls and servo motors, it’s ideal for films, wires, and adhesives testing.

WDW-20KN Computerized Electronic Universal Testing Machine

The WDW-20KN Machine delivers reliable tensile and bending tests up to 20kN. Features digital display, servo system, and extensometer options for small components.

WDW-50KN Computerized Electronic Universal Testing Machine

Our WDW-50KN Machine provides precise tensile and compression tests up to 50kN. With computerized controls and adjustable fixtures, it’s perfect for plastics and metals.

WDW-100KN Computerized Electronic Universal Testing Machine

The WDW-100KN Machine offers accurate tensile, compression, and bending tests up to 100kN. Features servo motors, digital interface, and extensometers for versatile material testing.

WDW-200KN Computerized Electronic Universal Testing Machine

Our WDW-200KN Machine handles tensile, compression, and bending tests up to 200kN. Equipped with computerized controls and video extensometers, ideal for metals and composites.

WDW-300KN Computerized Electronic Universal Testing Machine

The WDW-300KN Machine performs tensile, compression, and bending tests up to 300kN. Features AI-driven software, robust frame, and extensometers for precise material analysis.

Electronic Universal Testing Machine Technical Specifications

| Parameter | DETAILS |

|---|---|

| Load capacity | Ranges from 0.001 kN to 500 kN for diverse applications. |

| Testing types | Supports tensile, compression, and flexure tests. |

| Measurement accuracy | Features precision sensors with +0.5% accuracy. |

| Operating conditions | Functions from -40°C to 80°C and up to 90% RH. |

| Control systems | Includes digital interface with automated data logging. |

| Speed adjustment | Adjustable from 0.01 mm/min to 500 mm/min. |

| Crosshead movement | Offers up to ±1000 mm displacement for testing. |

| Sensor compatibility | Supports load cells and extensometers for measurements. |

| Power requirements | Compatible with 110V/60Hz or 230V/50Hz inputs. |

| Safety mechanisms | Equipped with emergency stop and overload protection. |

Application Industries of Electronic Universal Testing Machine

Manufacturing: Testing materials and products for quality control.

Automotive: Evaluating vehicle components and materials.

Aerospace: Testing critical materials and structures for safety.

Construction: Assessing building materials quality and standards.

Plastics & Polymers: Characterizing properties of various plastic products.

Textiles: Testing strength and stretch of fabrics and yarns.

Paper & Packaging: Evaluating strength of paper and packaging materials.

Biomaterials & Medical Devices: Testing materials and devices integrity.

Adhesives & Sealants: Measuring bond strength.

Research & Development: Characterizing new materials.

Request Information on Your Electronic Testing Solution!

Seeking a precise and versatile testing machine? Discover our advanced Electronic Universal Tester, engineered for reliable material analysis and component evaluation. Ideal for diverse testing needs, it offers accurate measurement and robust performance. Learn how this sophisticated equipment can enhance your quality control and R&D capabilities. Connect with us today for details and a custom consultation!

Frequently Ask Questions

Q: What is an electronic universal testing machine?

A: An electronic universal testing machine is testing equipment that uses precise electronic controls and digital data acquisition for performing various mechanical tests.

Q: How is a computerized tensile testing machine different from a standard one?

A: A computerized tensile testing machine offers automated control, data logging, real-time analysis, and reporting through integrated computer systems.

Q: What benefits does electronic testing equipment provide?

A: Electronic testing equipment delivers high accuracy, repeatability, versatile control options, and comprehensive data analysis compared to older mechanical systems.

Q: Are electromechanical universal testing machines suitable for metals?

A: Yes, electromechanical universal testing machines are commonly used for testing metals, plastics, and other materials requiring precise speed and position control.

Q: What kinds of tests are performed by a digital universal testing machine?

A: A digital universal testing machine can perform tensile, compression, flexure, peel, shear, and other mechanical tests on diverse materials and components.

Q: How do electronic UTMs ensure accuracy?

A: Electronic UTMs achieve accuracy through high-resolution load cells, precise encoders, and advanced digital feedback control systems.

Q: Can electronic universal testing machines test to specific standards?

A: Absolutely, modern electronic universal testing machines and their software are designed to meet numerous international and industry testing standards (ASTM, ISO, etc.).

Q: Why choose an electronic testing equipment over hydraulic for lower forces?

A: Electronic testing equipment typically offers better precision and control at lower force ranges, making them ideal for testing sensitive materials.